The infinityPV Roll-to-Roll Academy empowers researchers to innovate with slot-die coating and roll-to-roll processing, speeding development and smoothing the path to commercialization across electronics, energy, and pharma.

Learn step-by-step how to select, clean, and pattern PET and PET/ITO substrates for roll-to-roll perovskite solar cell fabrication.

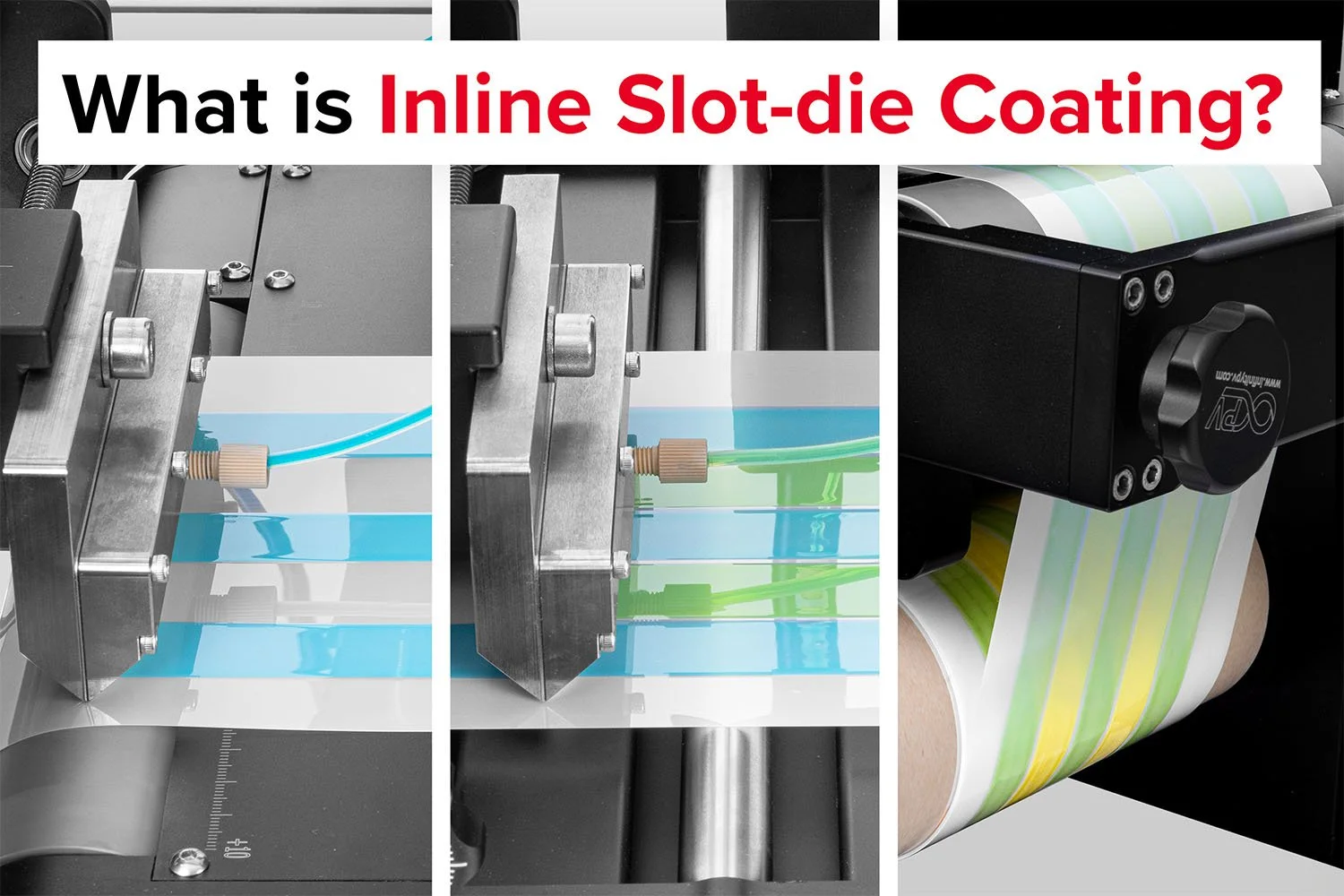

Learn how roll-to-roll inline slot-die coating works, including wet-on-wet and dual slot-die processes, and when each approach delivers the best results.

