Slot-die Coating for Membrane Fabrication: Quality and Process Optimization

Membranes are barriers that allow for some materials to pass through while preventing others. They come in many sizes and shapes and are used for a wide variety of applications, ranging from mechanical filters to ion selective or gas selective membranes. Examples from everyday life where membranes play a significant role could be water purification, desalination, fuel cells, electrolysis, flow batteries and removal of impurities from blood through dialysis.

Membranes can be prepared in many different ways involving procedures such as Electrospinning where thin fibres are prepared through exposure of polymer solutions to high electrical fields or Track-Etching where a combination of irradiation and etching creates a porous structure in a thin film, but most membranes are prepared through some kind of casting or coating of a solution or slurry.

Solvent Casting is the most basic form of coating, where a solution is coated onto a carrier substrate and the solvent of the solution is evaporated leaving behind a thin film. Several variations of this process involve induced phase inversion/separation of the solute causing it to precipitate before the solvent has evaporated by treatment with a “non-solvent”*, temperature changes, or a combination hereof, creating special properties in the final membrane. Techniques such as direct Non-solvent Induced Phase Separation (NIPS), Dry-Wet Phase Inversion and Thermally Induced Phase Separation (TIPS) are examples of this.

*A solvent that is miscible with the solvent of the cast solution but not with the solute. This “draws out” the cast solvent causing the solute to precipitate.

Advantages of Using Slot-die Coating in Membrane Preparation

Common for all the above is that they start with the coating of a wet film, which is where slot-die coating proves its worth, as slot-die coating is the only coating technique that directly and easily provides full control of the coated layer thickness. Other coating techniques such as blade coating, knife coating or rod coating, while still being valuable tools, does not have the same level of control.

