Next-Gen Perovskites: The Secret to Better Blade-Coated Solar Cells

Can Changing Shape Boost Solar Efficiency?

What if the efficiency of solar modules could be dramatically improved simply by changing the shape of the particles in the ink used to make them?

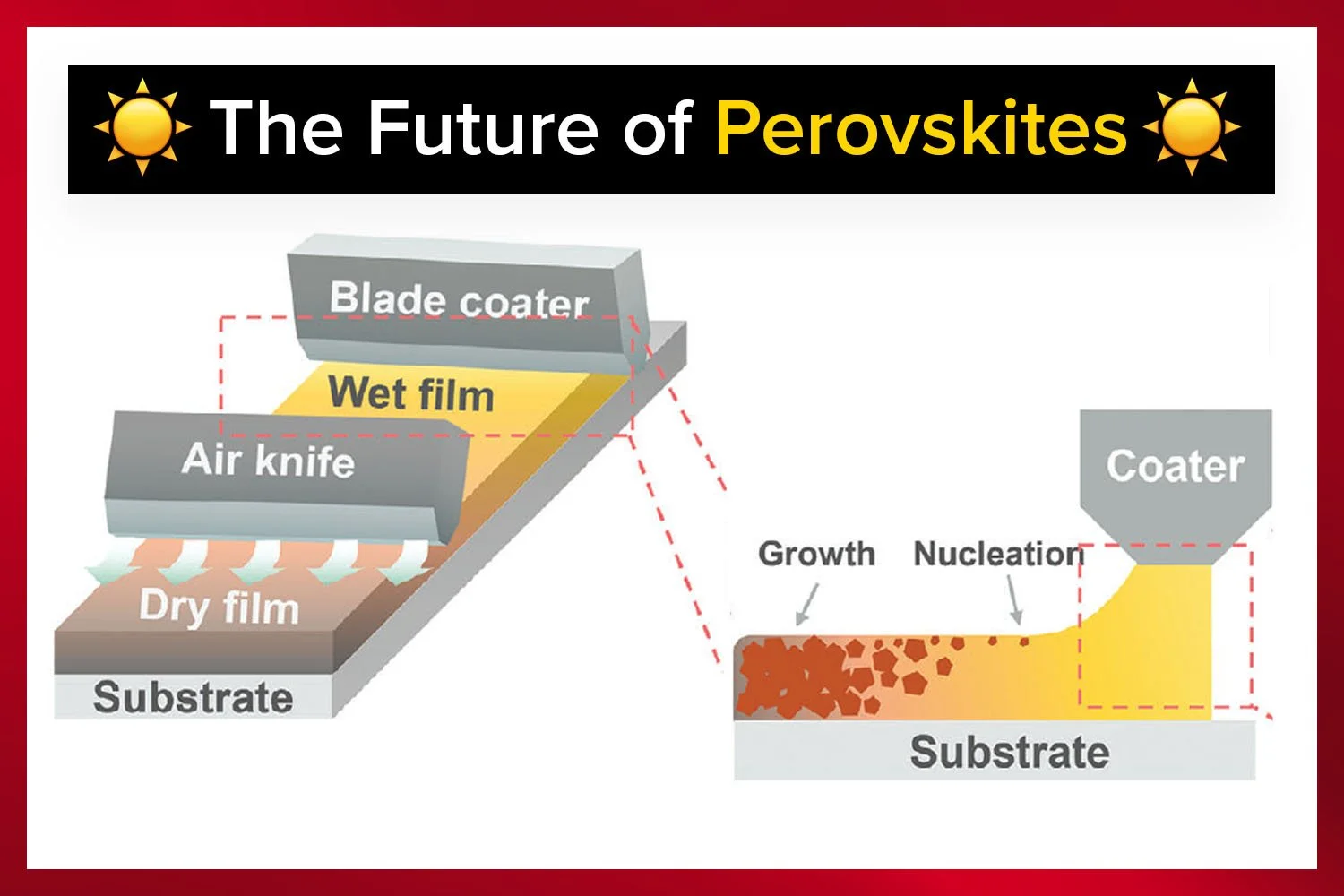

This is exactly what researchers explored in the recent article “Tailored Colloidal Shapes in Precursor Solutions for Efficient Blade-Coated Perovskite Solar Modules” by Yang and colleagues. Perovskite solar cells have already made headlines by rivaling silicon in laboratory settings, where spin-coating is typically used to fabricate small test devices. The problem comes when scaling up. Spin-coating cannot be applied to large panels, so scalable methods like blade-coating are needed. Unfortunately, blade-coated perovskite films tend to form with poor quality, lowering efficiency and making them less stable.