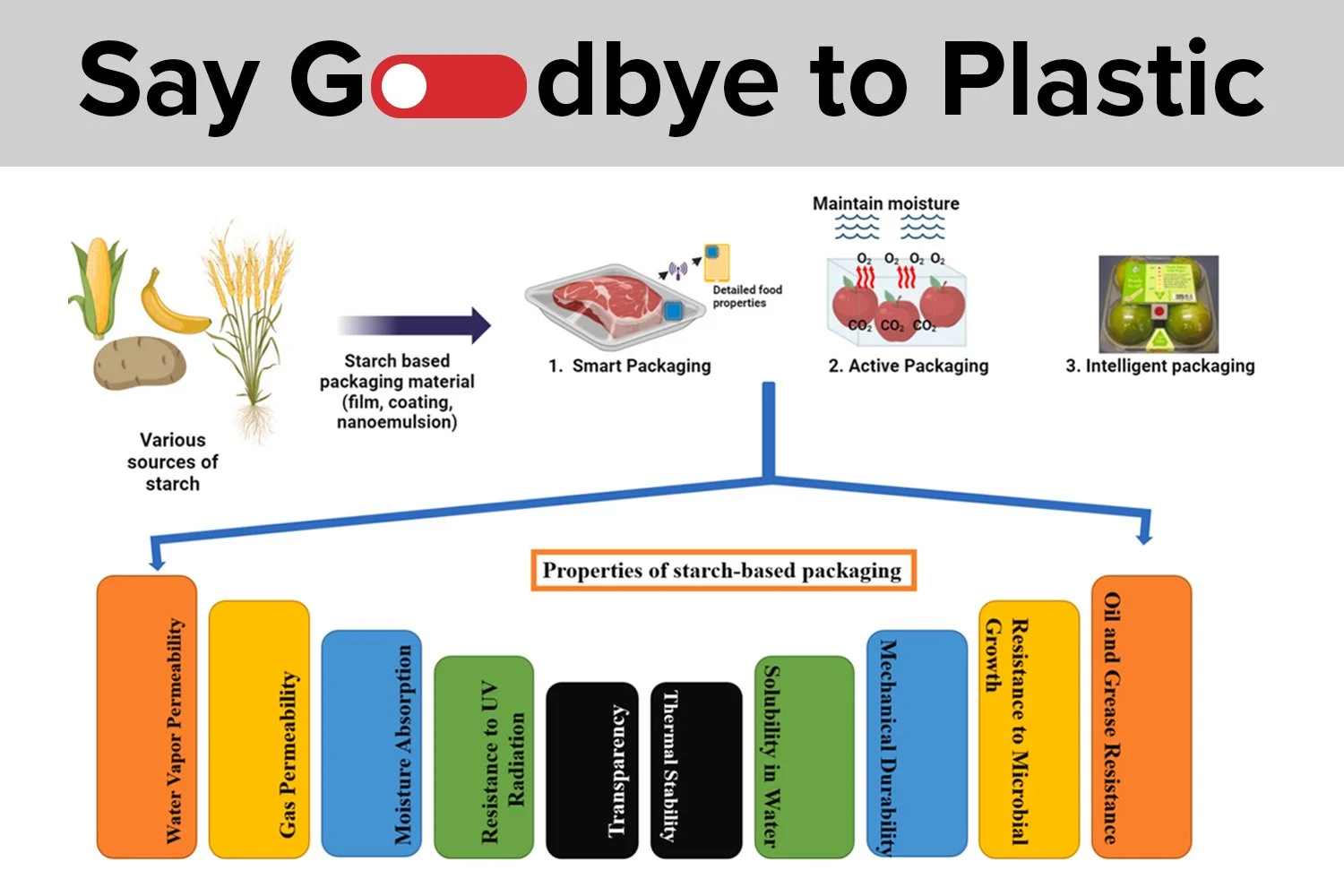

Discover how starch-based films are revolutionizing food packaging with sustainable, biodegradable, and functional solutions.

Learn how battery electrodes are prepared, coated, dried, and processed to achieve optimal performance. This comprehensive guide covers slurry preparation, coating techniques, drying, and post-processing for lithium-ion and other battery types.

