How to Choose a Slot-die Coater: Roll-to-Roll vs. Sheet Coaters — Which One Fits Your Research and Production Needs?

Choosing the right slot-die coater requires careful consideration of your current production or research needs as well as potential future requirements. Slot-die coaters are not inexpensive, and selecting the wrong system can lead to wasted substrate, lost time, and inconsistent results. By understanding the differences between sheet and roll-to-roll (R2R) systems—covering factors such as substrate type, coating size, drying methods, treatment flexibility, scalability, and experimental setup—you can make a more informed choice and avoid unnecessary frustration.

Roll-to-Roll versus Sheet Coaters

Slot-die coaters are divided into two broad categories: roll-to-roll, where the substrate moves continuously from one roll to another, and sheet or flatbed coaters, where individual substrates are processed one at a time.

Roll-to-roll systems are ideal for continuous, high-volume production and complex multi-step processes.

Sheet coaters, by contrast, are better suited for rigid substrates, small-scale experiments, or situations where precise control over a single unit is required. Deciding which system to use depends on the combination of factors that are most important for your specific application.

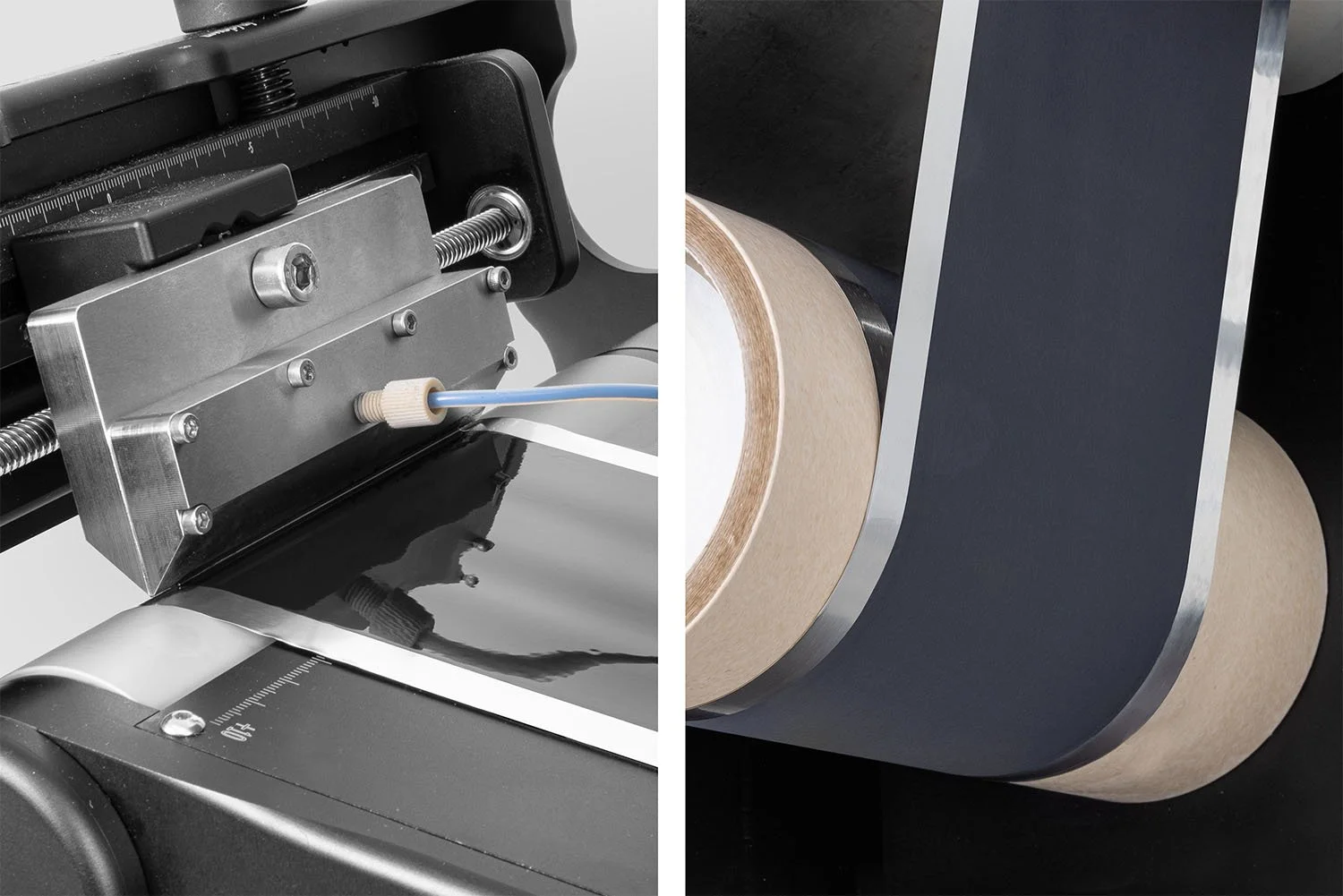

Example of Sheet Coater

Example of Roll-to-Roll Coater

Substrate Types

The type of substrate is often the first factor to consider. Roll-to-roll coaters can only handle flexible materials, so if your process requires rigid substrates such as glass, metal, or thick plastic sheets, a sheet coater is your only option. Sheet coaters, however, are versatile and can handle both