Breakthrough in Scalable Printed Biosensors Using Roll-to-Roll Slot-die Coating

How can we make medical diagnostics both smarter and easier to manufacture?

That question drives the research article “Laser-Patterned Slot-Die Carbon Electrodes Functionalized with Gold Nanostars for the Electrochemical Detection of C-Reactive Protein.” The work focuses on one of the biggest challenges in modern diagnostics: creating sensitive and reliable biosensors that can also be produced at scale.

C-reactive protein is a key indicator of inflammation and is widely used to assess infections, cardiovascular risk and chronic disease. Sensors that measure CRP need to be accurate, stable and affordable, yet many fabrication methods rely on complex or batch-based processes that are difficult to scale.

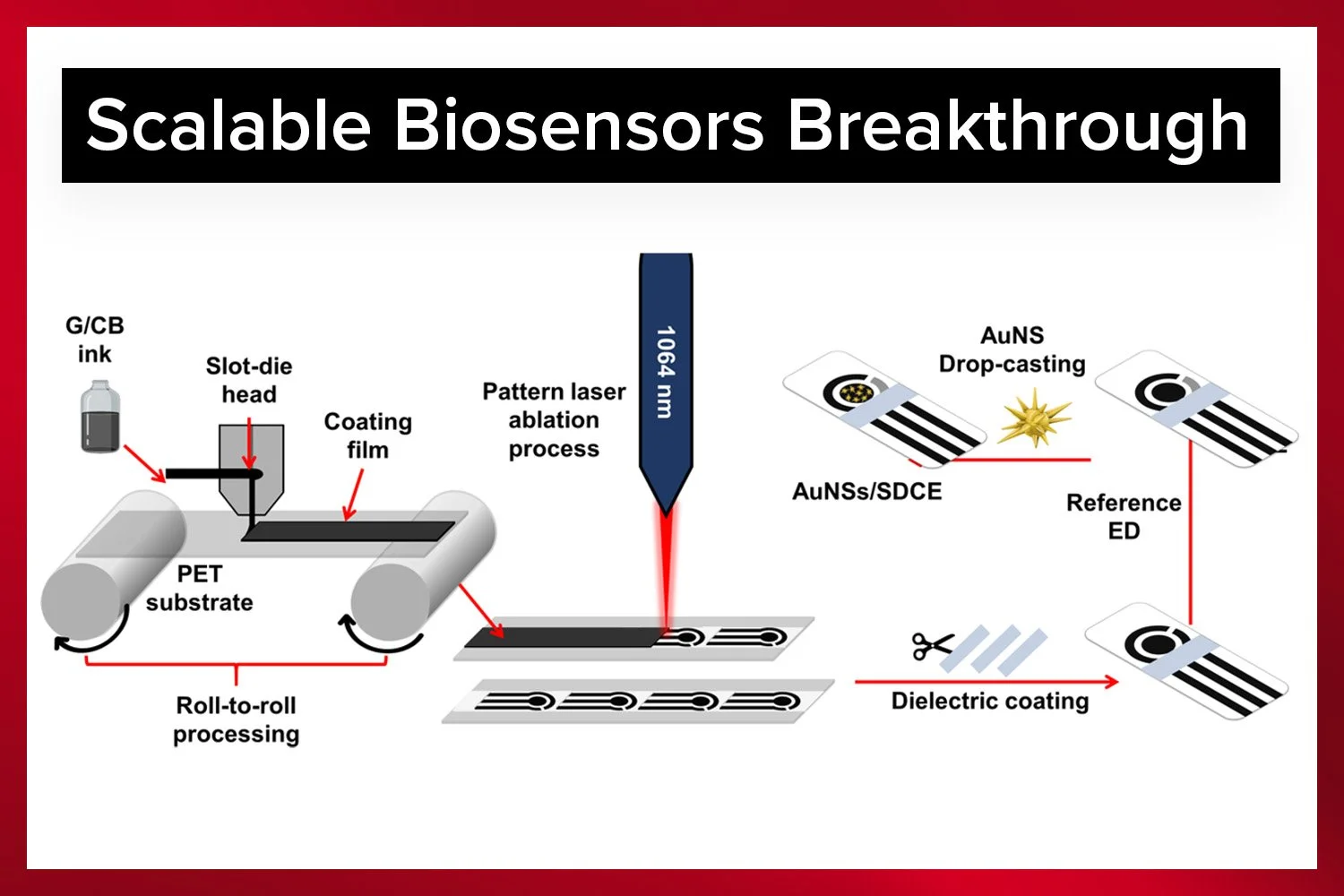

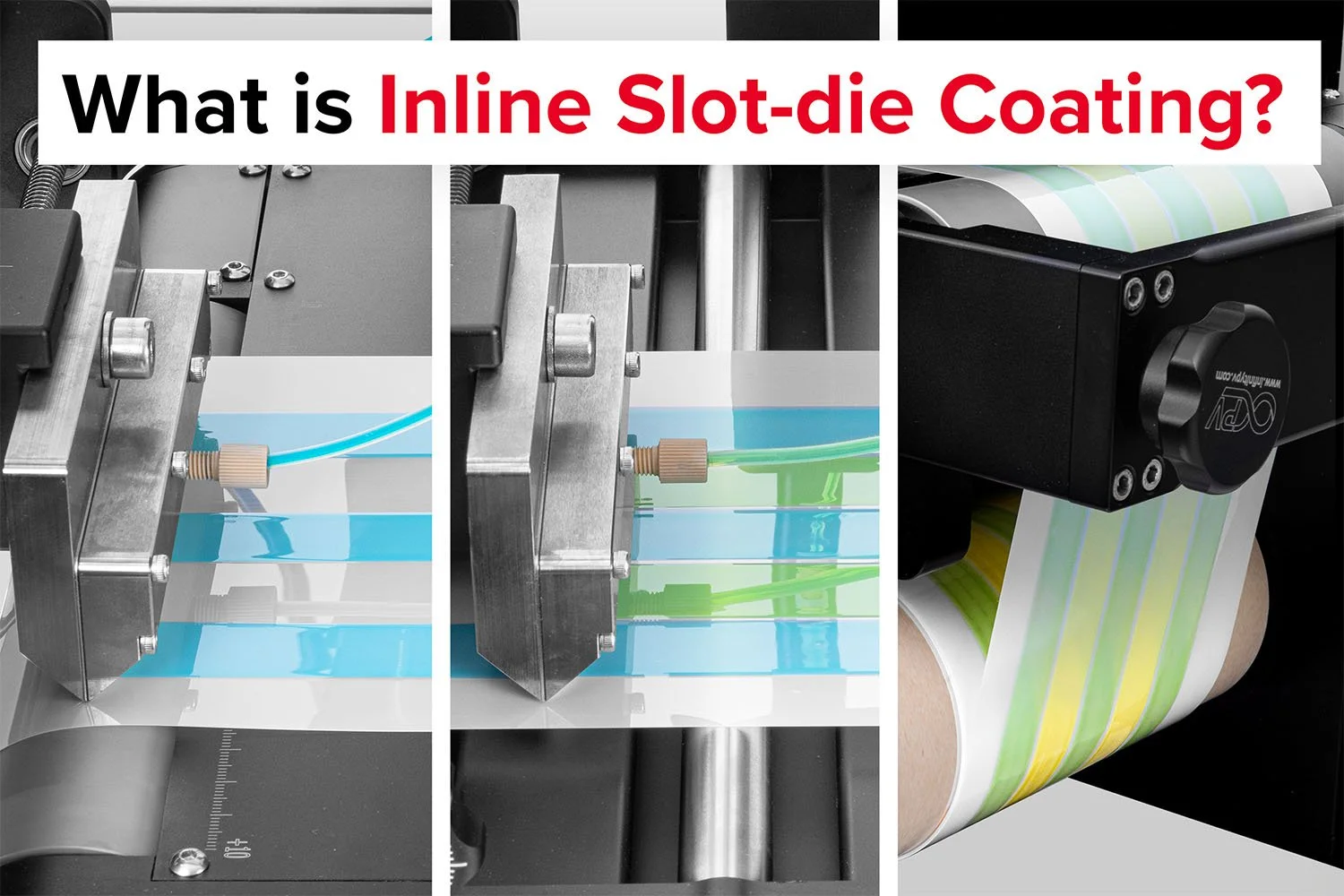

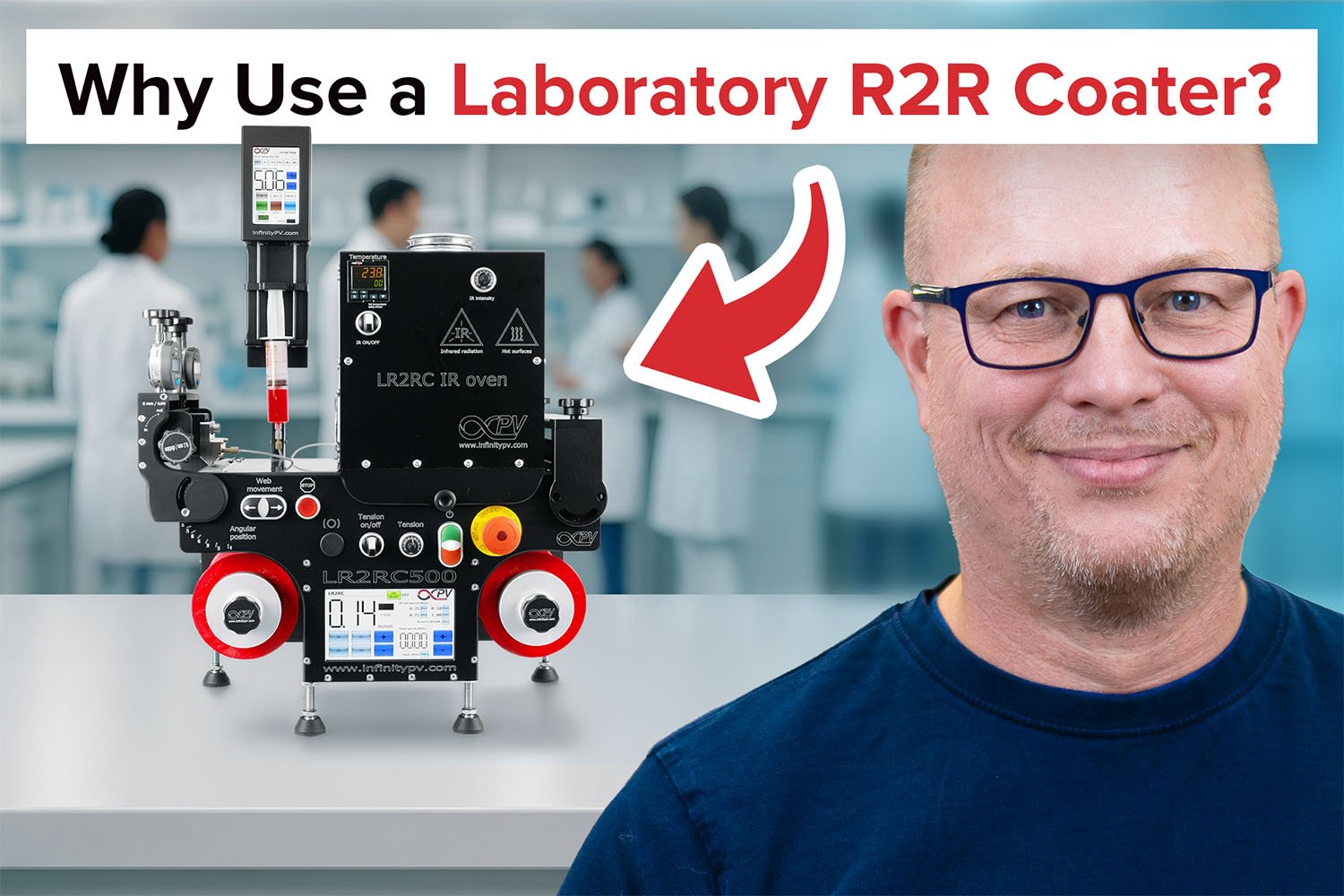

This study takes a different approach. By combining roll-to-roll slot-die coating, laser patterning and nanoscale gold functionalization, the authors demonstrate a miniaturized