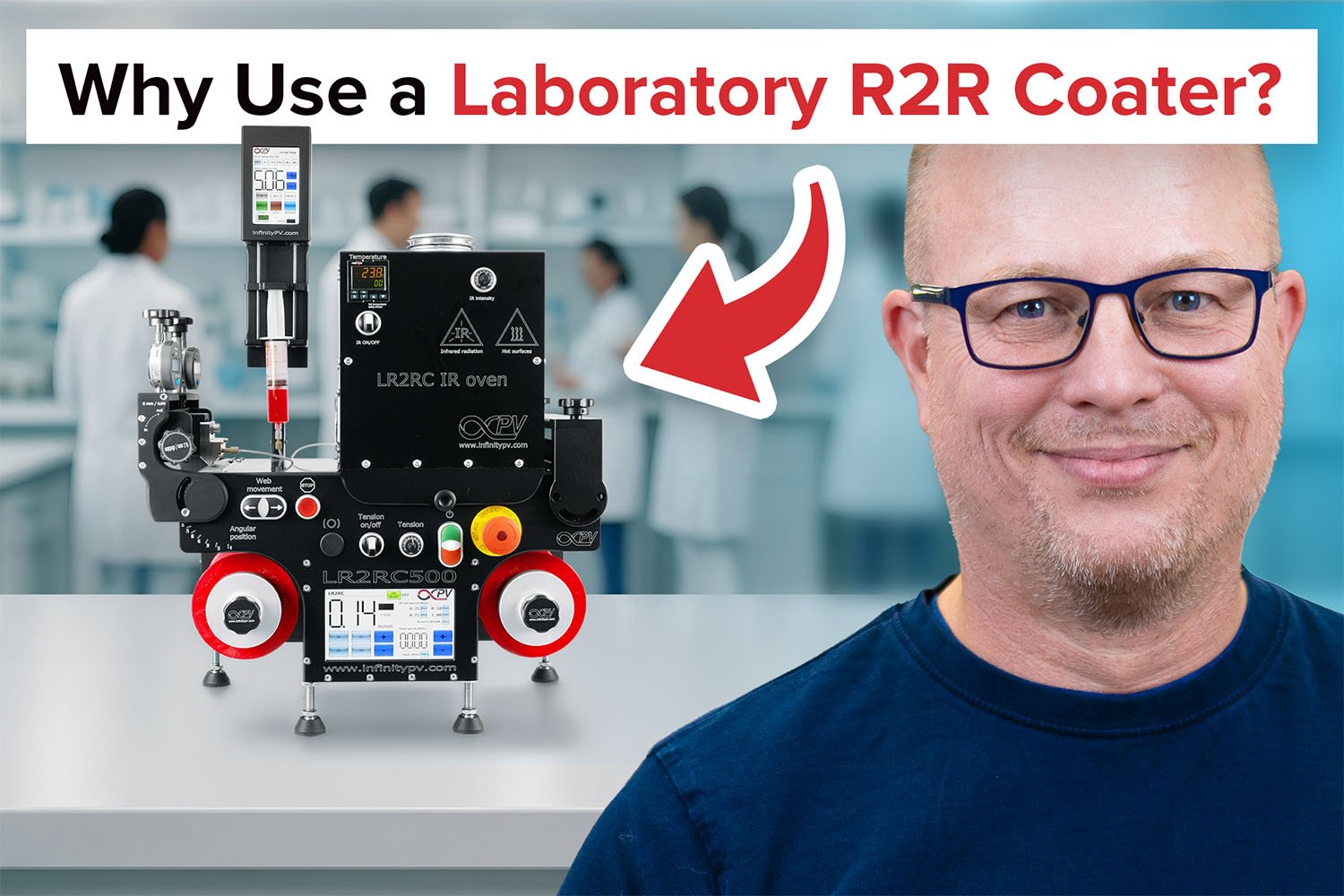

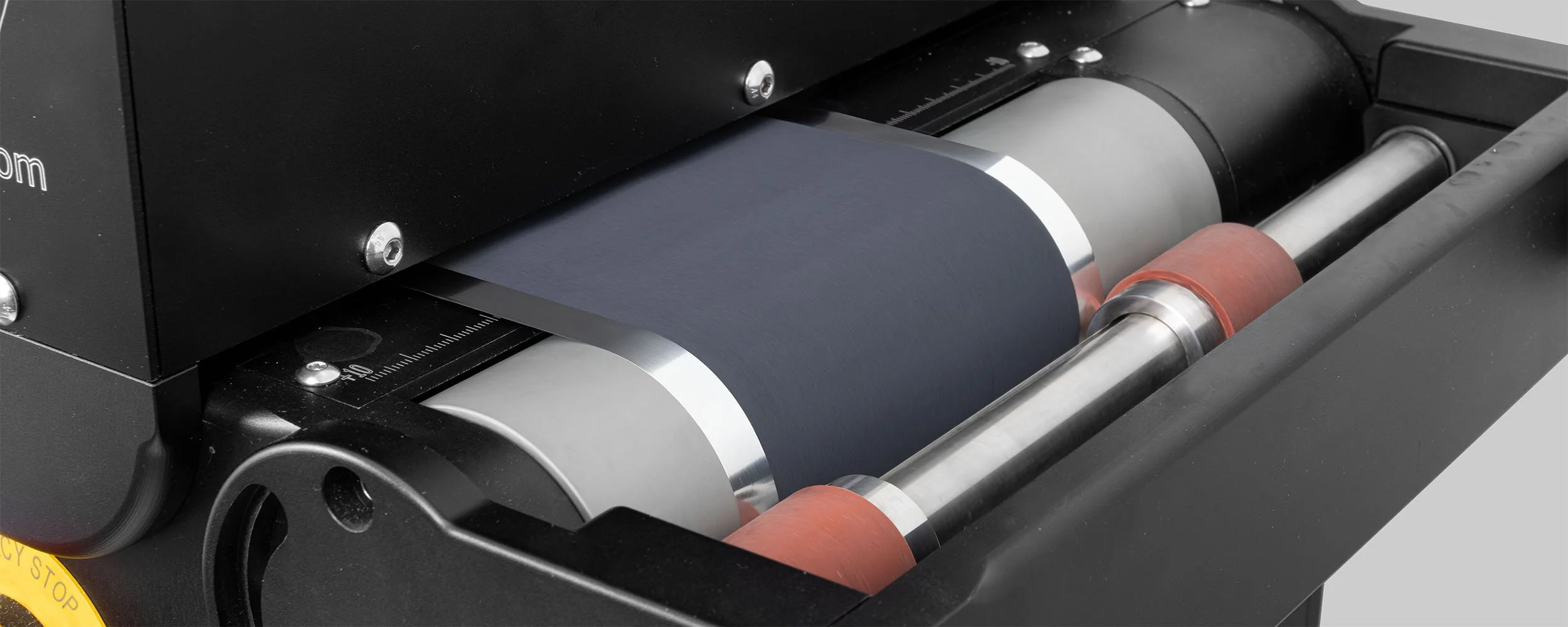

Why laboratory roll-to-roll coaters with modular design are ideal for thin-film research, offering flexibility, efficiency, and easy reconfiguration.

Learn why high-quality perovskite solar cells must be made using compact lab-scale roll-to-roll (R2R) equipment.

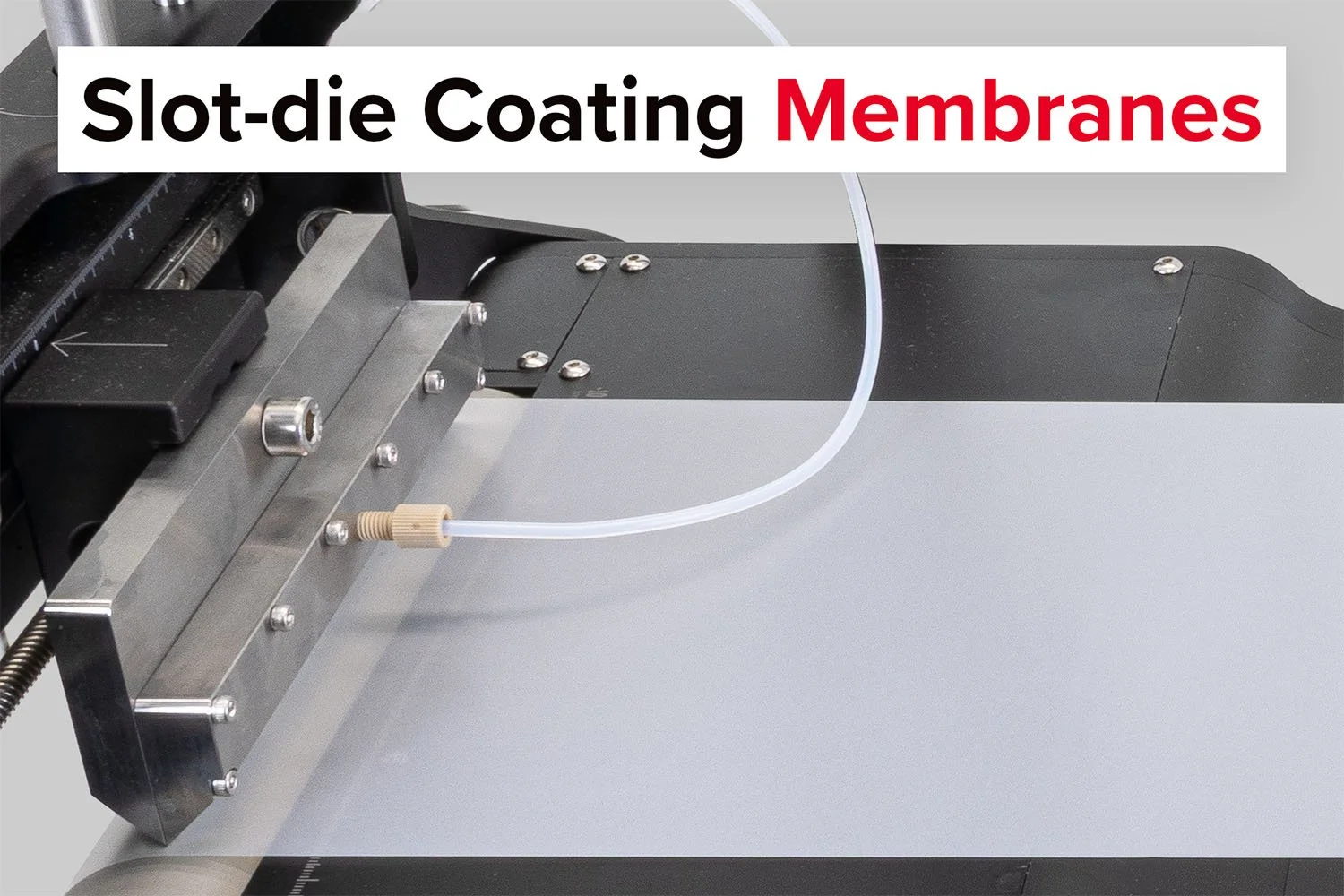

Discover how slot-die coating revolutionizes membrane fabrication, providing precise thickness control, gradient experimentation, and advanced Roll-to-Roll processing for high-performance membranes used in water purification, fuel cells, and more.

