Shaping the Future of Thin-Film Technology

At infinityPV, we push the frontiers of printed and flexible electronics. With innovation and sustainability at our core, we create compact lab equipment for slot-die coating and roll-to-roll processing that bridges research and industrial production.

Products

Pioneering Printed Electronics for Over 25 Years

We are infinityPV, a Danish company with a global footprint, pushing the boundaries of what’s possible in printed and flexible electronics. Driven by innovation and a commitment to sustainability, we design and manufacture state-of-the-art, compact laboratory equipment for slot-die coating and roll-to-roll processing that bridges the gap between research and industrial-scale production.

We Are Trusted by the World’s Top Scientists

Why R2R Coaters Are Ideal for Scalable Slot-Die Coating

In this video, Roar Søndergaard, PhD, introduces the advantages of Laboratory R2R Coaters with a modular design and explains why they are ideal for researchers working with functional thin films. You’ll learn how these compact systems fit into standard labs, gloveboxes, and fume hoods while still allowing hundreds of meters of foil to be processed.

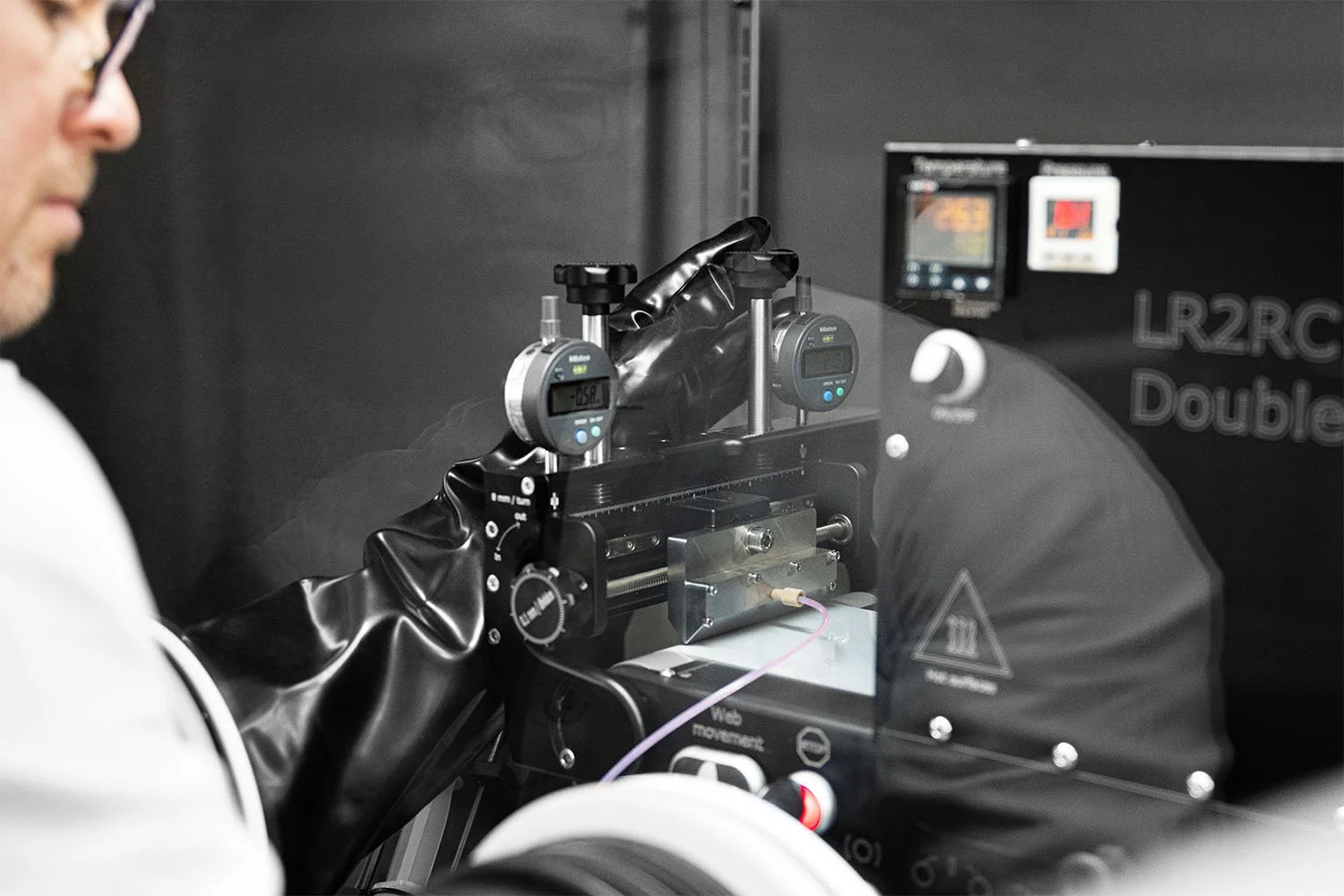

Visit Our Lab: Try Before You Buy

Experience infinityPV’s coating equipment in action using your own foils and solutions. Spend a full day in our professional laboratory, operate the Slot-die Coater and Laboratory Roll-to-Roll Coater yourself, receive hands-on guidance and tips from our expert team, and explore your processes in depth. Take real results home — no obligations, just opportunities.

