The Truth About Perovskite Solar Cell Stability In Real Climates

What Happens When Solar Cells Leave Controlled Conditions?

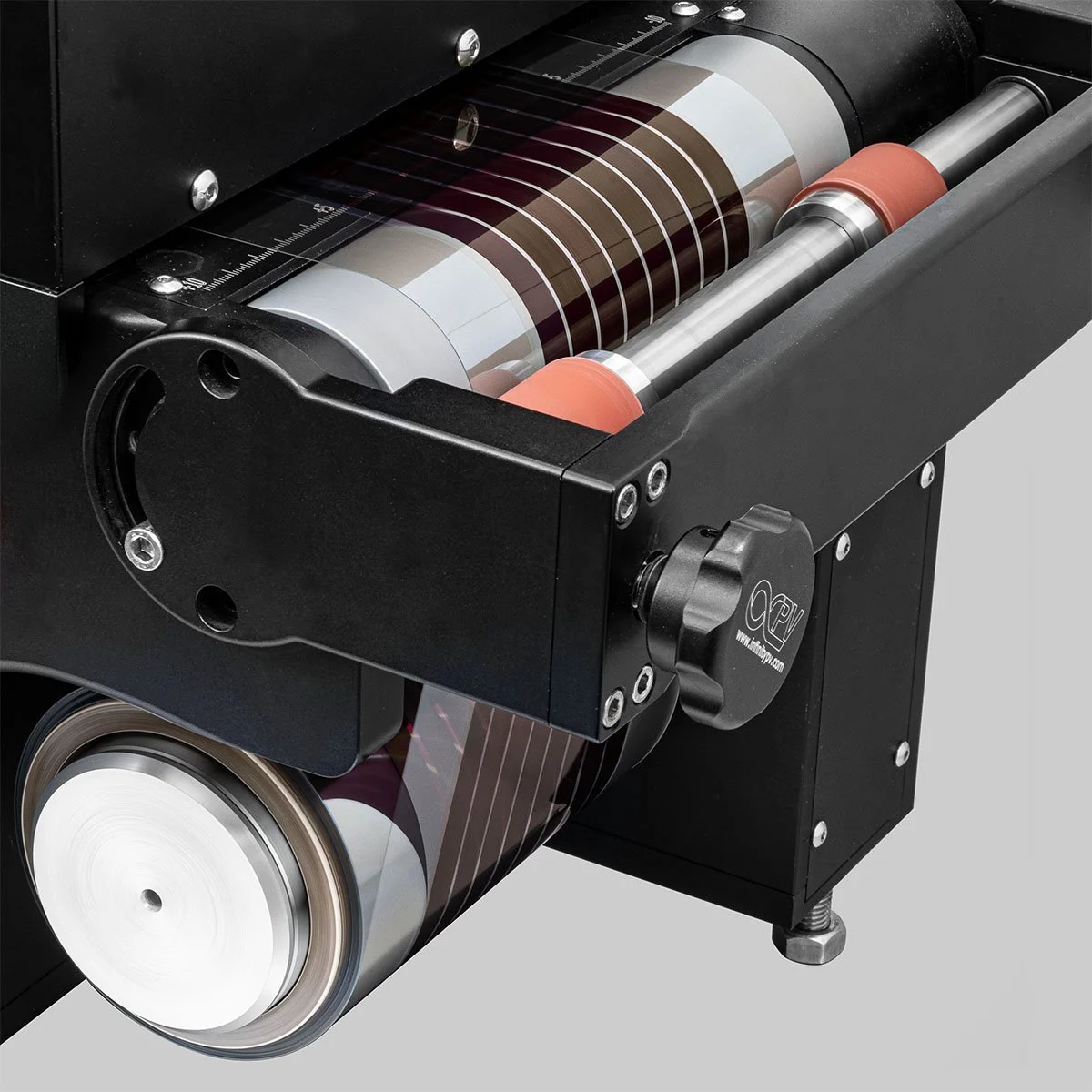

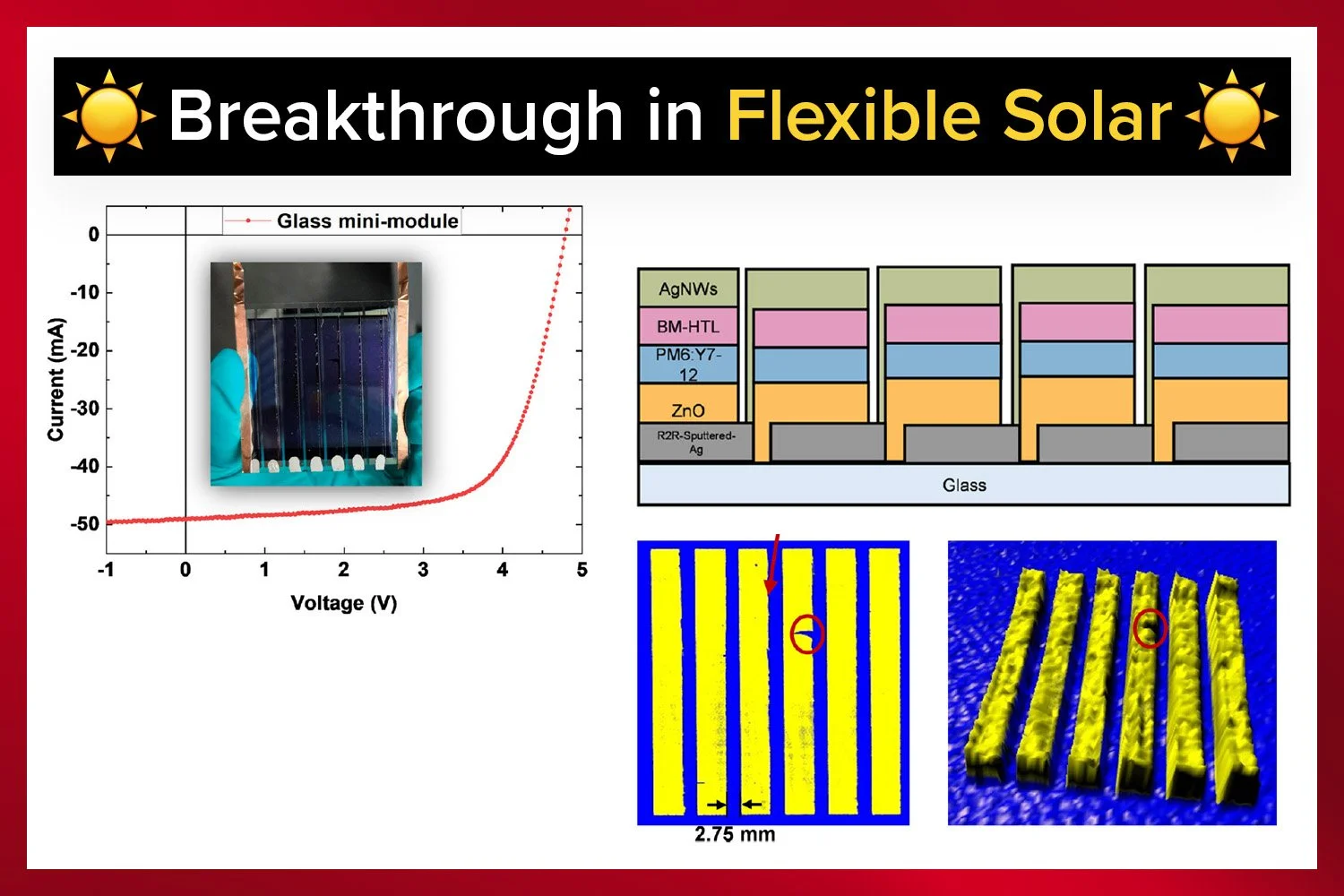

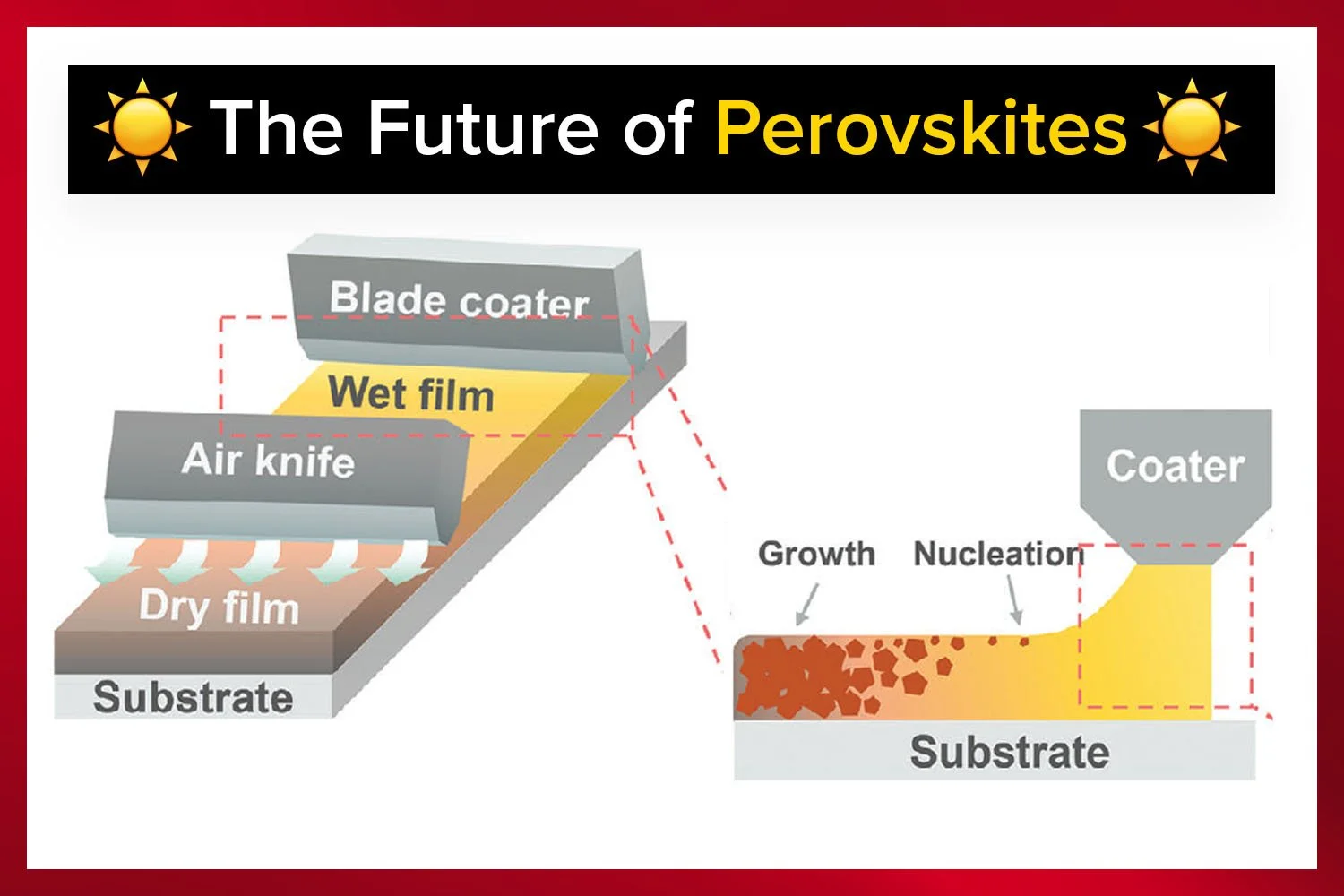

Perovskite solar cells (PSCs) have transformed the landscape of thin-film photovoltaics through their rapid rise in efficiency and compatibility with scalable, low-temperature processing. Their promise reaches even further when considering roll-to-roll manufacturing and printed electronics, where lightweight, flexible modules can be produced quickly and at low cost. However, the future of this technology depends not only on how well PSCs perform in the laboratory but also on how reliably they survive outdoors.