The research team asked a simple but powerful question: could reshaping the colloids in the perovskite precursor solution lead to better film formation? By carefully engineering the colloids to be ellipsoidal instead of spherical, they discovered that films became more ordered, solar cell efficiency improved, and stability increased dramatically.

Key Highlights

Ellipsoidal colloids were created by adding PMMA polymer to the precursor solution, changing the shape of the particles.

Films formed with ellipsoids showed better crystal orientation and larger grains compared to those formed with spheres.

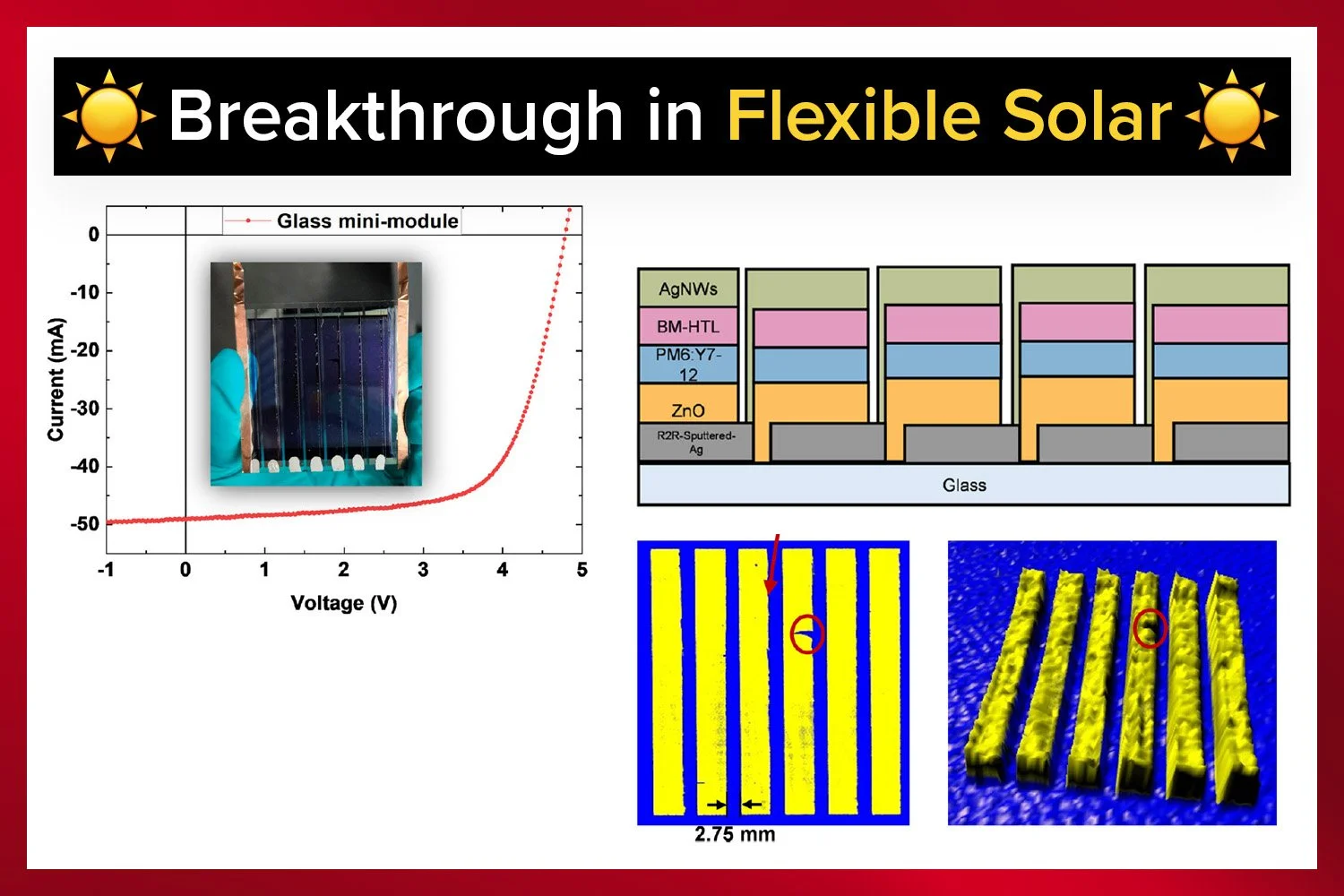

Solar cells achieved a power conversion efficiency of 24.31 percent, while modules reached 21.67 percent (21.37 percent certified).

Devices retained 89 percent of their efficiency after 600 hours of continuous operation.

The optimal PMMA concentration was 0.4 mg/mL; higher amounts led to film defects.