electrochemical sensor that is both high performing and compatible with continuous manufacturing. Importantly, all carbon electrode films were coated using the Laboratory Roll-to-Roll Coater from infinityPV, reinforcing that the method aligns with real industrial workflows rather than laboratory prototypes.

The result is a clinically relevant CRP sensor with excellent sensitivity, produced through a pathway that points directly toward scalable, next-generation diagnostic devices.

Key Highlights

Demonstrates a scalable slot-die and roll-to-roll process for fabricating carbon electrodes for electrochemical biosensing.

Uses laser patterning to define precise electrode geometries without photolithography.

Gold nanostars significantly improve electron transfer and sensing performance.

Achieves a low limit of detection of 11.5 pg/mL for C-reactive protein in serum.

Fabrication made using the Laboratory Roll-to-Roll Coater from infinityPV.

The entire electrode fabrication was performed using a Laboratory Roll to Roll Coater.

Understanding the Technology

Electrochemical biosensors are compact devices that convert biological interactions into electrical signals. They already appear in home glucose monitors and early wearable devices, yet their full potential remains largely untapped. Many international research groups see them as central to future diagnostics because they can measure biomarkers rapidly, at low cost and with high sensitivity. The difficulty lies in producing these sensors in large numbers while maintaining quality and uniformity.

Traditional microfabrication techniques often rely on photolithography or screen printing. These methods work well for laboratory prototyping but can be difficult to scale, sometimes requiring controlled environments and extensive processing steps. This research presents an alternative pathway that uses slot-die coating and roll-to-roll processing. Slot-die coating is a method where a liquid ink is delivered through a narrow slit and spread uniformly across a moving substrate. When placed onto a roll to roll system, it allows long strips of film to be coated continuously with precise thickness control.