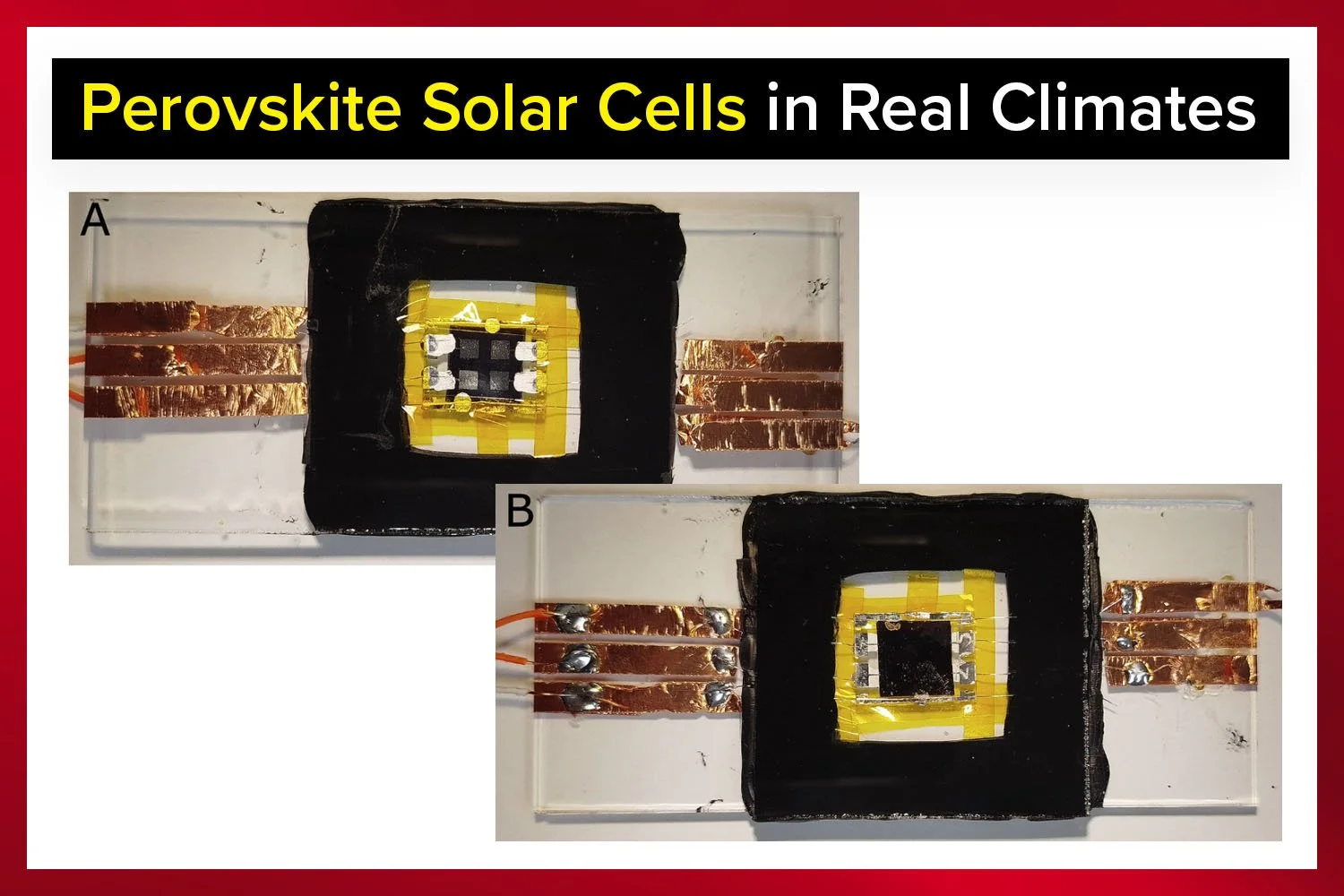

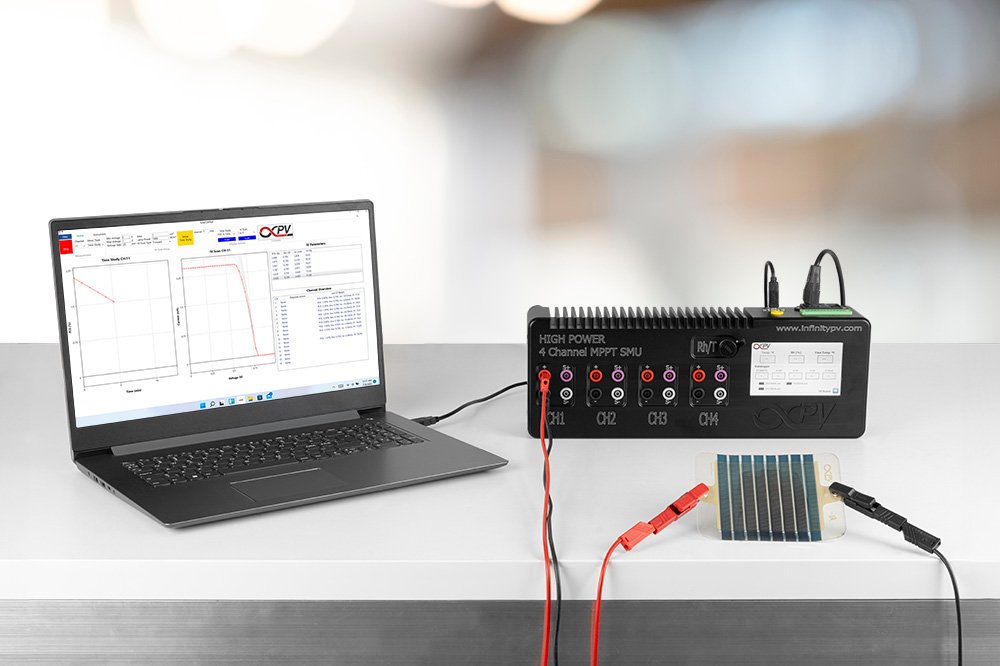

This is the central focus of the research article Degradation of perovskite solar cells: Insights from accelerated testing versus outdoor aging in two climate zones. The authors provide a detailed comparison between accelerated aging protocols and long-term outdoor operation in two contrasting climates, demonstrating that both environmental factors and electrical load conditions play crucial roles in determining device lifetimes. They also present a four-cell encapsulation strategy using polyisobutylene, allowing several pixels from the same batch to be tested under identical conditions. Throughout the indoor and outdoor tests, a range of characterization tools were used, including the infinityPV Source Measure Unit, which supplied a stable platform for maximum power point tracking during light-soaking experiments.

Key Highlights

New PIB-based encapsulation method allows four identical PSCs to be tested simultaneously

Accelerated aging reveals three degradation modes: perovskite loss, bulk defect formation and interfacial recombination

Outdoor stability differs sharply between Madrid and Gdańsk due to climate and operating conditions

Open-circuit operation accelerates degradation compared with MPP or short-circuit conditions

infinityPV Source Measure Unit used for light-soaking MPP tracking under controlled LED illumination

We believe perovskite solar cells can revolutionize renewable energy, but only if R&D bridges the gap between lab and industry. Success requires small-scale roll-to-roll platforms that replicate real-world conditions with precision.

