Image 1 of 11

Image 1 of 11

Image 2 of 11

Image 2 of 11

Image 3 of 11

Image 3 of 11

Image 4 of 11

Image 4 of 11

Image 5 of 11

Image 5 of 11

Image 6 of 11

Image 6 of 11

Image 7 of 11

Image 7 of 11

Image 8 of 11

Image 8 of 11

Image 9 of 11

Image 9 of 11

Image 10 of 11

Image 10 of 11

Image 11 of 11

Image 11 of 11

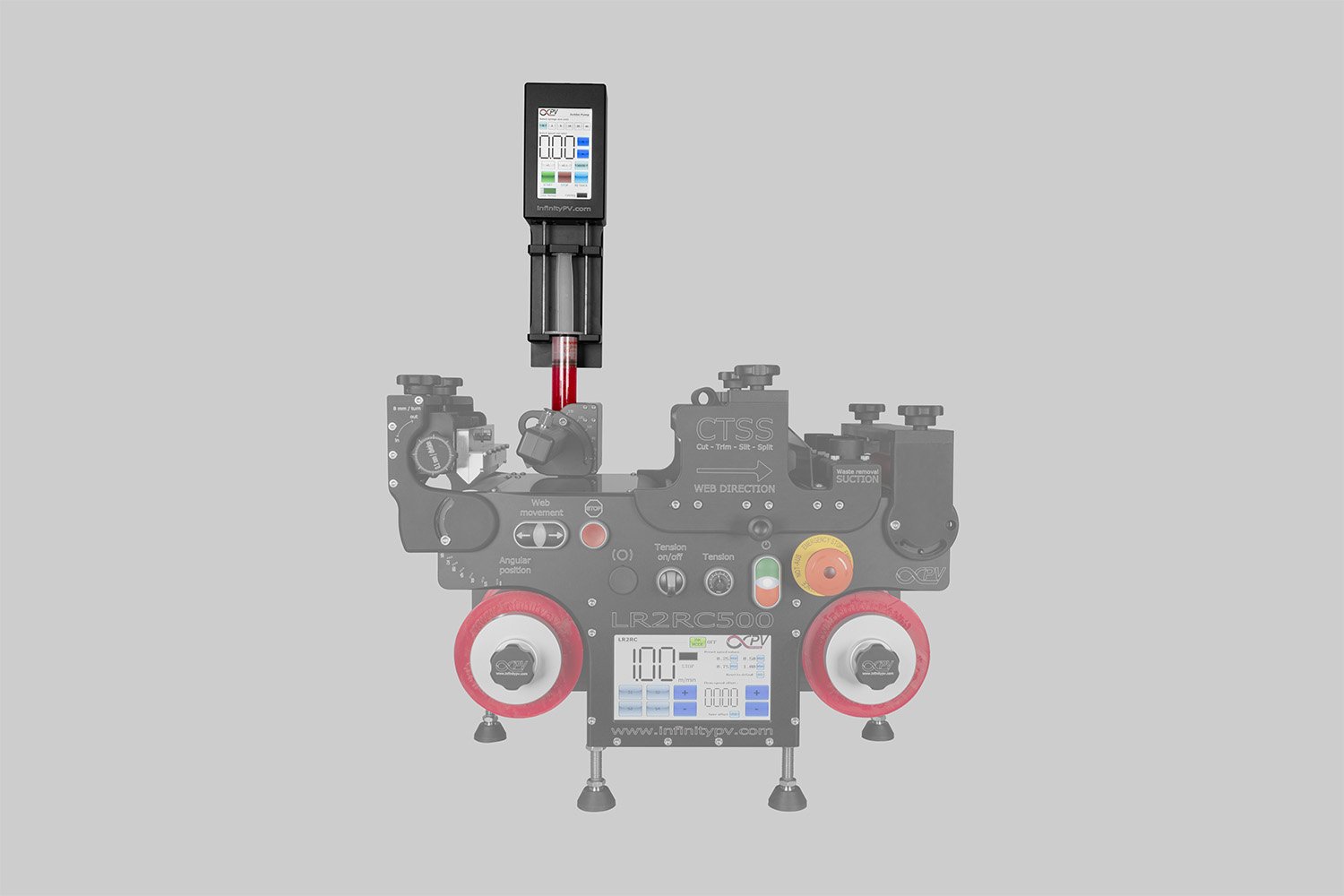

