Scalable Perovskite Solar Modules: 10 cm × 10 cm Devices Reach 11% Efficiency; Separate Tests Show 80% PCE Retention After 600 Hours

Can We Build Solar Cells in the Open Air?

Solar energy is one of the most promising tools in the fight against climate change, but even with rapid advances in technology, today’s solar panels face limits. Silicon dominates the market, and while it is reliable, its manufacturing is energy-intensive and relatively costly. For more than a decade, researchers have looked to perovskite solar cells (PSCs) as the next step forward. These materials can be processed from solution, allowing for potentially much cheaper production, while also offering impressive light absorption and conversion efficiencies.

The problem has always been scalability. Many of the record-breaking perovskite devices reported in the lab are made using techniques like spin-coating inside controlled nitrogen environments. Such methods deliver high efficiency but are impractical for large-scale production. The need for nitrogen-filled glove boxes and high-precision lab conditions limits their commercial potential.

That is why a new study, “Sequential slot-die coating of perovskite solar cell modules under ambient conditions with precise phase-transition control”, is so significant. Researchers from Taiwan developed a new approach that allows perovskite modules to be made entirely in ambient air while still delivering competitive performance. Their method combines sequential slot-die coating, near-infrared (NIR) heating, and an additive engineering strategy using methylammonium thiocyanate (MASCN). Together, these innovations produced large-area films with improved stability and efficiency, marking a milestone on the path from laboratory experiments to industrial-scale manufacturing.

Key Highlights

Developed a scalable slot-die coating process for perovskites under ambient air conditions (no gloveboxes required).

Integrated near-infrared (NIR) heating to speed up solvent removal, reducing moisture interference and improving film quality.

Replaced moisture-sensitive MACl with MASCN, leading to more controlled crystallization, fewer defects, and higher stability.

Achieved power conversion efficiency (PCE) of 17.37% for perovskite solar cells.

Fabricated 10 × 10 cm² solar modules with PCE of 11.08%, proving large-area scalability.

Demonstrated devices that retained 80% of their performance after 600 hours in ambient storage without encapsulation.

Showed that sequential deposition allows better control of crystallization dynamics, improving reproducibility.

Validated a cost-effective and industrially viable route to large-area solar manufacturing.

Learn how to fabricate solar cells using slot-die coating and flexo printing on a Slot-die Coater.

What is Slot-Die Coating and Why Does it Matter?

