Breakthrough in R2R Slot-die Coating: Coating Quality Now Predictable in Real Time

Can We Predict Coating Quality in Real Time?

A recent study titled "Predicting Quality of Coated Layer Based on Meniscus Features Associated with Thickness for Sustainable Roll-to-Roll Processes" explores a powerful idea: using the shape of the meniscus in slot-die coating to predict the final thickness of the coated layer in real time. If you’ve worked with roll-to-roll (R2R) systems, you know that maintaining consistent coating quality is tough. Small variations in tension or coating gap can lead to defects, waste, and lower product performance. This study brings us closer to solving that challenge by analyzing visual data of the meniscus and developing a model to predict coating thickness with over 85% greater accuracy than traditional mathematical models.

Key Highlights

Real-time vision data of the meniscus was used to predict coating layer thickness.

The model focused on adjustable in-process variables like tension and coating gap.

Four key meniscus features were defined: dynamic flow rate, downstream meniscus curvature, downstream meniscus angle, and upstream meniscus angle.

The prediction model outperformed traditional mathematical models by 85.9%.

Increased tension led to thinner coatings due to better ink spreading.

Larger coating gaps led to thicker coatings due to shear thinning behavior.

A support vector machine (SVM) regression model was used for prediction.

The model enables smarter, greener R2R manufacturing by reducing waste and radiation-based inspections.

