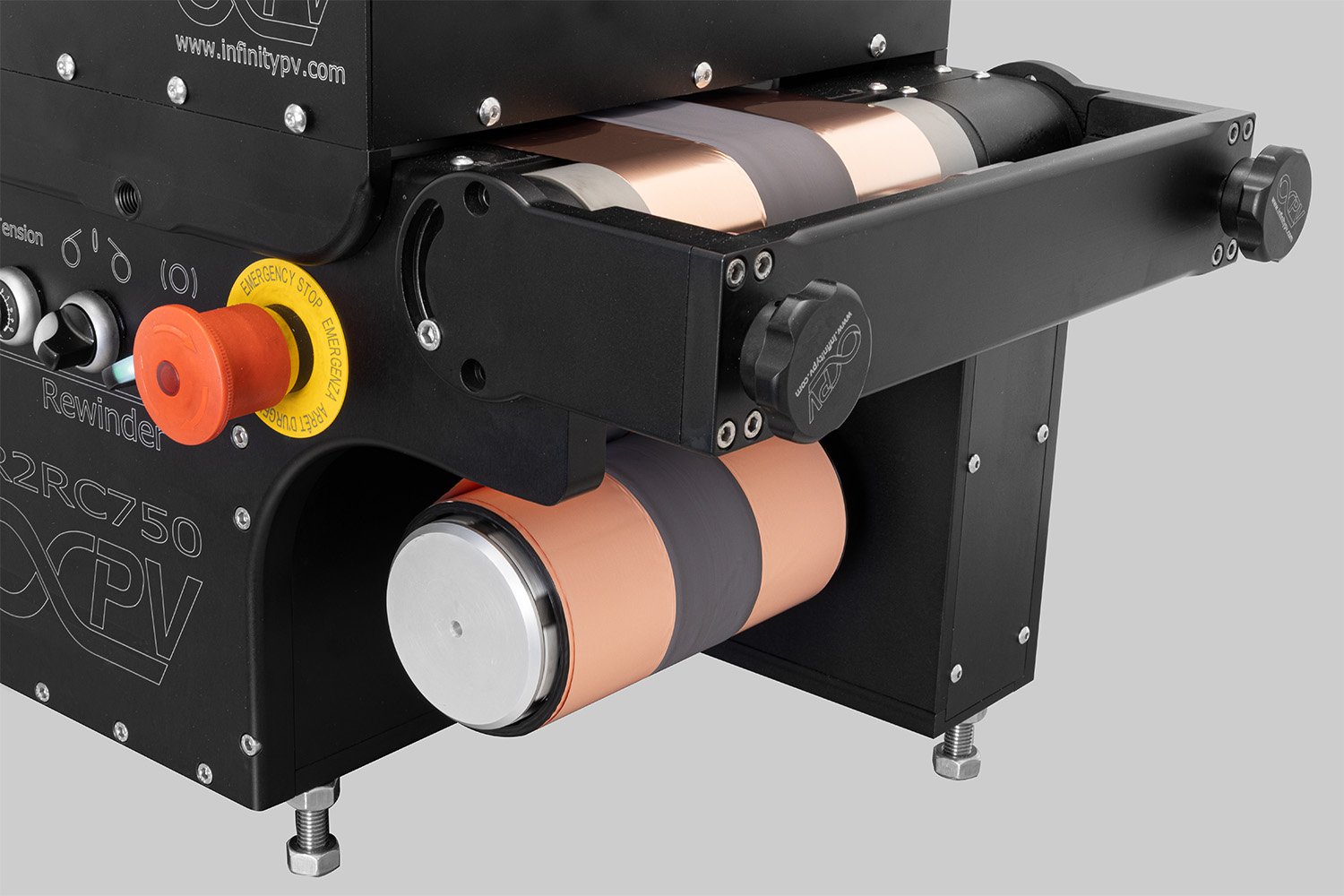

Image 1 of 7

Image 1 of 7

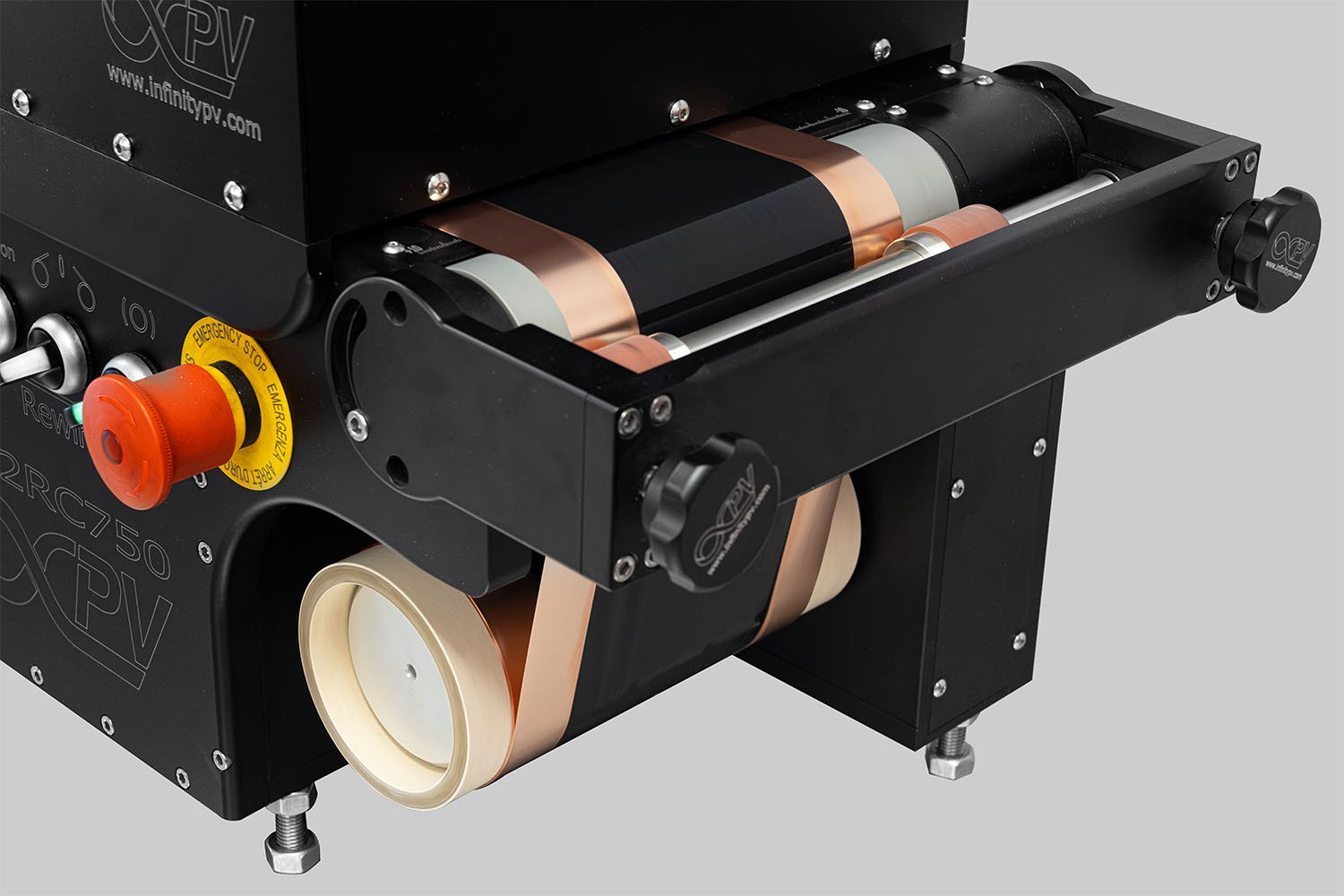

Image 2 of 7

Image 2 of 7

Image 3 of 7

Image 3 of 7

Image 4 of 7

Image 4 of 7

Image 5 of 7

Image 5 of 7

Image 6 of 7

Image 6 of 7

Image 7 of 7

Image 7 of 7

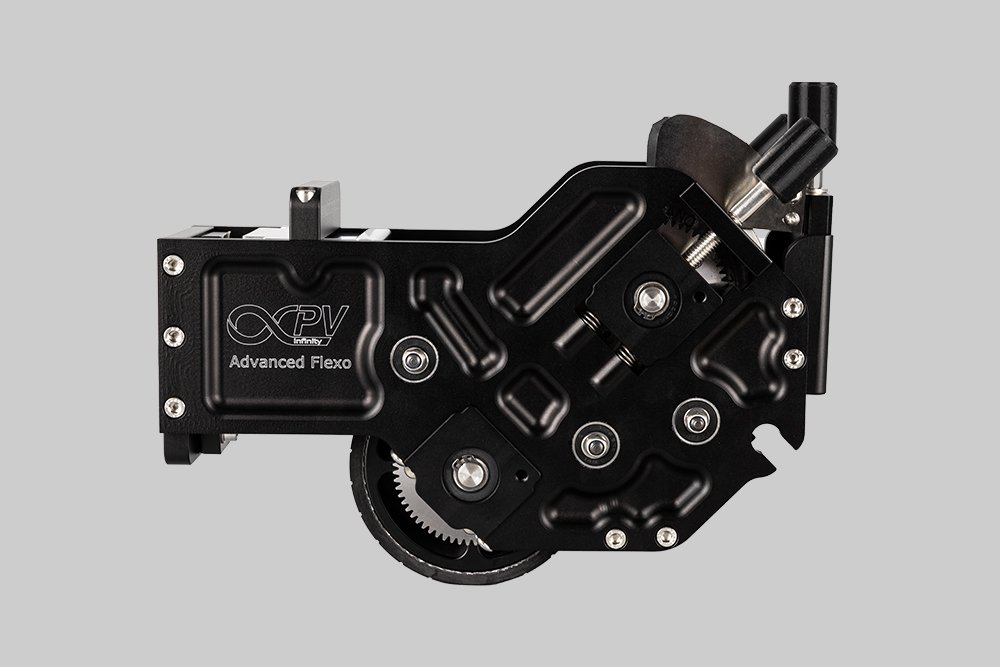

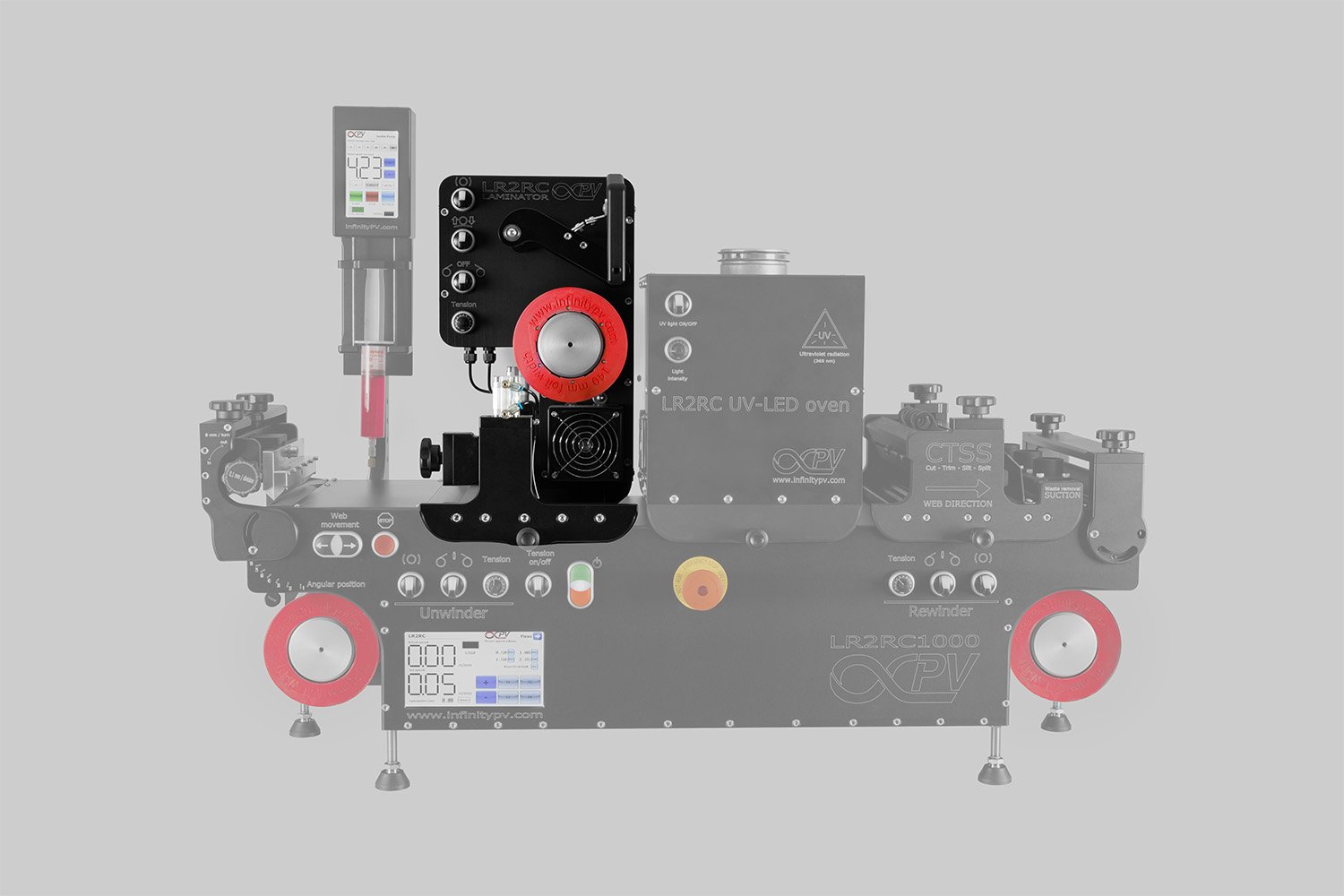

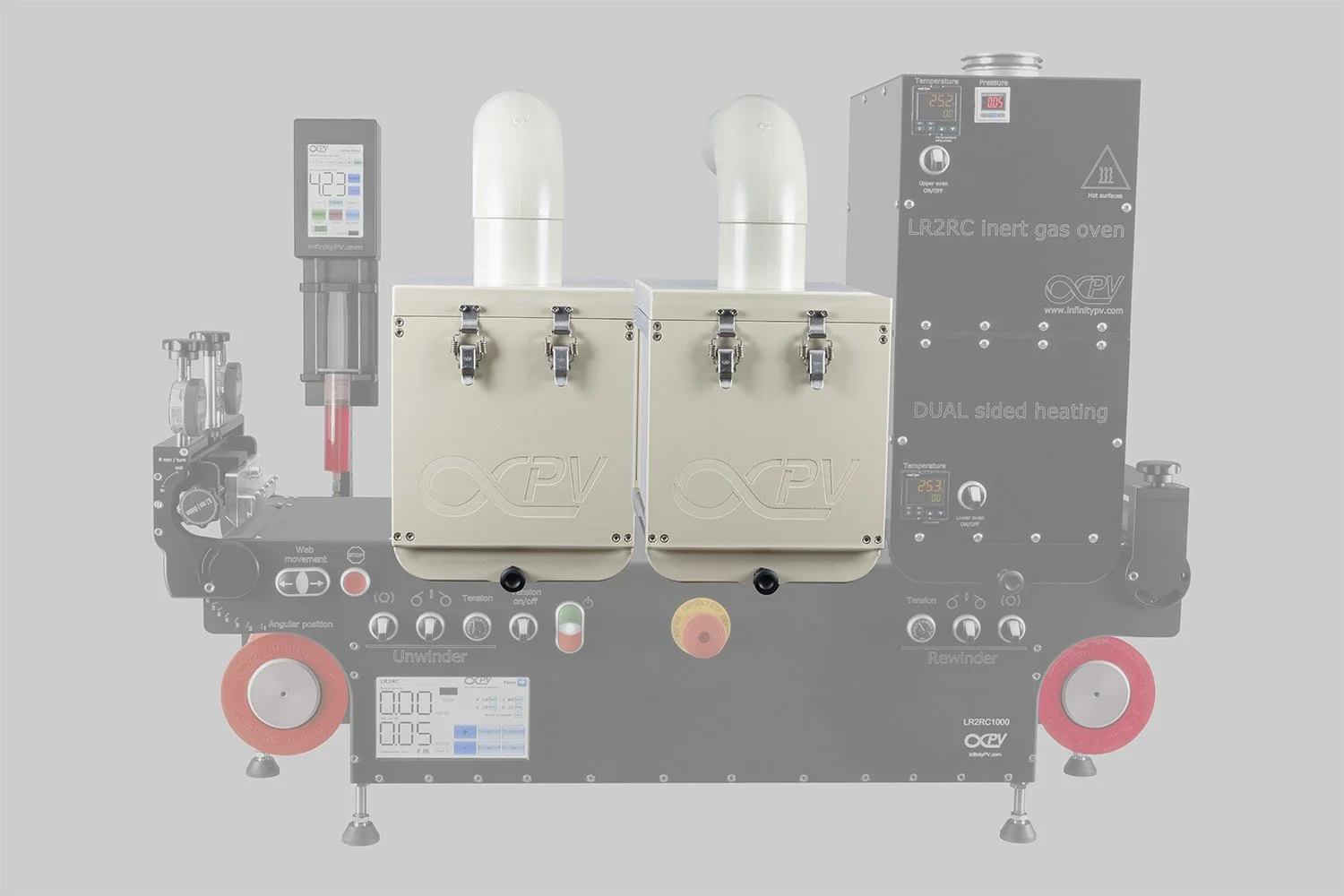

Slurry Coater

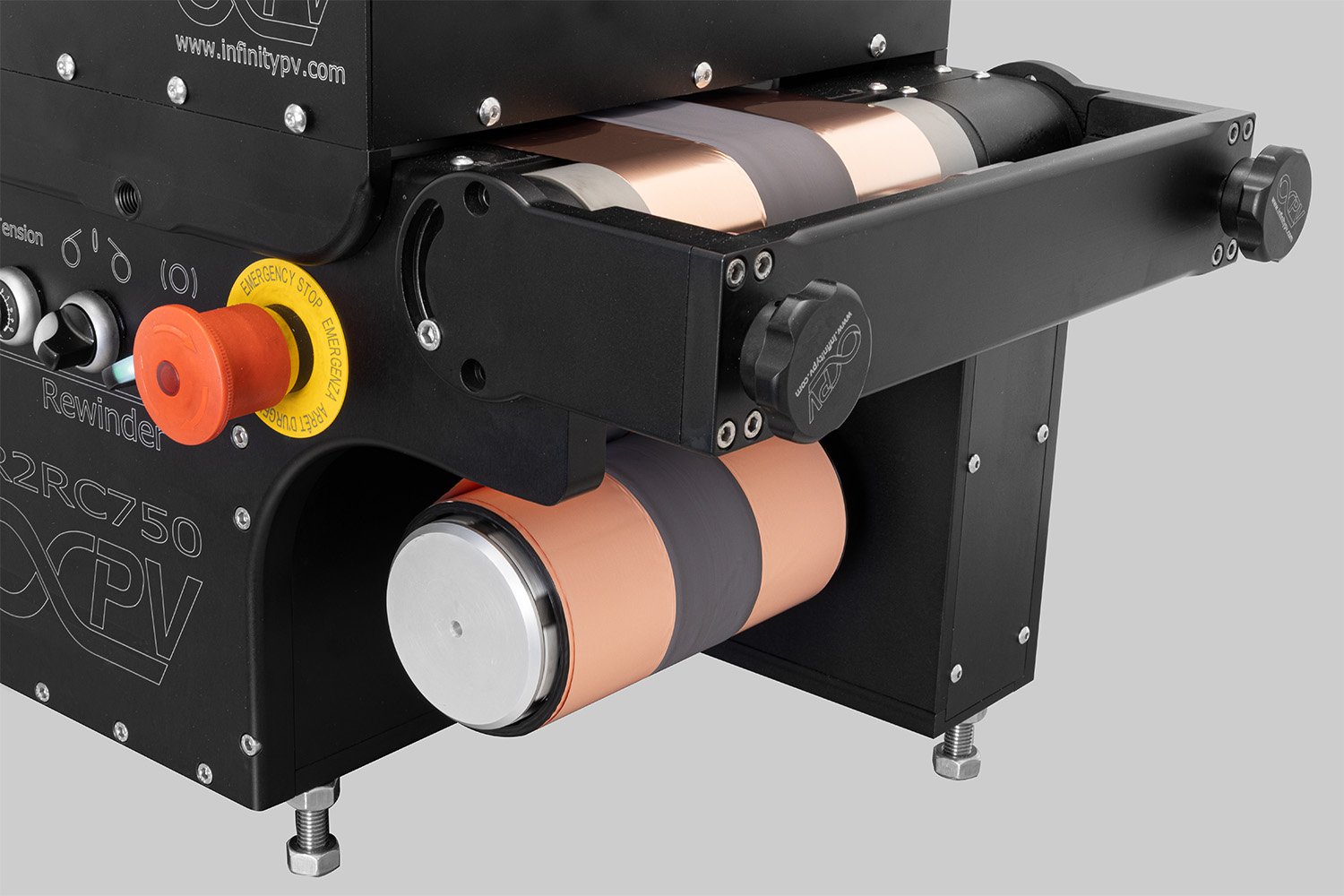