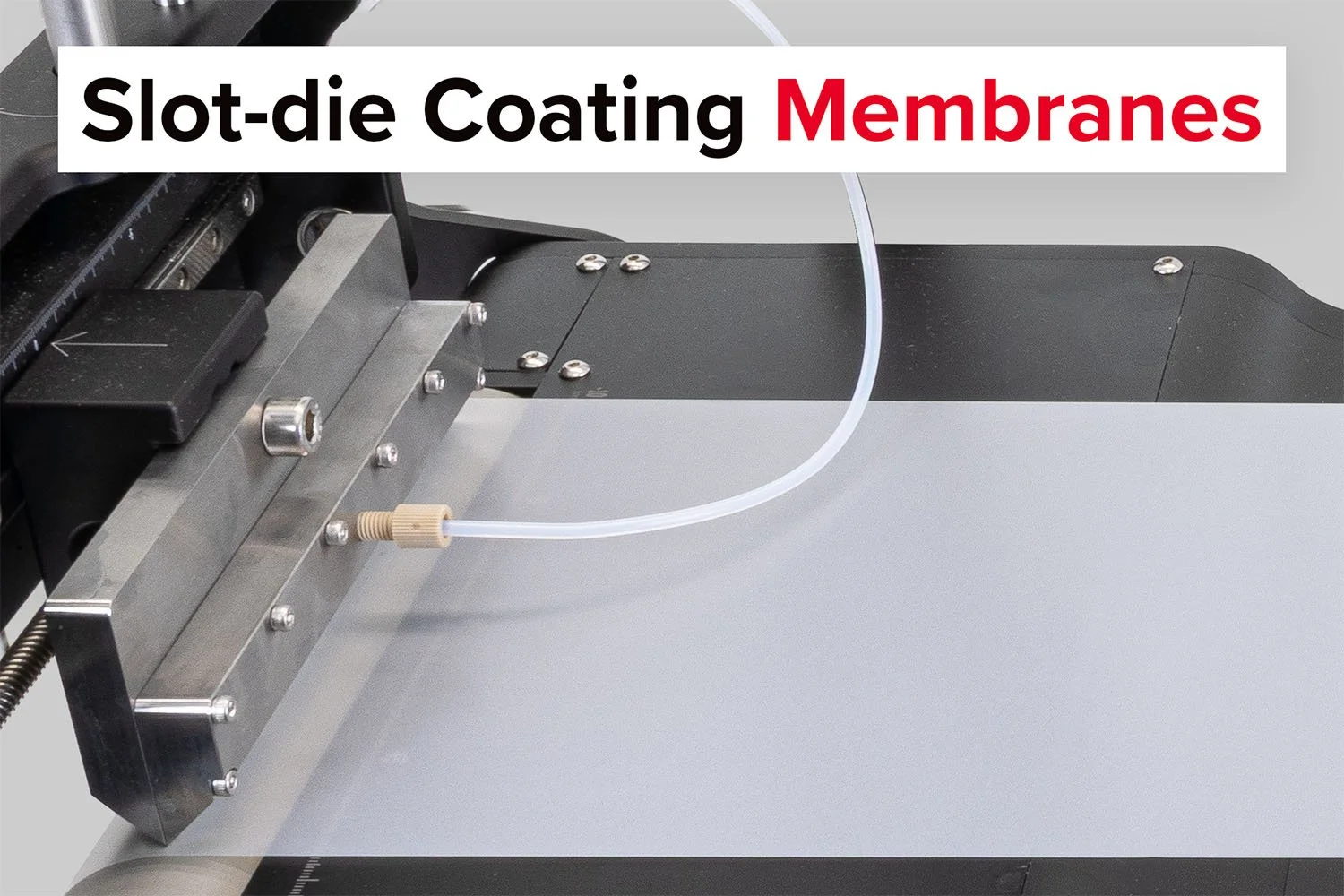

In slot-die coating the ink (coating solution) is provided by continuous pumping through a narrow slit/slot in the slot‑die head that is placed right above the substrate. A meniscus is created between the slot-die head and the substrate and as either the substrate or the slot-die head is moved a thin film of the ink is created. The width of the coat corresponding to the width of the slot and the thickness of the wet film being a direct function of the pumping speed and how fast the substrate/slot-die head are moving relative to each other (web speed) at the given slot-width. The wet layer thickness can thus quickly and precisely be altered by either changing the pumping rate and/or the web-speed.

Process Optimization Using Slot-die Coating

The easy tuning of coating parameters makes slot-die coating ideal for optimisation of processes, especially if used in a Roll-to-Roll (R2R) process using flexible substrates, as a multitude of different experiments can be carried out “on the fly” simply by adjusting the various parameters. This is especially true if a multi-pump system is used as an addition, also called differentially pumped slot-die coating, as this furthermore allows for adjusting the ink composition supplied to the slot-die head simply by adjusting the ratios of the pumps.

Example of roll-to-roll processing.

As an example, the most basic experiment could be a gradient experiment where the concentration of the solute is reduced from x percent to y percent by gradually changing the relative pumping speed of two pumps - one controlling the pumping speed of a solution containing x percent solution and the other pure solvent. The supplies of the two pumps are then mixed in a manifold before reaching the slot-die head and depending on the setup the final output could be:

If the overall pumping speed is kept constant (same wet thickness): -> gradient thickness of the membrane

If the supply of solute is kept constant -> same amount of solute (solid) per cm², but a gradient wet thickness/concentration of wet film. This could be used to examine the effect of solute concentration on the porosity characteristic and membrane morphology in the final membrane when exposed to non-solvents.

More complex experiments could be varying the composition of hybrid inks for hybrid membranes containing more than one component. Increasing the number of pumps set the limit to the number of parameters that can be examined simultaneously.

Gradient Control

Advanced Slot-die Coating Using Double Slot-die Head

Specially designed slot-die heads allow for simultaneous coating of two different layers on top of each other. Instead of having a single slot, the double slot-die head has two discrete slots, both feeding the same meniscus. In a coating situation, with a moving substrate, one of the two supplied inks naturally becomes the bottom part and the other the top part. Some mixing of the two is inevitable, but can to some degree be controlled by adjusting the viscosities of the inks – for some processes such mixing is even an advantage as it provides a gradual transition from component 1 to components 2 with the interface being a gradient mixture of the two.

An alternative way to obtain a similar outcome, could be to perform two or more consecutive slot-die coatings, if needed with a partial drying in between, before the final removal of solvent.

Membrane Preparation Using Roll-to-Roll Processing

R2R processing is ideal for the processing of flexible membranes as many of the discrete operations and handling of discrete units can be carried out in a continuous flow of processes starting with an empty roll of substrate and finishing up with a roll of finished membrane – the principle being, that if you need a processing/treatment step, then you simply add it to the process in the relevant order from unwinding the untreated roll in the beginning of the process to rewinding the roll of substrate with the final membrane.

Depending on the type of membrane and treatments needed, the setup could involve one or more of the units below in any given order:

Coating:

Slot-die Head, Knife Coater, Slurry Coater

Drying

Non-solvent treatment:

Lamination:

Membrane Trimming:

Membrane Separation

Stripping Unit for separating the membrane/carrier substrate (if used).

Conclusion

Slot-die coating is a transformative technology in membrane fabrication, offering unparalleled precision and flexibility in controlling film thickness, solute concentration, and multilayer structures. When combined with Roll-to-Roll processing and advanced gradient or double-slot techniques, it allows researchers and manufacturers to optimize membrane properties efficiently, enabling innovations across water treatment, energy storage, and medical applications. By mastering slot-die coating parameters, one can achieve membranes with consistent performance, reproducibility, and tailored functionality for virtually any industrial or scientific need.

We Are Scientists — Not Salesmen

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.