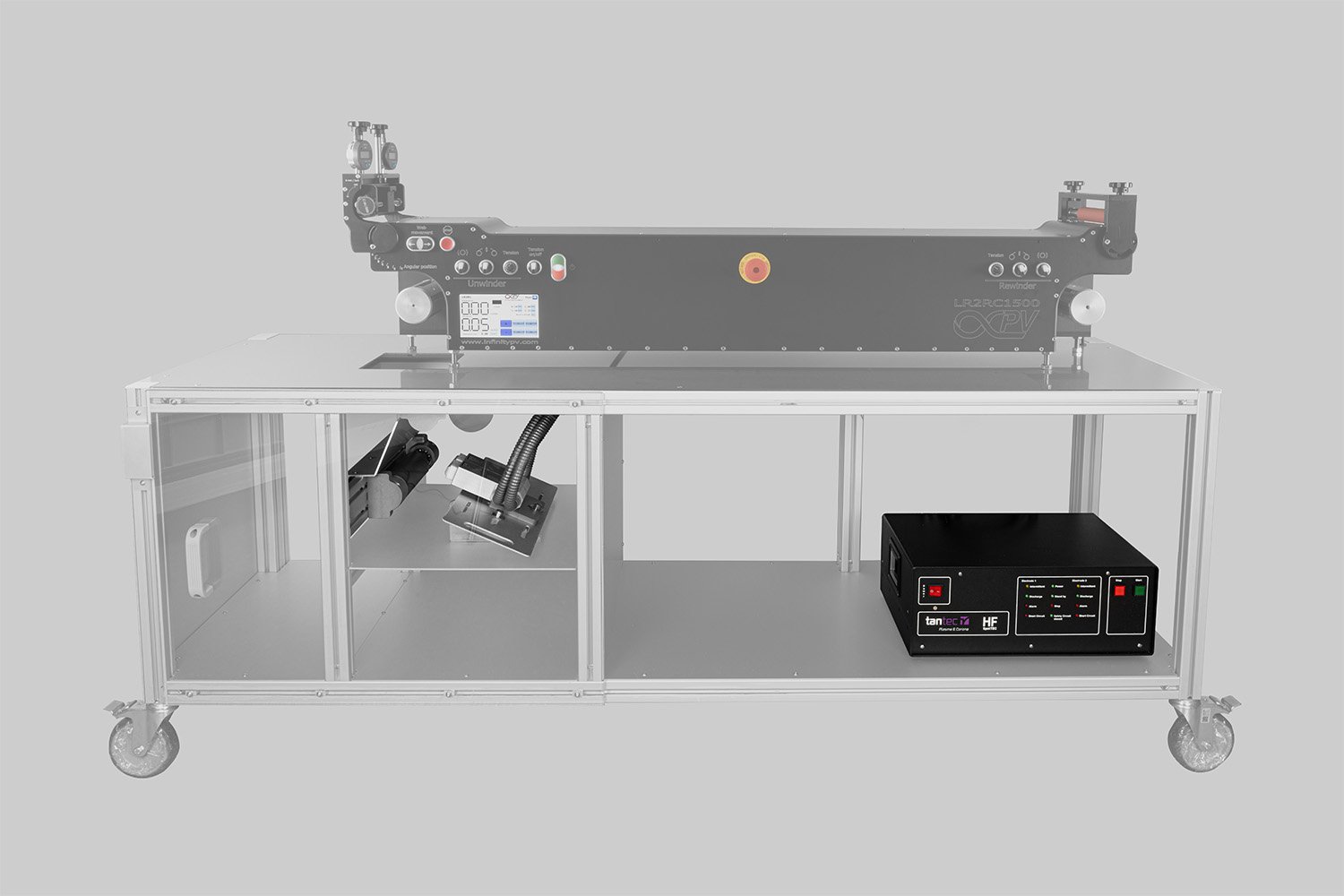

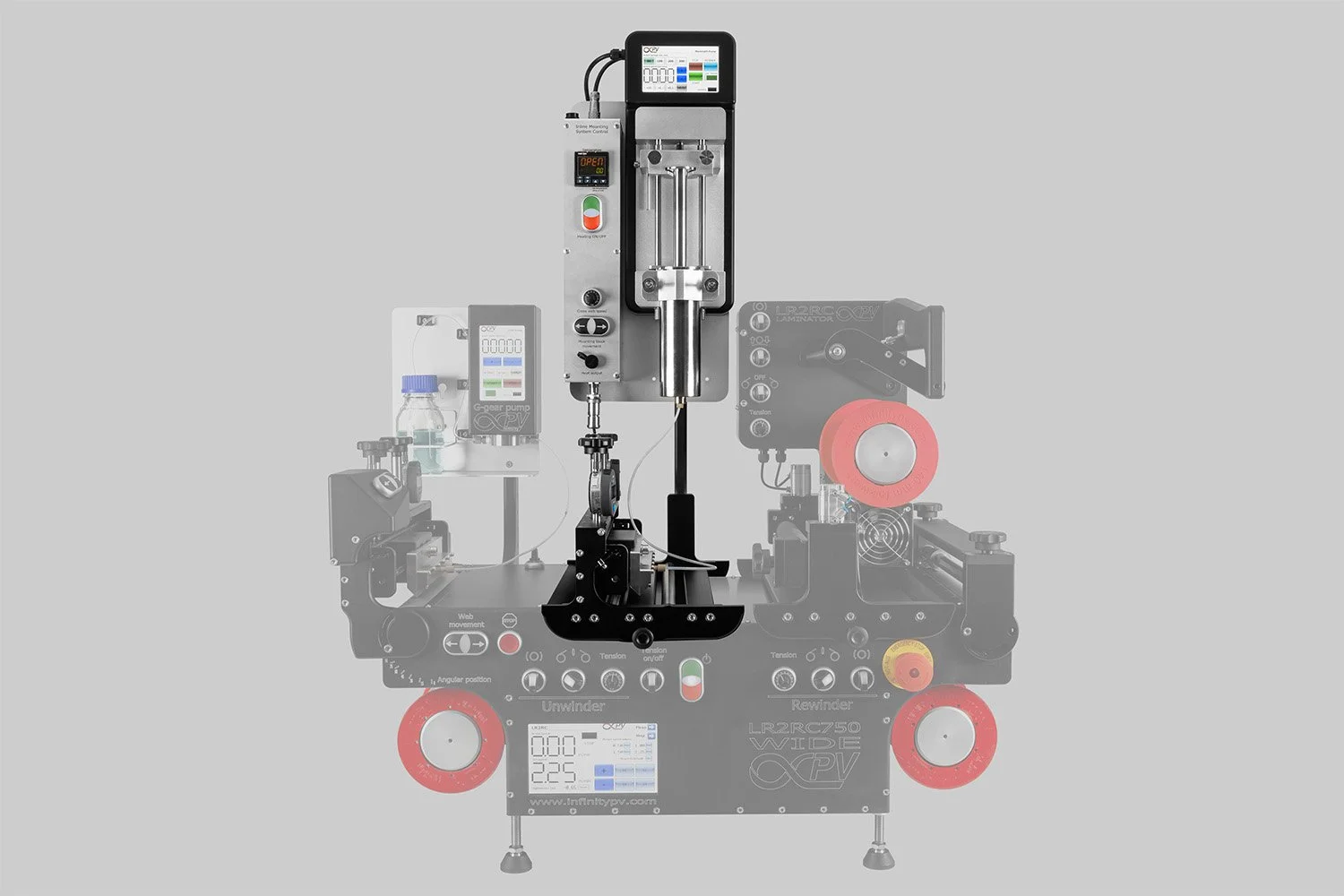

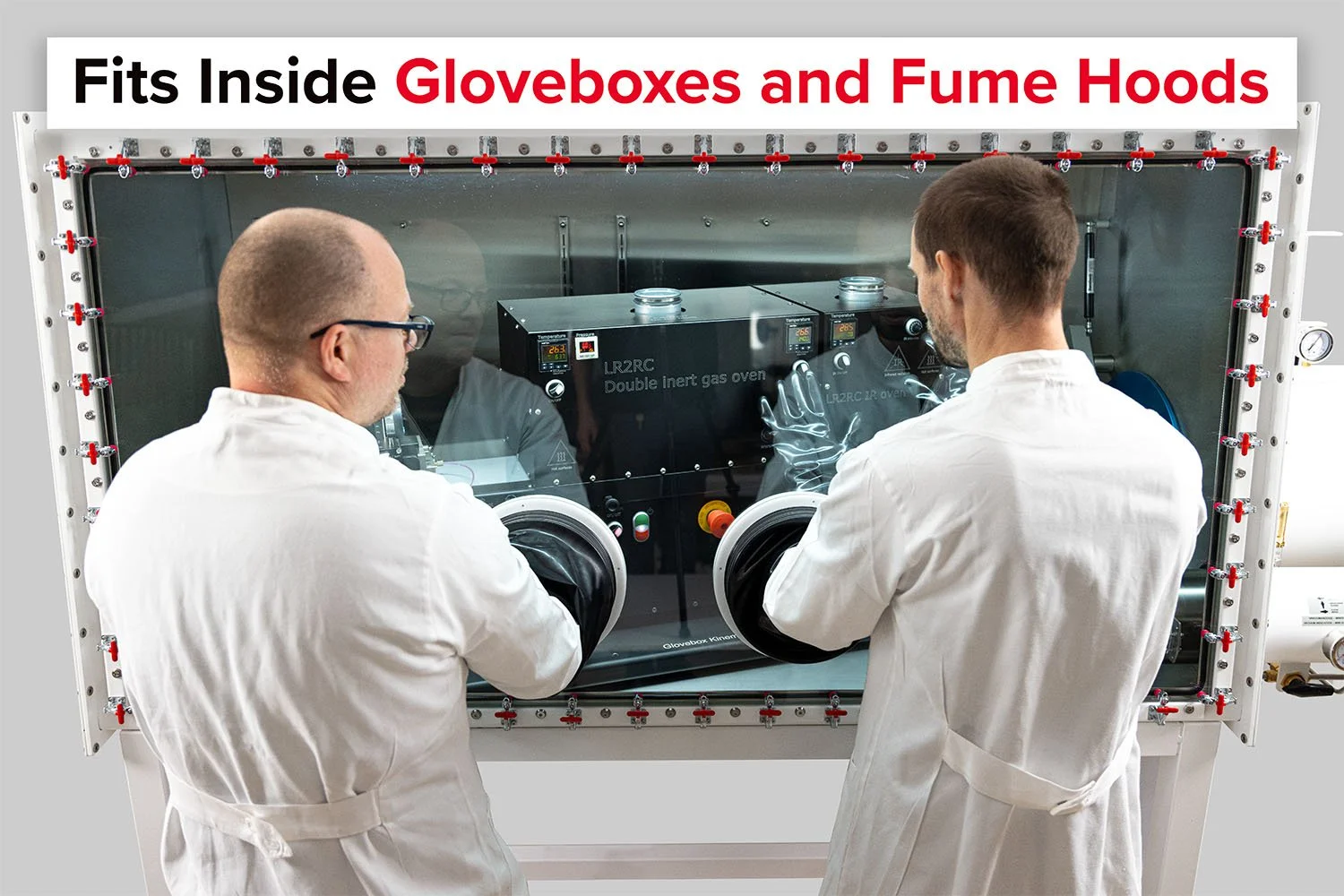

The Wet Processing Center enables precise roll-to-roll handling of foil while subjecting it to a variety of wet processes in a fully enclosed, safe, and versatile environment. Designed for research, prototyping, and pilot production, it supports immersion, spraying, and electrochemical treatments tailored to thin-film, printed electronics, solar cells, and other advanced materials applications.