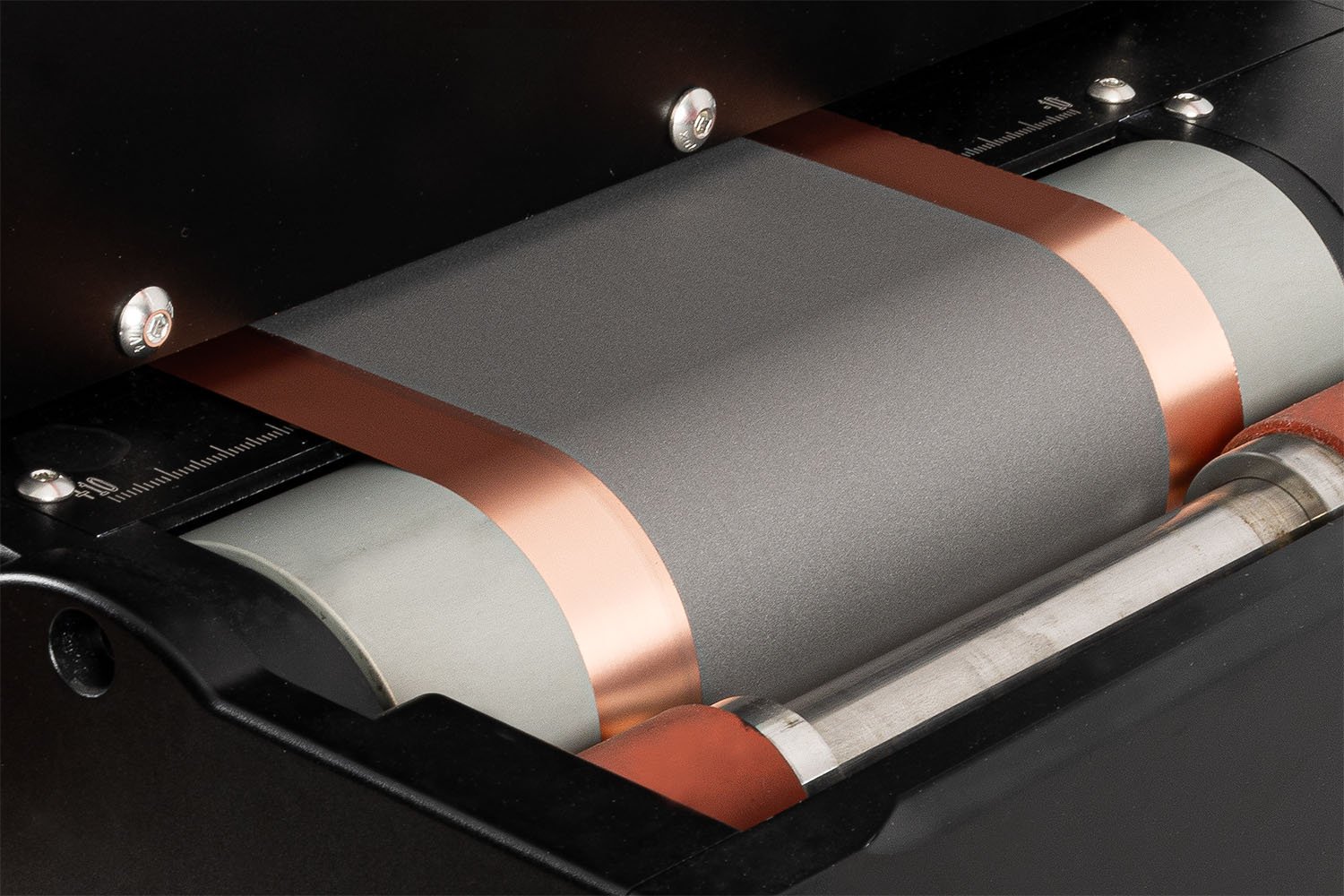

The Slurry Coater is a fundamental wet film forming tool, enabling lab scale production of advanced functional thin films. This includes thin film batteries, fuel cells and printed solar cells. View video.

The Slurry Coater is a fundamental wet film forming tool, enabling lab scale production of advanced functional thin films. This includes thin film batteries, fuel cells and printed solar cells. View video.

