Latest News in Printed and Coated Technologies

We’re here to help you stay up-to-date with the latest developments in slot-die coating, roll-to-roll processing, solar cells, printed batteries, fuel cells, pharmaceuticals, OLEDs and more. Whether you're working in research, production, or application development, we keep you informed with relevant and reliable updates from across the field.

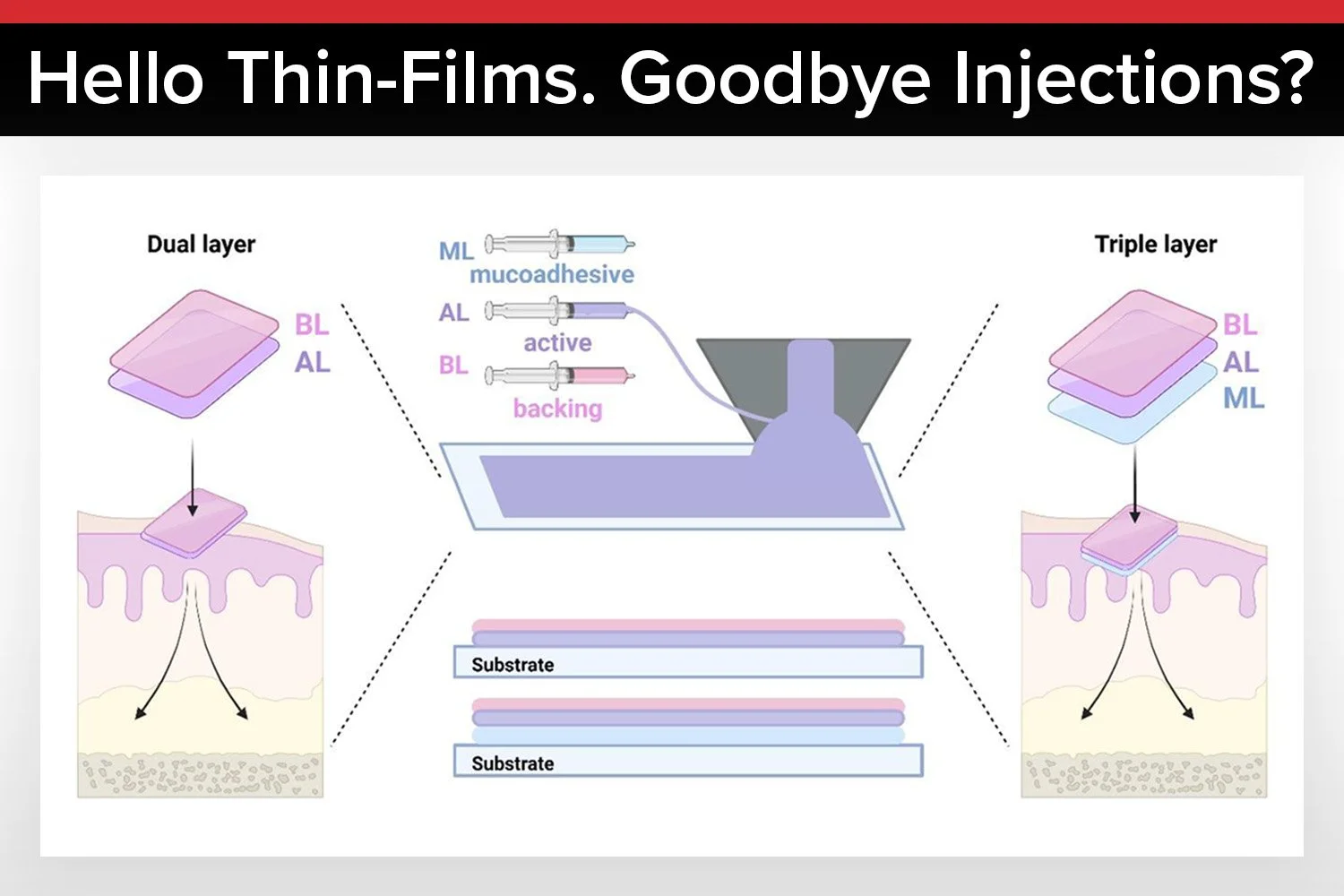

A new study demonstrates how multilayer polymer thin films can deliver GLP-1 therapeutics through buccal drug delivery, offering a potential injection-free alternative using advanced coating and thin-film technologies.