Key Features

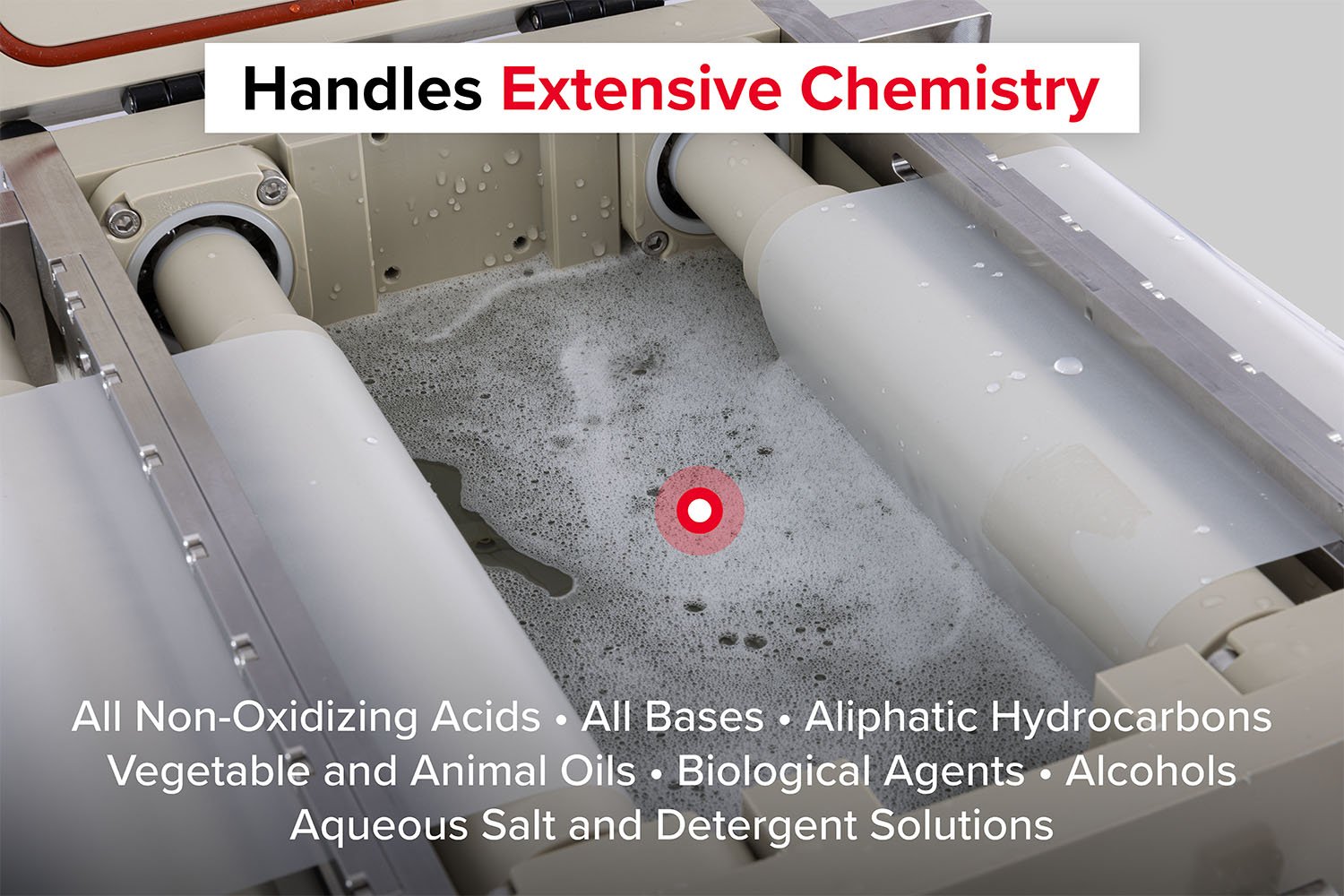

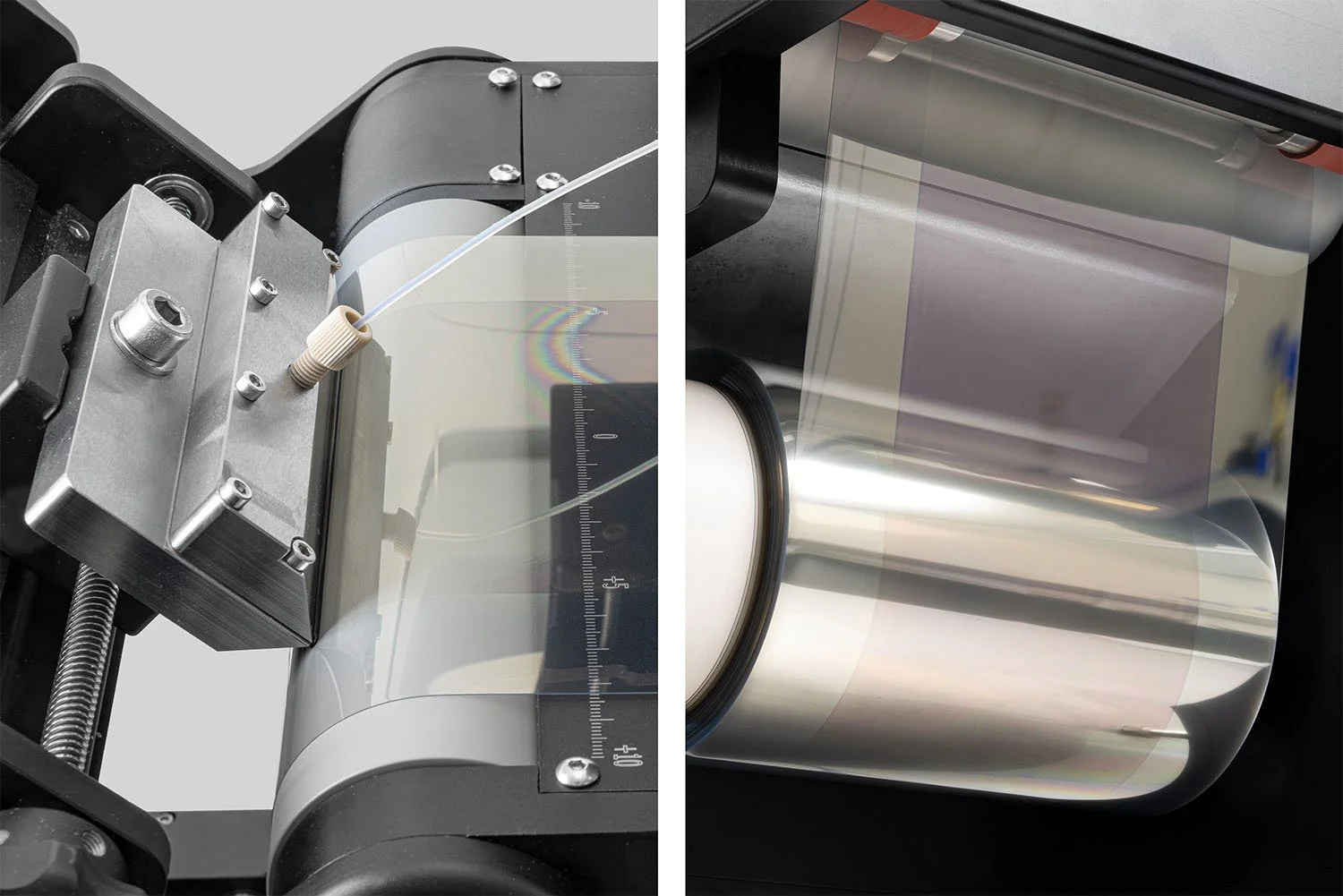

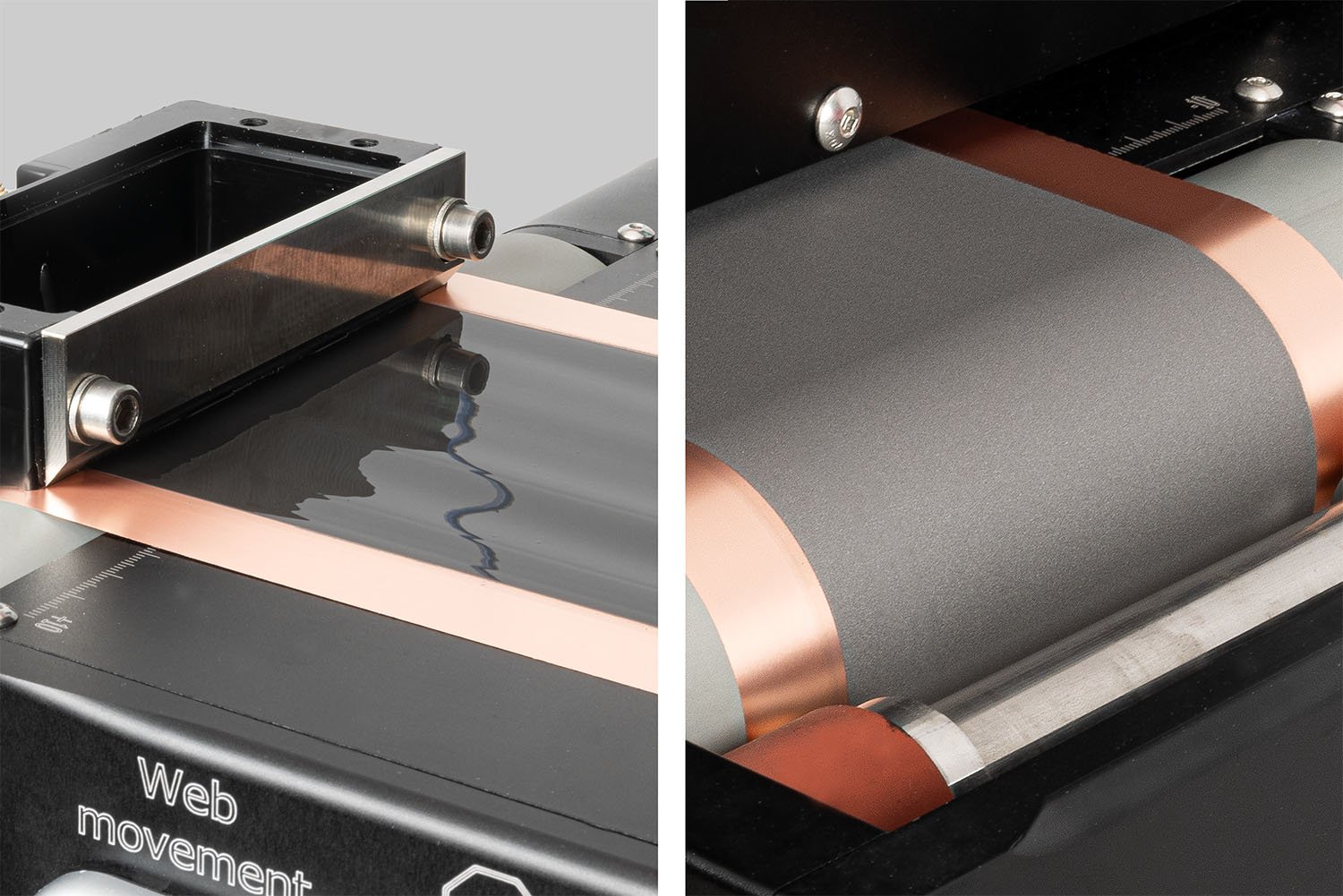

Immersion in liquid: Ideal for etching, washing, coagulation, imbibition, or the exchange of ions, solutes, and solvents.