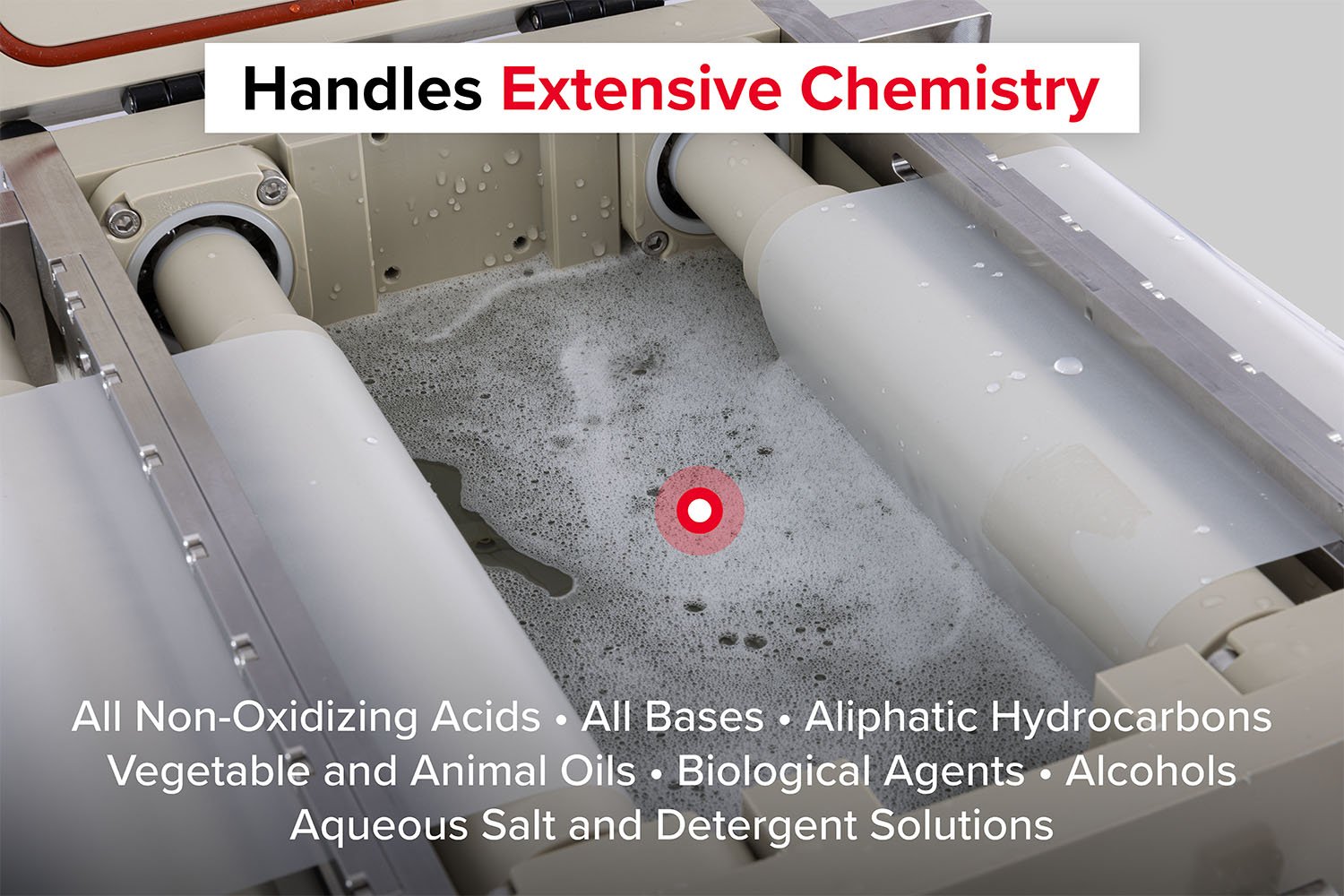

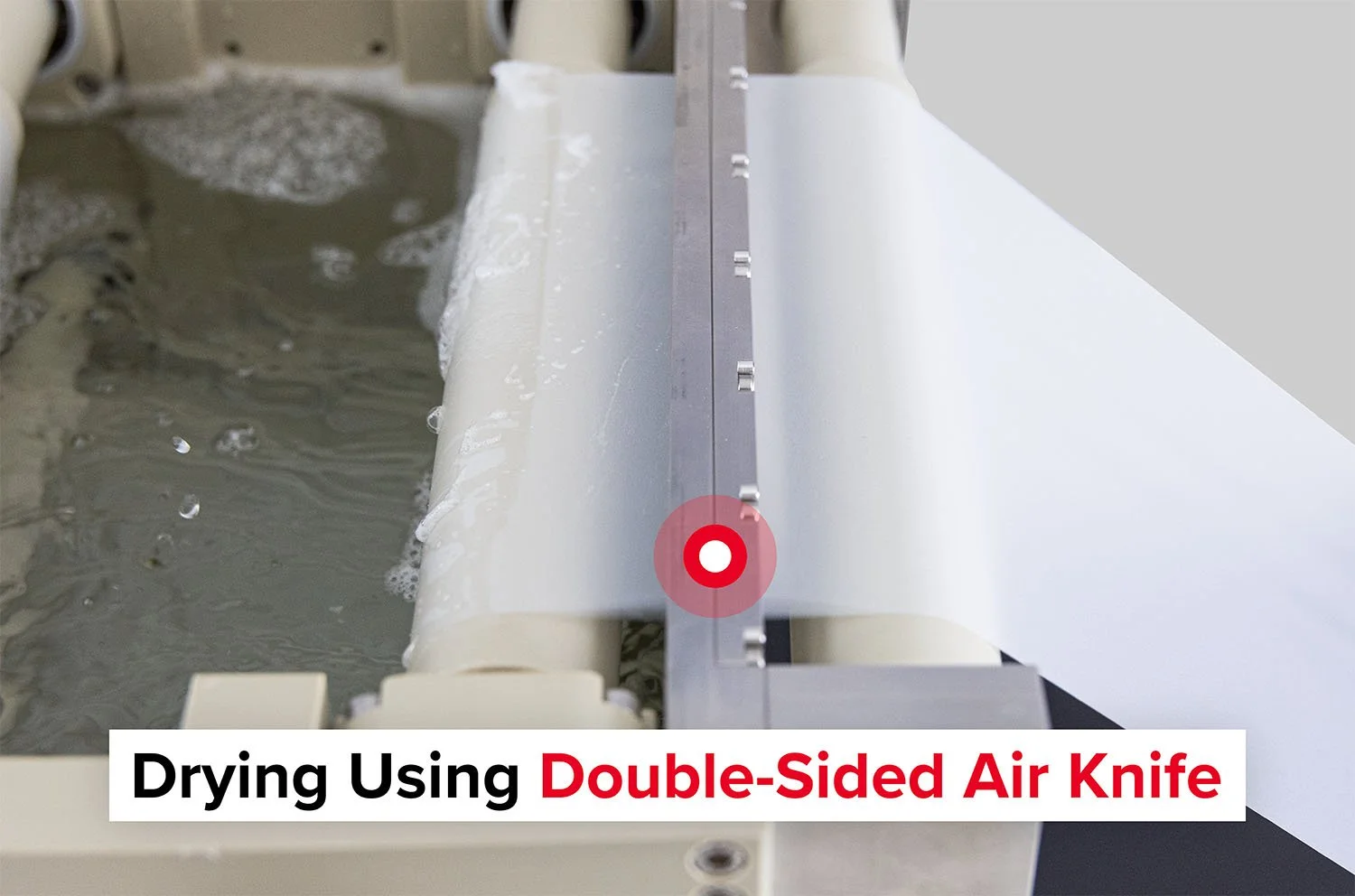

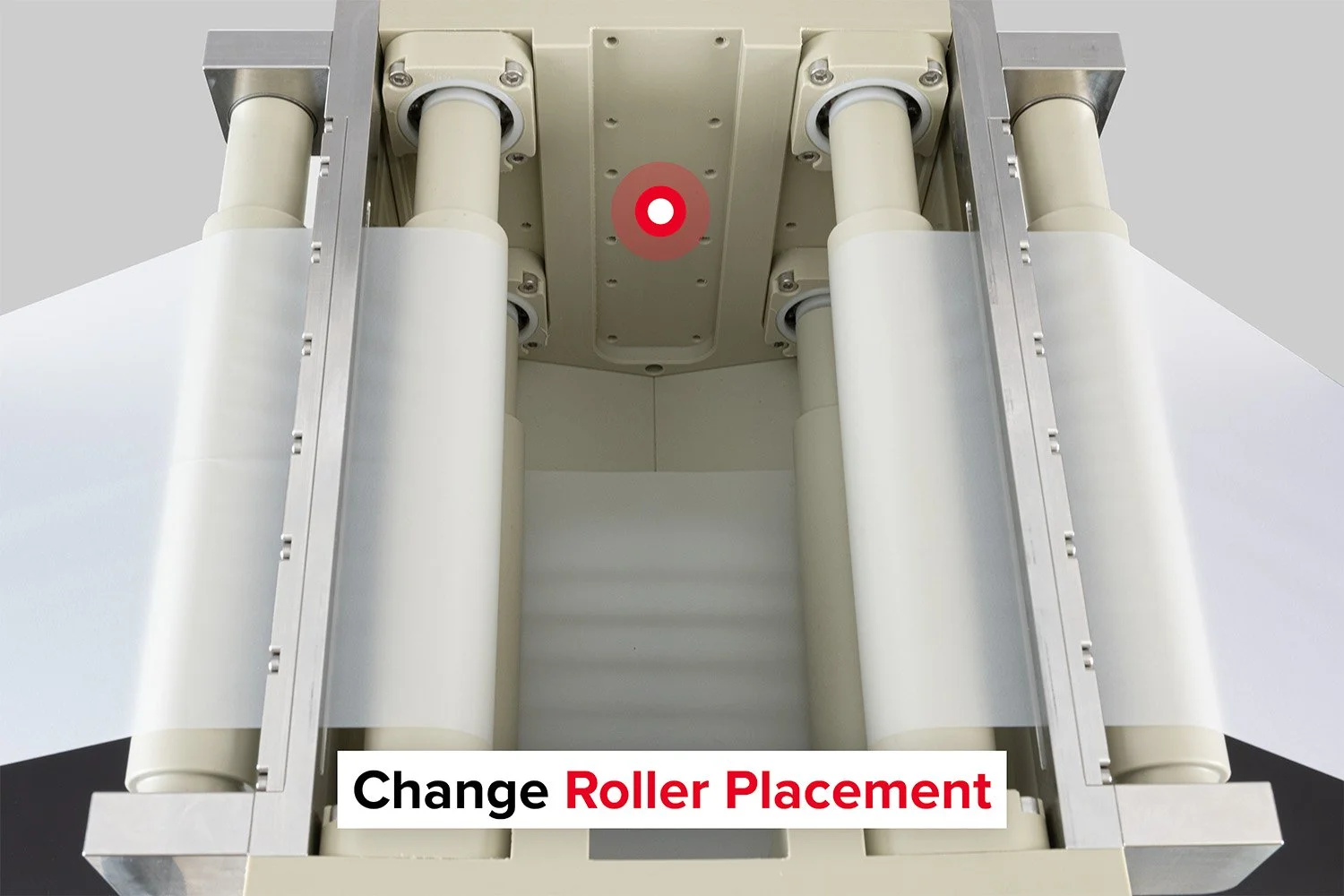

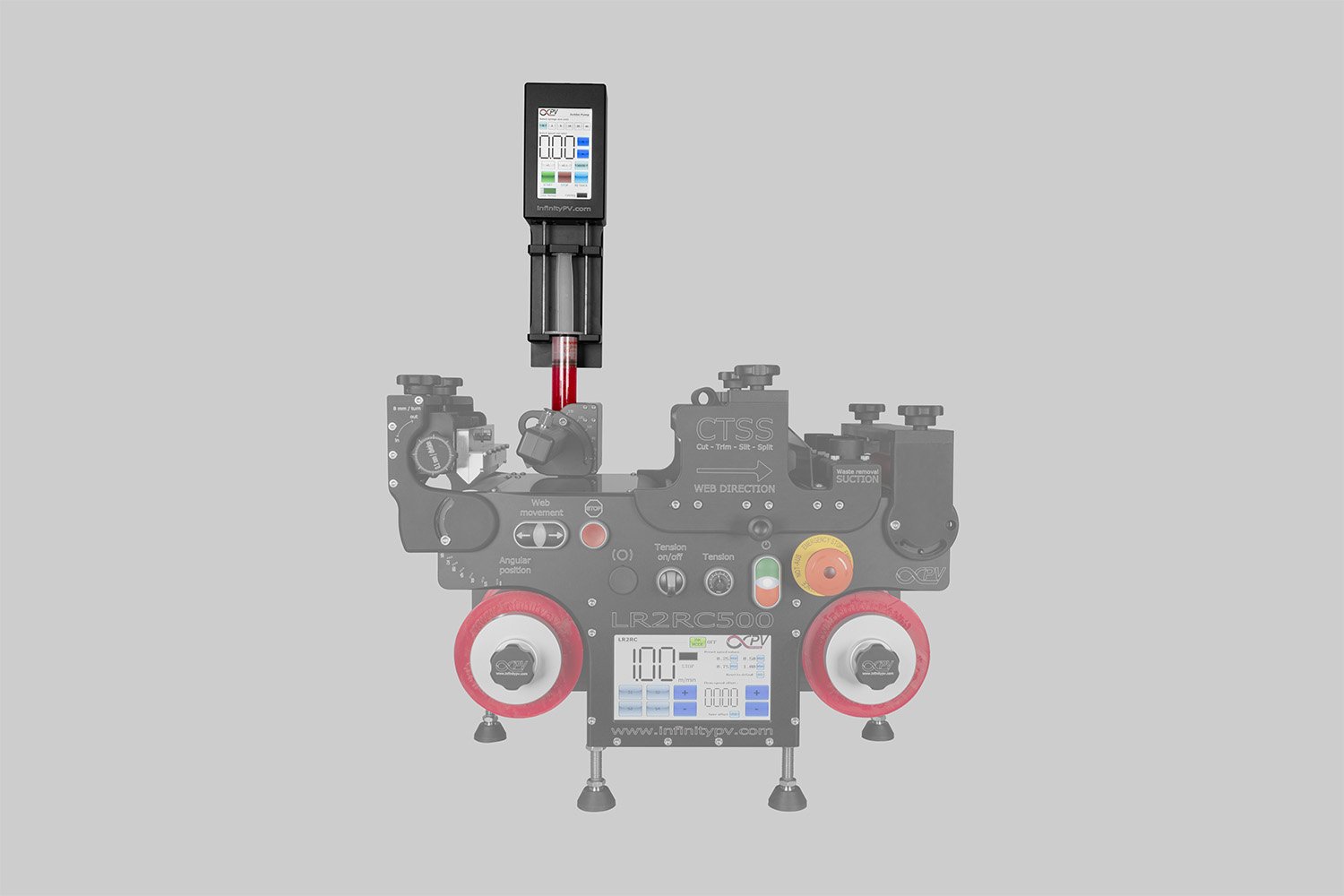

