Solar Cells Breakthrough: Biodegradable OPVs Could Power Tomorrow’s Smart Farms

Can Electronics Disappear Without a Trace?

What if the solar cells that power our smart farms could simply vanish when their work was done? No waste, no pollution, just clean energy followed by natural decomposition. That idea might sound futuristic, but it is becoming reality thanks to a study titled “Sustainable materials for organic photovoltaic devices towards transient electronics in digital agriculture,” published in the Journal of Materials Chemistry A in 2025.

The study, conducted by researchers from the Institute of Microelectronics and Photonics - Lukasiewicz Research Network in Poland and the VTT Technical Research Centre of Finland, explores how solar cells can be built from biodegradable and soil-friendly materials. These organic photovoltaic (OPV) devices could one day power agricultural sensors and digital monitoring systems without leaving a trace once their job is done.

By replacing traditional fossil-based materials like PET (polyethylene terephthalate) and metal electrodes with renewable and compostable alternatives such as regenerated cellulose and carbon-based conductive pastes, the team demonstrated that solar devices can be both functional and environmentally responsible. Their results suggest a future where electronics naturally rejoin the environment instead of adding to the global waste stream.

Key Highlights

The study developed biodegradable organic photovoltaic (OPV) devices using soil-compatible materials.

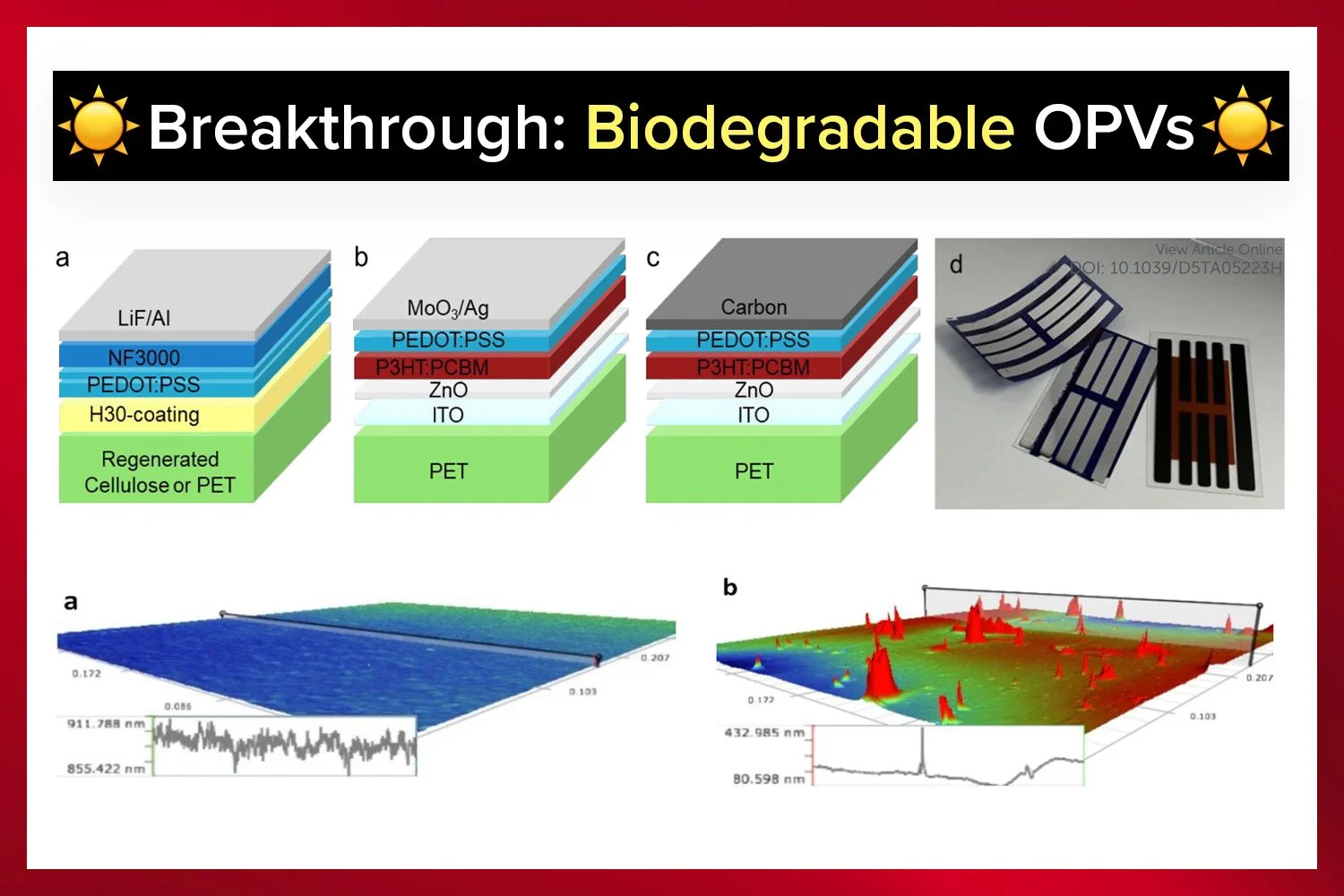

Regenerated cellulose (RC) successfully replaced fossil-based PET as the device substrate, achieving a power conversion efficiency (PCE) of 15.88%.

Biopolymer-based hybrid (H30 BrightBio, BrightPlus) coatings were deposited on PET and RC substrates using slot-die coating with the infinityPV Slot-die Coater.

A newly formulated soil-compatible carbon paste (SCP) outperformed a commercial carbon paste as an electrode material.

The devices showed strong adhesion and stable electrical performance after mechanical bending.

Water solubility tests confirmed the biodegradable components did not harm soil quality or pH balance.

OPVs operated effectively under low-light (1000 lux) conditions, suitable for greenhouse and IoT applications.

Learn how to fabricate solar cells using slot-die coating and flexo printing on a Slot-die Coater.

What Are Organic Photovoltaics and Why They Matter

Organic photovoltaics are a new generation of solar cells made from carbon-based molecules rather than crystalline silicon. These materials can be printed onto thin, flexible films using manufacturing techniques similar to printing newspapers. The result is a light, bendable, and even transparent solar cell that can harvest energy from indoor or outdoor light sources.