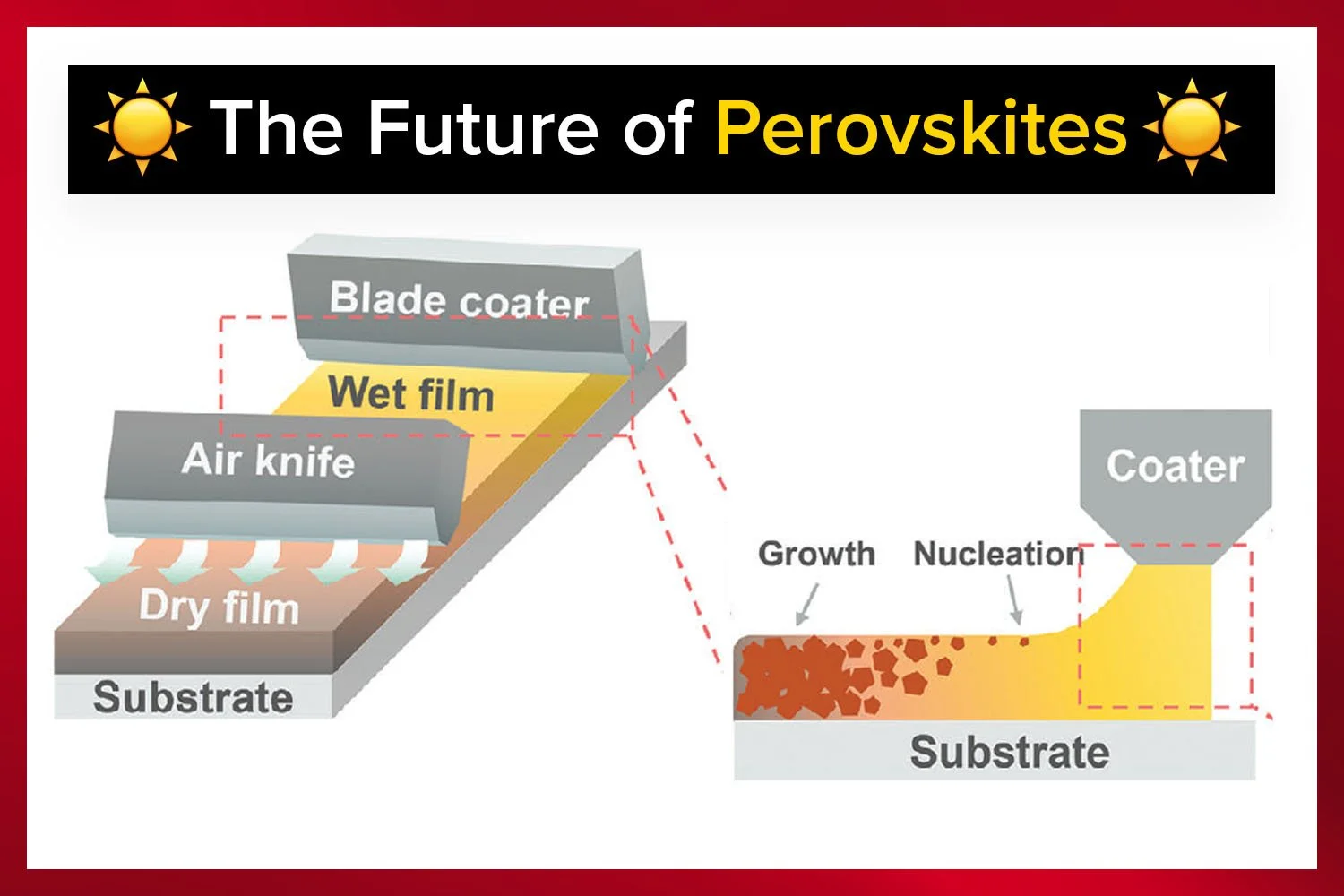

At the heart of this breakthrough lies a technique called slot-die coating. Unlike spin-coating, which wastes much of the material and works only on small areas, slot-die coating can continuously deposit thin films over large surfaces. A nozzle precisely dispenses liquid solution onto a moving substrate, allowing the film thickness and uniformity to be carefully controlled. This makes it especially suitable for roll-to-roll manufacturing, where flexible sheets of material can be coated in a continuous process.

For solar cells, this means that films can be fabricated in ways similar to printing newspapers or packaging, opening the door to low-cost mass production. However, slot-die coating also introduces challenges. Perovskite materials are highly sensitive to humidity and temperature. In ambient air, water molecules and oxygen can disrupt crystallization, leading to films with defects, pinholes, or poor uniformity. Overcoming these obstacles has been one of the biggest hurdles for researchers.

The study at hand demonstrates that with the right adjustments, slot-die coating can indeed produce high-quality perovskite films in air. By combining rapid NIR heating and careful additive control, the researchers showed that it is possible to achieve the uniformity and stability needed for solar technology to scale.

The Significance of the Study

The importance of this work extends beyond a single scientific achievement. It directly addresses the most pressing questions for perovskite commercialization: Can the technology be scaled up? Can it be manufactured outside a laboratory environment? And can it retain its efficiency and stability long enough to be viable?

The answer, based on the results, is yes. The team achieved efficiencies above 17 percent in small cells and over 11 percent in large 10 × 10 cm² modules, with very little efficiency loss between the two scales. This is rare in perovskite research, where scaling up usually leads to dramatic drops in performance. The devices also showed strong stability, with MASCN-containing cells retaining most of their performance after 600 hours of storage.

In practical terms, this means the method could reduce manufacturing costs by eliminating the need for controlled-atmosphere facilities. It also proves that scalable coating techniques can match or even exceed the quality of traditional lab-based processes.

Key achievements include:

Proving scalability: The method works not just on lab-scale devices but also on modules up to 10 cm × 10 cm.

Maintaining efficiency: Unlike many large-area perovskite attempts, efficiency losses here were minimal.

Improving stability: MASCN reduces defect density and ion migration, two of the biggest causes of perovskite degradation.

R2R slot-die coating for solar cells is easy with the Laboratory Roll-to-Roll Coater.