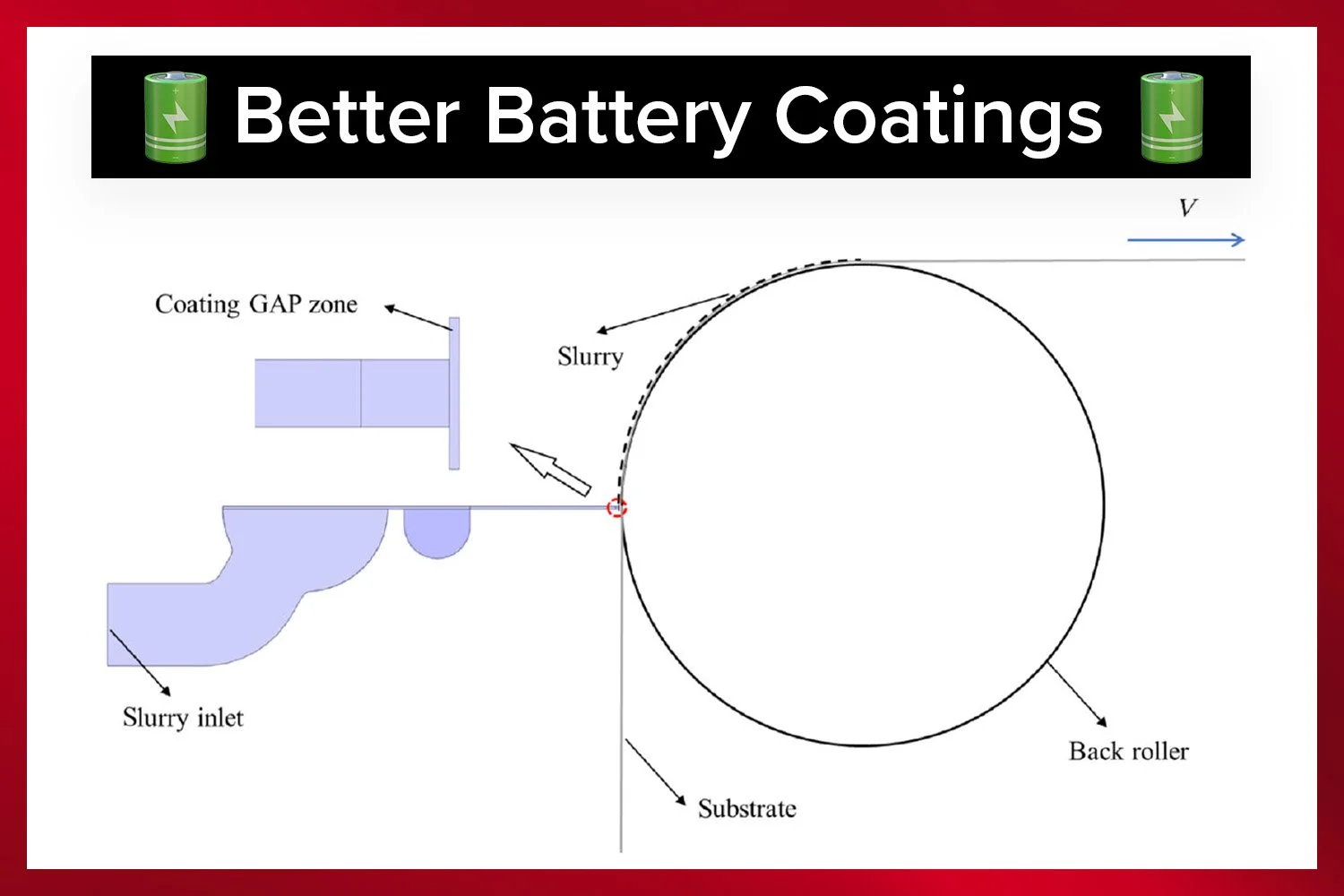

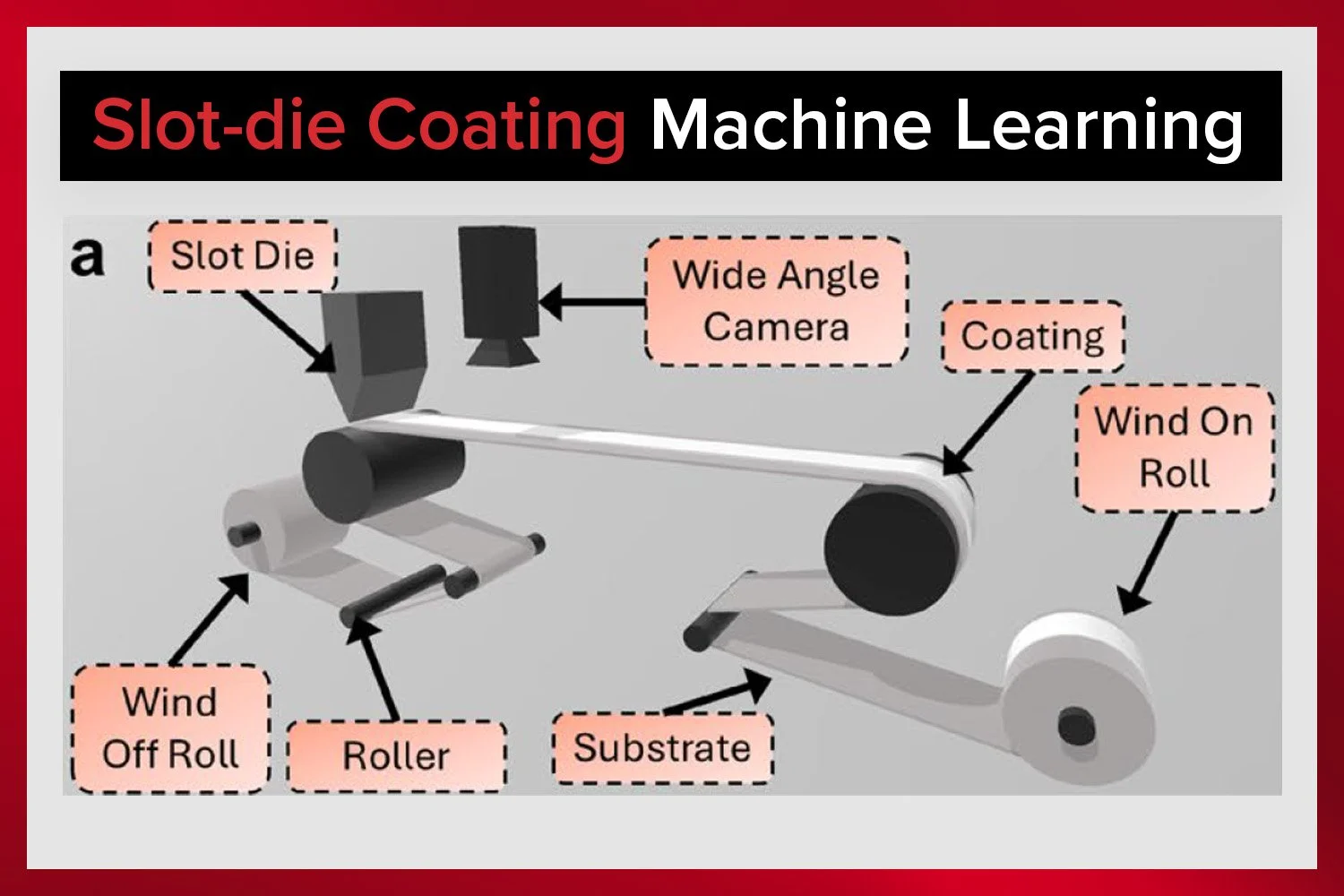

New research shows how advanced simulations reveal the causes of wet film defects in slot-die coating and help improve lithium-ion battery electrode manufacturing.

Glovebox kinematic platforms that make it easy to move and precisely position coating equipment. Choose roller mobility or a stable, lockable mounting block with custom options.

A research article demonstrates how roll to roll printing can mass produce smart wound dressings with integrated color changing sensors for pH, temperature, and humidity, offering a new path toward scalable and affordable wound monitoring.