Roll-to-Roll Coating? We Got You Covered.

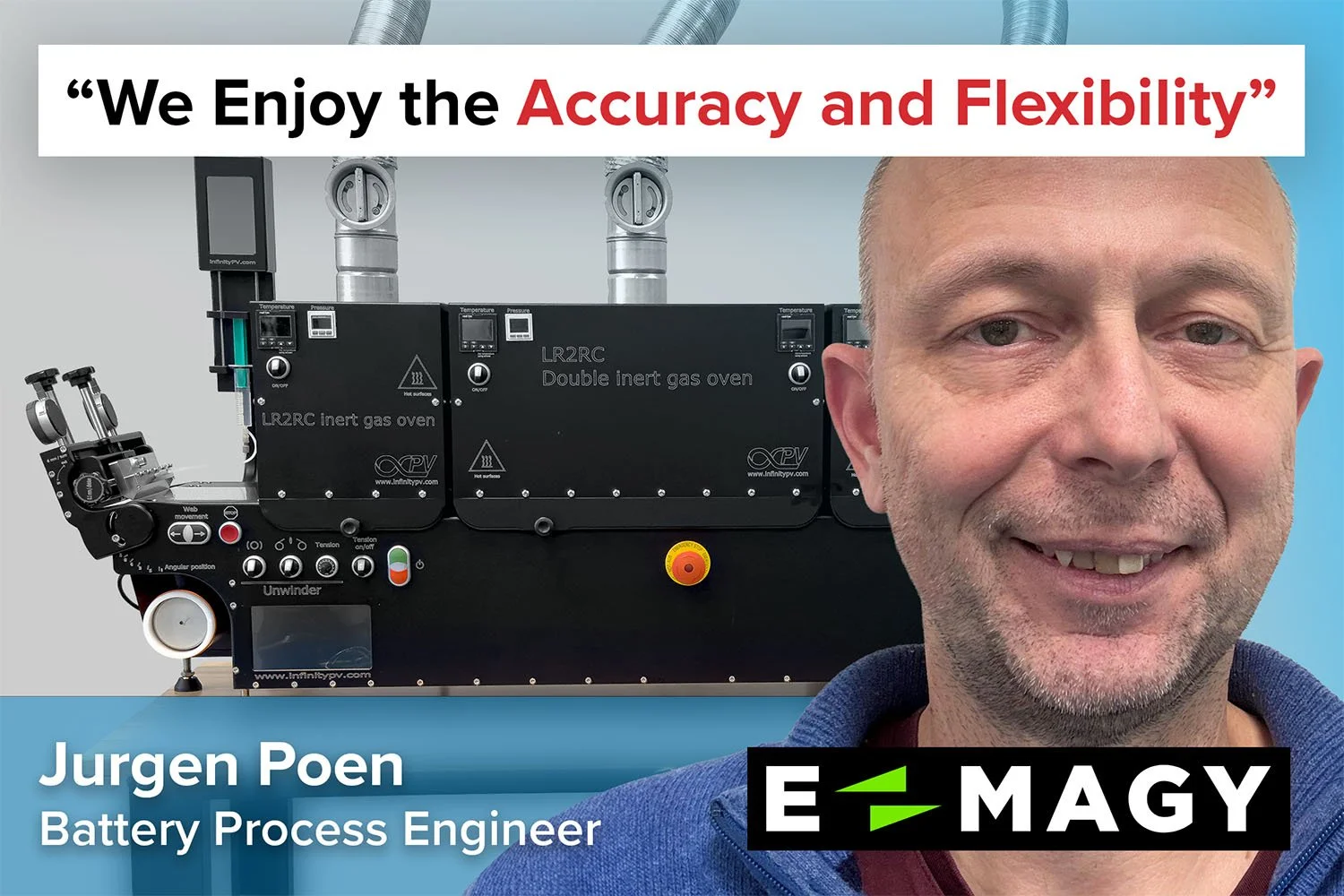

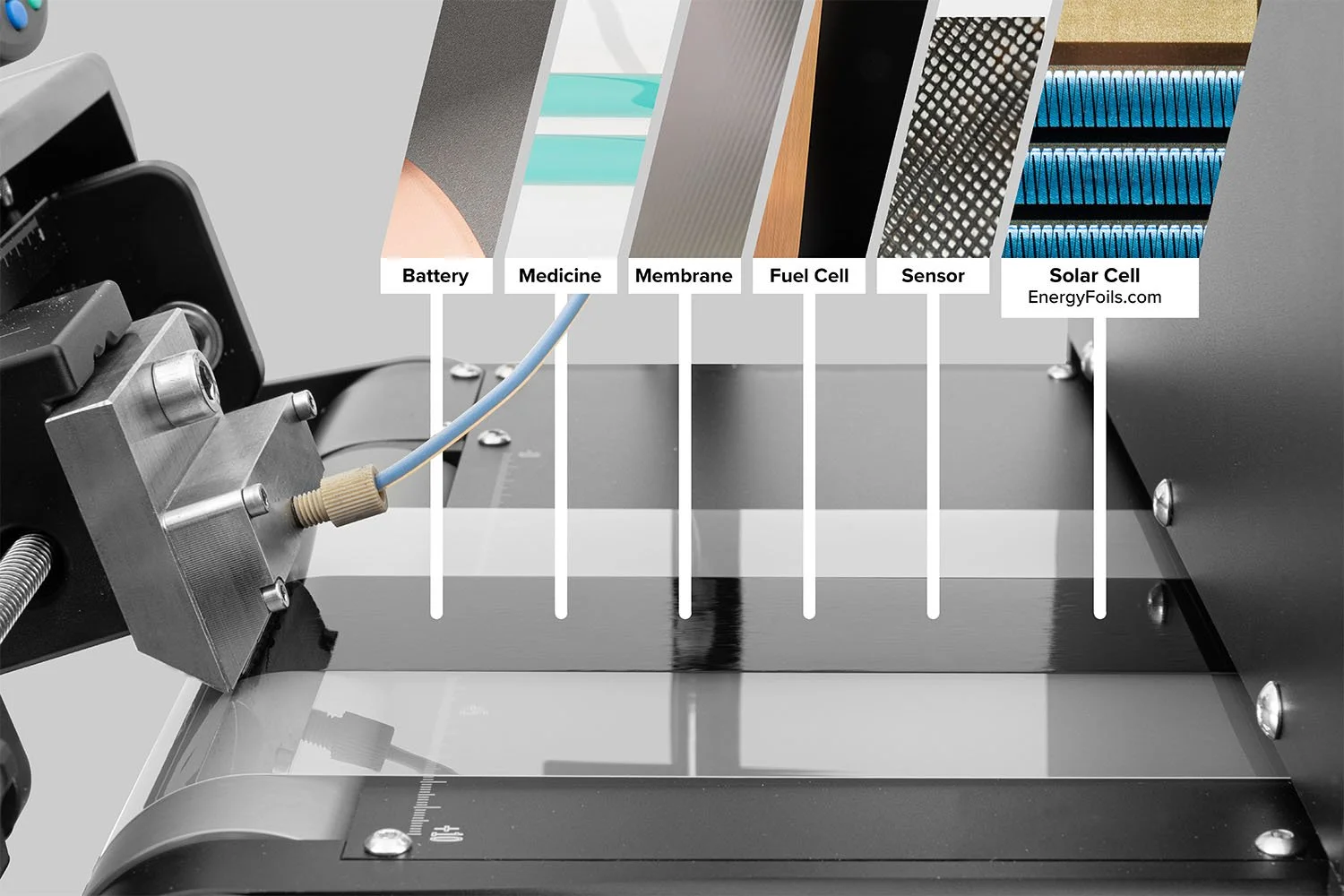

Whether you're working within batteries, pharma and medtech, fuel cells, solar cells, or other thin-film technologies, we offer scalable Roll-to-Roll (R2R) equipment built for the lab. Our modular systems are designed for precision, repeatability, and flexibility, supporting everything from coating and drying to surface treatment and characterization.

What is Slot-die Coating?

Slot-die coating is a cutting-edge technique that lets you precisely spread ultra-thin, uniform films onto flexible surfaces to unlock faster innovation in everything from solar cells to next-gen batteries.

Which Slot-die Head Do YOU Need?

Your coating process is only as good as the head that delivers it. Whether you’re developing batteries, solar cells, fuel cells, pharmaceuticals, or something else, selecting the right slot-die head is critical for quality, efficiency, and cost-effectiveness. In our guide, we break down how to evaluate your needs and help you understand which size and material slot-die head suits your application best.

Roll-to-Roll Academy

The Roll-to-Roll Academy aims to educate and engage people, enabling them to explore the potential of R2R applications in their respective field of technology, like next-gen batteries, fuel cells, printed solar, and beyond.

How to Slot-die Coat on Pristine Clean Surfaces

Discover how pristine clean surface coating eliminates defects by applying functional layers onto untouched substrates. Ideal for medtech, solar cells, OLEDs, and advanced electronics.

Company & Industry News and Updates

Public Projects

We participate in publicly funded projects that are ambitious and driven by a vision for the advancement of the field of printed solar cells.

LUMINOSITY

LUMINOSITY is an industry driven project aimed at leveraging the flexible perovskite solar cells (PSC) technology to commercially relevant production scales, using established industrial processes.

EIFFEL

The EIFFEL project aims to advance NFA materials and OSCs to regain Europe's leadership from Asia. It will use goal-driven design strategies, stakeholder collaboration, and investigate vacuum processing to address stability issues.