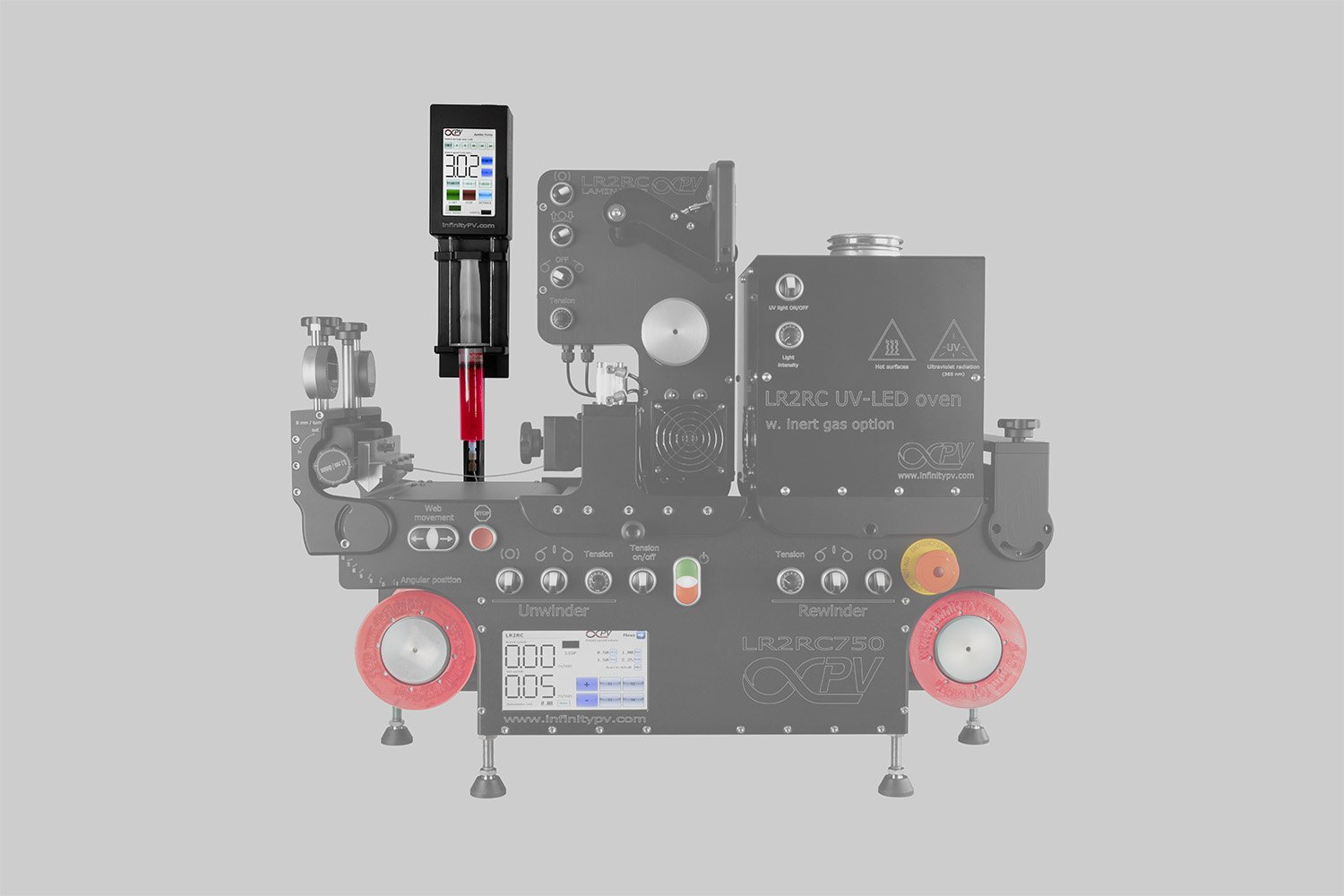

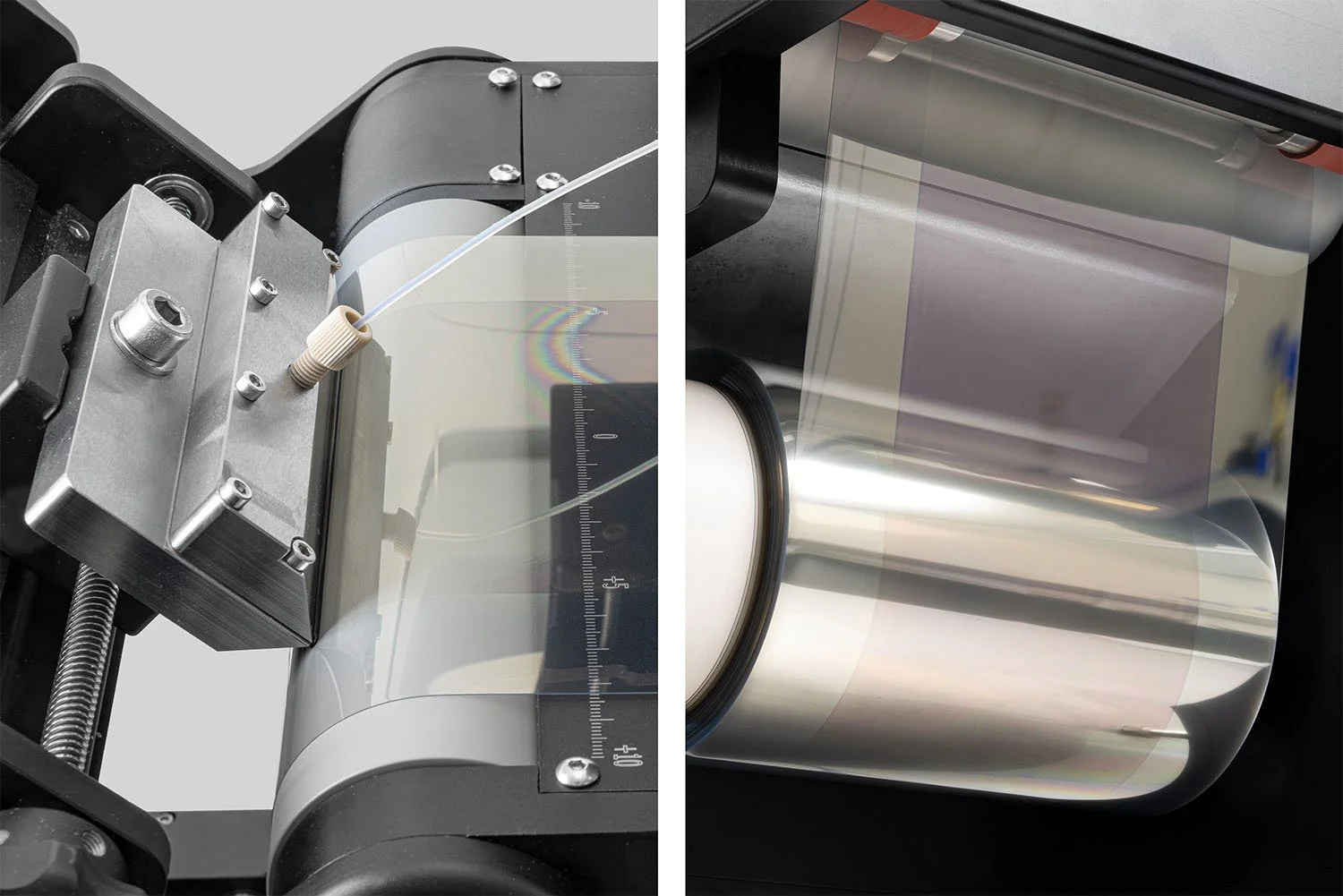

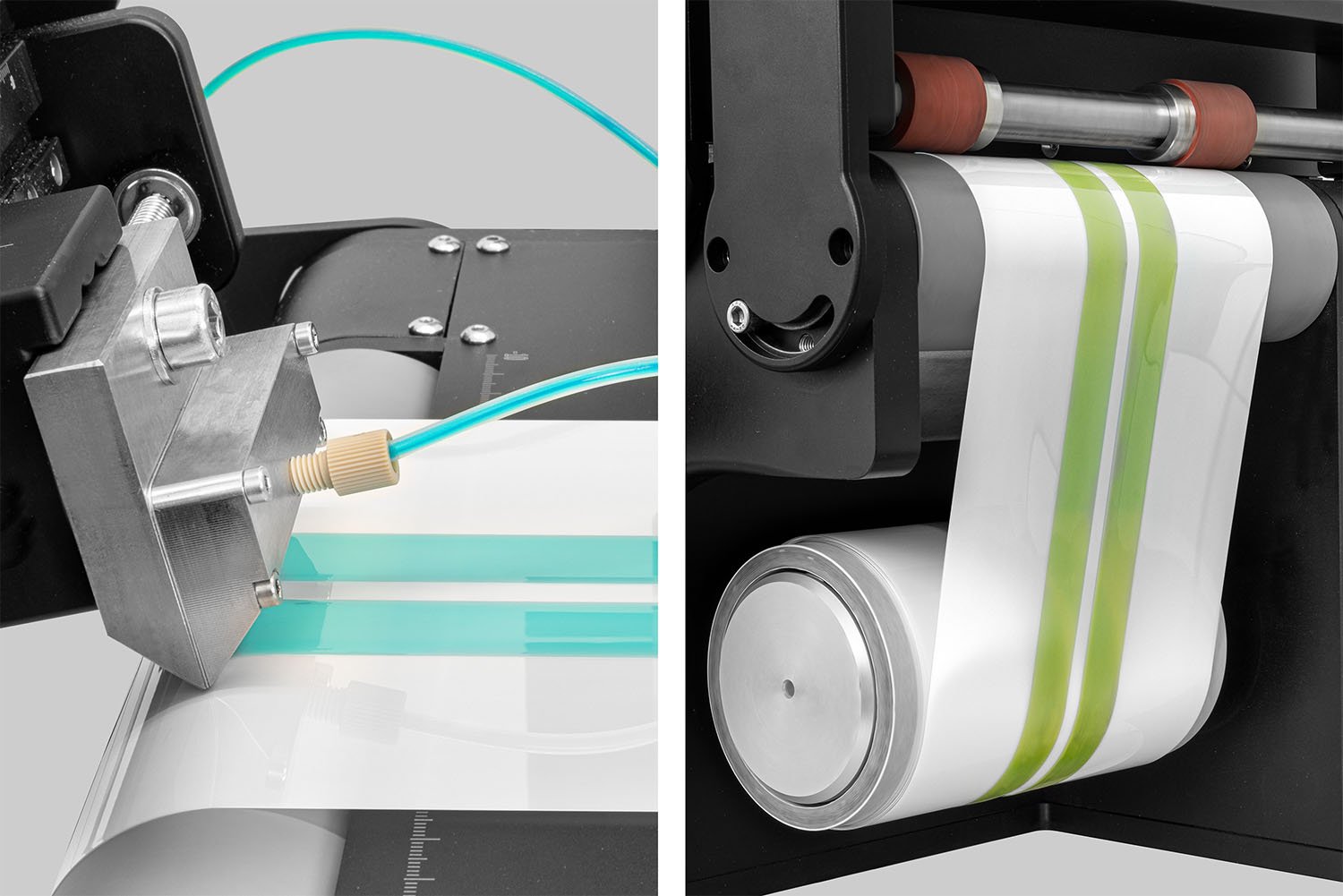

Air Knife Pro

With micrometer screws and a digital display, the Air Knife Pro allows for fine-tuning the air knife position, giving you reliable control that’s ideal for applications requiring consistent, repeatable results.