rigid and flexible substrates. Even when flexible substrates are acceptable, other factors such as coating size, post-treatment needs, and production volume will influence your decision. Understanding the limitations and capabilities of each system relative to your substrate ensures that your choice will not create unforeseen obstacles later in the process.

Coating Size

The size of the coating area is another important consideration. Sheet coaters scale directly with the size of the substrate, meaning large coatings require correspondingly larger machines, which can become unwieldy. Roll-to-roll systems, on the other hand, primarily scale with the width of the substrate, while the length of the coating is limited only by the length of the roll. This makes R2R systems far more suitable for applications requiring large-area coatings or high throughput. For smaller coatings or experiments that involve multiple iterations of the same process, sheet coaters remain practical and efficient.

Roll-to-roll coaters primarily scale with the width of the substrate, while the length of the coating is limited only by the length of the roll.

Drying Methods

Drying is a critical step in slot-die coating, and the method used varies between sheet and roll-to-roll systems. Sheet coaters typically heat the base on which the substrate rests, transferring heat from the bottom to the wet film. Roll-to-roll systems usually pass the coated substrate through an oven where hot air/gas circulates above the surface, drying primarily from the top. Which drying process is best very much depends on the composition of the wet film, but it is important to note that a drying process optimized for one is not necessarily easily transferred to the other.