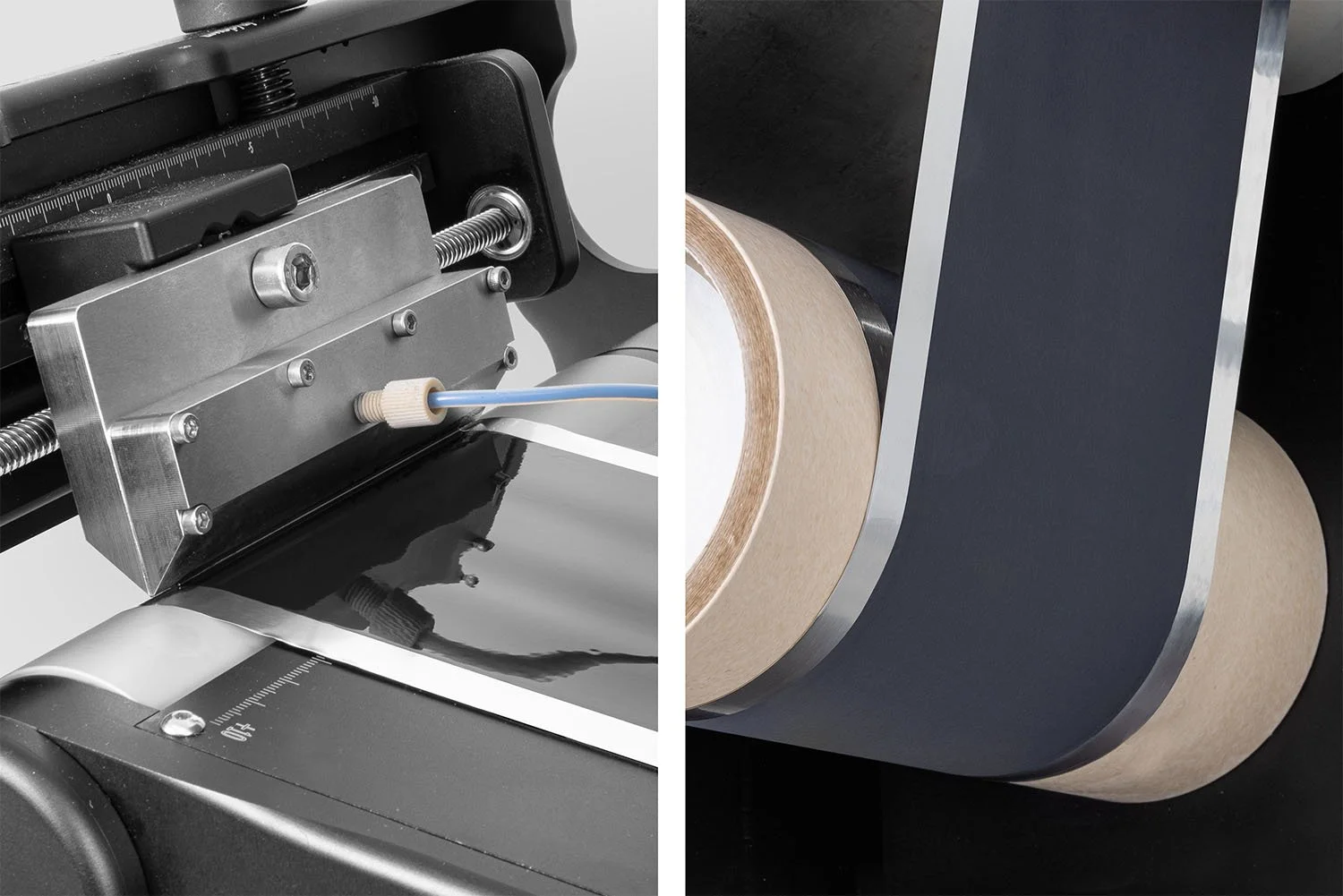

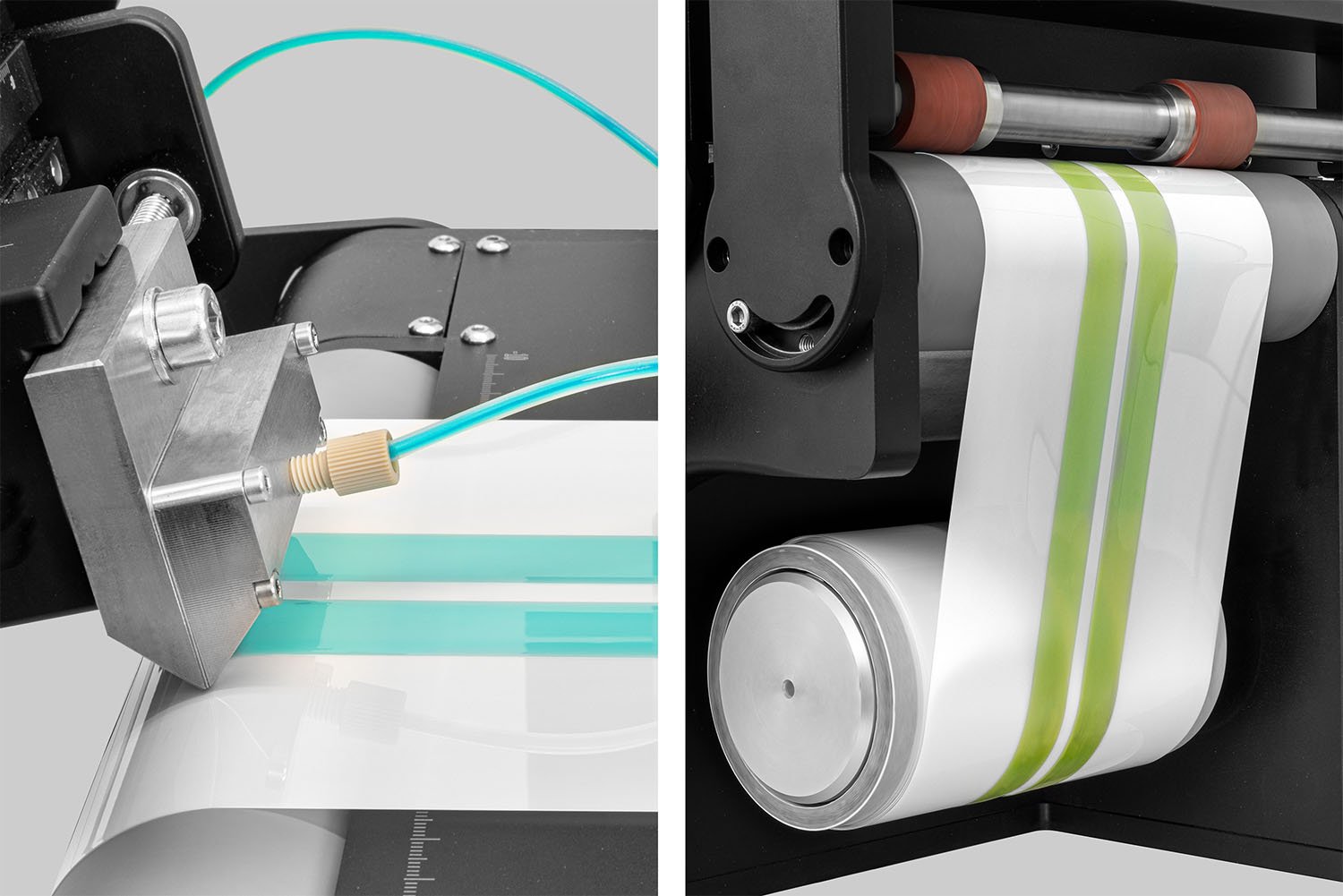

Spray treatment: Apply liquids across foil surfaces while recovering or safely discarding the washings.

Electrochemical functionality: Heating, cooling, agitation, and electrical connection to the foil with counter electrodes for electrochemical surface processes.

Series connectivity: Multiple wet processing tanks can be linked for sequential treatments such as etching, developing, stripping, and washing.

Flexible configurations:

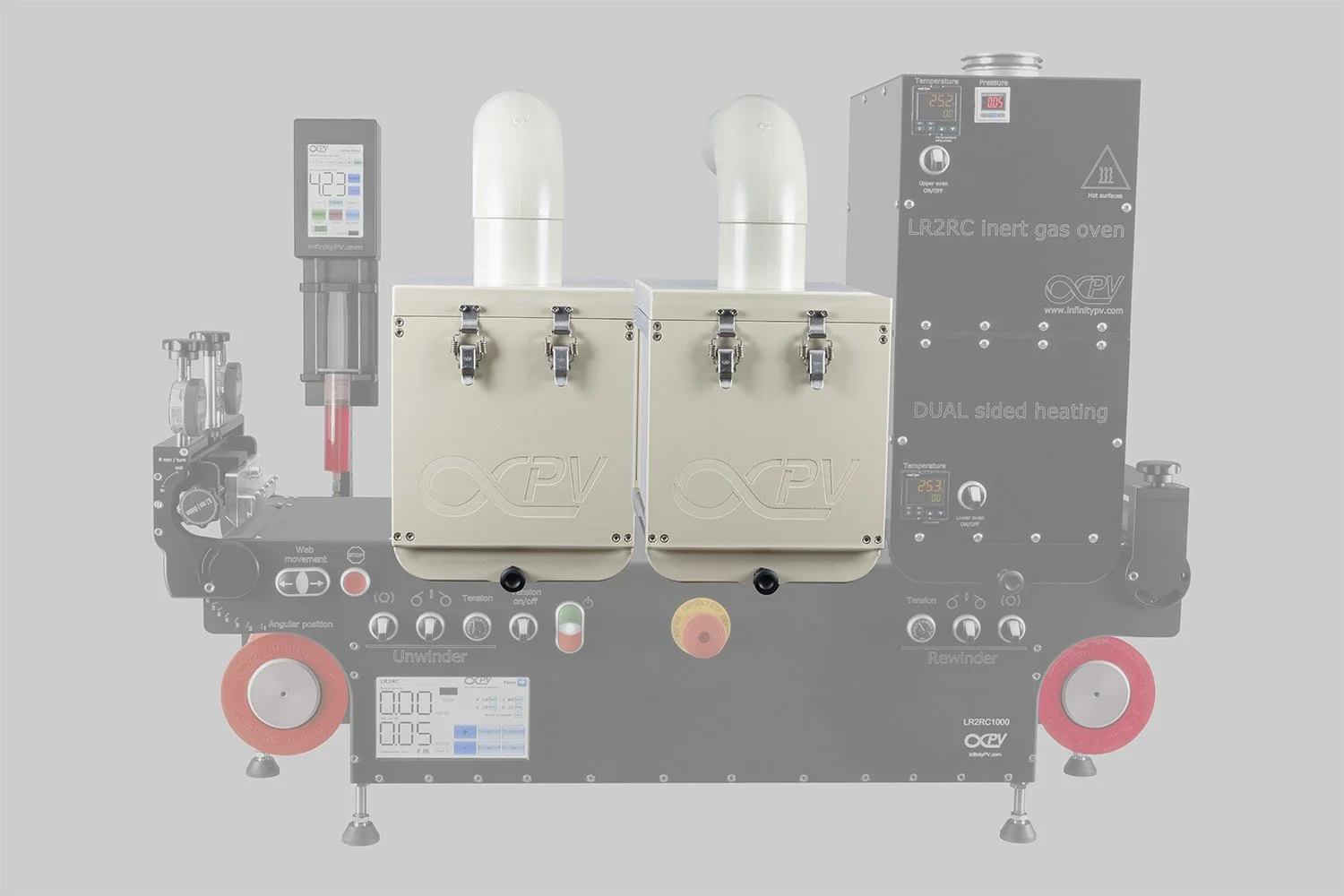

Direct docking on the Laboratory Roll-to-Roll Coater (10 L volume)

Stand-alone system (50 L volume)