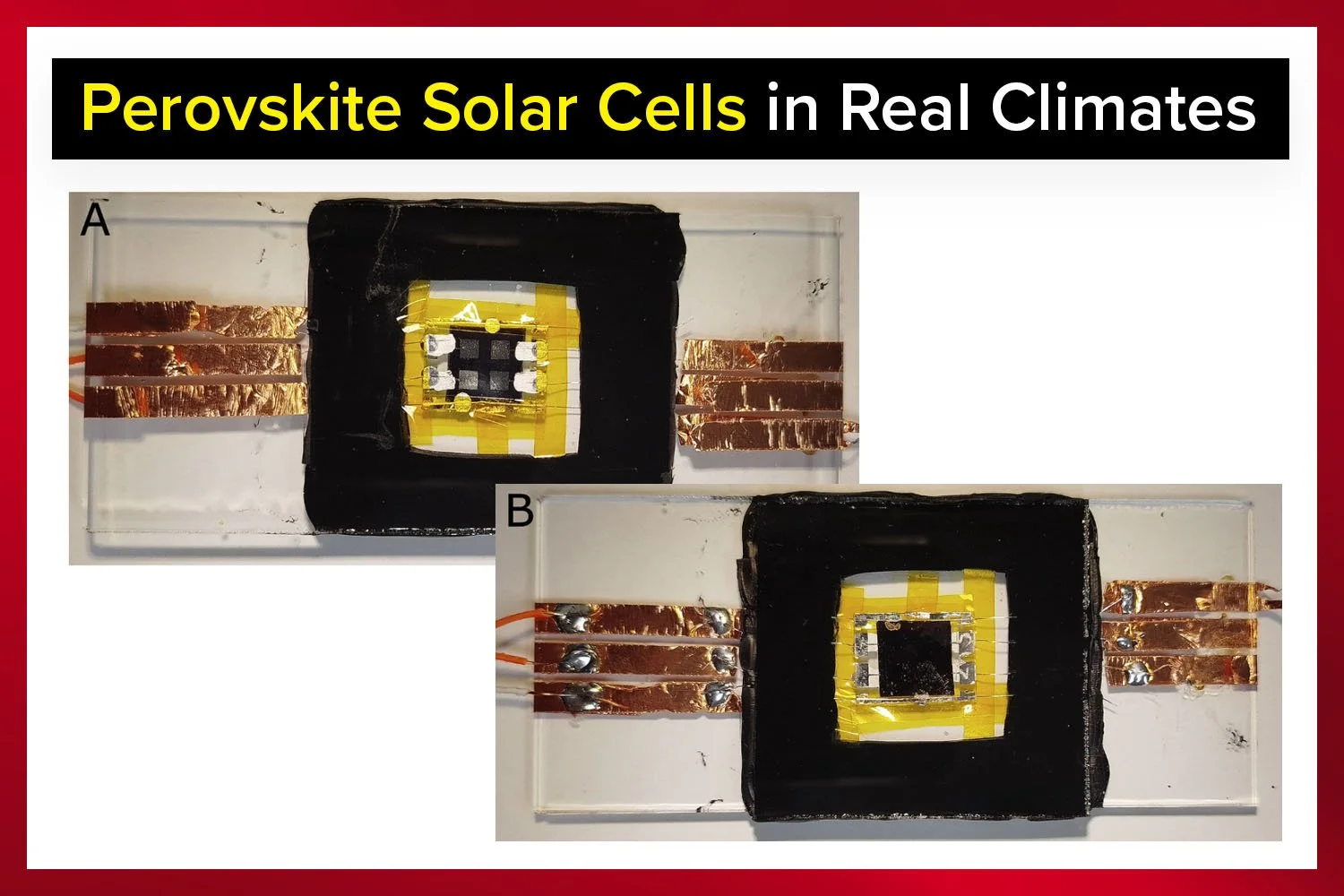

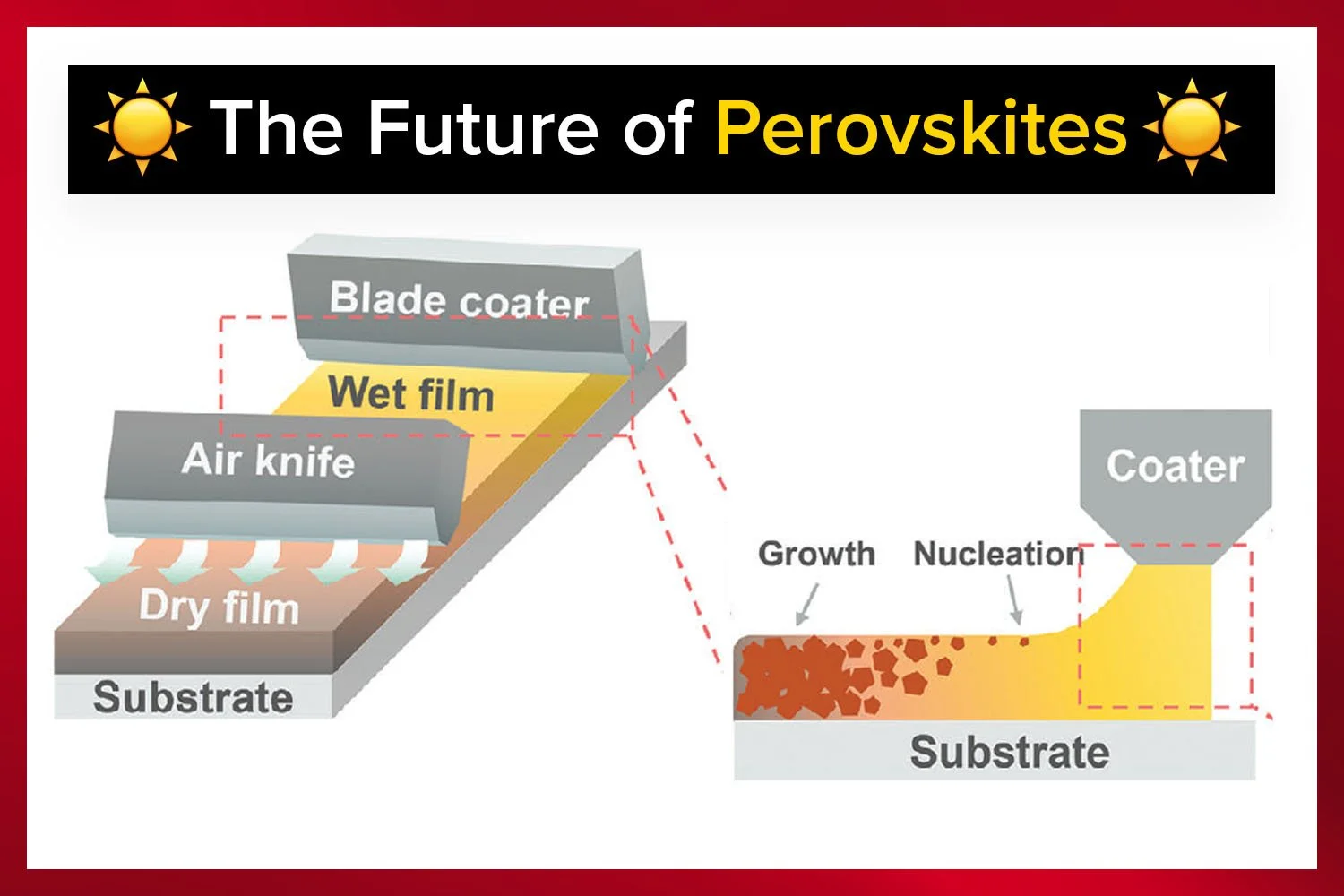

A detailed comparison of accelerated and outdoor aging shows how climate, load and encapsulation influence perovskite solar cell stability.