With micrometer screws and a digital display, the Air Knife Pro allows for fine-tuning the air knife position, giving you reliable control that’s ideal for applications requiring consistent, repeatable results.

Maximize Efficiency and Precision with the Air Knife Pro

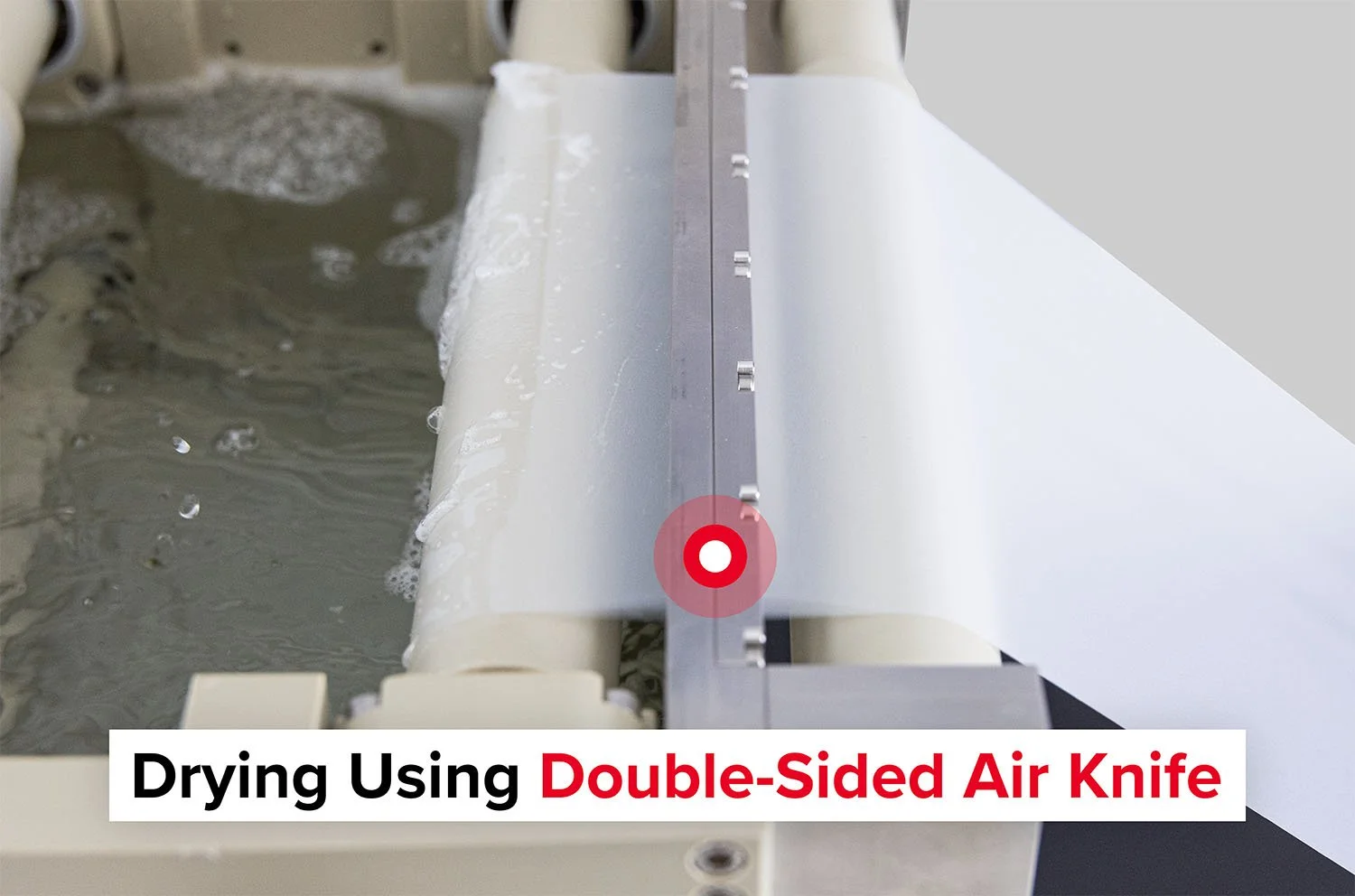

