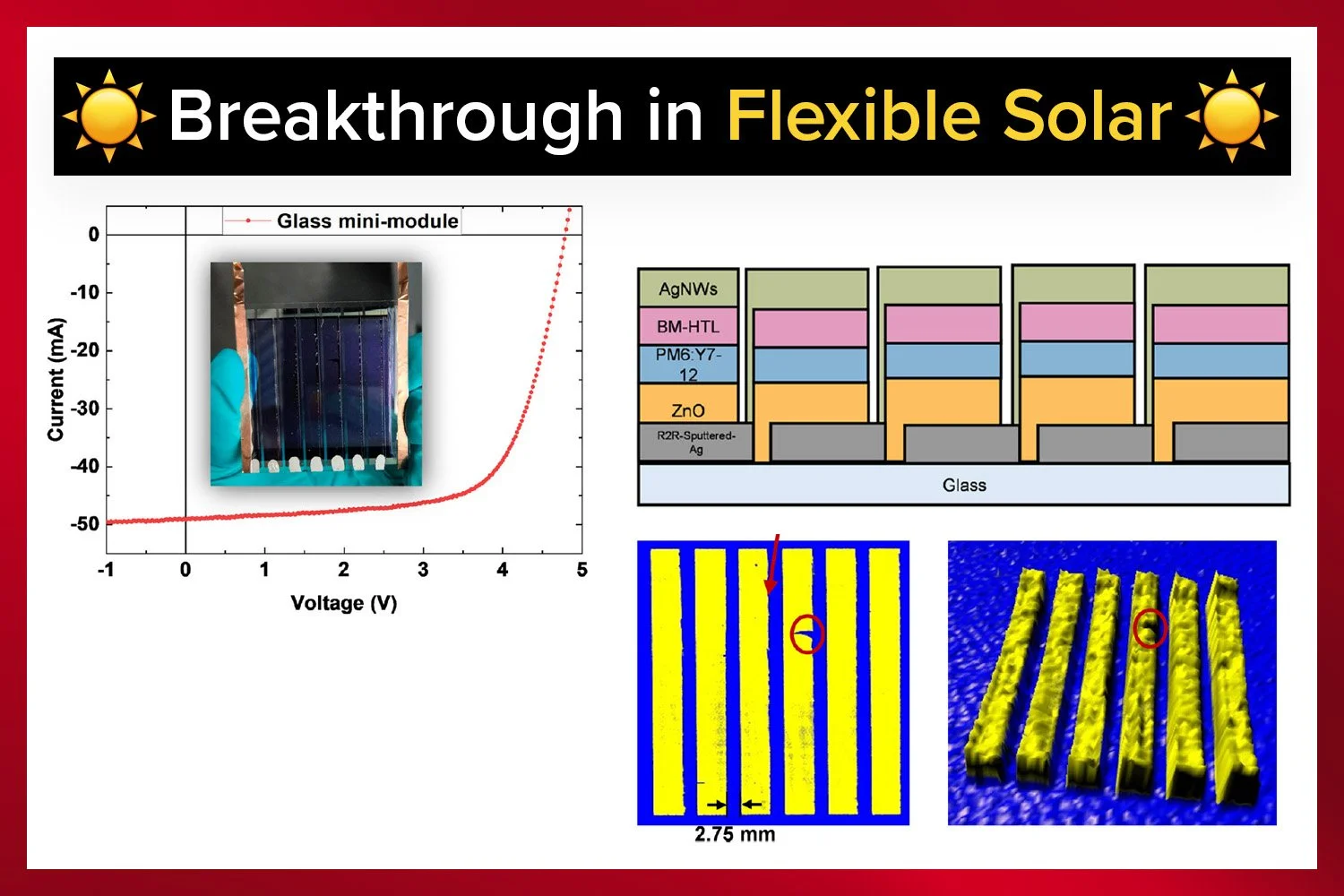

Breakthrough in R2R Solar: Scientists Hits 13.5% Efficiency Without ITO Using Slot-die Coating and LBIC

The team employed laser beam induced current (LBIC) mapping to verify current uniformity and detect fabrication defects

Can Flexible, Scalable Solar Panels Power the Future?

