Custom Foil Converting Solutions

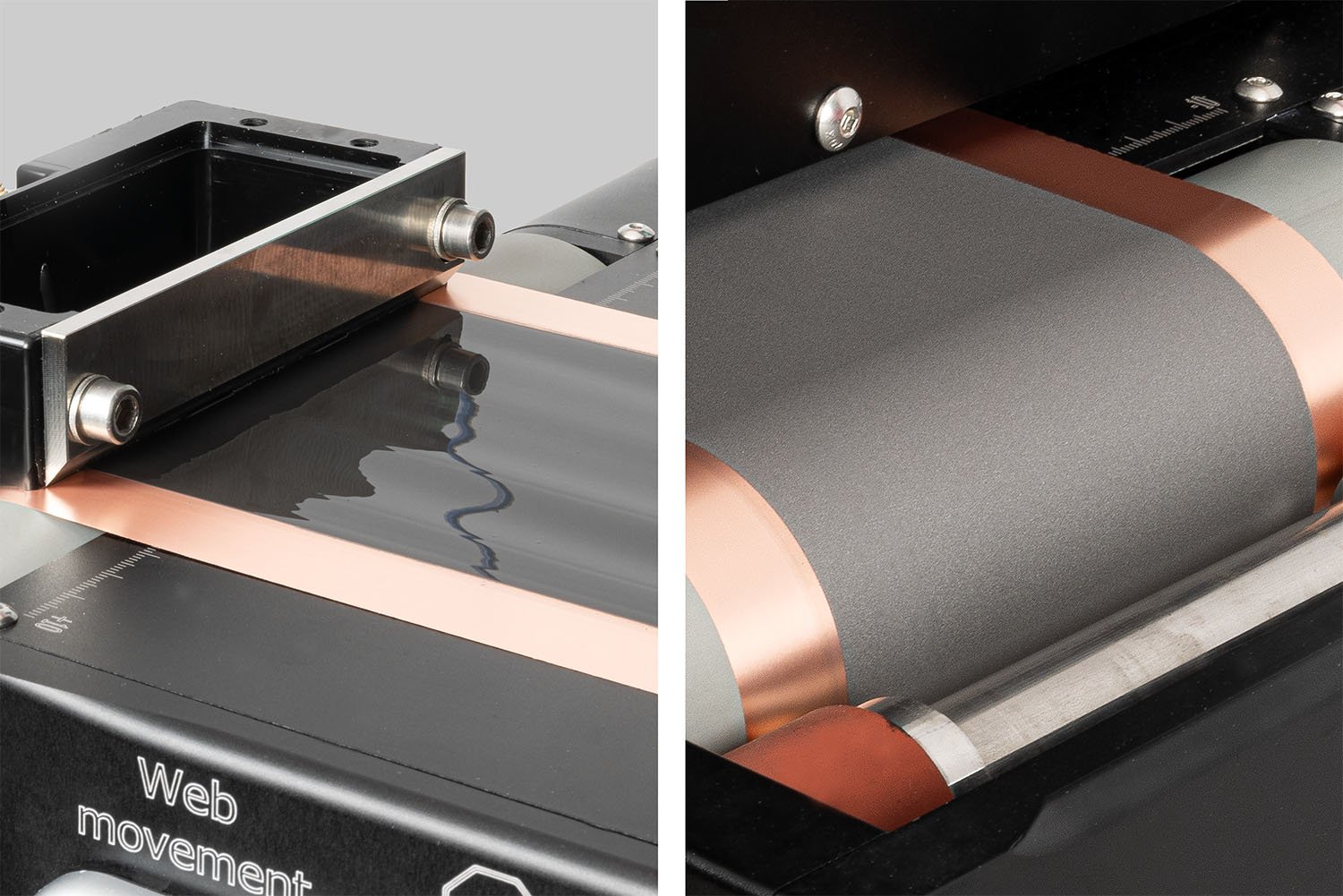

High-Quality Foil Converting for Aluminium, Copper, Plastic, and More

We offer comprehensive foil converting services, transforming your raw foil or substrate materials into precisely tailored products ready for seamless integration into your infinityPV processing platform or other manufacturing lines. We understand that raw materials rarely meet the exact requirements of specialized applications. That's why we offer to modify the dimensions, structure, and properties of your foil rolls, ensuring they perfectly align with your specific application or process.

We provide a wide range of converting services to meet the diverse needs of industries ranging from packaging and printing to electronics and medical devices. Our goal is to empower our clients with expertly converted foil materials that enhance their product quality, streamline their manufacturing processes, and reduce their overall costs.

Foil Types We Work With

Aluminium Foil

Copper Foil

Plastic Foil

Paper

Membranes

Bio Based Foil

More

Applications We Serve

Hydrogen Technology

More

Our Foil Converting Services:

Slitting: Achieve precise widths to match your equipment or application requirements. We expertly slit wide rolls of foil, paper, film, and other materials into multiple narrower rolls while minimizing waste.

Rewinding: Optimize roll quality, handleability, and downstream processing with our rewinding services. We provide controlled tension, edge guiding, and defect removal for consistent performance.

Even Tension Distribution: Precise tension control during rewinding is important as the foil is rolled up. This helps create a roll with uniform density and prevent issues like telescoping or starring (where the roll becomes distorted). A well-rewound roll will unwind smoothly and consistently, which is crucial for roll-to-roll processing. Controlled tension can also help to remove or minimize wrinkles and creases in the foil, ensuring a smooth surface for printing, coating, or laminating.

Edge Guiding: Precise edge alignment during rewinding is important with edge guiding systems to ensure straight edges as the roll is formed. This creates a roll with clean, straight edges, which is essential for many downstream processes.

Core Size Conversion: We offer core size changes when converting foil from one core size to another is a common and feasible converting operation. A specific core size might be required for compatibility with a customer's equipment. It is possible to convert foil from a 6-inch inner core to a 3-inch inner core (or vice versa).

Precise Foil Length Rolls: We offer rolls with a specific length where many applications require foil rolls with a specific length to fit a particular machine or process (e.g., a certain length of foil for a sealing operation). A master roll can be split into several rolls with defined lengths.

Trimming: Ensure clean, even edges and precise dimensional accuracy with our trimming services. We remove edge imperfections and correct any misalignment that may occur during printing, coating, or laminating.

Achieving Precise Widths: Precise width can be achieved with careful slitting. There can be slight variations in width but trimming ensures the final rolls or sheets have the exact width needed for their intended application.

Removing Edge Imperfections: The edges of the foil web can sometimes be uneven or have slight imperfections (e.g., burrs, tears, wrinkles). Trimming removes these imperfections, providing a clean, professional finish.

Correcting Misalignment: Proper alignment can be applied if the foil has been printed, coated, or laminated, trimming can be used to correct any slight misalignment between the printed image/coating and the edge of the foil.

We Are Ready to Help You

With decades of experience in printed electronics, our team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project.

Roll-to-Roll Coating? We got you covered.

Whether you're working within batteries, pharma and medtech, fuel cells, solar cells, or other thin-film technologies, we offer scalable Roll-to-Roll (R2R) equipment built for the lab. Our modular systems are designed for precision, repeatability, and flexibility, supporting everything from coating and drying to surface treatment and characterization.