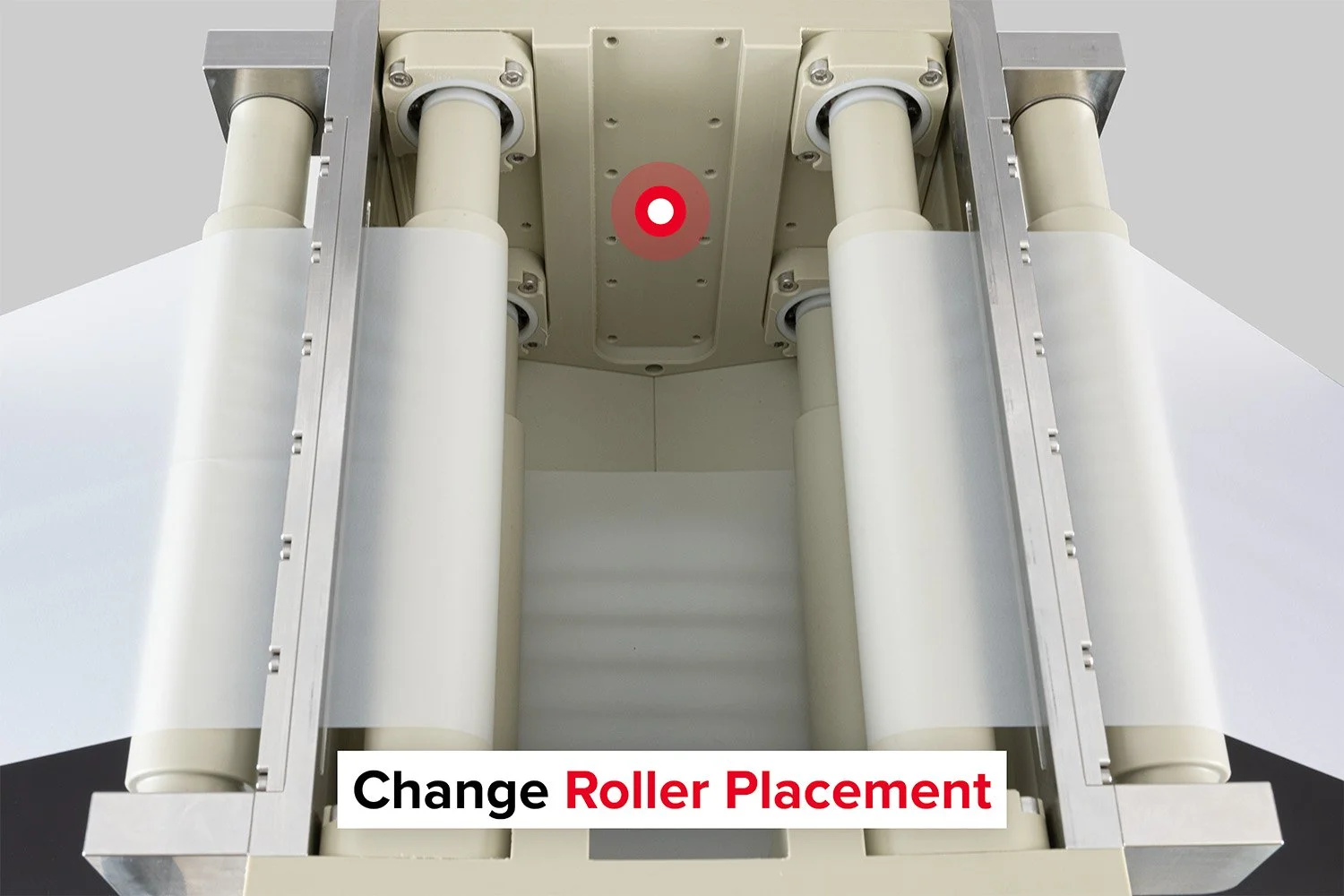

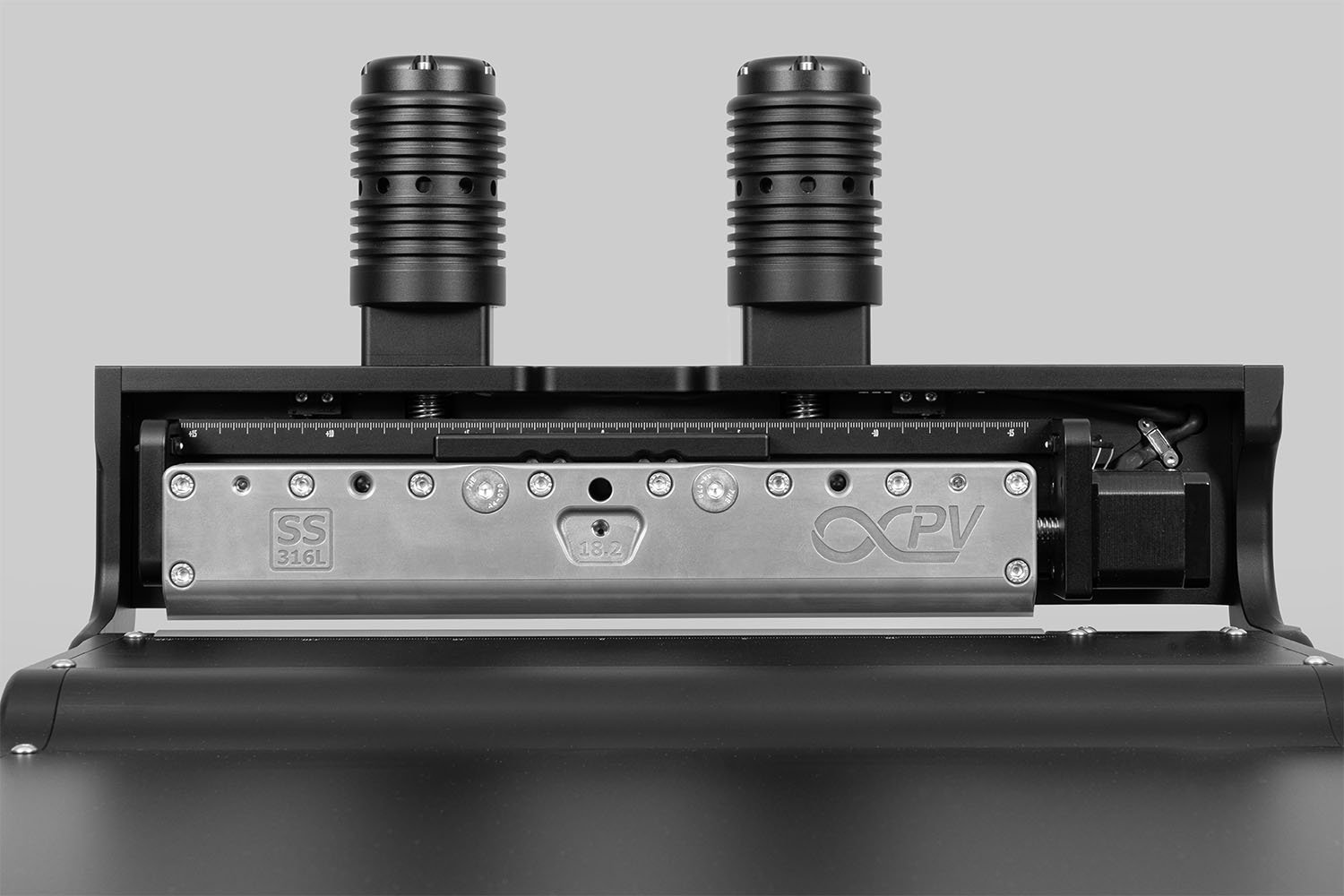

Variable processing lengths: From a few centimeters up to 5 meters per tank.

Roller variety: Extensive options for foil handling, including auxiliary rollers for integration with ovens, coaters, knives, and laminators.