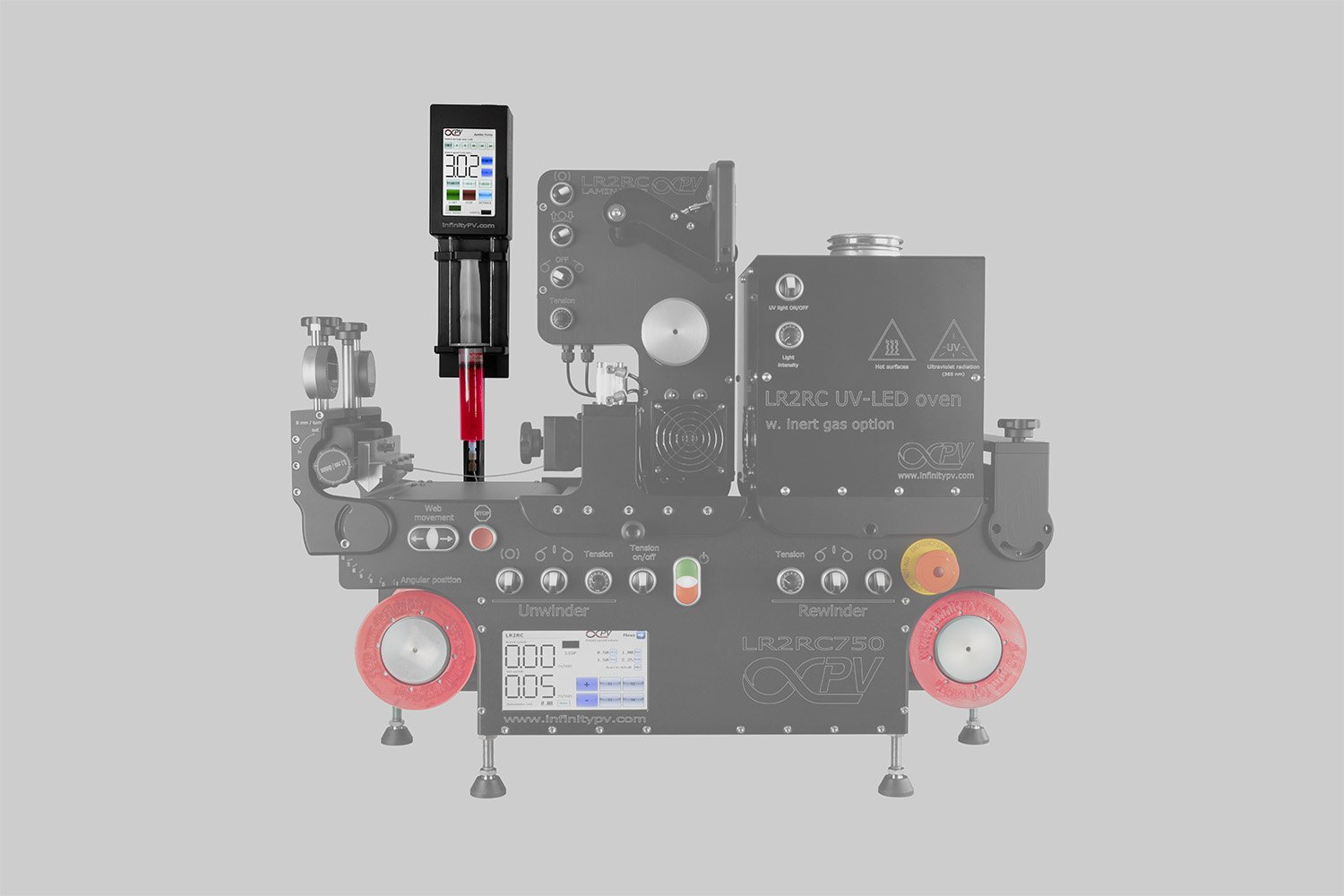

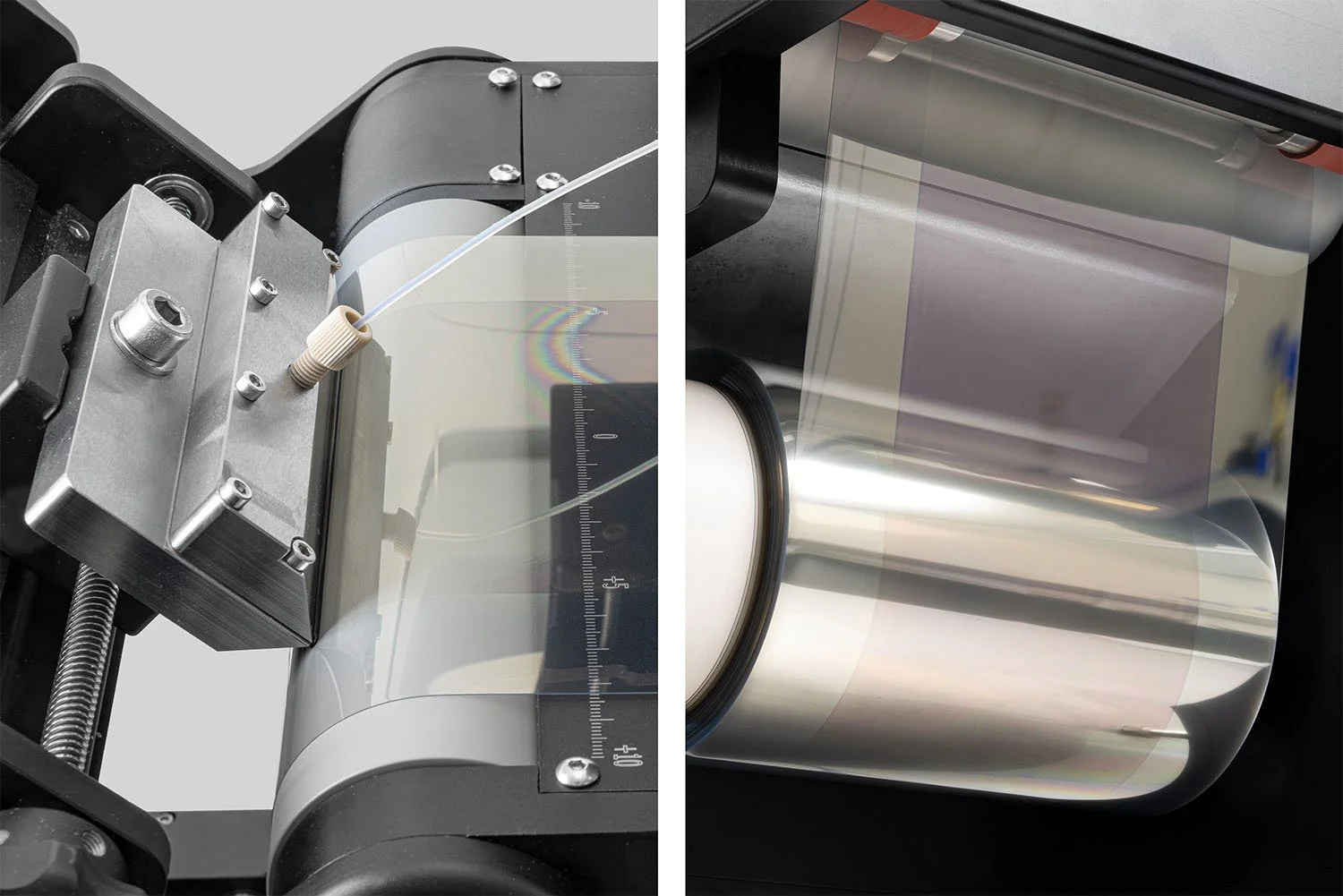

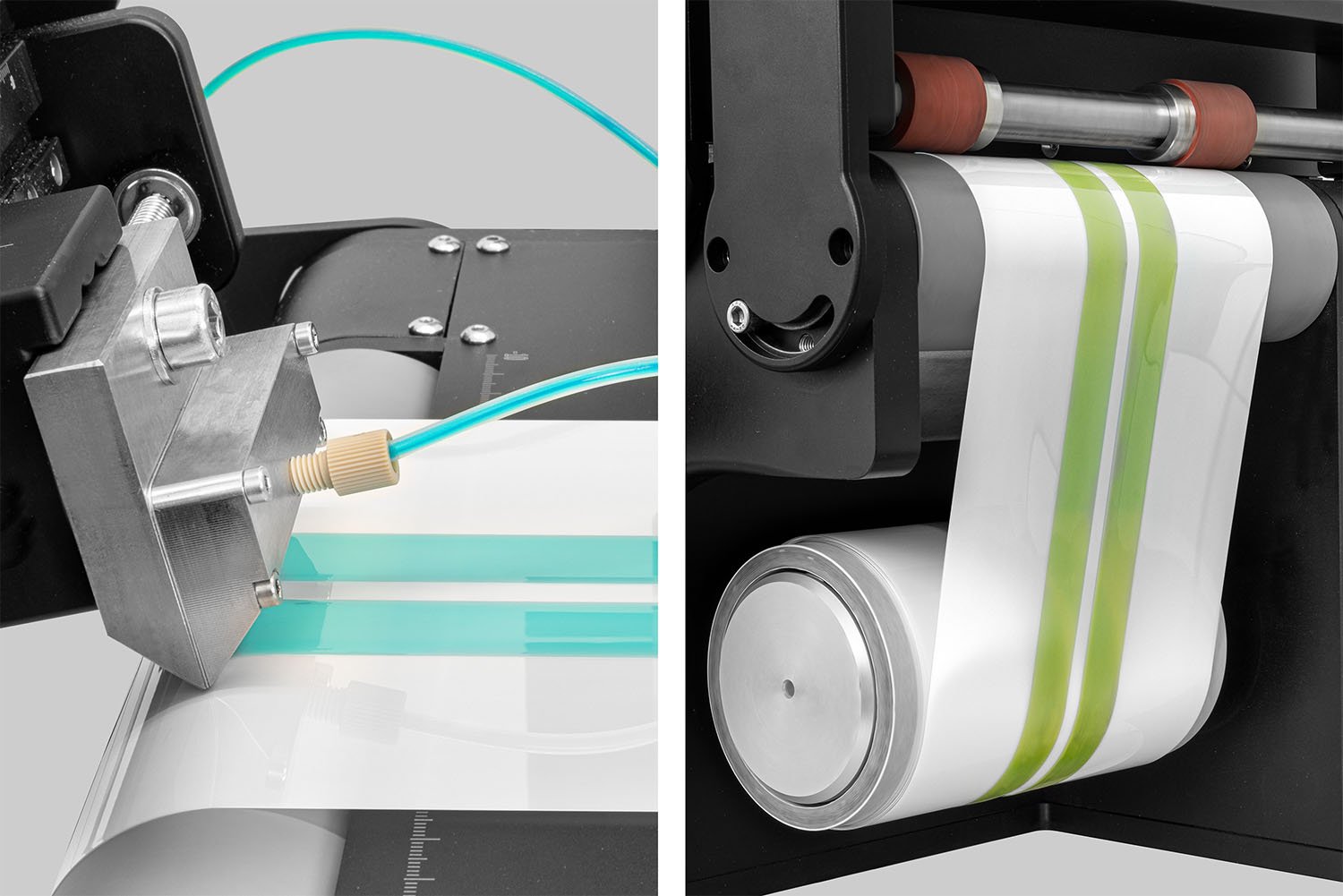

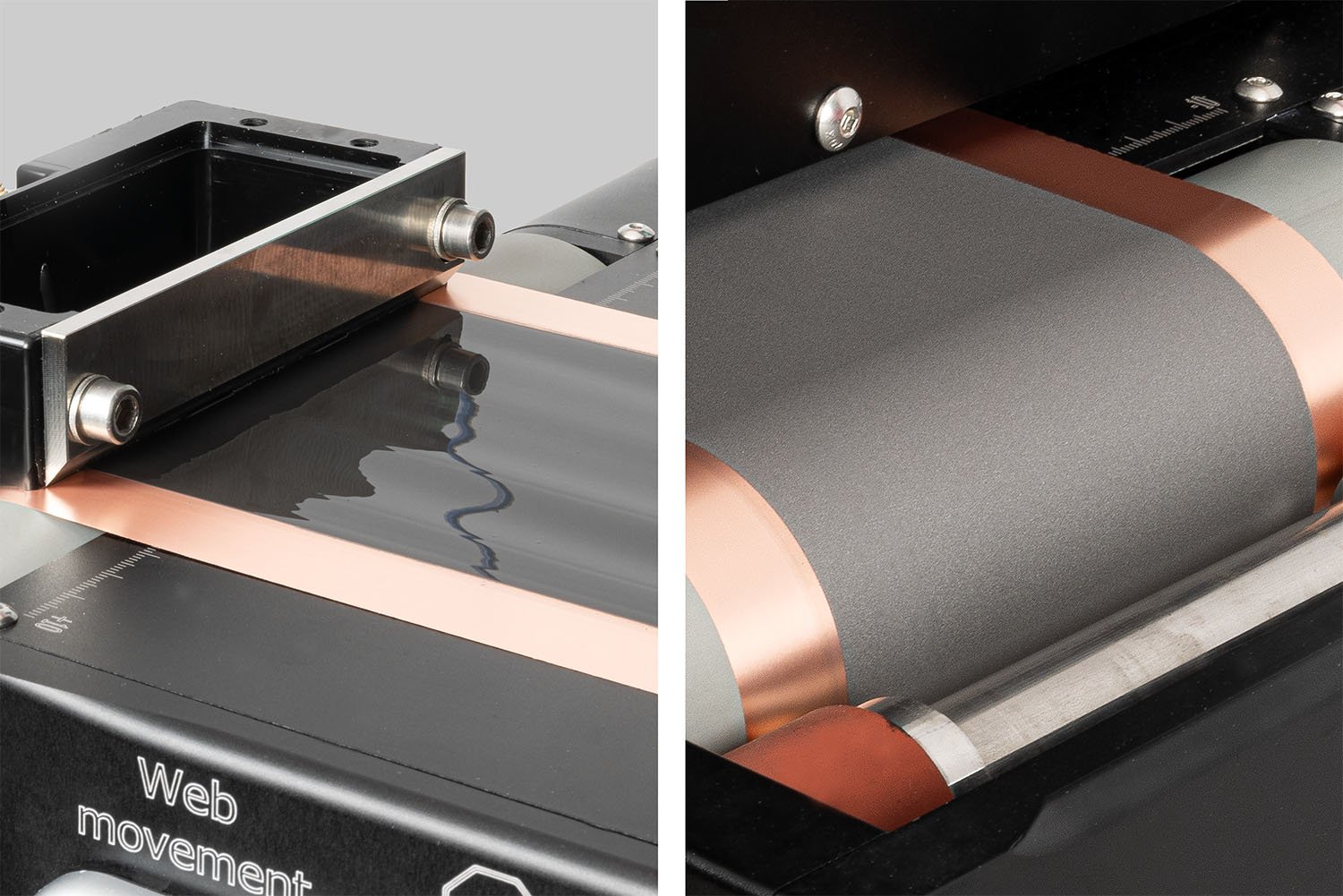

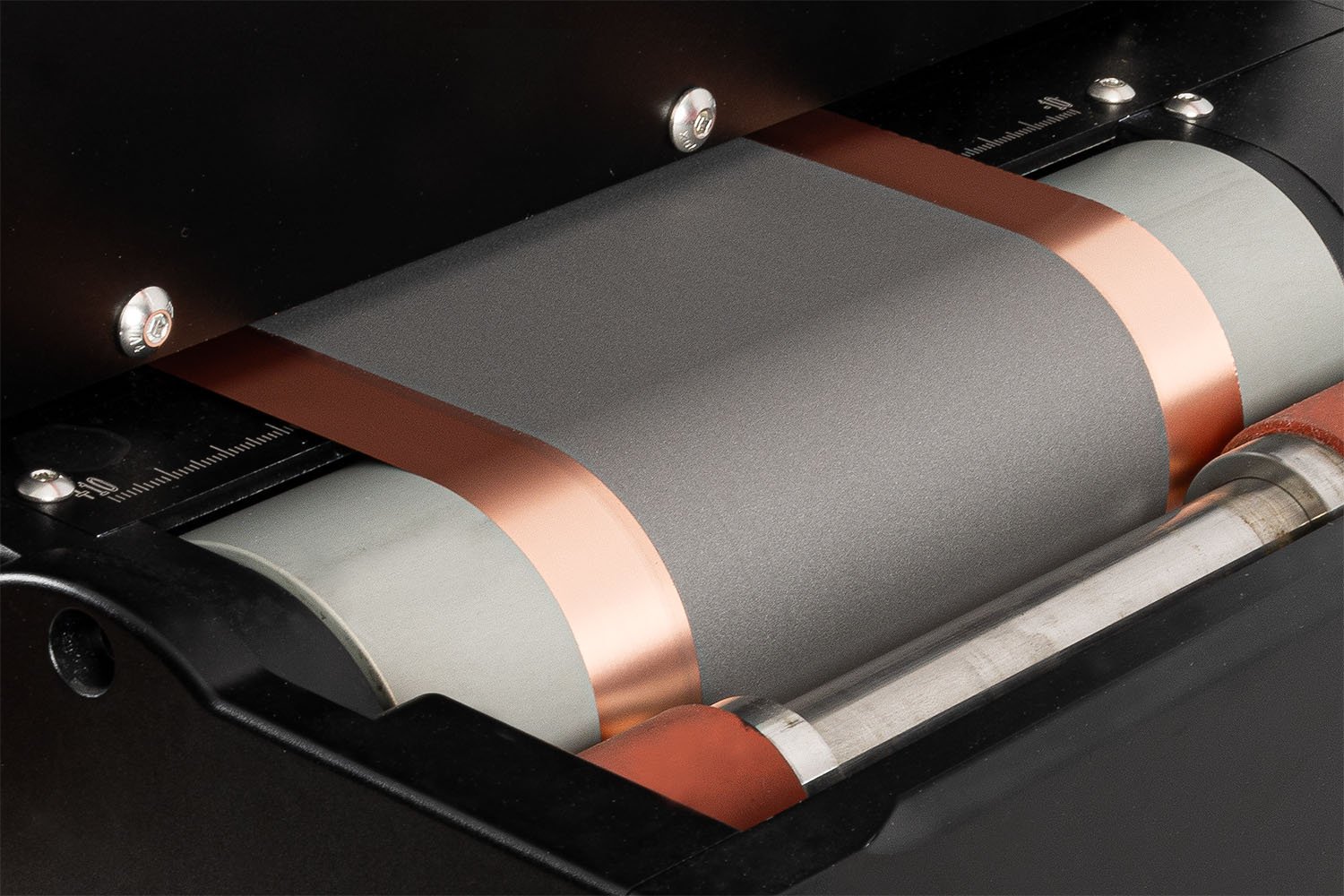