Learn how to choose the right slot-die coater for your needs. Compare sheet vs. roll-to-roll (R2R) systems, understand substrate compatibility, drying methods, treatment options, and scalability to make informed coating decisions.

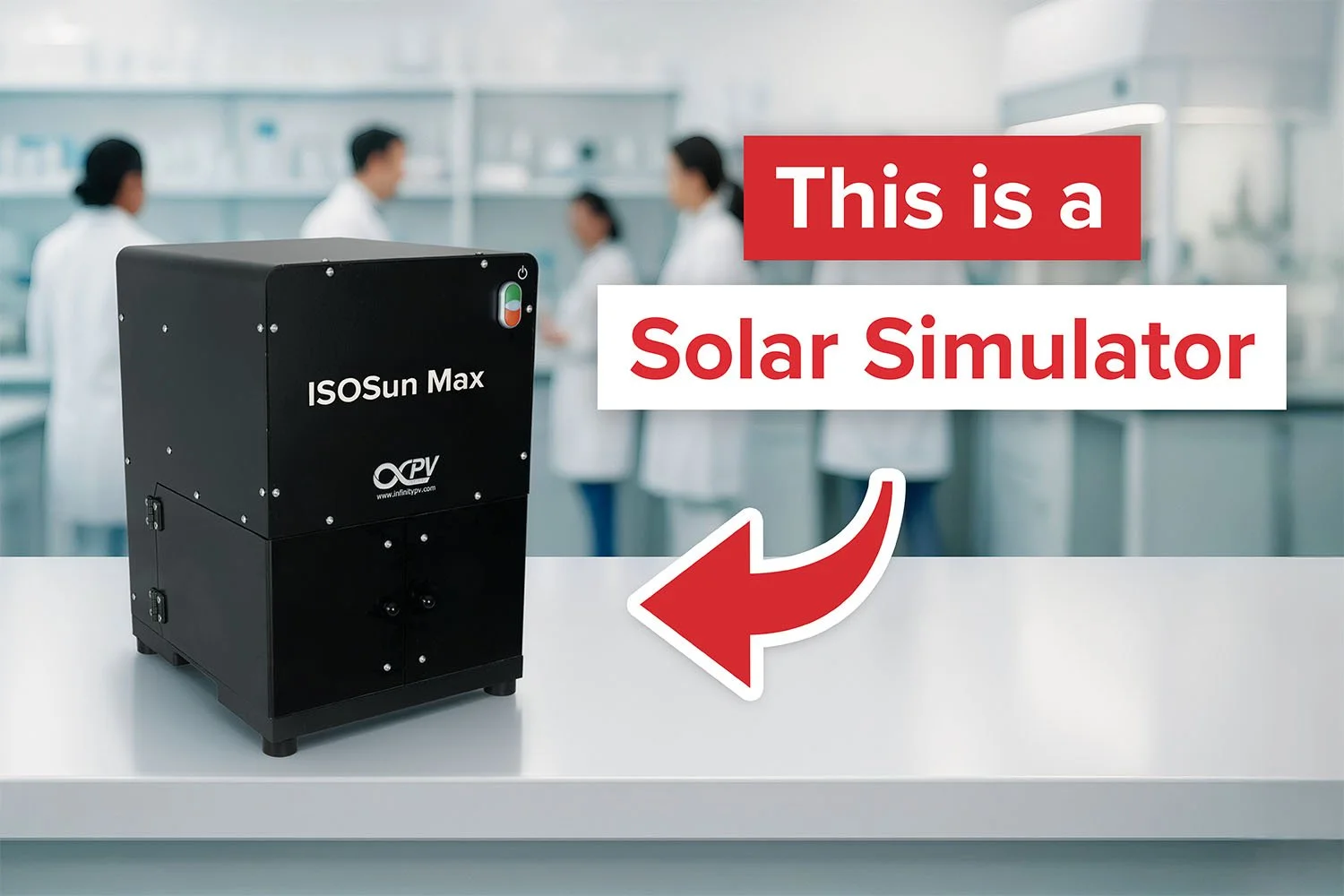

Learn about solar simulator classifications for photovoltaic testing. Understand A, B, C, and A+ ratings based on spectral match, spatial uniformity, and temporal stability according to IEC, ASTM, and JIS standards.

Learn how LBIC (Light Beam Induced Current) maps solar cell performance, detects defects, and helps researchers and manufacturers optimize efficiency and stability.