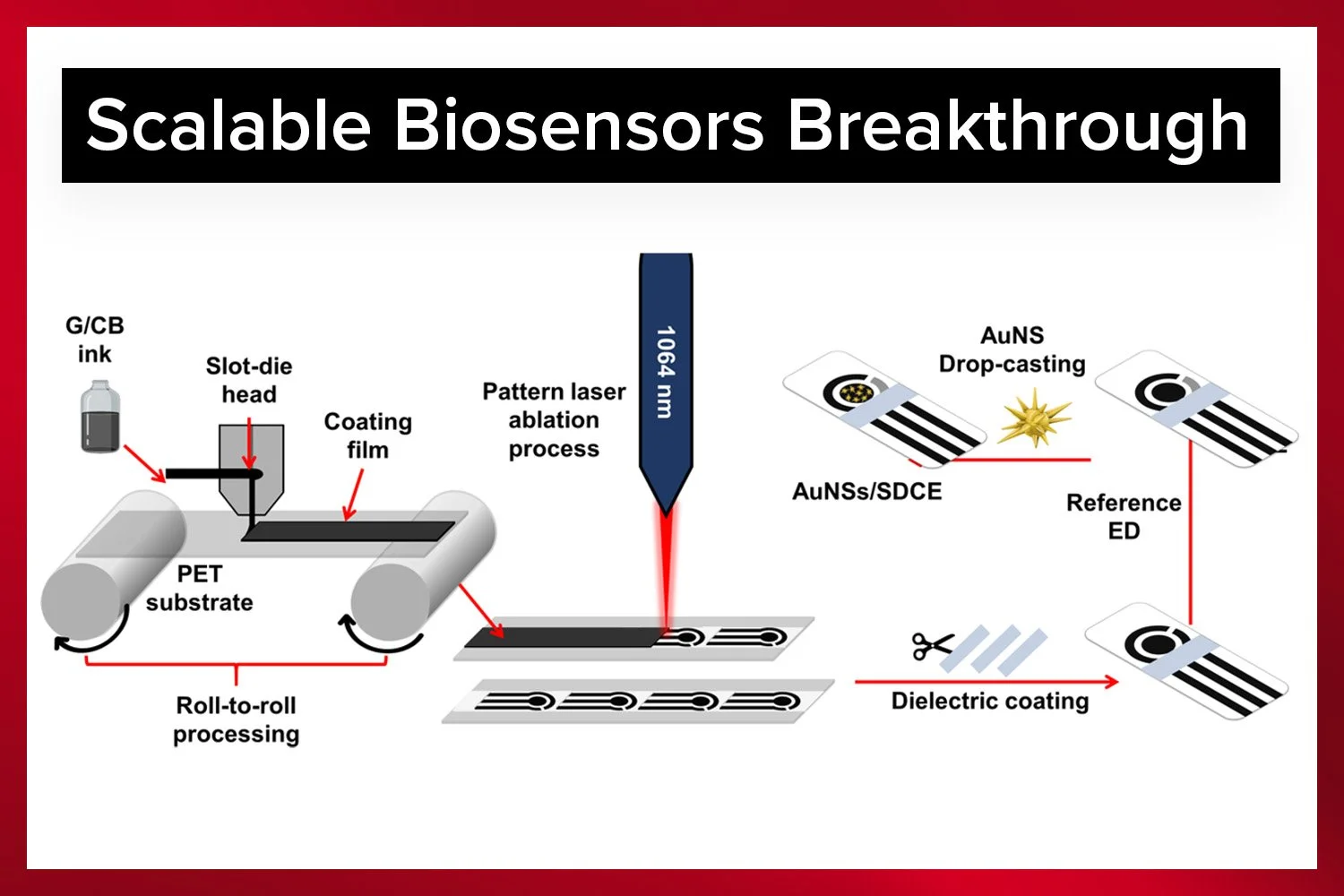

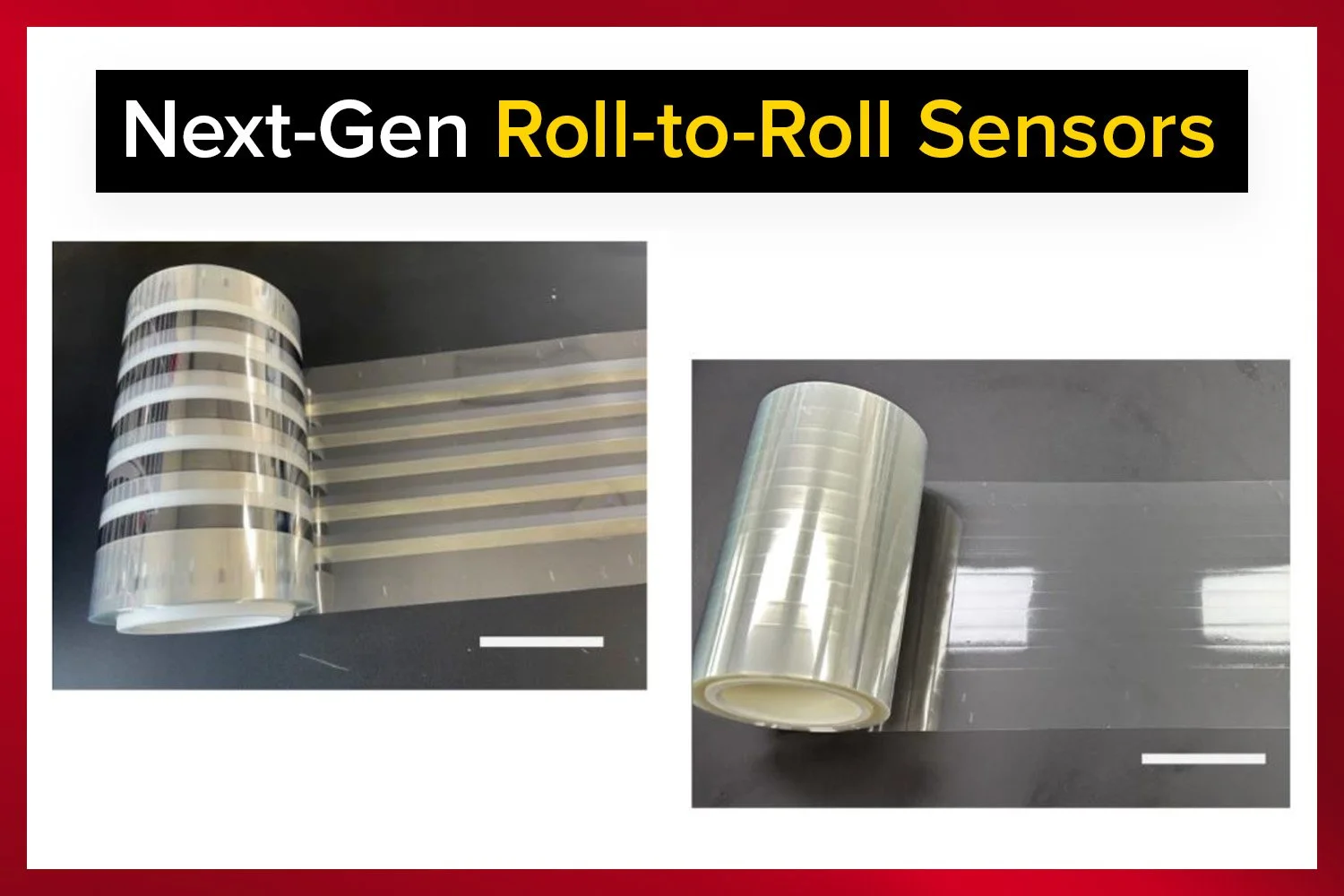

How roll-to-roll slot-die coating and laser patterning can produce high performance gold nanostar enhanced electrochemical biosensors for detecting C reactive protein with excellent sensitivity and industrial scalability.

Researchers have developed a roll-to-roll process to mass-produce foil-based