As the demand for sustainable and cost-effective energy solutions continues to rise, the question of how to produce solar technologies that are both efficient and easily scalable has become increasingly critical. Traditional silicon-based solar panels, while effective, remain limited by rigid form factors and energy-intensive production methods. In parallel, organic photovoltaics (OPVs) have emerged as a promising alternative, offering lightweight, flexible, and low-cost solar solutions that can be integrated into a wide range of applications—from building materials to portable electronics.

However, one major barrier has persisted: most high-performance OPVs rely on indium tin oxide (ITO), a brittle, expensive, and resource-limited material that is unsuitable for large-scale, flexible manufacturing. Addressing this challenge, a research team from the University of Southern Denmark has introduced a new approach in their study, “Flexible ITO-Free Organic Solar Modules Using Fully Roll-to-Roll Processable Top Illumination Design.”

In this work, the authors present a fully roll-to-roll (R2R) processable, ITO-free organic solar module architecture, marking a significant advancement toward industrial-scale production of flexible solar films. By combining R2R sputtering for metallic layers with slot-die coating for the remaining functional layers, all processed under ambient conditions and using greener solvents, the team achieved record efficiencies of 13.5 percent on glass substrates and 11.5 percent on flexible PET films.

Key Highlights

Achieved 13.5 % efficiency on glass and 11.5 % on flexible PET using fully R2R-compatible fabrication

Replaced expensive indium tin oxide (ITO) with flexible, solution-coated silver nanowires (AgNWs)

Demonstrated record performance for scalable, ITO-free solar modules over 100 cm² active area

Used greener solvents and ambient-air processing for sustainability and safety

Employed laser beam induced current (LBIC) mapping to verify current uniformity and detect fabrication defects

We believe perovskite solar cells can revolutionize renewable energy, but only if R&D bridges the gap between lab and industry. Success requires small-scale roll-to-roll platforms that replicate real-world conditions with precision.

What Is ITO-Free Solar and Why Does It Matter?

Traditional solar devices rely on ITO as a transparent electrode that conducts electricity. It is effective but brittle, costly, and dependent on the rare element indium. Its rigid nature limits its use on flexible substrates, while the high processing temperatures make it incompatible with most plastics.

To overcome these limitations, the research team replaced ITO with a network of silver nanowires. These nanowires form an electrically conductive mesh that is both flexible and transparent. More importantly, they can be applied using slot-die coating—a scalable printing technique already common in industrial processes. When combined with a sputtered silver layer on the bottom electrode, the architecture results in a completely ITO-free design that is durable, bendable, and ready for mass production.

This change has far-reaching implications. It allows manufacturers to move from rigid glass panels toward lightweight, rollable solar films that could one day be integrated directly into construction materials, vehicles, or even consumer products.

The Significance of the Study

For years, one of the major challenges in bringing organic solar cells to market has been the difficulty of translating laboratory processes into industry-ready production. Spin coating and vacuum deposition—standard in research environments—simply cannot be scaled efficiently.