Traditional silicon panels, while efficient, are energy-intensive to manufacture and generate enormous amounts of waste at the end of their lifespan. The International Renewable Energy Agency estimates that by 2050, up to 78 million tons of discarded PV panels will need disposal or recycling. The situation becomes more pressing in agriculture, where devices are often small, distributed across large areas, and rarely recovered.

This is where organic photovoltaics stand out. They can be produced using low-energy processes such as printing or coating, and they can be designed to biodegrade safely when no longer needed. The study shows that it is possible to combine sustainability with performance, paving the way for electronic systems that work with nature instead of against it.

Replacing Plastic and Metal with Sustainable Materials

The researchers focused on two of the most environmentally challenging parts of OPVs: the substrate and the electrode. Both are typically made from materials that are non-biodegradable or resource-intensive to produce.

The first innovation involved the use of regenerated cellulose, a transparent and compostable film derived from wood pulp. It serves as the base on which all other layers of the OPV are built. Compared to the conventional PET film, the cellulose substrate not only offered high optical transparency but also achieved a strong power conversion efficiency of 15.88 percent. This demonstrates that a biodegradable material can compete with fossil-based substrates while maintaining good mechanical integrity.

The second innovation replaced the traditional silver or aluminum electrode with a soil-compatible carbon paste. This paste, made from graphite and a conductive polymer known as PEDOT:PSS, eliminates the use of scarce or toxic metals. It is also cost-effective, as graphite is more than a hundred times cheaper than silver. The team compared this new material, named SCP, with a commercially available carbon paste and found that the SCP provided higher conductivity and better integration with other OPV layers.

The combination of these materials marks a major step toward developing fully compostable electronic systems that can eventually disintegrate without harming the environment.

R2R slot-die coating for solar cells is easy with the Laboratory Roll-to-Roll Coater.

The Significance of the Study: Why It Matters

Agriculture is one of the industries most dependent on small, distributed sensor systems. From monitoring soil moisture to tracking plant growth and nutrient levels, modern farming relies increasingly on electronic data. But most of these devices are powered by batteries or contain electronic components that persist in the environment long after they stop functioning.