microfluidic neuron chips, enabling high-throughput, low-cost brain-on-a-chip technologies for neuroscience and biomedical research.

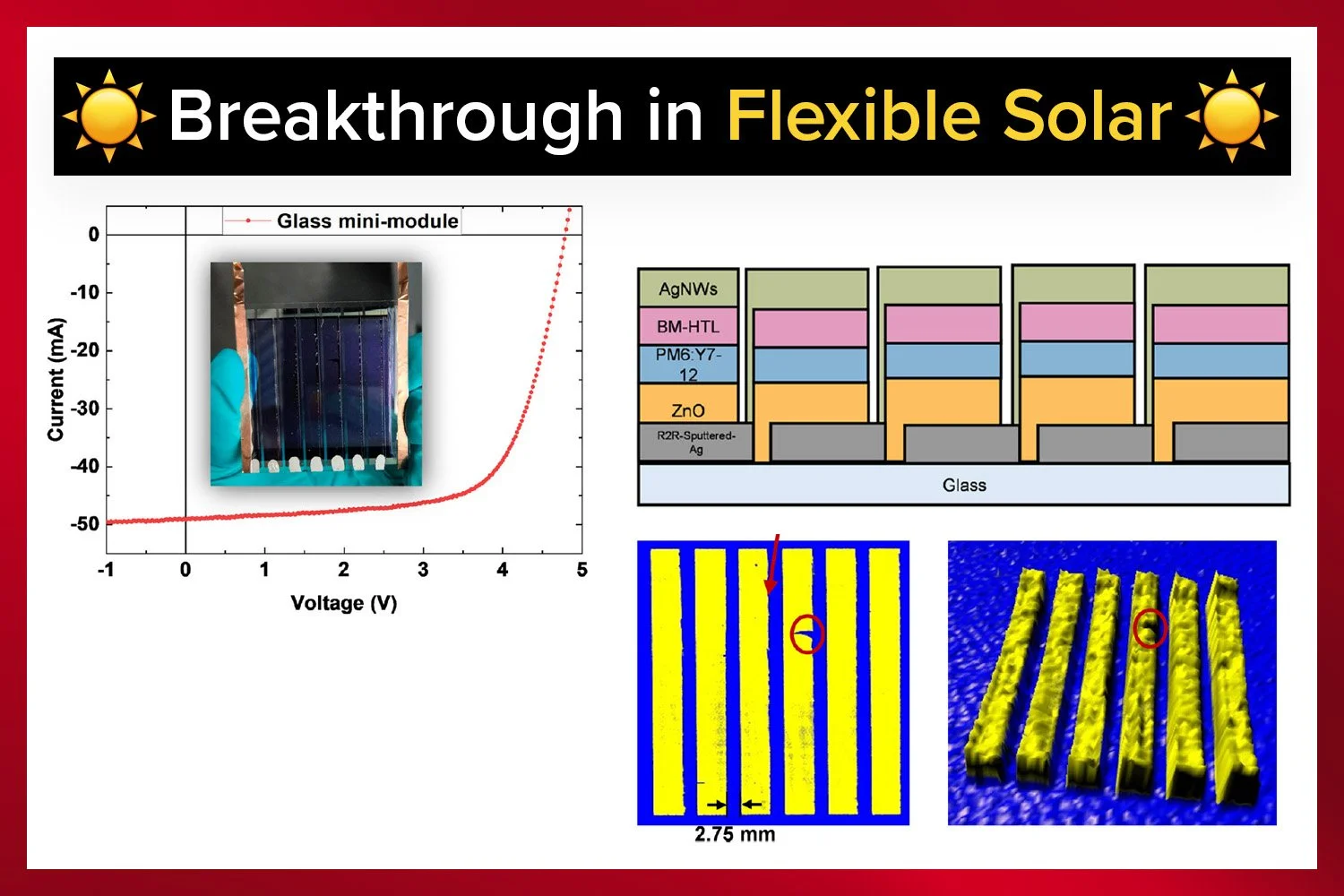

Researchers have developed record-efficient, flexible, ITO-free organic solar modules using a fully roll-to-roll process. The breakthrough shows scalable, sustainable manufacturing for next-generation solar energy.