How the Process Works

The researchers used a sequential deposition strategy, which separates the formation of the perovskite into two steps.

First, an inorganic precursor layer of lead iodide (PbI₂) is coated onto the substrate. This layer acts as a scaffold. Next, an organic salt solution containing formamidinium iodide along with the additives MACl and MASCN is applied. When the two layers react, they form the perovskite crystal structure.

Controlling this reaction is the key to success. To achieve high-quality films, the team used two innovations.

The first is near-infrared heating, which accelerates solvent removal. This rapid drying step minimizes the exposure of the wet film to humidity and oxygen, both of which can disrupt crystallization. Without NIR heating, the films risk forming with pinholes, rough surfaces, or incomplete conversion.

The second innovation is the use of methylammonium thiocyanate (MASCN) as a crystallization additive. Traditionally, methylammonium chloride (MACl) has been used to guide perovskite growth, but under ambient conditions it can react with water to form unwanted byproducts. MASCN is more stable in air and plays a dual role: it promotes larger grain growth while also passivating defects in the crystal lattice. The result is smoother films with fewer boundaries and longer carrier lifetimes, both of which directly enhance efficiency.

The team discovered that an equal balance of MACl and MASCN delivered the best results. Too much MASCN sped up the crystallization too quickly, while too little led to incomplete conversion. At the optimal ratio, the films showed uniform coverage, reduced trap density, and better stability.

How to test solar cells using a source measure unit and solar simulator.

From Crystals to Modules

Once the process was optimized, the researchers tested it on both small cells and larger modules. Small-area devices achieved efficiencies of 17.37 percent, placing them among the higher-performing perovskite cells made in air. More impressively, the method scaled to 10 × 10 cm² modules without significant efficiency loss, delivering 11.08 percent.

The stability results were just as promising. Devices that included MASCN maintained 80 percent of their initial performance after 600 hours of storage without encapsulation. In contrast, devices without MASCN degraded within 200 hours. Further analysis showed that MASCN helped suppress ion migration, one of the main causes of perovskite degradation.

By showing that both efficiency and stability can be preserved in larger modules, the study demonstrates that this method is not just a laboratory curiosity but a realistic path toward industrial application.

Looking Ahead

The broader implications of this work are clear. If perovskite solar cells are to compete with silicon, they must be cheap to manufacture, scalable to large areas, and stable over time. This study delivers on all three fronts.

The elimination of controlled nitrogen environments reduces costs. The use of slot-die coating ensures compatibility with roll-to-roll production, a well-established industrial method. The introduction of MASCN tackles stability, one of the most persistent challenges for perovskite devices.

In the future, this method could be integrated into pilot production lines, where flexible solar panels could be manufactured on large rolls of plastic or glass. Such panels could be used not only on rooftops but also on building façades, vehicles, and portable devices. The combination of light weight, high efficiency, and low cost has the potential to reshape how we think about solar power.

While further work will be needed to push efficiencies higher and extend stability over years rather than months, this study provides a strong foundation. It proves that the transition from laboratory research to industrial production is not only possible but already underway.

Join our hands-on Printed Electronics Workshop and gain practical experience in every step of printed solar cell manufacturing, from ink preparation to testing and final integration

Conclusion

The work by Chia-Feng Li, Shih-Han Huang, and colleagues marks an important advance in the commercialization of perovskite solar technology. By demonstrating that high-quality films can be made in ordinary air, the researchers removed one of the biggest barriers to scaling up.

Through the combination of sequential slot-die coating, NIR heating, and MASCN additive engineering, the team achieved efficiency, stability, and reproducibility in both small cells and large modules. These innovations bring perovskite solar cells significantly closer to real-world applications.

The path from lab to factory is always challenging, but this research shows that perovskite technology is well on its way. The prospect of affordable, scalable, and efficient solar panels made using printing-like processes is no longer a distant goal. It is within reach.

Authors of the Study

Chia-Feng Li

Shih-Han Huang

You-Ren Chen

Hou-Chin Cha

Ssu-Yung Chung

Yu-Hung Hsiao

Feng-Yu Tsai

Yu-Ching Huang

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Compact solar simulator (390–700 nm) with six tunable LEDs, Class A uniformity, and excellent temporal stability. Ideal for small to medium solar cells and controlled illumination experiments.