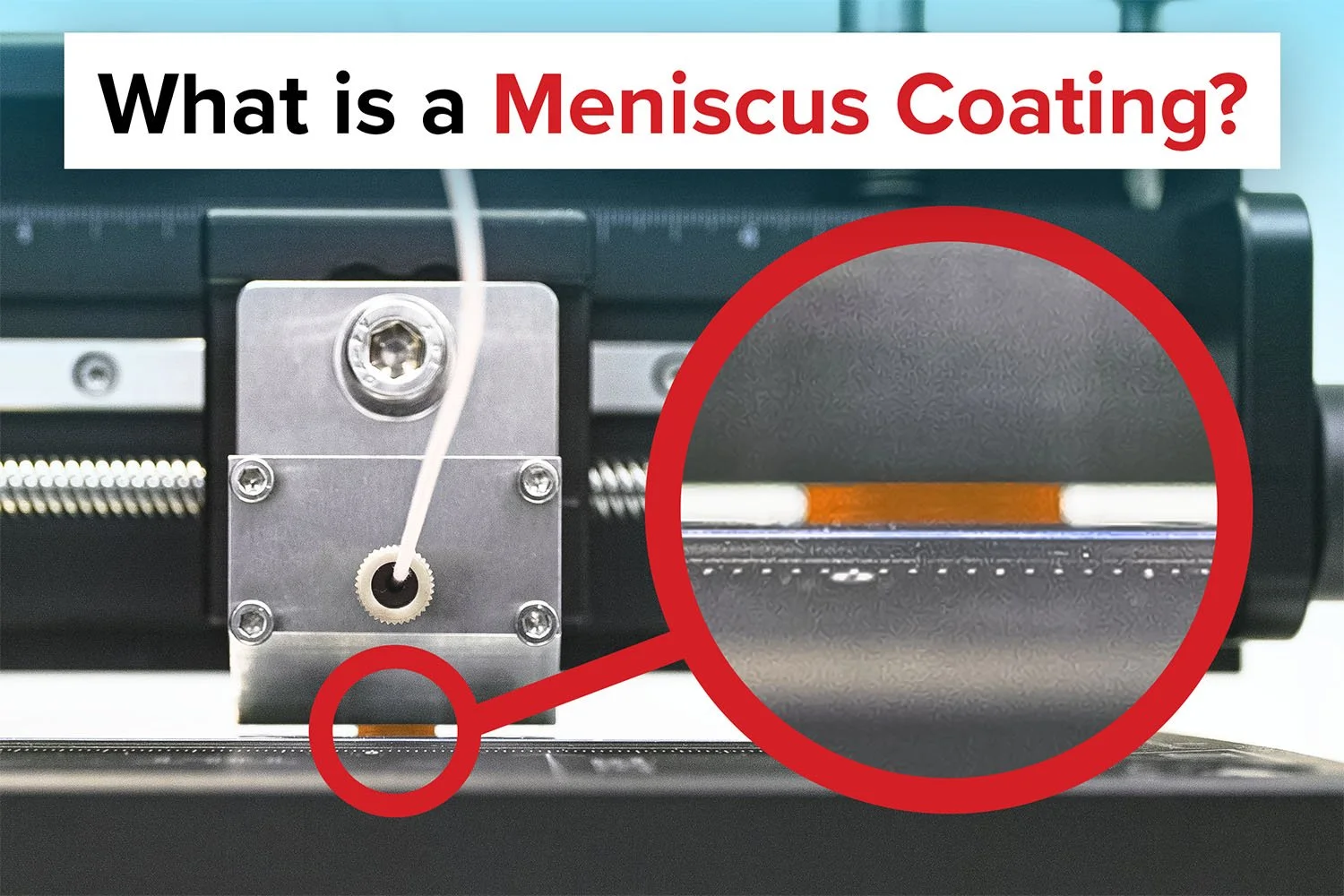

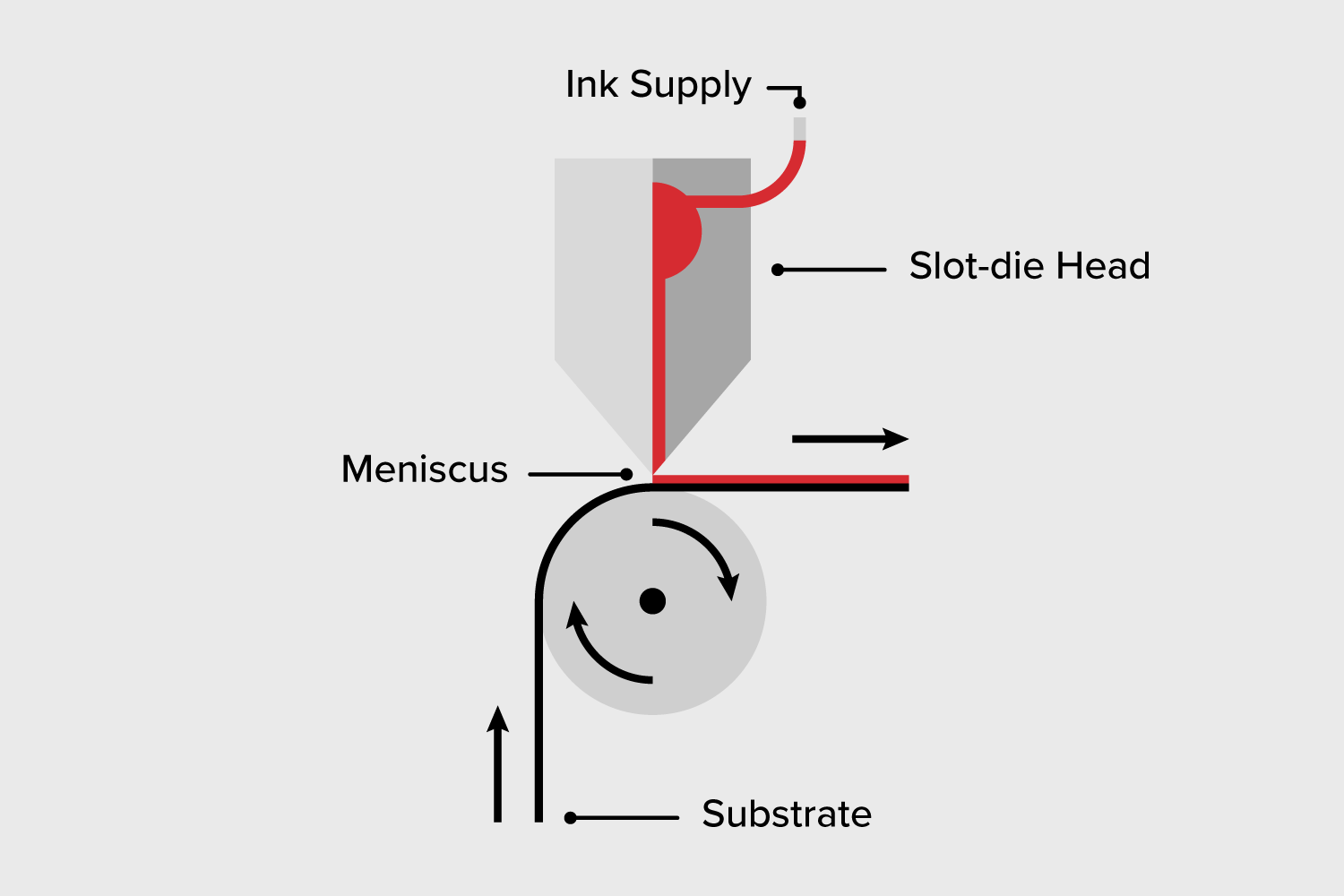

Learn the fundamentals of meniscus coating, where surface tension, substrate compatibility, and ink supply determine film uniformity.