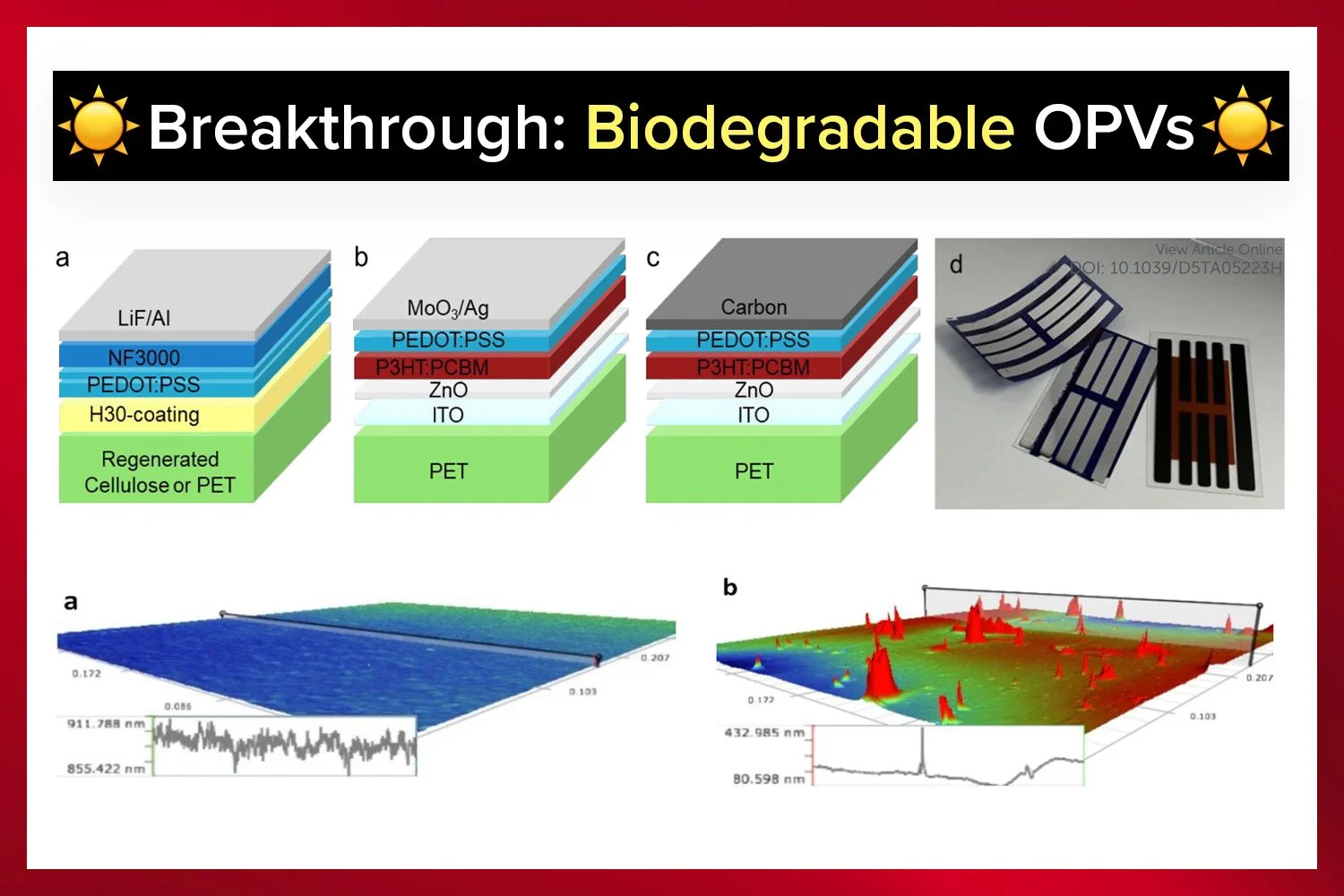

Scientists have built solar cells that can biodegrade naturally after use. Instead of using plastic and metal, they used materials such as cellulose (from plants) and carbon paste, both safe for soil.

Learn why organic and perovskite solar cells, despite record efficiencies, remain slow to commercialize and how collaboration and standardization can bridge the research-to-market gap.

CEO Frederik Krebs recently attended ISOS16, where he gave a talk on roll-to-roll coating of perovskite solar cells.

Researchers developed a roll-to-roll coating method that creates dendrite-free zinc anodes with 99.9% efficiency and long lifetimes, paving the way for scalable and safer aqueous zinc batteries.

Discover how 25 years of Danish research in organic solar cells and slot-die coating turned public funding into global high-tech innovation.

infinityPV welcomed new European reseller JP Kummer for a two-day visit with hands-on training in slot-die coating.