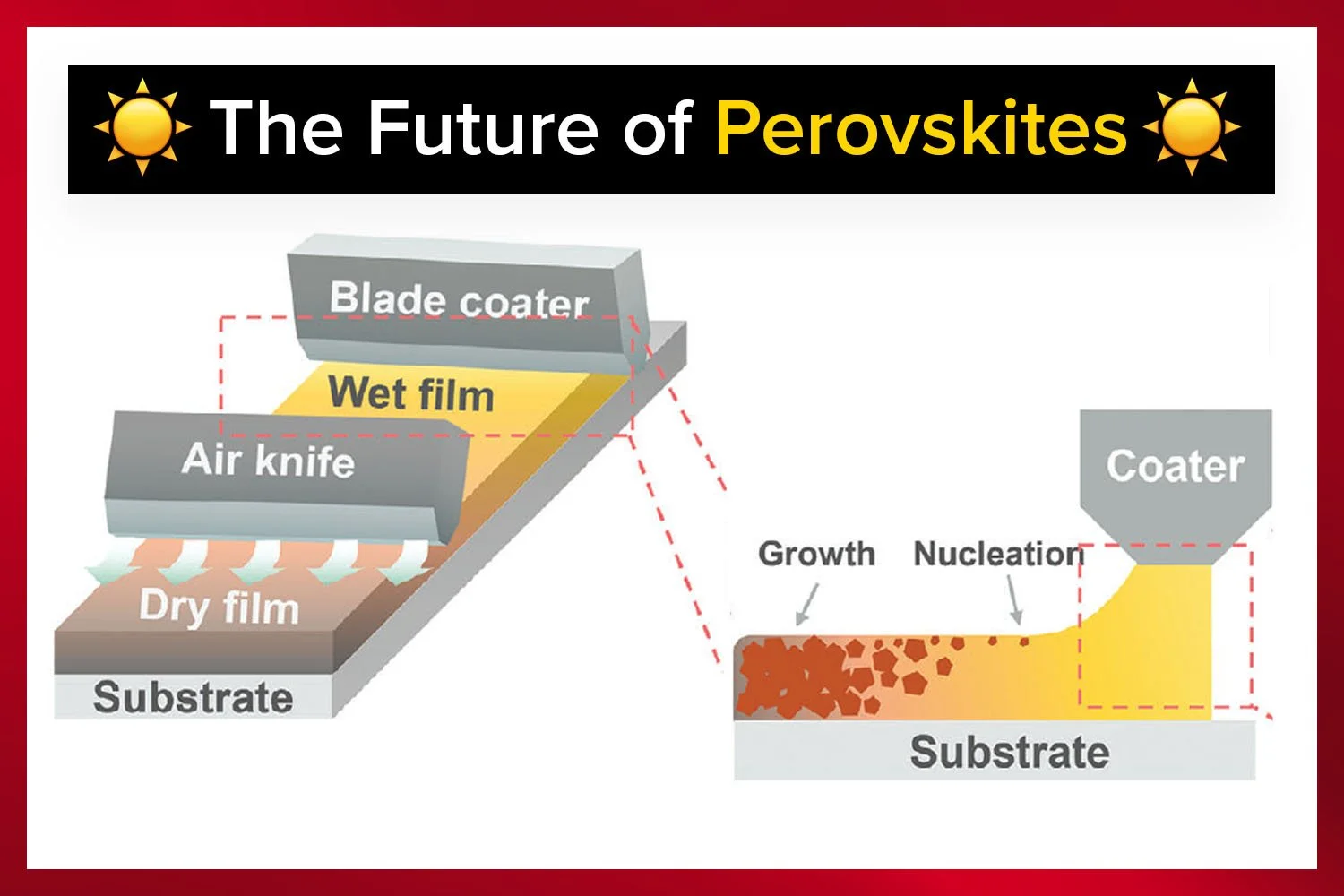

The new study bridges this divide. By using roll-to-roll sputtering for metallic layers and sheet-to-sheet slot-die coating for the rest of the solar stack, the team demonstrated that high efficiency can be maintained even with large-area fabrication. The process supports ambient-air coating and uses greener, non-halogenated solvents, aligning with global goals for sustainable manufacturing.

Equally important is that this work combines all these steps into a single compatible system. The result is a fully roll-to-roll process where every layer—from electrodes to the light-absorbing film—is applied using industrially viable methods. It brings OPV technology closer to the assembly line than ever before.