Understanding Perovskite Solar Cells and the Stability Challenge

Perovskite solar cells offer compelling material advantages that have fueled intense global research efforts. Their high absorption coefficient, long diffusion lengths and excellent charge-transport properties enable strong photovoltaic performance at relatively low processing temperatures. These characteristics support the development of lightweight solar modules and roll-to-roll manufactured devices that fit naturally into flexible and portable energy systems.

Yet stability remains one of the most difficult barriers. Perovskites can degrade through interactions with moisture, oxygen, heat and continuous illumination. The material structure itself can change over time due to ion migration, most notably involving iodine vacancies. These vacancies can trigger the formation of iodine vapor, which in turn drives a self-propagating decomposition of the absorber layer. Degradation products may also migrate into transport layers or react with electrode materials. Silver, for example, is known to form silver iodide under certain conditions, affecting conductivity and charge extraction.

For this reason, encapsulation plays a pivotal role. Polyisobutylene edge sealing is widely adopted because it minimizes lateral moisture ingress while remaining compatible with industrial procedures. However, sealing must occur after contact formation, which introduces its own thermal and mechanical stresses. Understanding how PSCs behave during and after these steps is essential for realistic lifetime assessments.

The Source Measure Unit supplied a stable platform for maximum power point tracking during light-soaking experiments.

Why This Work Matters for the Photovoltaics Community

There is currently no universal agreement on how closely accelerated tests reflect real field performance. While protocols such as ISOS provide guidance, deviations in illumination sources, thermal conditions and biasing modes occur frequently due to practical constraints. Investors and industrial users require reliable testing that correlates laboratory lifetimes with real outdoor operation.

The present study addresses this gap directly. By comparing identical devices exposed to accelerated tests and two distinct outdoor climates, the authors highlight where the correlations are strong, where they break down and why operating conditions must be standardized. Their analysis incorporates optical and electrical diagnostics and shows how different stress pathways dominate under different test modes. These findings support ongoing efforts to establish measurement strategies that are comparable across laboratories and relevant to real-world installations.

With the Laboratory Roll-to-Roll Coater, fabricating perovskite solar cells has never been easier.

How the Study Was Carried Out

The authors fabricated inverted perovskite solar cells with a glass/ITO/PTAA/perovskite/PCBM/BCP/Ag architecture. All samples were processed using the same precursor formulation and deposition conditions to ensure consistency between pixels. After fabrication, the cells were encapsulated using a multi-layer PIB frame sandwiched between two glass plates. Silver wires and indium pads completed the electrical connection, producing a mechanically stable structure suitable for both indoor and outdoor measurements.

Indoor stability was assessed by light-soaking and damp-heat tests. Light-soaking was conducted using an LED source calibrated to 1000 W m⁻² equivalent solar intensity, with the infinityPV Source Measure Unit maintaining operation at the maximum power point. This was accompanied by periodic JV scans and temperature monitoring to avoid thermal artifacts. Damp-heat tests were performed at 65 °C and 65 percent relative humidity for 1000 hours. The combination of these two tests allowed thermal, photonic and moisture-related degradation processes to be evaluated.

Outdoor testing took place in Madrid and Gdańsk. The Madrid system operated the devices at open-circuit conditions on a dual-axis sun tracker, with frequent measurements taken throughout the day. Gdańsk samples were tested on a fixed-tilt rooftop station under maximum power point operation, with measurements taken every hour. These contrasting setups provided a clear view of how load, irradiance profile and climate influence long-term performance.

Learn how to fabricate solar cells using slot-die coating and flexo printing on a Slot-die Coater.

What the Light-Soaking and Damp-Heat Tests Revealed

During light-soaking, the devices first exhibited a short stabilization period before showing a continuous decline driven primarily by a reduction in short-circuit current. By the 1000-hour mark, Jsc had fallen significantly, which corresponded directly with the observed drop in power conversion efficiency. The fill factor also decreased gradually, while the open-circuit voltage remained comparatively stable. This pattern suggests that the charge-generation and extraction pathways were affected long before voltage losses became significant.