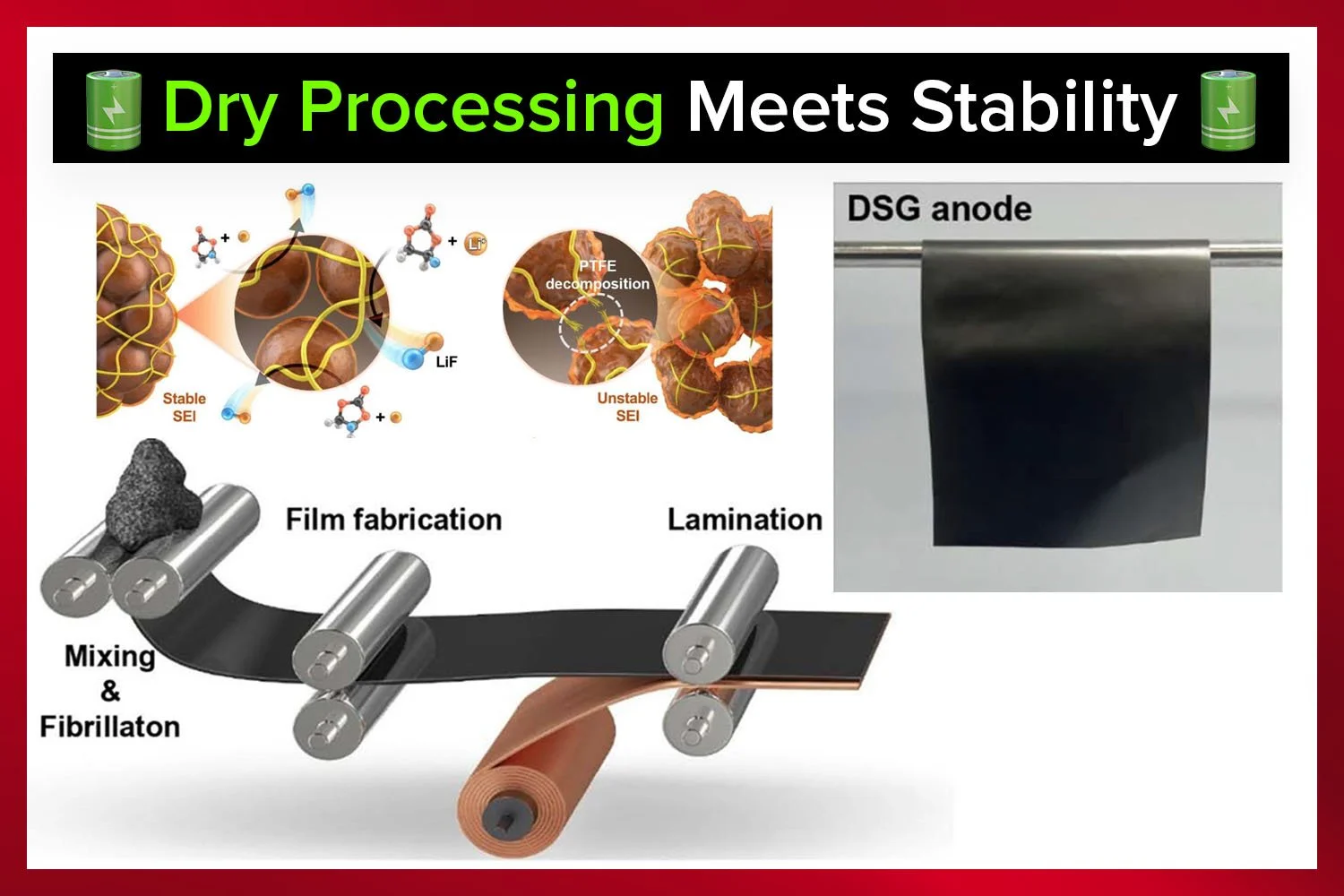

A new study shows how tailoring FEC electrolyte additives stabilizes dry-processed silicon anodes and Ni-rich cathodes, achieving high efficiency and long cycle life for next-generation EV batteries.

A new transferring and bonding method enables roll-to-roll printed touch sensors to achieve unprecedented miniaturization and sensitivity, solving long-standing challenges in scalable flexible electronics.

A new study shows how machine learning can optimize roll-to-roll slot die coating, delivering record coating uniformity, reducing waste.

A new study reveals that reshaping colloids in perovskite inks boosts blade-coated solar modules to record efficiencies and stability.

Researchers develop a scalable slot-die process for perovskite solar modules in air, reaching 17% efficiency and record stability.

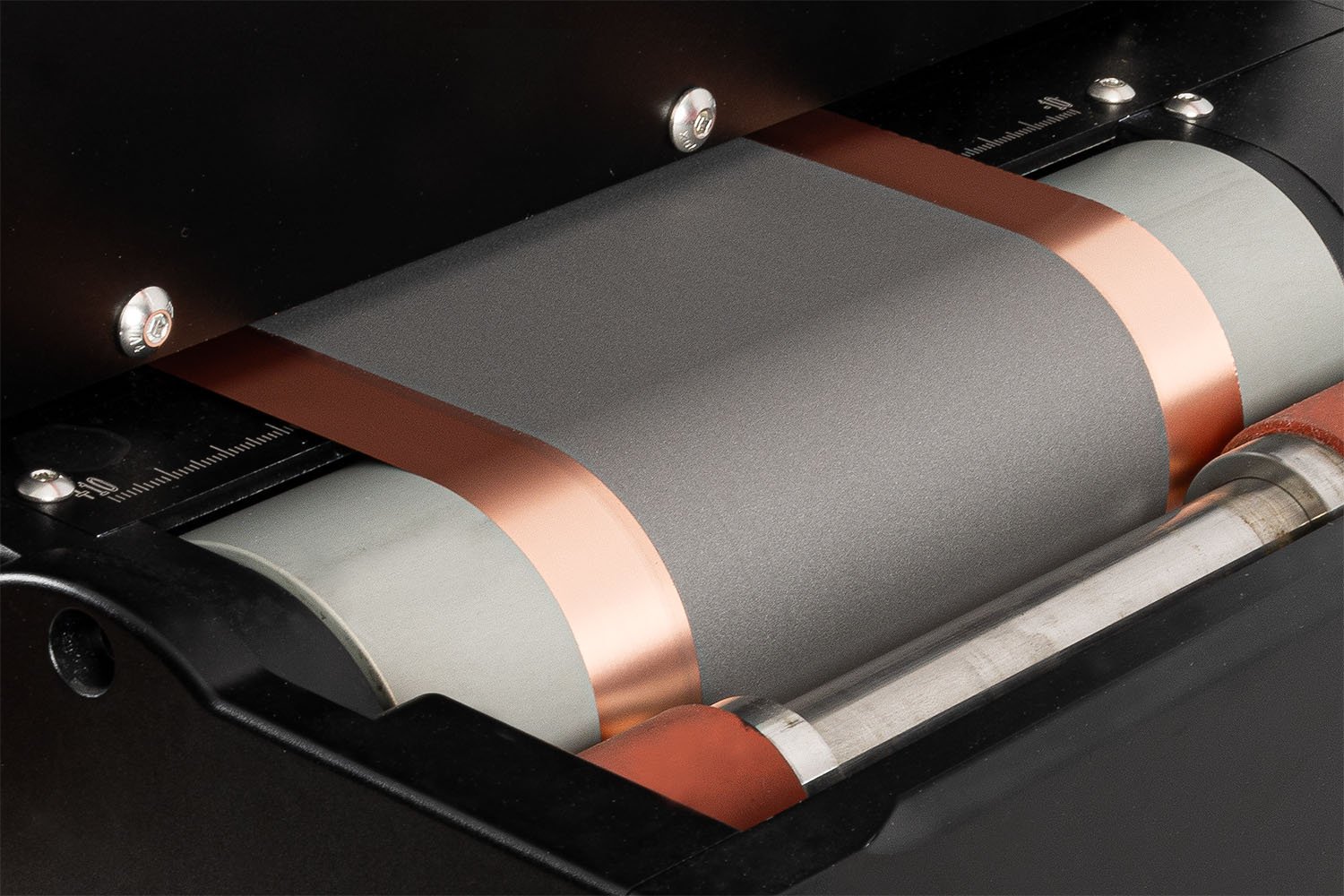

infinityPV offers precision foil converting services for aluminium, copper, plastic, paper, and bio-based foils. Slitting, rewinding, trimming, and core conversion ensure rolls are ready for batteries, solar cells, MedTech, packaging, and more.

infinityPV now offers coating supplies for sheet and roll-to-roll coating. Shop copper foil, aluminium foil, and more.