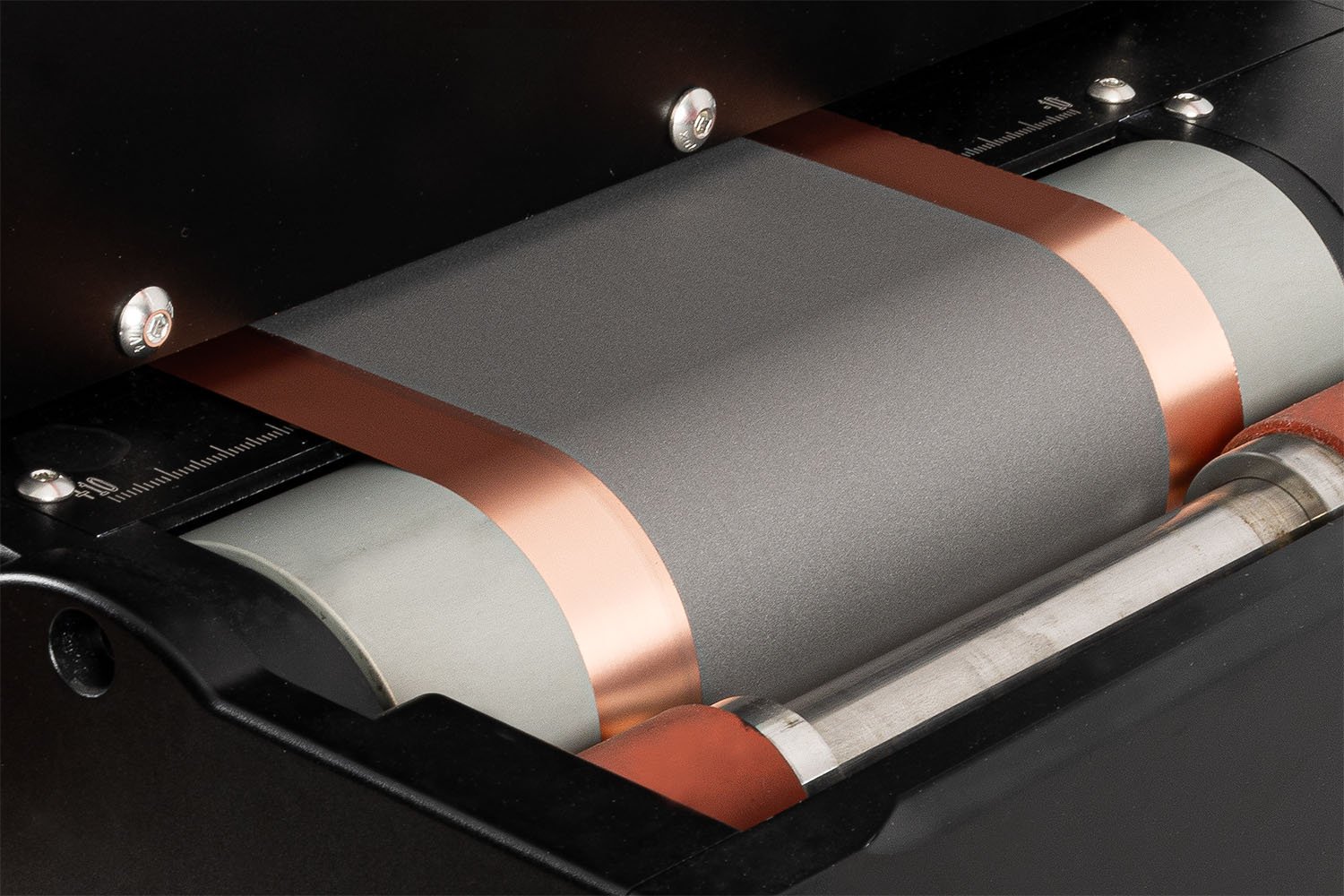

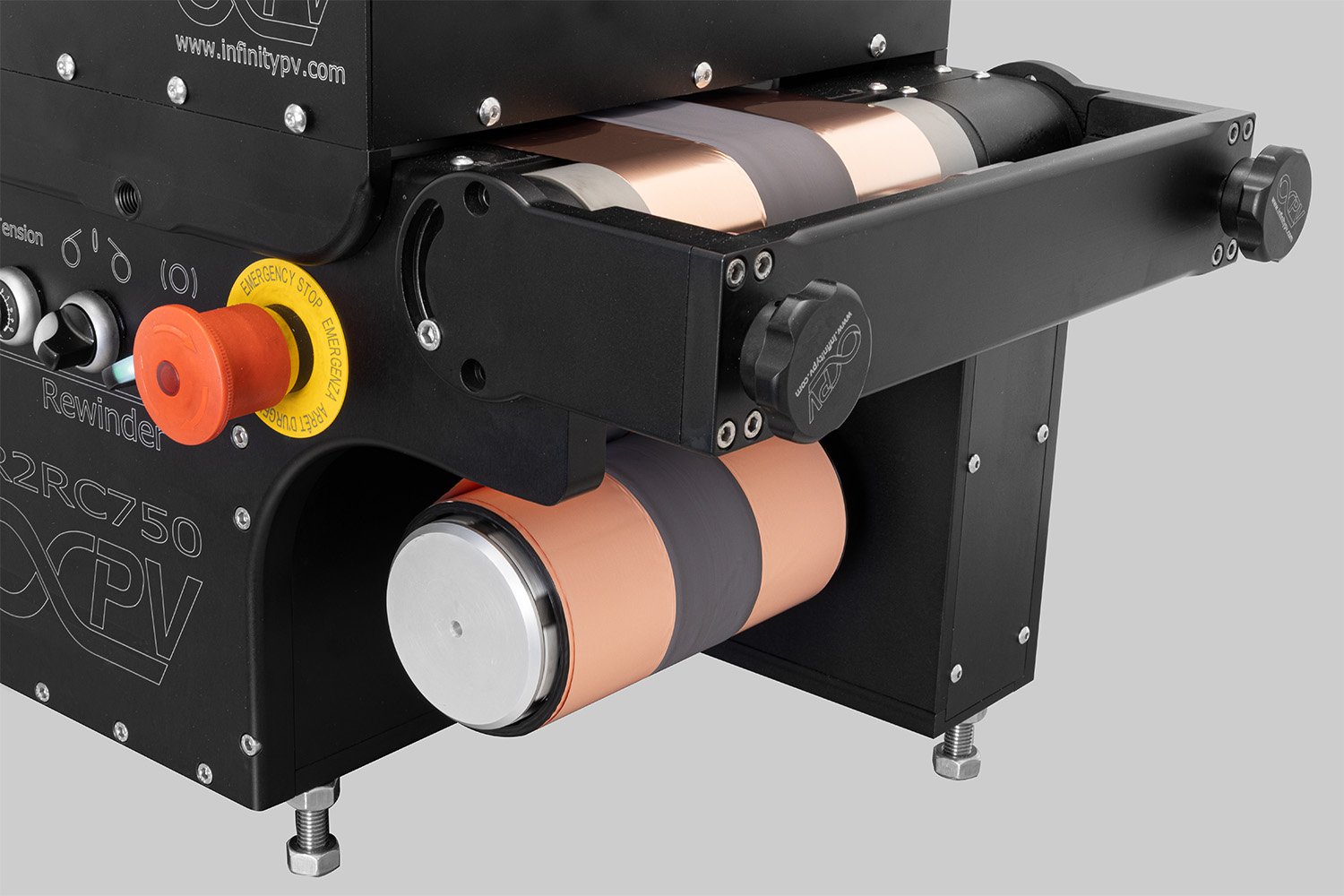

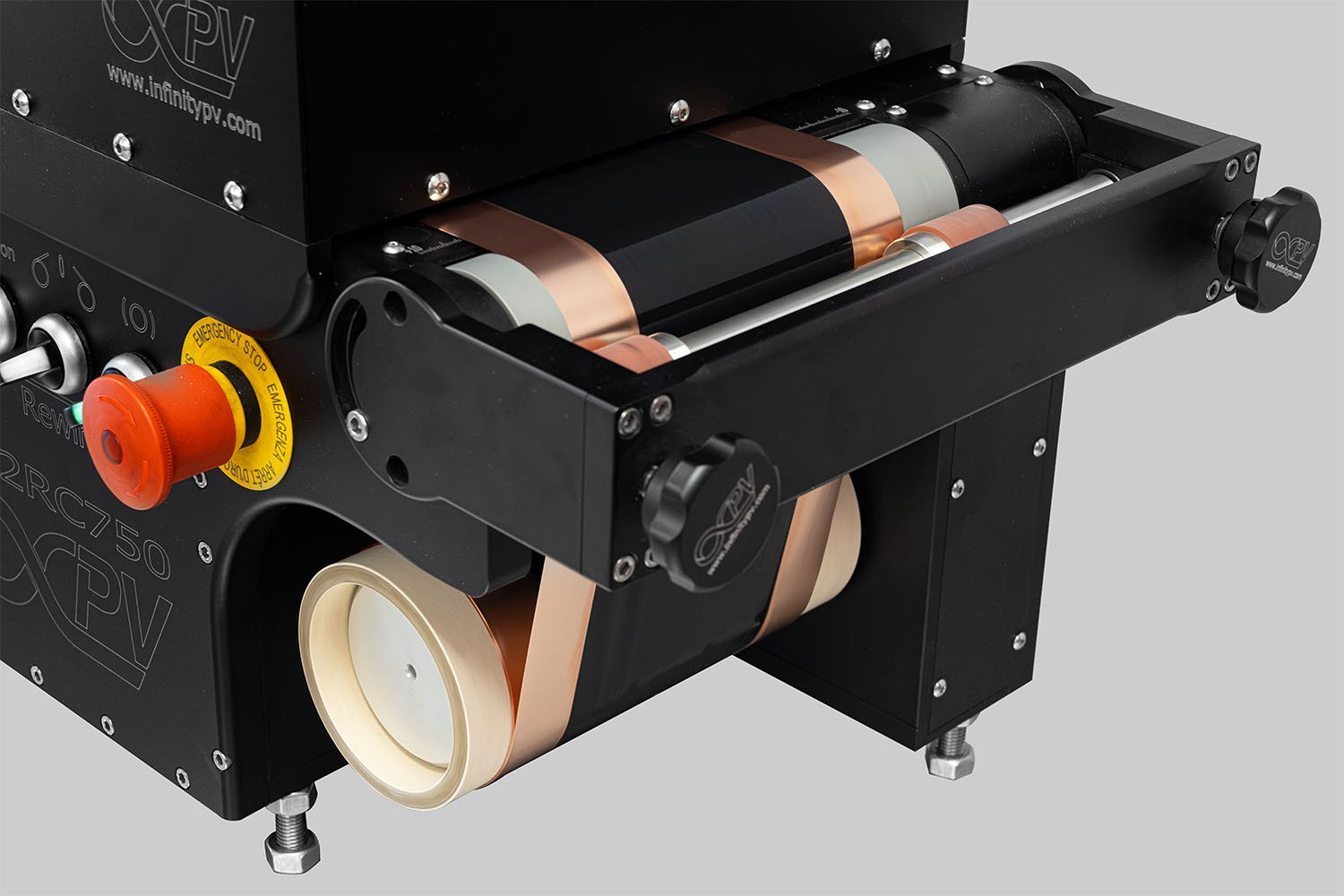

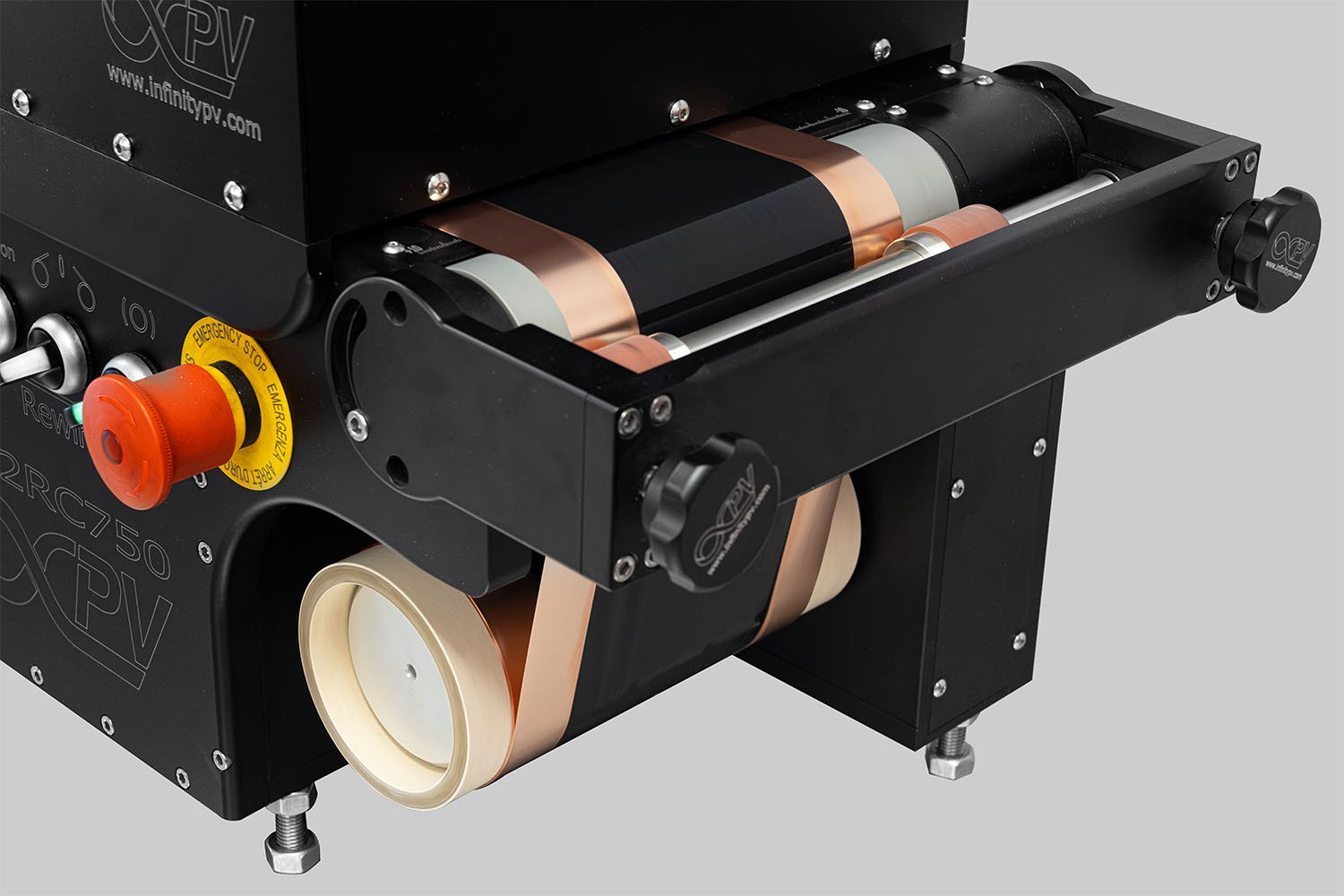

The Slurry Coater is a precision tool designed for wet film deposition in laboratory-scale R&D, ideal for coating functional materials like battery slurries, perovskite inks, conductive pastes, and sensor formulations. Seamlessly integrating with the Laboratory Roll-to-Roll Coater, it ensures uniform, repeatable coatings with micro-precision control over the wet film thickness.