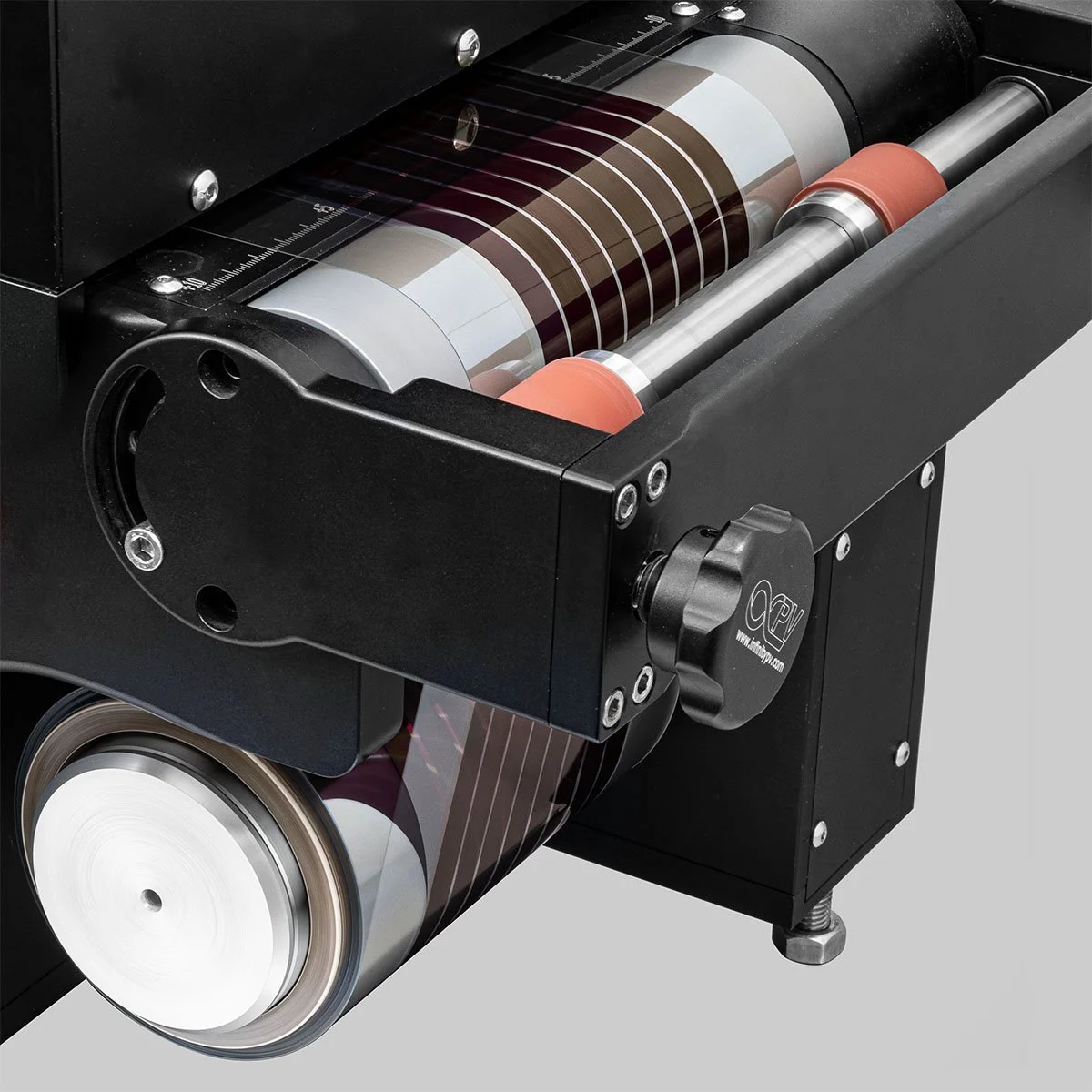

Learn how to fabricate solar cells using slot-die coating and flexo printing on a Slot-die Coater.