The films produced in this study are based on a composite of graphite, carbon black and a polymer binder that together create a conductive network. The mixture is carefully tuned to have the right viscosity and flow behavior for smooth coating. Once deposited, the film forms the base of the sensor. From there, a second process takes over. A finely controlled infrared laser selectively removes regions of the film. This defines the working electrode, counter electrode and reference electrode areas. Instead of relying on masks or chemicals, the laser performs clean, direct patterning that is both fast and adaptable.

This approach reduces waste, removes dependency on complex lithography processes and supports customization for a variety of sensor layouts. It also aligns naturally with industrial web based manufacturing. For sectors exploring flexible electronics or wearable devices, the combination of slot-die and laser-processing represents a versatile toolkit.

Why the Research Matters Today

The significance of this work reaches beyond the characterization of a single sensor. It illustrates how to bring nanoscale enhancements into a scalable production line. The integration of gold nanostars is particularly notable. These star shaped metallic structures have sharp tips that concentrate electric fields, enabling highly efficient charge transfer at the electrode surface. In electrochemical sensing, improved charge transfer often translates to improved sensitivity.

By incorporating these nanostructures into a roll-to-roll produced electrode, the authors show that complex nanoscale interfaces do not have to be confined to small batch laboratory experiments. They can be part of a continuous manufacturing strategy. This is crucial because diagnostic devices require both scientific precision and the ability to be produced affordably.

The area of point-of-care diagnostics is growing quickly. It is a field where rapid tests for inflammation, infection and disease biomarkers could transform clinical decision making. For that reason, the ability to fabricate sensors continuously, on flexible substrates, using low waste processes, has strategic importance. It positions biosensors to move from laboratories into mainstream healthcare products.

What is roll-to-roll processing, and why is it revolutionizing the way we make flexible devices?

Significance of the Research

The study is important because it demonstrates how nanostructured biosensors can be integrated into scalable production. Gold nanostars are a key element. Their sharp, branched morphology enhances electron transfer, creating a more responsive sensing interface. Integrating them into a continuously manufactured electrode gives the sensor both high sensitivity and industrial feasibility.

With interest in point of care diagnostics growing rapidly, the ability to fabricate sensors in an efficient and sustainable way has become essential. The process described here is compatible with large area manufacturing and offers a clear path toward flexible and wearable diagnostic platforms.

Methods and Technical Approach

The authors formulated a conductive carbon ink optimized for slot-die coating. The film thickness, uniformity and resistivity were characterized and found to be suitable for electrochemical sensing. Laser ablation was then used to define the three electrode system with fine resolution.

Gold nanostars were synthesized via seed mediated growth and attached to the working electrode. The sensor surface was functionalized with streptavidin, biotinylated anti CRP antibodies and a blocking layer. Each modification step altered the electrochemical response in predictable ways, confirming successful assembly.

Performance was validated using cyclic voltammetry, impedance spectroscopy and measurements in human serum samples.

Choose the right slot-die head for your application Read our guide to understand which slot-die head is right for you.

Future Outlook for R2R Biosensor Manufacturing

This work suggests that roll to roll printed biosensors can be expanded to detect many biomarkers beyond CRP. The platform can be adapted for hormones, viral antigens, metabolic markers or environmental contaminants. Its scalability, low waste profile and compatibility with flexible substrates make it suitable for next generation diagnostic devices.

Industries developing wearable health systems or disposable test strips may find this manufacturing strategy highly relevant. The combination of scalable coating, digital patterning and nanomaterial functionalization forms a powerful foundation for future sensor technologies.

Conclusion

This research article provides an important demonstration of how electrochemical biosensors can transition from laboratory prototypes to scalable products. Through the combination of slot-die coating, roll-to-roll processing and laser patterning, the authors create carbon electrodes that are uniform, reproducible and compatible with flexible substrates. The addition of gold nanostars forms a highly efficient sensing interface capable of detecting extremely low concentrations of C-reactive protein.

Validation in human serum illustrates that this is not only a materials study but a practical diagnostic solution. The measured performance aligns closely with established immunoassays, supporting the sensor’s suitability for clinical contexts. The fact that the entire electrode fabrication was performed using the Laboratory Roll to Roll Coater from infinityPV underscores the accessibility and industrial relevance of the approach.

Overall, the work advances both technology and manufacturing methodology. It shows a path forward for large scale production of high performance electrochemical sensors. As demand for decentralized diagnostics and wearable health systems continues to grow, this type of research offers a foundation upon which future commercial devices can be built.

Authors

Yeison Monsalve

Andrés Felipe Cruz-Pacheco

Edwin A. Ramirez

Santiago Mesa

Daniel Ramirez

Katalina Munoz-Durango

Jelver Alexander Sierra

Juan Felipe Montoya

Jahir Orozco

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.