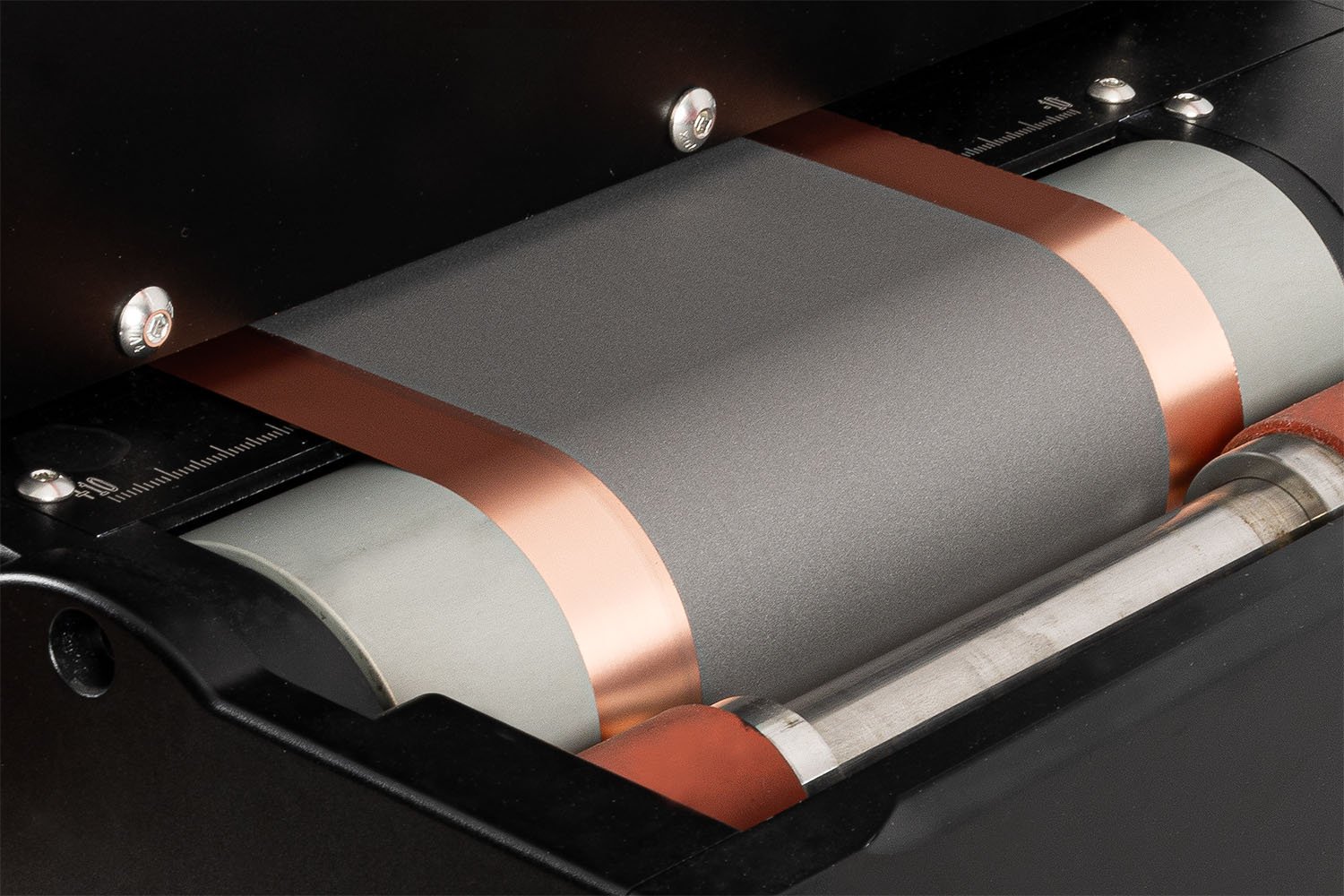

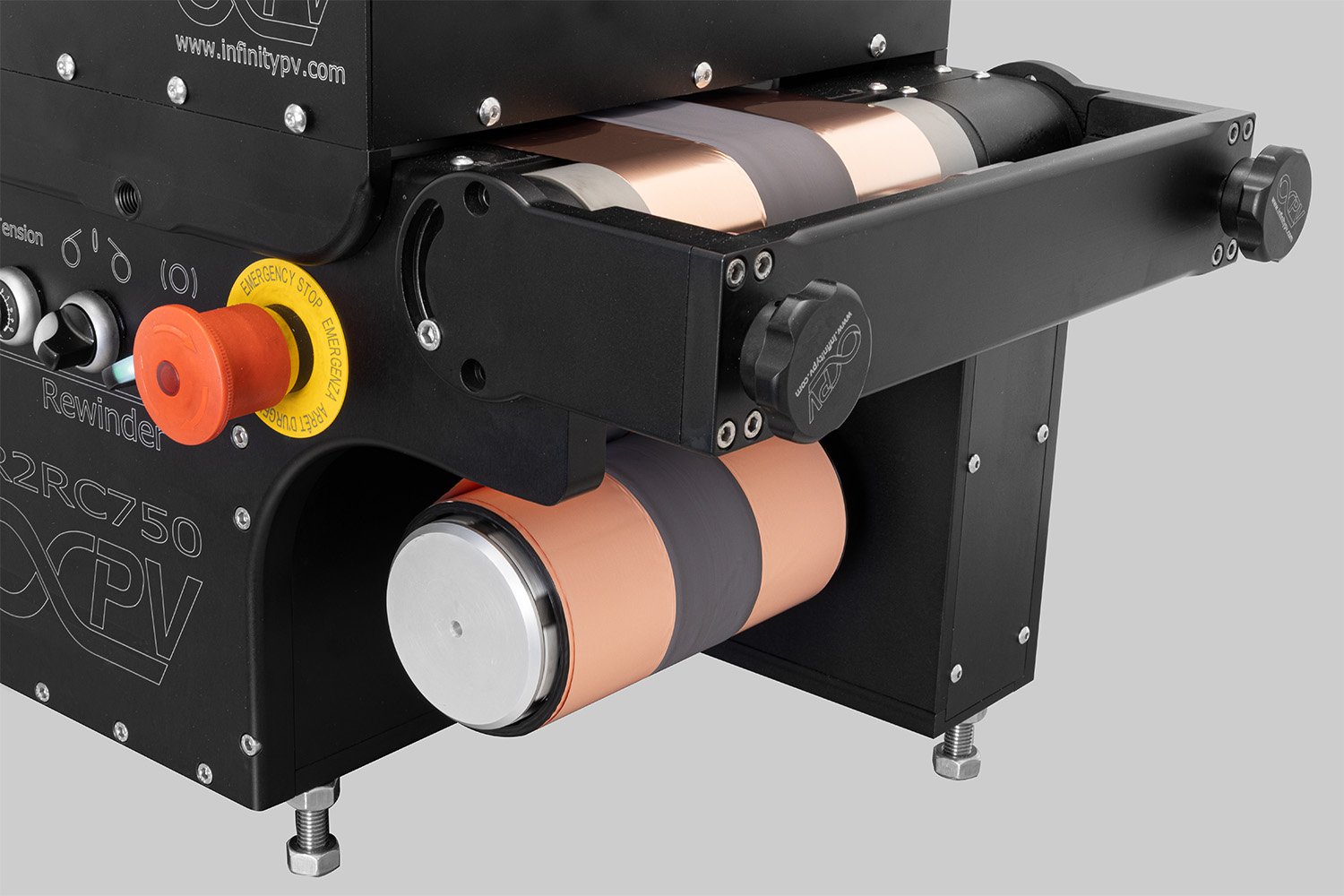

The Laboratory Roll-to-Roll Coater is the ideal coating machine for scaling up to roll-to-roll processing of battery electrode materials or for testing and optimizing battery electrode slurries.

What is Slot-Die Coating and Why Does it Matter?

Slot-die coating is a pre-metered coating technique widely used in roll-to-roll manufacturing for products like solar cells, batteries, and flexible electronics. It offers high precision and low material waste. During coating, ink flows through a narrow slot and forms a meniscus as it meets the moving web (substrate). The geometry of this meniscus is influenced by factors like ink viscosity, web speed, tension, and the coating gap. Because these parameters can fluctuate, predicting how they’ll affect the coated layer has traditionally required costly post-process inspection or inflexible models.

The Significance of the Study: Why Meniscus-Based Prediction is a Game-Changer

What sets this study apart is its focus on the meniscus itself. Instead of waiting until the coating is finished to inspect it, the researchers propose using visual data of the meniscus to make real-time predictions. This approach is not only faster but also safer, as it avoids radioactive measurement methods like beta-ray sensors. It supports green manufacturing goals by reducing waste and improving process control.

The Slot-die Coater is an excellent choice for researchers focused on developing and optimizing battery electrode slurries at the laboratory scale.

Diving Into the Methods: How the Model Was Built

The research team developed a predictive model using a combination of physics-based analysis and machine learning. Here’s how they did it. Meniscus images were captured during coating using a CMOS camera. Four features were extracted from the images: DFR, DMC, DMA, and UMA. The features were then used to train a support vector machine regression model. The model was validated using controlled experiments where tension and coating gap were varied. The prediction accuracy was measured and compared with that of a traditional mathematical model.