Diving Into the Methods: How It Was Done

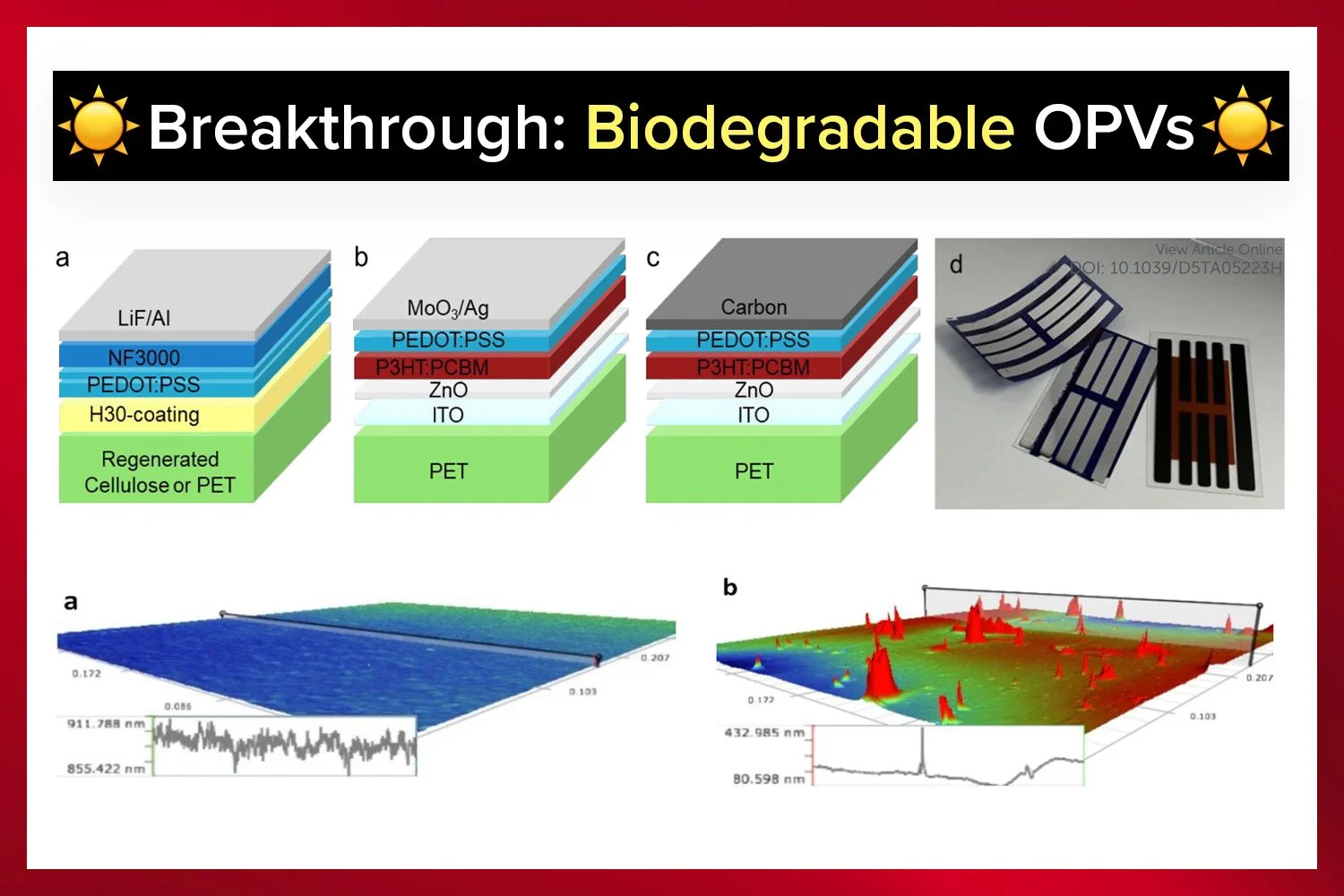

The devices follow a top-illumination architecture, consisting of a silver bottom electrode, a zinc oxide layer, a PM6:Y7-12 active layer, a hole transport layer (BM-HTL-1), and a transparent top electrode made from silver nanowires. The bottom silver electrode was created through roll-to-roll sputtering, resulting in an exceptionally smooth and reflective layer with roughness around 1.5 nm and sheet resistance below 0.5 Ω per square.

The remaining layers were applied using slot-die coating. The active layer—a blend of the donor polymer PM6 and the non-fullerene acceptor Y7-12—was processed from o-xylene, a non-halogenated solvent that is less harmful to the environment than traditional alternatives. The top AgNW electrode was optimized to achieve both high transparency (84 % at 550 nm) and low resistance (~11 Ω per square), outperforming even the reference ITO electrode.