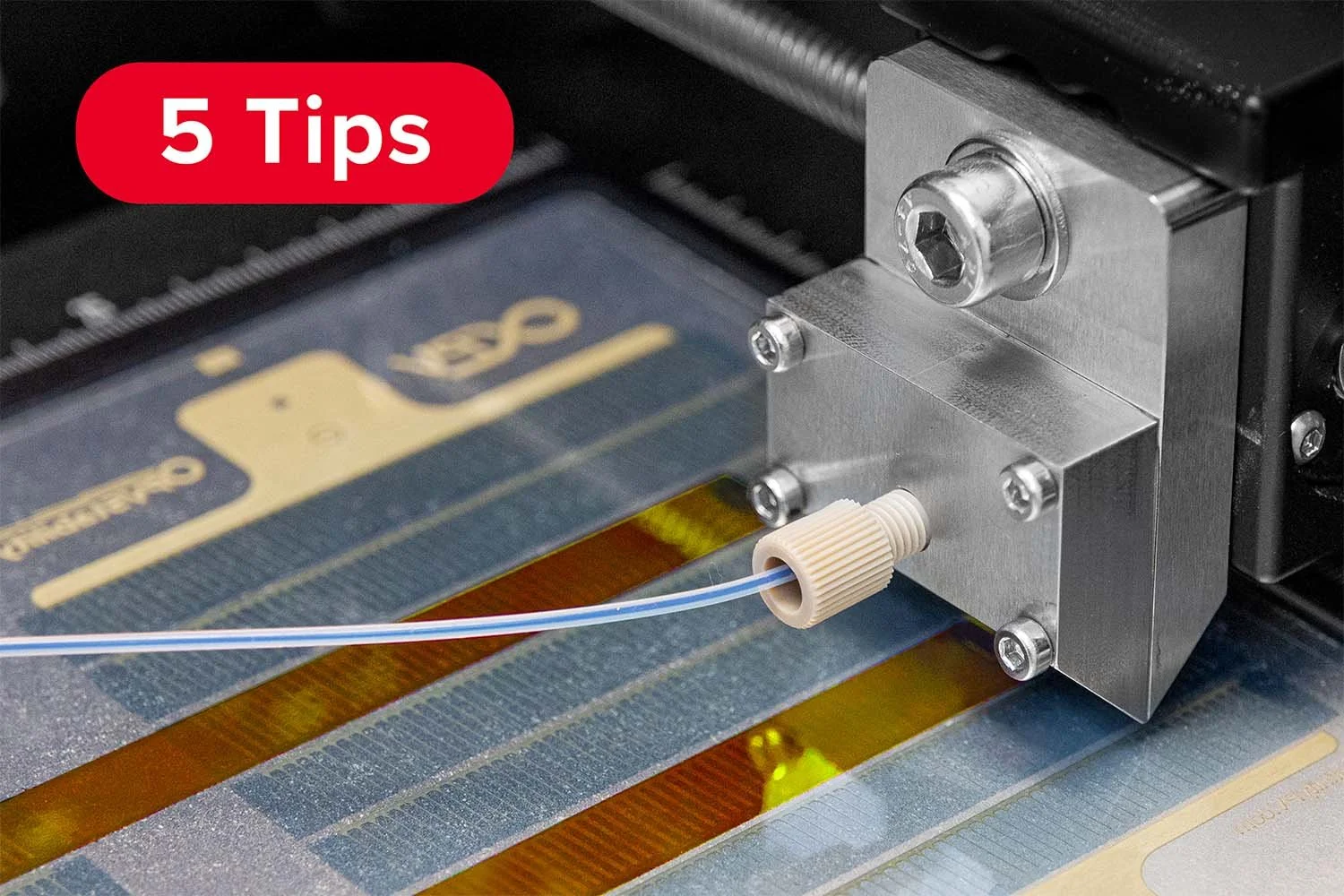

Before and after drying using a Laboratory Roll-to-Roll Coater.

Additional Treatments

Many coatings require additional treatments beyond conventional drying. Sheet coaters are generally limited in this area because the slot-die head and mounting system occupy the space above the substrate. Any additional treatments, such as UV or IR irradiation, chemical baths, secondary coatings (e.g. slot-die coating, flexographic printing, spray coating), or trimming or cutting, typically require separate equipment. Roll-to-roll systems, in contrast, allow in-line treatments immediately after coating. A roll can pass through ovens, irradiation units, acuttingdditional wet processing steps, and cutting stations without interrupting the process. This flexibility makes R2R systems well-suited for multi-step production processes or complex coatings that cannot be accommodated by a sheet coater alone.