The concept of transient electronics directly addresses this problem. Devices built from biodegradable components can perform their intended task for a limited period before naturally breaking down into harmless substances. For agriculture, this means self-powered sensors that monitor the environment and then safely decompose in it.

The findings of this study also have a broader societal impact. They contribute to reducing dependence on critical raw materials such as indium and silver, both of which are used extensively in electronics but are limited in supply. Furthermore, the development of renewable materials and low-energy production techniques aligns perfectly with global sustainability policies like the EU Green Deal and the United Nations’ Sustainable Development Goals.

By showing that compostable materials can perform effectively in working devices, the research provides a tangible step toward a circular electronics economy, where end-of-life no longer means waste.

How the Devices Were Built and Tested

Creating a working biodegradable solar cell required rethinking the entire production process. The researchers began by developing the new materials, then analyzing their properties in detail. This included studying how each material handled light transmission, surface roughness, and electrical conductivity.

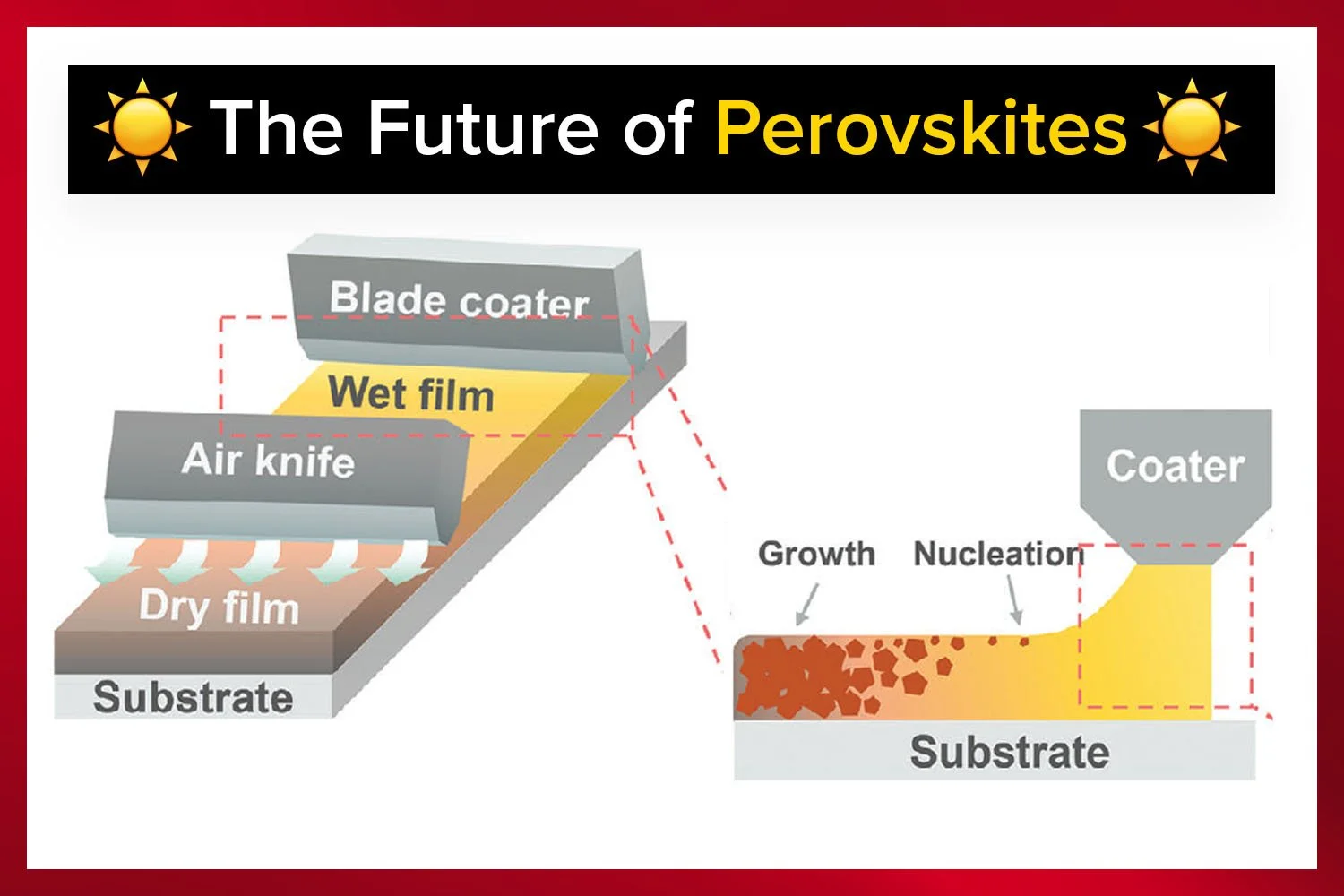

To fabricate the OPV layers, they used a combination of techniques including slot-die coating and gravure printing, both well-established methods in roll-to-roll manufacturing. These techniques allow precise control of film thickness and uniformity, essential for consistent solar cell performance.

The devices were tested under LED illumination at 1000 lux, a light intensity similar to greenhouse conditions. The regenerated cellulose-based cells reached a power conversion efficiency of nearly 16 percent, while those with the new soil-compatible carbon paste reached close to 2 percent. Although the latter value may sound modest, it represents a strong result for fully printed, biodegradable solar cells.

Mechanical bending tests further showed that the conductive layers could withstand up to 1000 bending cycles with less than a 30 percent change in resistance. This confirms that the materials are durable enough for flexible electronic applications, an important feature for roll-to-roll production.

With the Laboratory Roll-to-Roll Coater, fabricating perovskite solar cells has never been easier.

Safe for Soil and the Environment

A critical question was whether these biodegradable materials might negatively affect soil health when decomposing. To answer this, the team immersed the components in water for six months and monitored changes in conductivity and pH, which are indicators of potential environmental impact.

The results were promising. The pH values remained within a safe range of 6.0 to 7.5, meaning that the materials would not harm plant roots or microbial life. Conductivity changes were minimal, suggesting that there was no release of harmful ions or chemicals. The regenerated cellulose substrates absorbed water and began to disintegrate naturally, showing that they could biodegrade effectively without producing pollutants.