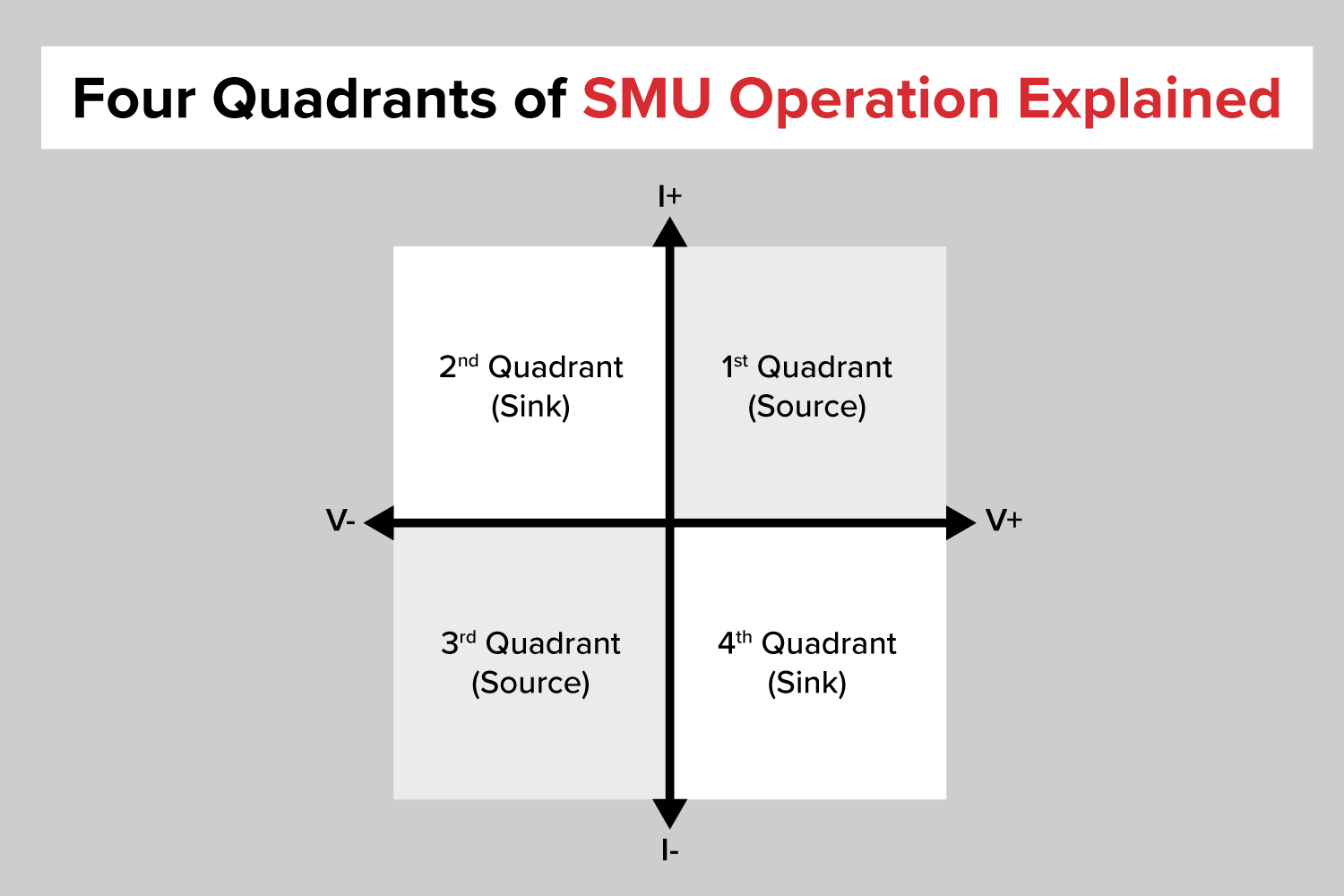

Learn how the four quadrants of SMU operation enable sourcing and sinking of current and voltage for battery, semiconductor, and solar cell testing.

Learn everything about solar simulators, how they reproduce sunlight in labs, types of light sources, standards, and applications in photovoltaics and research.

Learn how air knives and gas quenching improve perovskite solar cell efficiency, stability, and scalability in roll-to-roll processing.

Transdermal patches explained: Learn how slot-die coating enables precise, uniform drug delivery systems, accelerates development, and improves patient safety.

Discover how perovskite solar cells are revolutionizing solar energy with their tunable structure, lightweight design, and high efficiencies.