Understanding the Meniscus Features

Each feature captures a different aspect of how the ink behaves at the point of contact. Dynamic Flow Rate (DFR) reflects how much ink is flowing through the meniscus. Downstream Meniscus Curvature (DMC) influences the pressure gradient and coating stability. Downstream Meniscus Angle (DMA) affects how the ink detaches and spreads. Upstream Meniscus Angle (UMA) impacts how ink first contacts the web.

Why This Technology Matters for Industry

The implications are broad. Industries that rely on thin, functional coatings can now improve yield, reduce inspection costs, and move toward more automated, intelligent manufacturing. Since the method is based on visual data, it can be implemented without disrupting the existing process.

Future Outlook: Where This Could Lead

This study lays the groundwork for predictive, closed-loop control in roll-to-roll processes. Next steps may include accounting for post-coating changes like residual stresses after winding or integrating this model into commercial systems. The approach can also be adapted for other coating materials and geometries.

Conclusion

This research is a leap forward in smart manufacturing for roll-to-roll systems. By predicting coating quality based on the meniscus shape, manufacturers can achieve better control, higher quality, and greater sustainability. It turns a traditionally reactive process into a proactive one, making real-time quality assurance a reality.

Authors

Minjae Kim

Jaehyun Noh

Gyoujin Cho

Jeongdai Jo

Changwoo Lee

Get Professional Support for Your Battery Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Related Products

Laboratory Roll-to-Roll Coater

A compact and modular high precision roll-to-roll slot-die coater that transforms the way thin functional films are printed and coated.

LR2RC500 Bundle

Probably the world’s most compact R2R slot-die coater, featuring a syringe pump, a 65 mm slot-die head, and an infrared oven for precise lab coating.