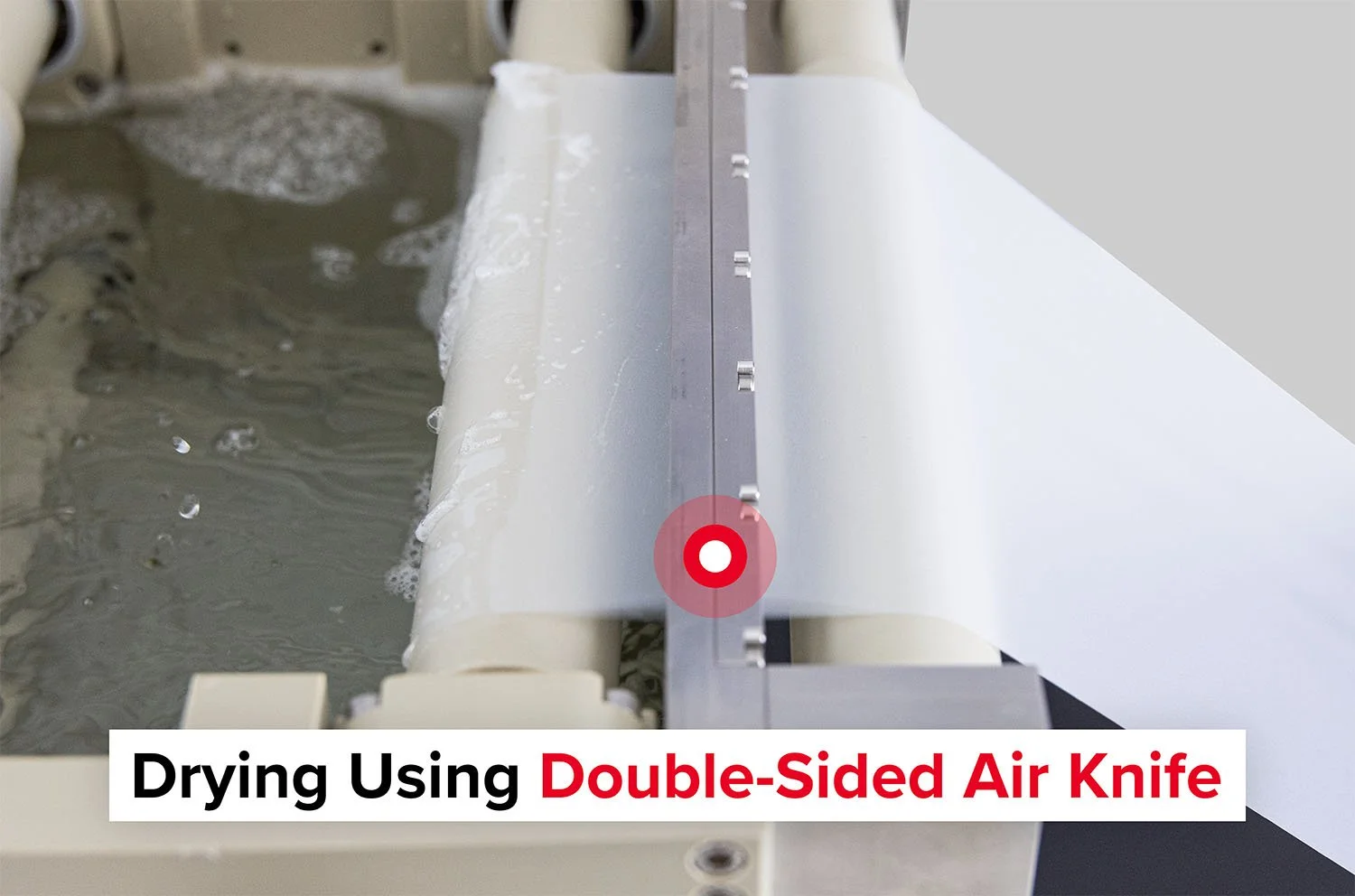

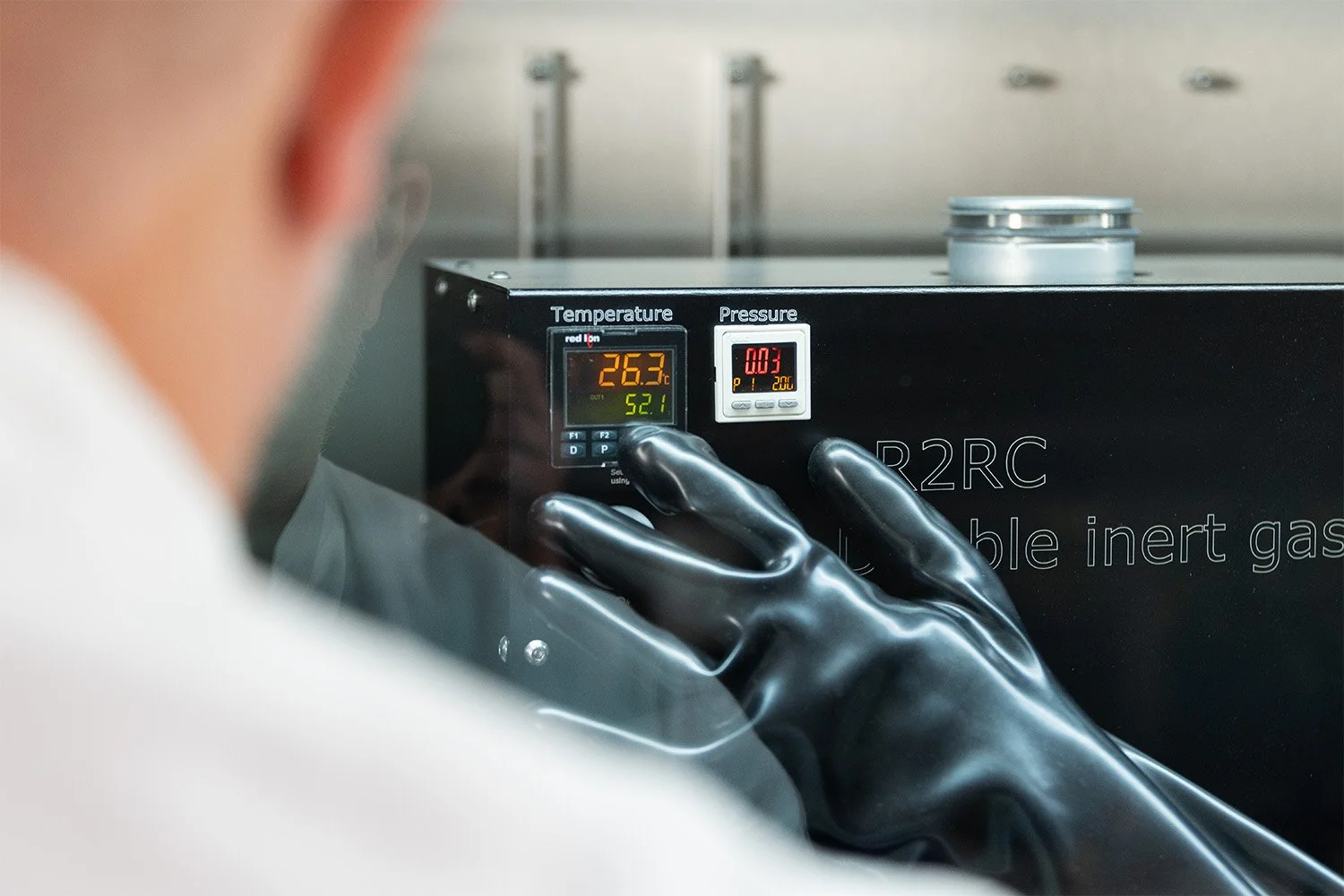

Closed system operation: Zero emission of solvents or liquids, ensuring safe and clean processing.

Enhanced drying: Double-sided air knives at entry and exit for rapid solvent removal.

Durable construction: Manufactured from high-quality plastics, ceramics, and stainless steel (316L) for longevity and chemical resistance.

This modular wet processing solution provides researchers and engineers with maximum flexibility, precision, and safety for their roll-to-roll foil treatments.

Wet Processing Center for the Laboratory Roll-to-Roll Coater

The Wet Processing Center is designed to seamlessly integrate with the Laboratory Roll-to-Roll Coater, a versatile and compact system for precise thin-film processing in lab and pilot-scale environments. Our modular components allow you to customize your coater for a wide range of applications including batteries, medtech, fuel cells, printed solar cells, sensors and more. Built for easy installation and interchangeability, these components help you optimize performance while maintaining flexibility and scalability.