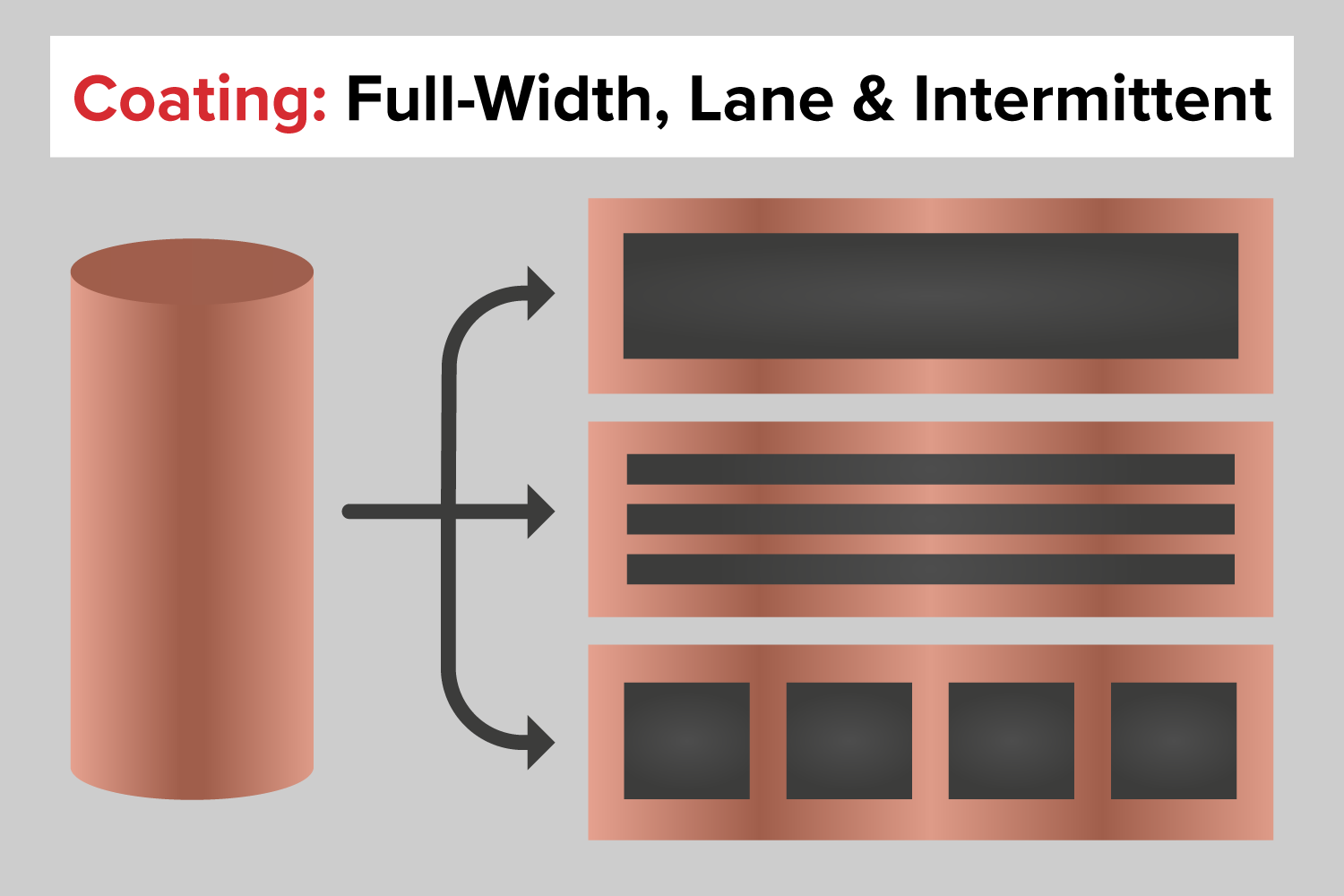

Explore full-width, lane, and intermittent slot-die coating methods, design challenges, and industrial applications.

Learn how slot-die coating is used to create precise, uniform layers in thin-film battery manufacturing. Discover techniques, materials, drying methods, and troubleshooting tips for lithium-ion and solid-state batteries.

Learn the key differences between roll-to-roll (R2R) and sheet coating techniques. Discover their advantages, challenges, and ideal applications to choose the right coating method for your lab or production needs.

Explore solution-based deposition techniques for printed solar cells, including spin coating, slot-die coating, inkjet, and screen printing. Learn how these methods enable scalable, cost-effective production for perovskite and organic solar technologies.

Discover how rheology and wetting behavior influence slot die coating performance. Learn how viscosity, surface tension, and viscoelasticity can be optimized to reduce defects and achieve uniform, high-quality coatings.

Discover the benefits, working mechanism, and formulation of fast dissolving oral thin films (OTFs) and learn how slot-die coating enables scalable, precise drug delivery solutions for modern pharmaceuticals

Discover how lab-scale slot-die coating improves pharmaceutical and medical device development through precise, uniform coatings for testing and prototyping.

Discover how pristine clean surface coating eliminates defects by applying functional layers onto untouched substrates. Ideal for medtech, solar cells, OLEDs, and advanced electronics.

Discover how roll-to-roll coaters enable continuous thin-film deposition on flexible substrates. Learn about slot-die coating, scalability, and lab-to-production transition with expert tips from infinityPV.

Discover how lab-scale roll-to-roll processing supports battery innovation, enabling scalable production, reducing development risks, and speeding up time to market.