Roll-to-roll systems allow in-line treatments immediately after coating

Upscaling Potential

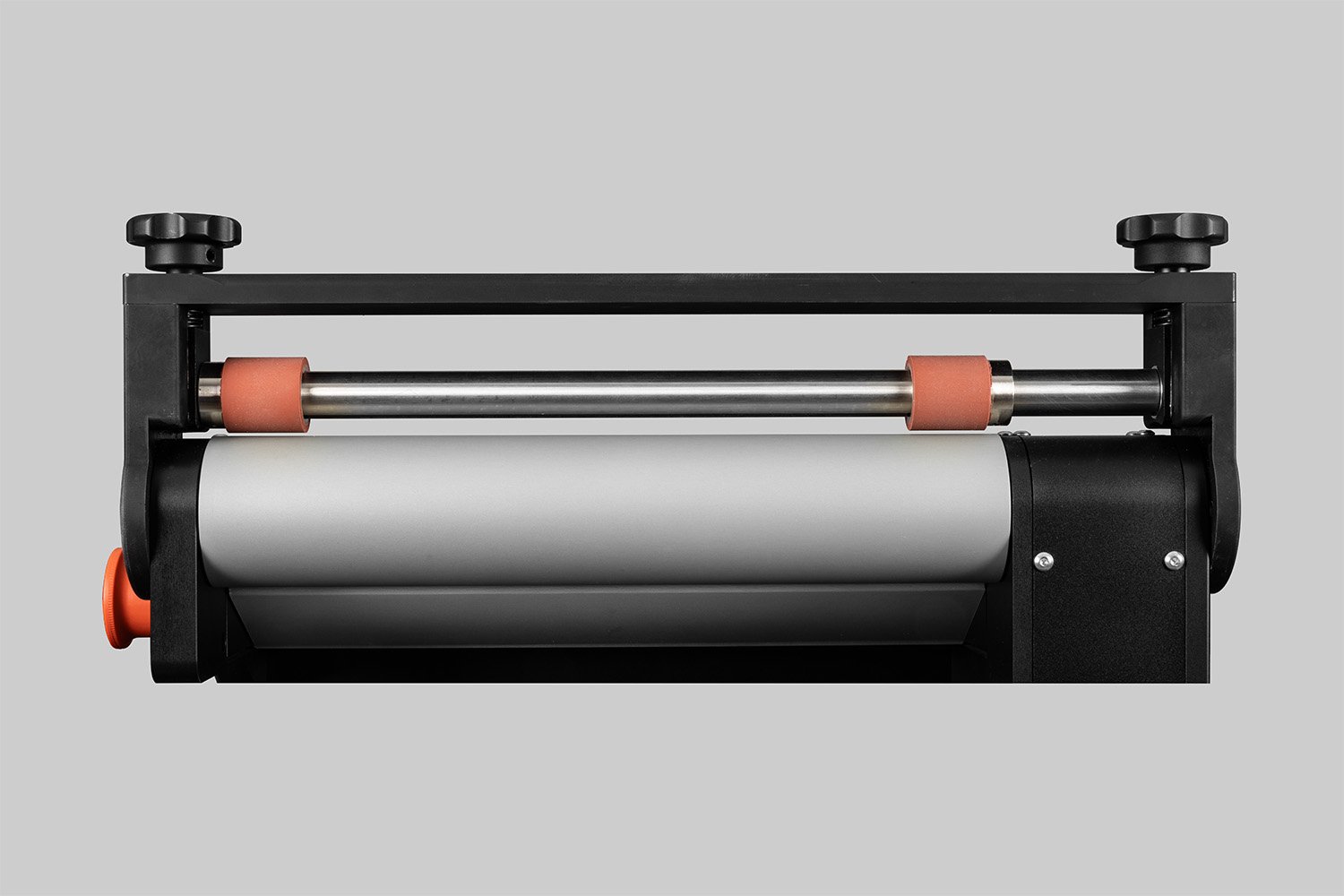

Roll-to-roll coaters excel when scaling production. Handling a single continuous roll is far more efficient than managing hundreds or thousands of individual sheets. Processing speed can be increased by extending drying sections or adding additional ovens to accommodate longer curing times.

The same is not the case for sheet coaters relying on a hot plate. Here drying of the individual sheet must be finished before the process of remove sheet/place new sheet/coating/drying can be repeated. In an industrial process, the solution to speeding up the sheet coating process is often carried out by separating the drying process from the coating, hence allowing for the coating to be the time-determining process. Drying can in such cases be carried by other means than the traditional “hot plate”, e.g. by placement on a conveyer belt that passes through an oven (much like in the R2R process). For small runs or laboratory experiments, this limitation is rarely an issue, but for larger-scale production, it is a crucial factor.

With the Laboratory Roll-to-Roll Coater, you can add more ovens for a longer drying time.

Setting Up Experiments

Sheet coaters are often faster and simpler to set up for small-scale experiments. Only the substrate needs to be aligned, and the slot-die head mounted, with minimal material required – at least for a single fast experiment. Also, only the exact amount of substrate needed for your experiment is required when operating with a sheet coater. Of course, when multiple consecutive coatings are to be carried out, there is a need for aligning the substrates every time before coating.

Roll-to-roll systems require more preparation, including mounting and threading the roll and aligning the machine. Some substrate is lost during the initial setup (generally 1 “machine-length”, the length the foil moves from the unwinder to the rewinder), although splicing valuable substrate into a roll of cheaper material can reduce waste. If the substrate is costly, it is possible to splice the more valuable substrate into a roll of more inexpensive foil, but this of course adds a step to the setup procedure.

For single experiments or occasional small runs, sheet coaters are convenient. For consecutive experiments or larger production runs, roll-to-roll systems become more efficient once the initial setup is complete.