This environmental compatibility makes the materials ideal for applications in soil or plant monitoring. Farmers could one day deploy hundreds of small biodegradable sensors without worrying about retrieving or recycling them, since they would safely break down in the soil over time.

Looking Toward the Future

The research is not just a proof of concept; it represents a direction for how electronics can evolve in the coming decades. Fully biodegradable OPVs have potential in many fields beyond agriculture, including healthcare, logistics, and environmental monitoring. Any application that involves short-term data collection or disposable sensors could benefit from these materials.

For agriculture specifically, this could transform how digital farming systems are powered. Instead of relying on batteries or non-recyclable components, future sensors could harvest their own energy from ambient light and degrade safely once their purpose is fulfilled.

The next steps for researchers include improving the long-term stability of biodegradable films, developing environmentally friendly encapsulation layers, and testing real-world degradation behavior in soil conditions. Scaling up the production using roll-to-roll techniques will also be essential for commercial applications.

If successful, these efforts could lead to a new class of sustainable electronics that generate energy, perform their function, and then return harmlessly to nature—a true circular technology.

How to test solar cells using a source measure unit and solar simulator.

Conclusion

This research demonstrates that sustainable design and high performance do not have to be opposites. By replacing conventional plastics and metals with regenerated cellulose and carbon-based materials, the study presents a credible path toward biodegradable, soil-safe organic solar cells.

The devices achieved strong optical transparency, mechanical flexibility, and energy output suitable for powering agricultural sensors. Perhaps most importantly, they decomposed without disturbing soil chemistry, showing that electronics can be both functional and environmentally benign.

Such developments could help shape the future of digital agriculture, where data collection, energy harvesting, and sustainability all work together. In a world that increasingly depends on technology, the idea of electronics that disappear gracefully when no longer needed might just be one of the most powerful innovations yet.

Authors

Beata Synkiewicz-Musialska

Marja Välimäki

Kaisa-Leena Väisänen

Kiranmai Uppuluri

Krzysztof Szostak

Maria Smolander

Liisa Hakola

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Compact solar simulator (390–700 nm) with six tunable LEDs, Class A uniformity, and excellent temporal stability. Ideal for small to medium solar cells and controlled illumination experiments.