This hybrid approach merges the precision of vacuum processing with the scalability of solution coating. The design enables devices that can be produced continuously in a roll-to-roll environment, paving the way for truly large-scale solar manufacturing.

From Cells to Modules: Scaling Up

After optimizing the small devices, the team scaled up the process to build mini-modules consisting of six interconnected solar cells. These modules were fabricated both on glass and on flexible PET substrates. The glass modules achieved a power conversion efficiency of 12.5 %, while the flexible modules reached 11.5 %.

A large module covering more than 100 cm² was also produced, achieving nearly 10 % efficiency and demonstrating its ability to power small electronics such as a mobile phone through a standard voltage converter. This represents one of the highest reported efficiencies for an ITO-free, roll-to-roll-compatible solar module of this size.

R2R slot-die coating for solar cells is easy with the Laboratory Roll-to-Roll Coater.

Mapping Uniformity with LBIC

To confirm that performance was consistent across the large modules, the team used Laser Beam Induced Current (LBIC) measurements. This technique scans the surface of the module with a focused laser beam to create detailed current maps, allowing researchers to visualize how uniformly each part of the device generates power.

The LBIC images revealed highly uniform current generation across all six cells, confirming the reliability of the coating process. Minor defects such as slightly uneven scribing lines were identified but had minimal effect on overall performance. The study showed that mechanical scribing could later be replaced with laser scribing to further improve precision and reduce electrical losses.

This analysis provided direct evidence that the roll-to-roll and slot-die methods produce consistent film quality over large areas—an essential milestone for scaling OPV technology to industrial production.