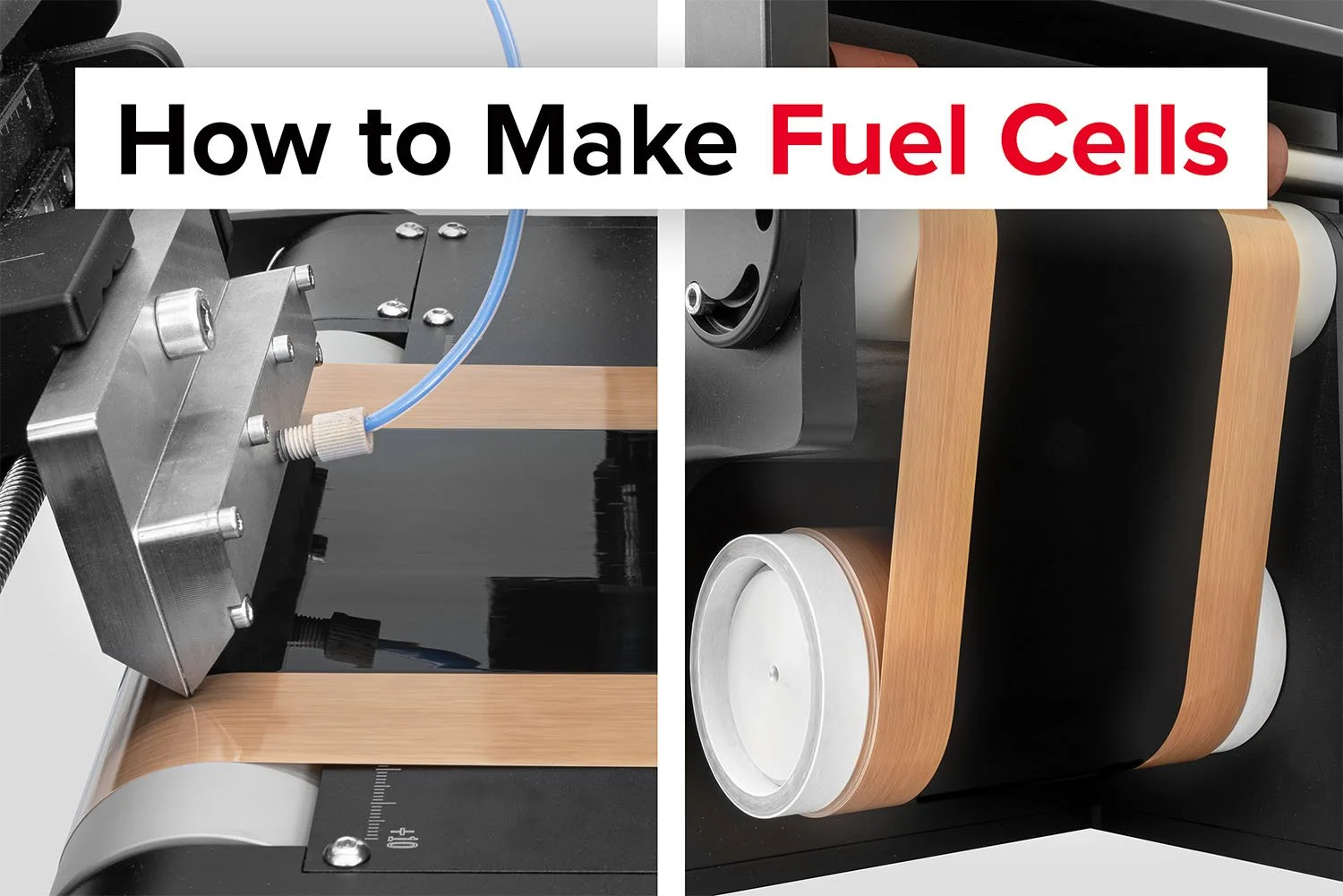

Discover how to make fuel cells using slot-die coating, a precise method for applying catalyst, electrolyte, and gas diffusion layers. Ideal for R&D and scalable production

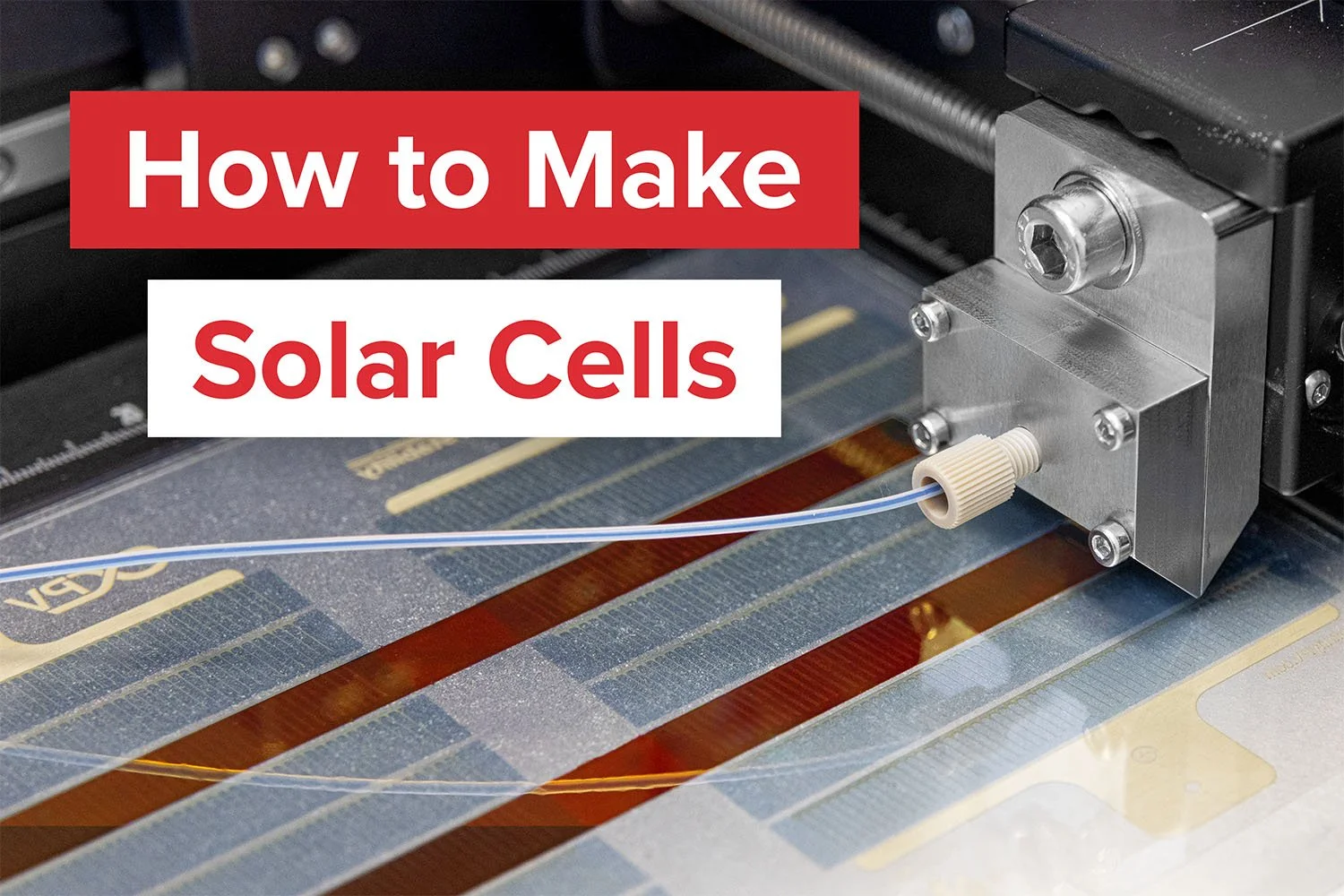

Discover how to fabricate solar cells using slot-die coating in this detailed, lab-focused guide. Learn about ink preparation, substrate handling, layer coating, and printing electrodes.

Learn how to properly mount a slot-die head on a slot-die coater with this step-by-step guide. Follow these tips for a secure, precise installation to ensure high-quality, consistent coatings every time.

Learn how to clean your slot-die head for optimal performance and longevity. This comprehensive guide covers tools, cleaning steps, and maintenance tips to keep your coating equipment in top condition.

Slot-die Heads for High-Performance Precision Coating

Whether you're working on batteries, pharmaceuticals, solar cells, or other thin-film technologies, this video guides you through the full process of using infinityPV’s slot-die heads—from assembly and mounting to precision adjustment, coating, and cleaning. Available in stainless steel, titanium, and PEEK, and in widths from 40 to 305 mm, these slot-die heads are engineered for accuracy, repeatability, and compatibility with all infinityPV platforms.

We Are Ready to Help You

With decades of experience in printed electronics, our team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project. Contact us to discuss how we can support your solar cell development.

Build Your Own R2R Slot-die Coater

With its modular design, the Laboratory Roll-to-Roll Coater empowers you to customize your system with the components you need. Choose between slot-die heads, flexographic printers, slurry coaters, air knives, drying and curing units, knife cutters, laminators, laser systems and more.