Fewer defects and longer charge carrier lifetimes were observed in ellipsoidal films, resulting in lower energy losses.

The approach is scalable and directly relevant to roll-to-roll manufacturing.

Learn how to fabricate solar cells using slot-die coating and flexo printing on a Slot-die Coater.

Why Colloid Shape Matters

At first glance, the idea of changing the shape of microscopic colloids may not sound revolutionary. Yet in the world of perovskite solar films, it matters enormously. When a precursor solution is spread during blade-coating, the colloids are carried along by fluid flows and concentration gradients in the thin film of liquid beneath the blade. Spherical colloids, which are symmetrical in all directions, tend to pack randomly. This random packing leads to films with disordered crystal growth and smaller grains, both of which hurt performance.

Ellipsoidal colloids behave differently. Their elongated shape means that when they experience directional flow, they naturally align along their long axis. This alignment encourages ordered stacking and more uniform film formation. The result is a perovskite film with improved crystallinity, fewer defects, and better orientation for charge transport. In other words, by tweaking the shape of colloids, the entire architecture of the film improves.

The Significance for Solar Technology

The importance of this discovery lies in its scalability. Lab-scale perovskite solar cells already exceed 26 percent efficiency, but modules made with scalable techniques have not yet matched that level. The main reason is film quality. Blade-coating, while industrially viable, often produces less ideal films compared to spin-coating.

By introducing ellipsoidal colloids, the researchers have narrowed this gap significantly. With modules reaching over 21 percent efficiency and showing improved long-term stability, this study demonstrates that high-performance perovskite modules can indeed be produced with scalable processes. For the solar industry, this represents a critical step toward commercialization of perovskites.

R2R slot-die coating for solar cells is easy with the Laboratory Roll-to-Roll Coater.

How the Researchers Did It

To create ellipsoidal colloids, the team added polymethyl methacrylate (PMMA) to the perovskite precursor solution. This addition changed not only the size but also the shape of the colloids, as confirmed by small-angle X-ray scattering. The team then used advanced in situ techniques, including grazing-incidence wide-angle X-ray scattering, to observe how these differently shaped colloids crystallized during blade-coating.

The data revealed that ellipsoidal colloids delayed nucleation, which gave crystals more time to grow larger and form in a more ordered fashion. Importantly, the out-of-plane crystal orientation was much stronger in films made with ellipsoidal colloids, a factor that directly benefits charge carrier transport in solar cells.

When tested in devices, the films prepared with ellipsoidal colloids showed both higher efficiency and lower defect density. Charge carrier lifetimes were significantly longer, and trap densities were reduced by almost half compared to spherical colloid films.

Efficiency and Stability Gains

The improvements reported were striking. Solar cells with ellipsoidal colloids achieved 24.31 percent efficiency, while modules with areas of nearly 14 cm² reached 21.67 percent efficiency, certified at 21.37 percent. These values put them among the best reported for blade-coated perovskite modules.

Equally impressive was the stability. After 600 hours of continuous operation under illumination, the devices retained 89 percent of their original efficiency. For comparison, films made with spherical colloids only retained 58 percent under the same conditions. The addition of PMMA not only reshaped the colloids but also helped stabilize the films by reducing ion migration at the grain boundaries.

Future Outlook

This discovery shows that sometimes the key to solving a big problem lies in a small change. By moving from spheres to ellipsoids, the researchers have demonstrated a scalable and practical way to enhance perovskite film quality for blade-coating.

Looking forward, this insight could be combined with other approaches, such as controlled drying techniques or surface treatments, to push efficiencies even higher. More broadly, it highlights the importance of colloid engineering in roll-to-roll manufacturing of perovskite solar modules. With continued progress, large-area, low-cost, and highly efficient perovskite panels could soon become a reality.

How to test solar cells using a source measure unit and solar simulator.

Conclusion

The research by Yang and colleagues proves that the shape of colloids in perovskite precursor solutions is far from a trivial detail. By tailoring these particles into ellipsoids, blade-coated films gain better structure, improved efficiency, and remarkable stability. This innovation narrows the gap between lab-scale devices and industrial-scale modules and brings us one step closer to seeing perovskites become a mainstream solar technology.

Authors of the Study

Yongrui Yang

Jingjing Wu

Kun Zhang

Yang Wang

Jie Gao

Mengmeng Guo

Fanyi Min

Yumeng Wang

Lutong Guo

Yu Chen

Yali Qiao

Yanlin Song

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Compact solar simulator (390–700 nm) with six tunable LEDs, Class A uniformity, and excellent temporal stability. Ideal for small to medium solar cells and controlled illumination experiments.