EQE spectra recorded before and after degradation confirmed that the device was generating fewer charge carriers across nearly the entire visible spectrum. XRD measurements showed a decrease in the main perovskite peak intensity along with the appearance of a reflection associated with hydrated perovskite phases. Importantly, photoluminescence spectra showed no change in emission peak position, indicating that the fundamental band gap remained unchanged and that degradation mainly produced non-radiative recombination sites rather than shifting material stoichiometry.

A single encapsulated device successfully completed the full damp-heat test with more than 80 percent of its initial efficiency remaining. Although this is presented as a proof-of-concept, it demonstrates that the PIB-based encapsulation can perform effectively under combined heat and humidity.

R2R slot-die coating for solar cells is easy with the Laboratory Roll-to-Roll Coater.

Outdoor Performance in Two Contrasting Climates

The most striking contrast emerged during outdoor testing. The device tested in Madrid, under high irradiance and low humidity but with elevated temperature cycles, performed well initially but began to decline steadily after approximately eighty days. Eventually, the output fell to zero, marking complete degradation.

In Gdańsk, by contrast, the device operated under maximum power point tracking remained stable throughout the monitoring period, apart from a small burn-in phase at the beginning of the measurement campaign. Even so, suns-JV analysis revealed the early formation of shunting and defect-related recombination that would not have been visible from power output alone. These subtle changes highlight the importance of using light-intensity-dependent diagnostics when evaluating stability.

Additional experiments using short-circuit, maximum power point and open-circuit operation demonstrated that degradation rate is directly linked to electrical load. The device kept at open-circuit degraded fastest, followed by the maximum power point device, while the short-circuit device degraded least. This supports the well-established idea that high carrier density accelerates photodegradation and underscores the need to define operational modes when comparing stability data.

Implications for Future Testing and Industrial Adoption

The results of this research emphasize that climate cannot be treated as an afterthought when predicting perovskite solar cell lifetime. Temperature profiles, irradiance dynamics, humidity levels and operating mode all interact to produce unique degradation pathways. Accelerated tests must therefore be complemented with outdoor measurements that cover a broad range of climatic zones if they are to serve as predictive tools.

For manufacturers and researchers engaged in roll-to-roll processing, the encapsulation strategy demonstrated in this study is particularly relevant. It enables controlled, multi-pixel testing while maintaining compatibility with scalable production concepts. As PSCs progress toward commercial readiness, harmonizing testing methodologies and sharing comparable datasets will be essential.

How to test solar cells using a source measure unit and solar simulator.

Conclusion

This study provides a comprehensive comparison of accelerated and outdoor stability for perovskite solar cells and demonstrates that environmental conditions, electrical load and encapsulation design all play central roles in determining long-term performance. Devices exhibited clear degradation during light-soaking, driven by reduced charge generation, increased defect formation and interfacial recombination. Damp-heat tests produced promising results for well-encapsulated cells.

Outdoor results revealed profound differences between Madrid and Gdańsk, with the hot Mediterranean climate causing rapid degradation while the cooler and more humid environment allowed stable operation under maximum power point conditions. Additional experiments showed that open-circuit operation accelerates degradation significantly more than maximum power point or short-circuit operation. The inclusion of suns-JV analysis and the use of the infinityPV Source Measure Unit strengthened the reliability of the characterization throughout the study.

Together, the findings provide valuable guidance for future protocol development and highlight the need for standardized, climate-inclusive approaches when evaluating the real-world durability of perovskite photovoltaics.

Authors

Łukasz Haryński

Kamil Trocki

Satish Bykkam

Gonzalo del Pozo

Beatriz Romero

Beata Bochentyn

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Compact solar simulator (390–700 nm) with six tunable LEDs, Class A uniformity, and excellent temporal stability. Ideal for small to medium solar cells and controlled illumination experiments.