| Roll-to-Roll Coating | Sheet Coating | |

|---|---|---|

| Substrate Type | Flexible | Rigid and Flexible |

| Coating Size | cm² - m² | cm² - dm² |

| Drying (Typical) | Heating from top / all sides | Heating from the bottom |

| Additional Post Treatment | Many | Few |

| Upscaling Potential | High | Low-medium |

| Time to Set Up | Medium (only once per "run") | Fast (every experiment) |

Hybrid Systems

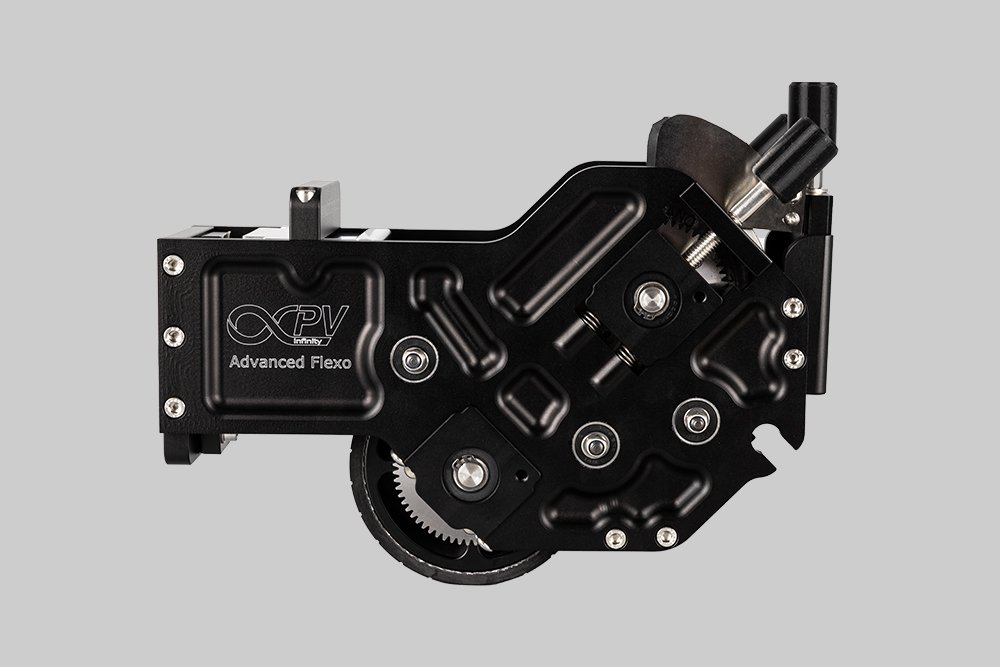

Hybrid approaches are also possible, combining the benefits of both sheet and roll-to-roll technologies. In these systems, a sheet coater is integrated into a roll-to-roll setup, allowing precise sheet-based processing at specific points along a continuous roll. One example could be if drying with heating below with a hot plate is preferable to the standard R2R ovens.

A hybrid coating process is typically carried out in a step wise manner, allowing for the sheet coating part to be finished before moving the foil the correct distance forward before repeating the process – resulting in a single roll with multiple units of coating, which could potentially be treated further in a R2R process (extra drying, additional coatings, cut out, etc.).

Hybrid systems are ideal when a specific step, such as bottom-up drying, is crucial but high-volume, continuous production is also desired. The trade-off is increased complexity and cost, which must be weighed against the advantages of precision and flexibility.

The R2R Hybrid Coater combines the power of roll-to-roll with the precision of sheet coating.

Choosing a Slot-die Coater Checklist

To guide your choice, consider the following key questions:

What type of substrate do you need to coat?

If rigid substrates are required, a sheet coater is the only option. If flexible substrates suffice, both types are viable.What is the size of your coating area?

Large-area coatings favor roll-to-roll systems. Small areas or variable sizes may be more practical with sheet coaters.What drying method is suitable for your coating?

Bottom-up heating favors sheet coaters, while top-down oven drying favors roll-to-roll systems.Will you need additional treatments or multi-step processes?

Complex treatments are easier to integrate with roll-to-roll systems. Sheet coaters may require separate equipment.What is your expected production volume or scaling requirement?

High-volume production favors roll-to-roll systems, while occasional small runs favor sheet coaters.Are you planning multiple consecutive experiments?

For a single, quick experiment, sheet coaters are convenient. For multiple experiments, roll-to-roll may become more efficient over time.Do you require a hybrid approach?

If you need precise sheet-like treatment but also want continuous processing, a hybrid system may be the best solution.

Conclusion

Choosing the right slot-die coater requires balancing multiple factors, from substrate type and coating size to drying method, treatment flexibility, and production scale. Sheet coaters excel when working with rigid substrates, small areas, or rapid experimental setups, offering simplicity and minimal material waste. Roll-to-roll systems, on the other hand, are ideal for high-volume production, large-area coatings, and complex multi-step processes, providing scalability and the ability to integrate additional treatments inline.

Hybrid systems offer a way to combine the precision of sheet coaters with the efficiency of roll-to-roll setups, though they come with added complexity and cost. Ultimately, the best choice depends on your specific application, production goals, and the balance between speed, flexibility, and throughput. Careful consideration of these factors ensures efficient operation, reduced waste, and consistent coating quality, whether for a laboratory experiment or a full-scale industrial process.

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.