Key Features

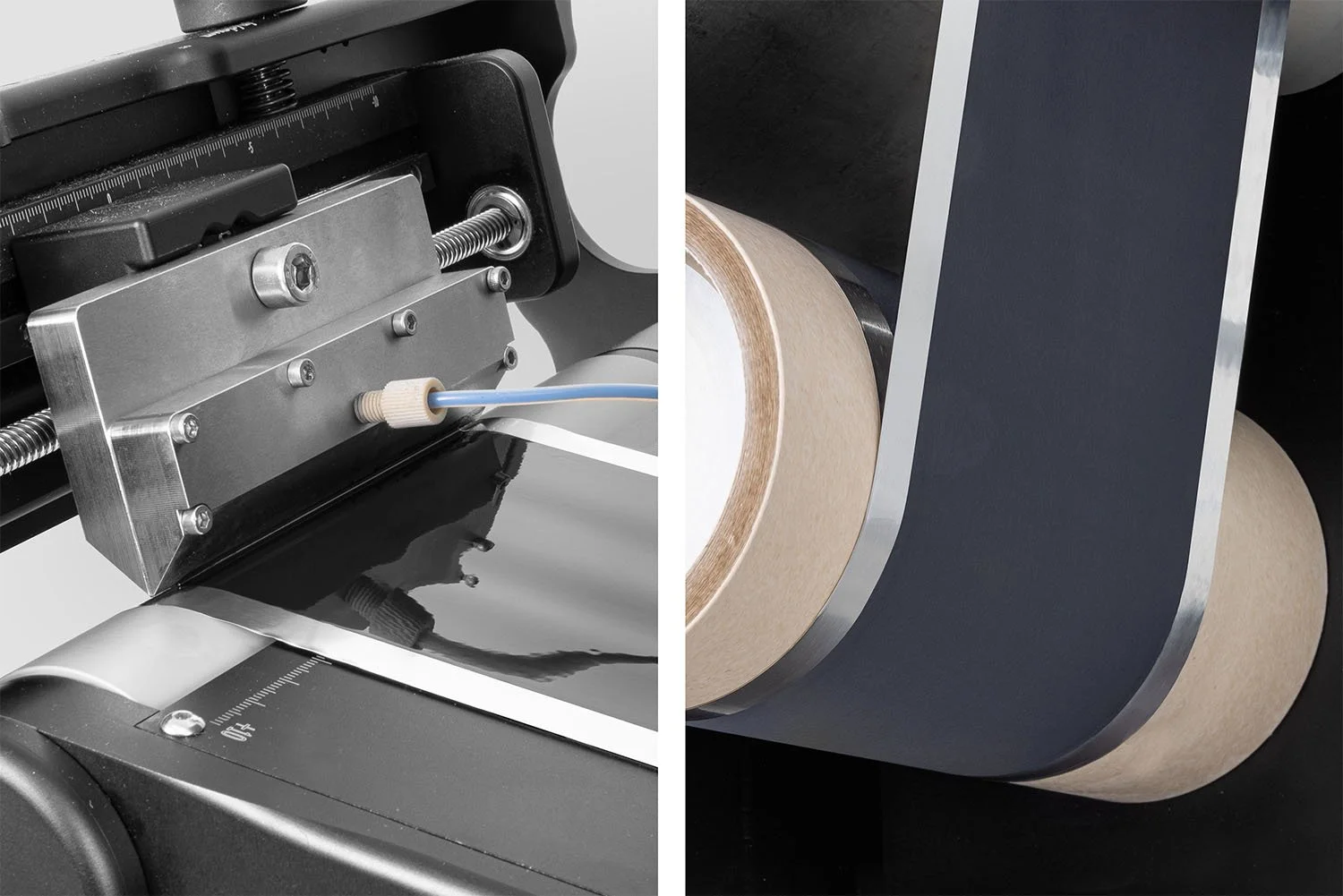

Designed for Coating of Slurries

Made from POM and Stainless Steel (316L)

100 mm Coating Width

Works With Thin Substrates (5-25 um)

Simple Adjustment of the Substrate - Knife Gap

Precise Ink Delivery from the Laboratory Roll-to-Roll Coater Pumping System

Option for Inert Conditions

Slurry Coater for the Laboratory Roll-to-Roll Coater

The Slurry Coater is designed to seamlessly integrate with the Laboratory Roll-to-Roll Coater, a versatile and compact system for precise thin-film processing in lab and pilot-scale environments. Our modular components allow you to customize your coater for a wide range of applications including batteries, medtech, fuel cells, printed solar cells, sensors and more. Built for easy installation and interchangeability, these components help you optimize performance while maintaining flexibility and scalability.

Applications

Learn More About Slot-die Coating

Learn how to choose the right slot-die coater for your needs. Compare sheet vs. roll-to-roll (R2R) systems, understand substrate compatibility, drying methods, treatment options, and scalability to make informed coating decisions.

Learn the key differences between roll-to-roll (R2R) and sheet coating techniques. Discover their advantages, challenges, and ideal applications to choose the right coating method for your lab or production needs.

Discover how pristine clean surface coating eliminates defects by applying functional layers onto untouched substrates. Ideal for medtech, solar cells, OLEDs, and advanced electronics.

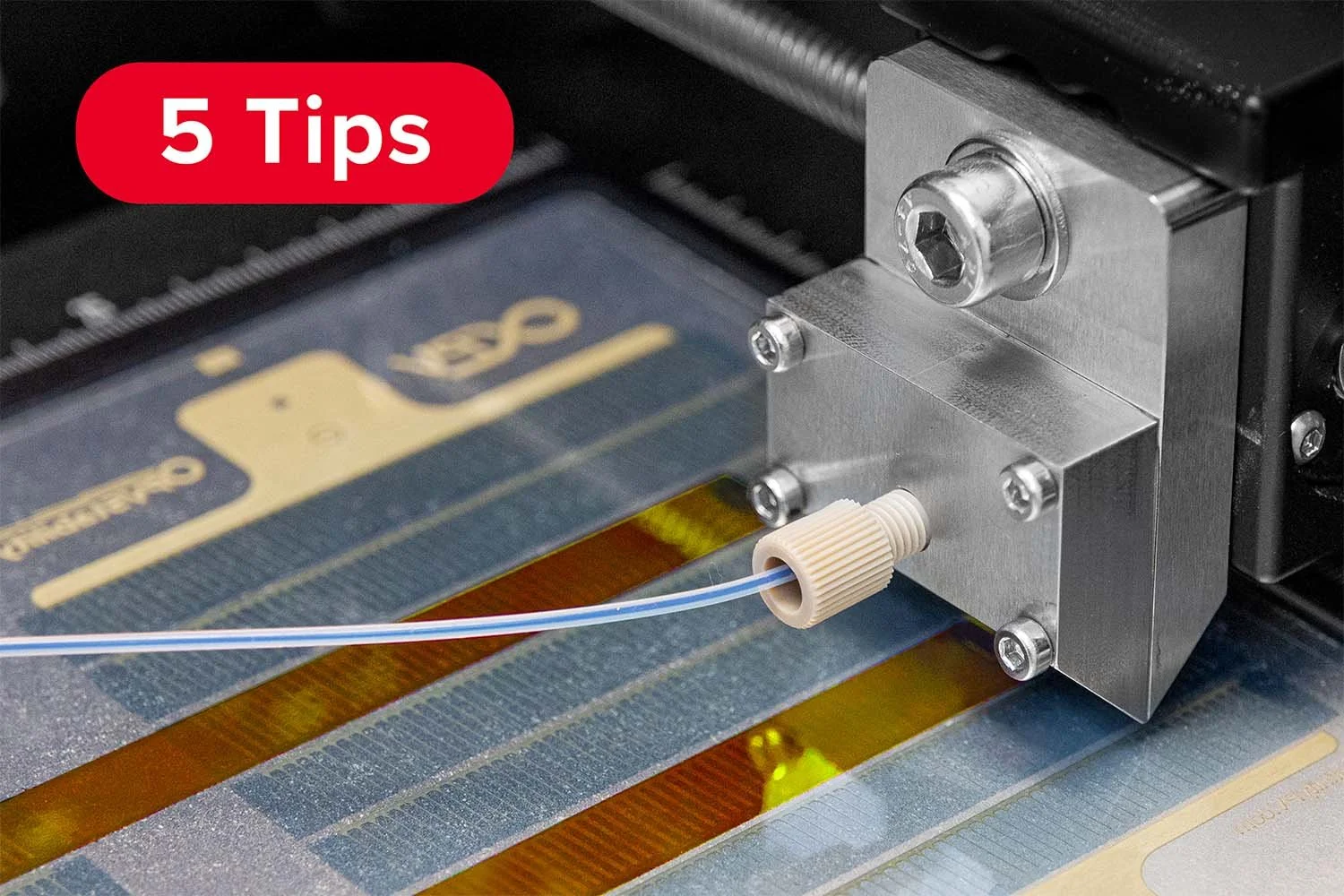

Master slot-die coating with these 5 helpful tips. Avoid common pitfalls, improve coating precision, and ensure smooth, consistent results. Perfect for beginners and experienced professionals alike.

Choosing the right pump for slot-die coating is crucial for achieving precise and consistent results. Our guide covers various pump types, including syringe, gear, and peristaltic pumps, and explains how each contributes to efficient ink delivery, ensuring high-quality coatings for applications such as solar cells, batteries, and printed electronics.