A new study shows how viscosity affects slot-die coating of nanocellulose barrier layers, revealing why higher viscosities shrink the coating window and how industry can overcome it.

Researchers are using natural cell membranes to create “stealth” nanoparticles that evade the immune system, target disease sites, and deliver drugs with unprecedented precision.

A new study shows how the indirect roll-to-roll method for catalyst coated membranes can match commercial fuel cell performance while using 25 percent less platinum.

A new study demonstrates that high-efficiency solar cells and modules can be fabricated using marker pens, offering a low-cost and flexible alternative to traditional solar manufacturing methods.

A new study introduces the WING process, a scalable roll-to-roll method that enables high-throughput printing of durable, omniphobic, and multifunctional reentrant surfaces for industrial applications.

A new study reveals how device architecture affects the performance and degradation of slot-die coated organic solar cells, showing pathways to scalable, stable, and efficient OPV modules.

Discover how oral thin films are transforming nutraceutical delivery with faster absorption, improved bioavailability, and superior consumer convenience.

Discover the future of drug delivery in this expert review on transmucosal systems. Learn how films, nanocarriers, and nasal routes are changing medicine.

Researchers have developed a smart antibacterial coating that releases drugs only when needed and signals drug depletion through visible color changes.

We Are Ready to Help You

With decades of experience in printed electronics, our team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project. Contact us to discuss how we can support your solar cell development.

Roll-to-Roll Coating? We got you covered.

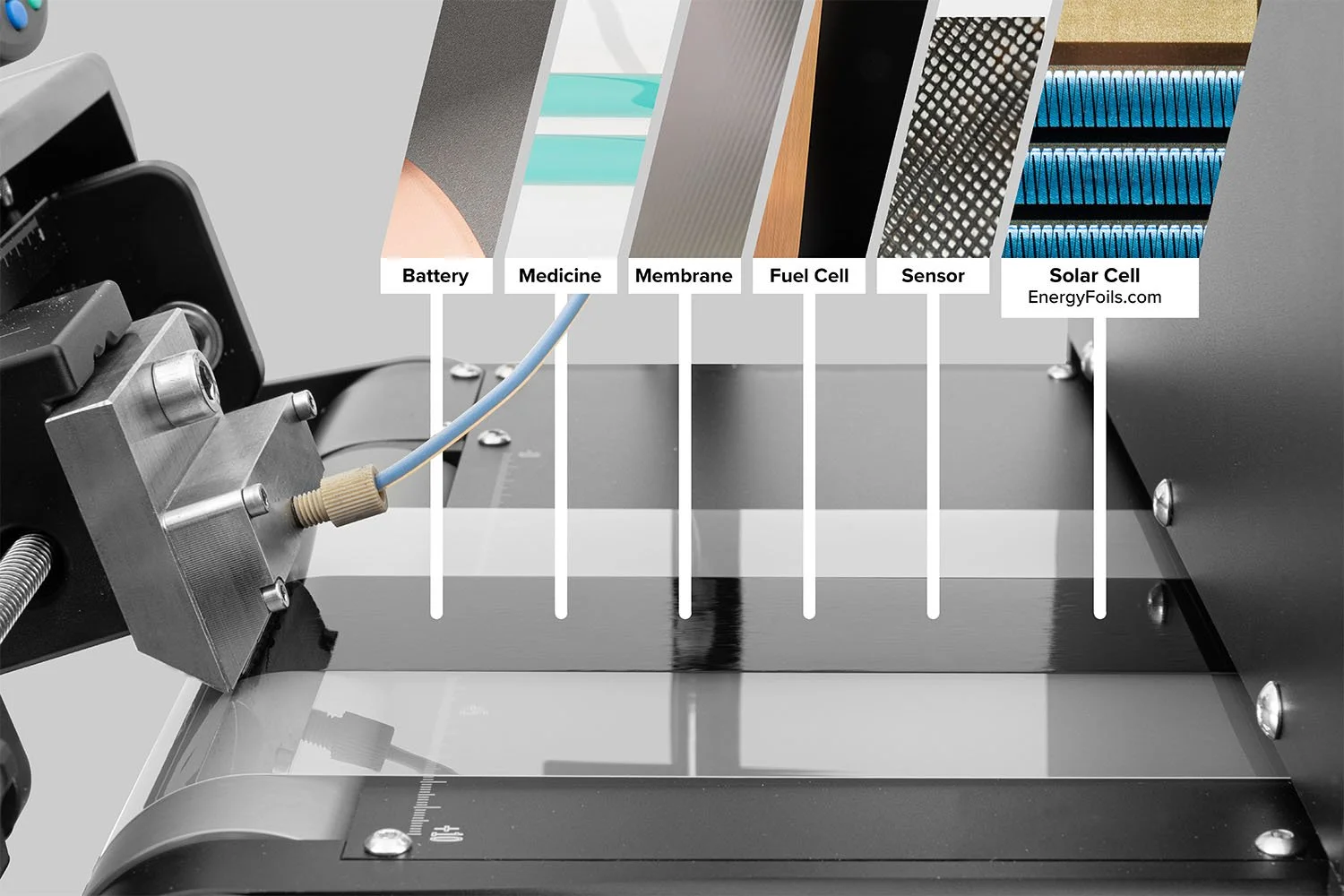

Whether you're working within batteries, pharma and medtech, fuel cells, solar cells, or other thin-film technologies, we offer scalable Roll-to-Roll (R2R) equipment built for the lab. Our modular systems are designed for precision, repeatability, and flexibility, supporting everything from coating and drying to surface treatment and characterization.