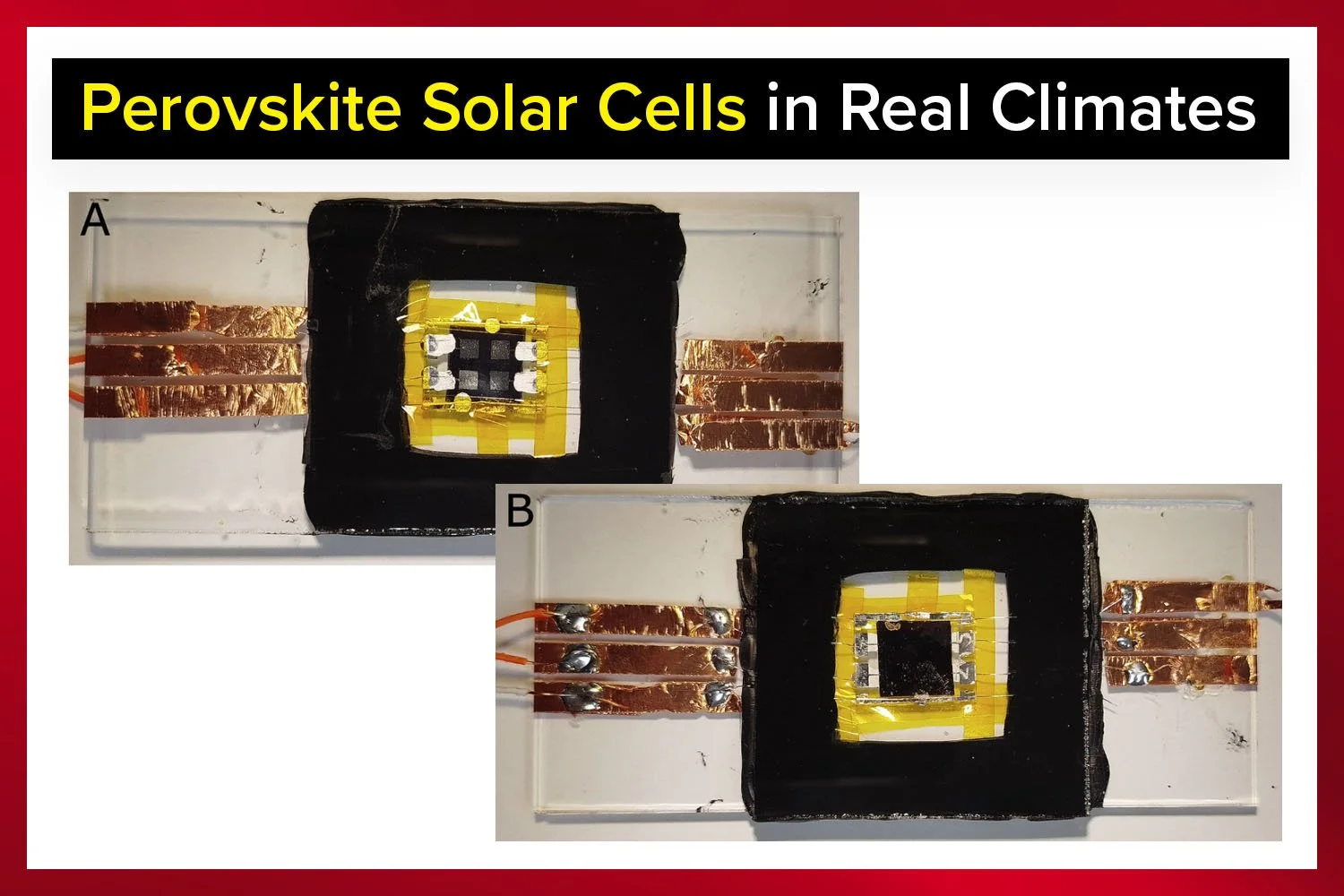

Stability and Durability

To test real-world viability, the researchers conducted light-soaking experiments under one-sun illumination at ambient conditions. Even though some degradation occurred during the first few hundred hours, the devices maintained 50 % of their initial performance after about 800 hours. For a flexible, ITO-free device made under open-air conditions, this represents a significant achievement.

Future studies will likely focus on improving encapsulation and understanding degradation mechanisms. However, even at this stage, the stability results demonstrate that these flexible modules are not only efficient but also sufficiently robust for practical applications.

With the Laboratory Roll-to-Roll Coater, fabricating perovskite solar cells has never been easier.

Future Outlook and Industry Relevance

The implications of this research extend far beyond the laboratory. The demonstrated roll-to-roll approach could allow solar modules to be produced in continuous sheets—just like newspaper printing. This opens opportunities for new applications in building-integrated photovoltaics, portable power sources, and lightweight energy solutions for transportation and consumer goods.

By replacing indium-based materials with more abundant and recyclable metals, the process also improves supply-chain sustainability. Furthermore, the ability to operate under ambient conditions reduces manufacturing costs and energy consumption. The result is a technology that is both environmentally and economically viable.

As performance and durability continue to improve, flexible OPVs could transform how we think about solar energy. They offer a route to energy systems that are embedded directly into products and surfaces rather than mounted as separate panels. The research from the University of Southern Denmark represents one of the most complete demonstrations yet that such a future is within reach.

Conclusion

The development of flexible, ITO-free organic solar modules using a fully roll-to-roll process represents a milestone for solar technology. By integrating sputtered silver electrodes with solution-coated functional layers, the research team achieved high efficiency and scalability using only industrial-compatible methods.

The study demonstrates that it is possible to build large-area, flexible solar modules without sacrificing performance, all while using greener materials and low-cost production techniques. Laser beam induced current mapping confirmed the uniformity and quality of these large modules, providing confidence in the manufacturing process.

Together, these results move organic photovoltaics closer to real-world deployment and bring the concept of printed, flexible solar power one step closer to everyday use.

Authors

Eswaran Jayaraman

Michela Prete

Abhinav Chandel

Fathimath Faseela

Kun Wang

Chun Yuen Ho

Jani Lamminaho

Morten Madsen

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Compact solar simulator (390–700 nm) with six tunable LEDs, Class A uniformity, and excellent temporal stability. Ideal for small to medium solar cells and controlled illumination experiments.