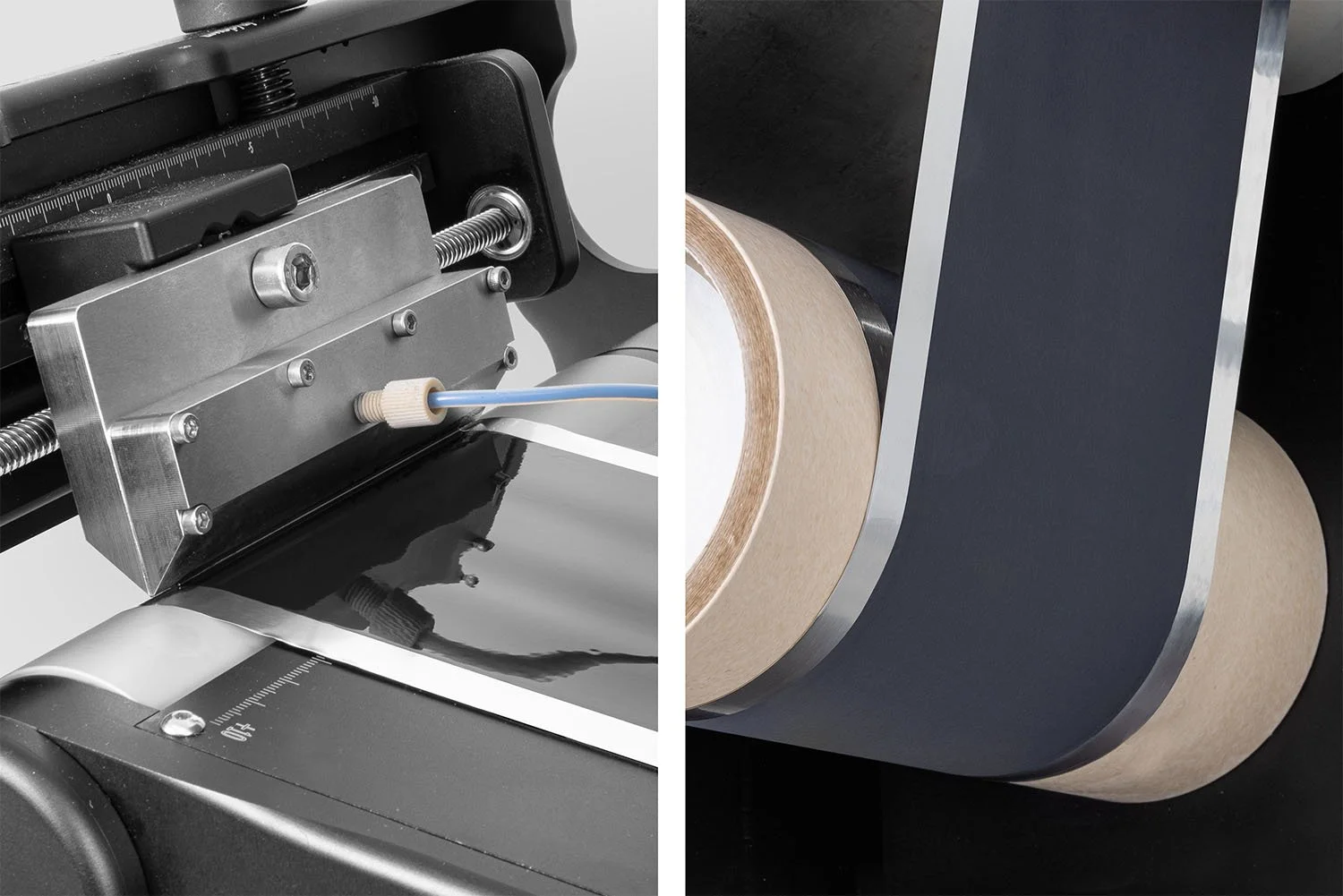

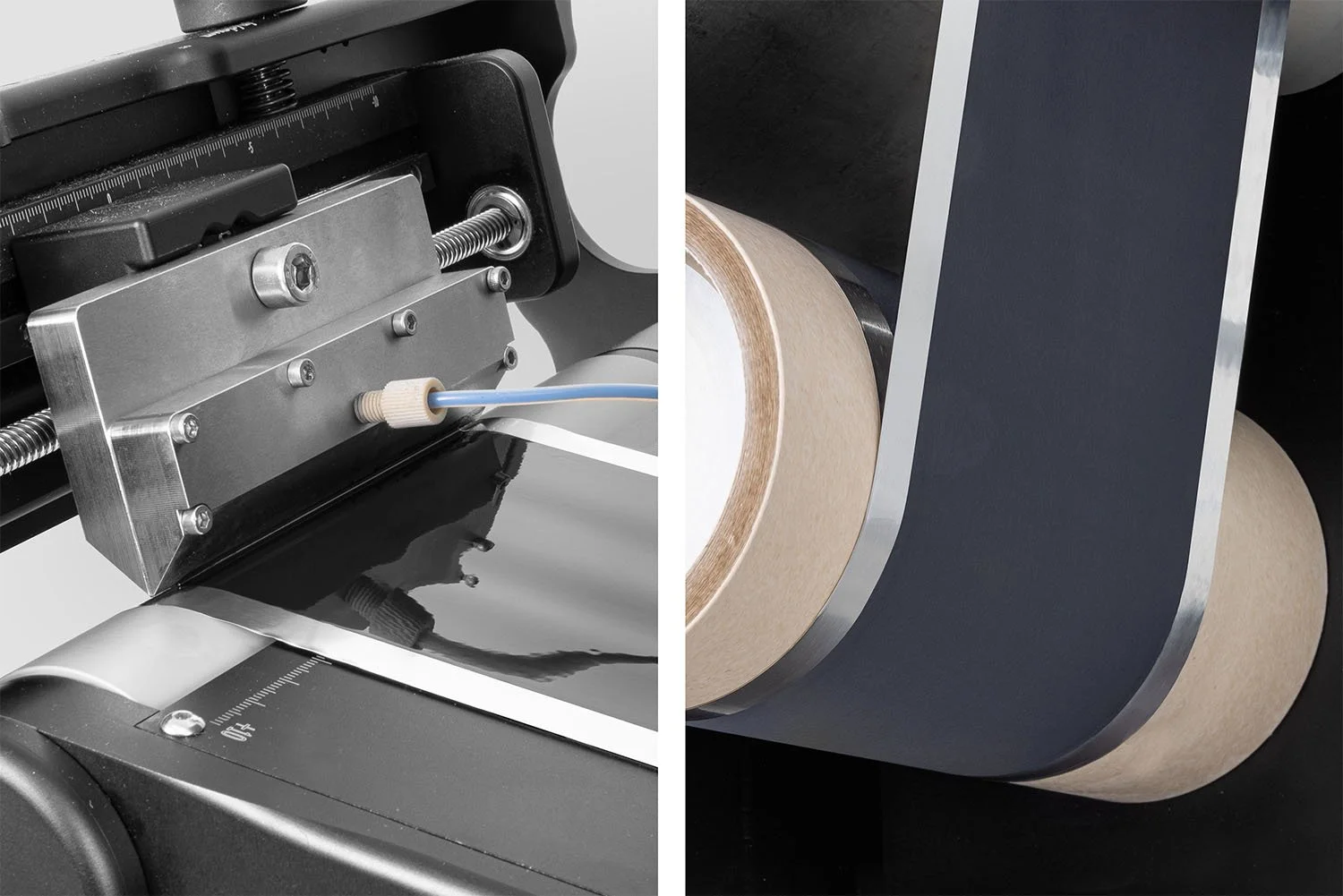

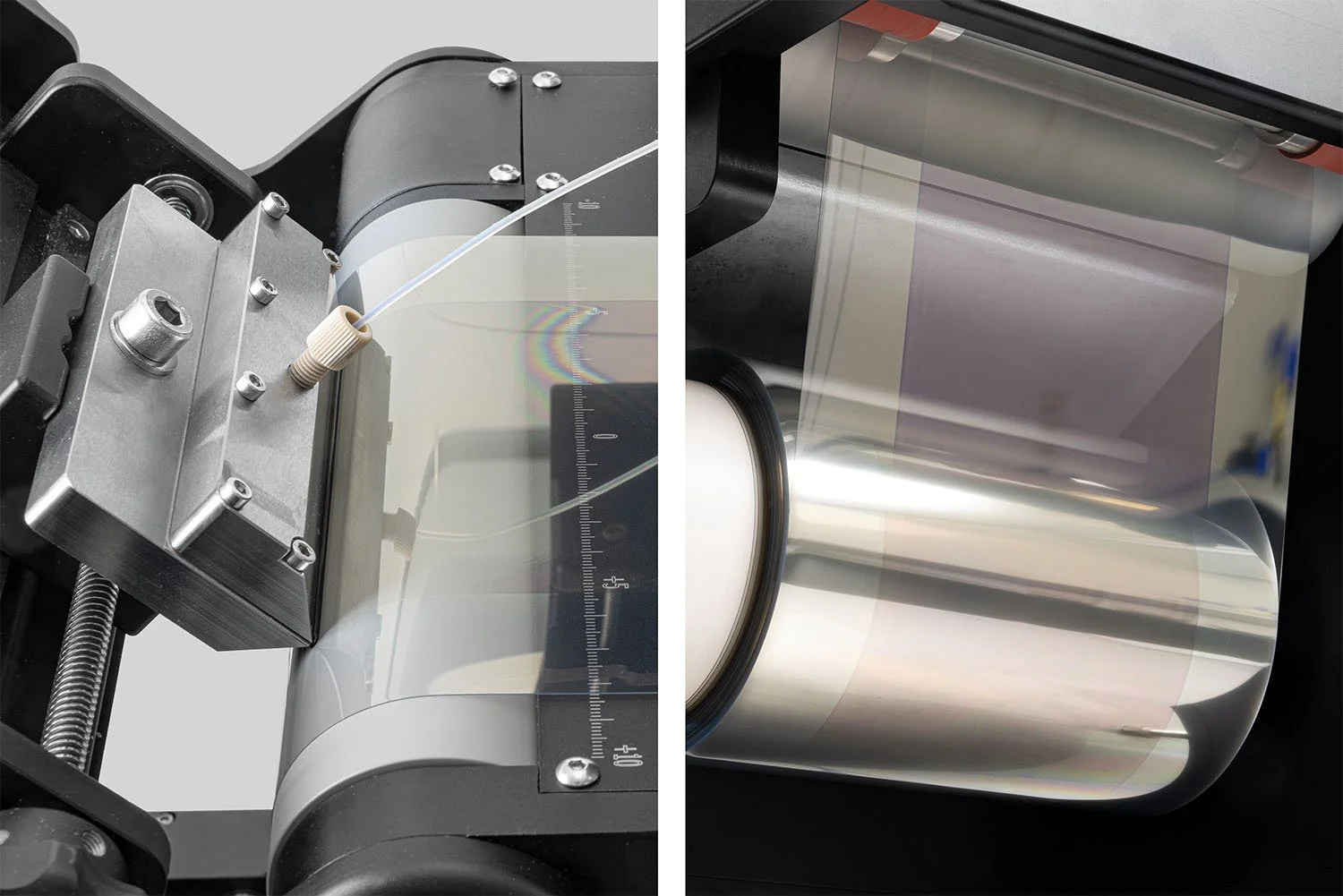

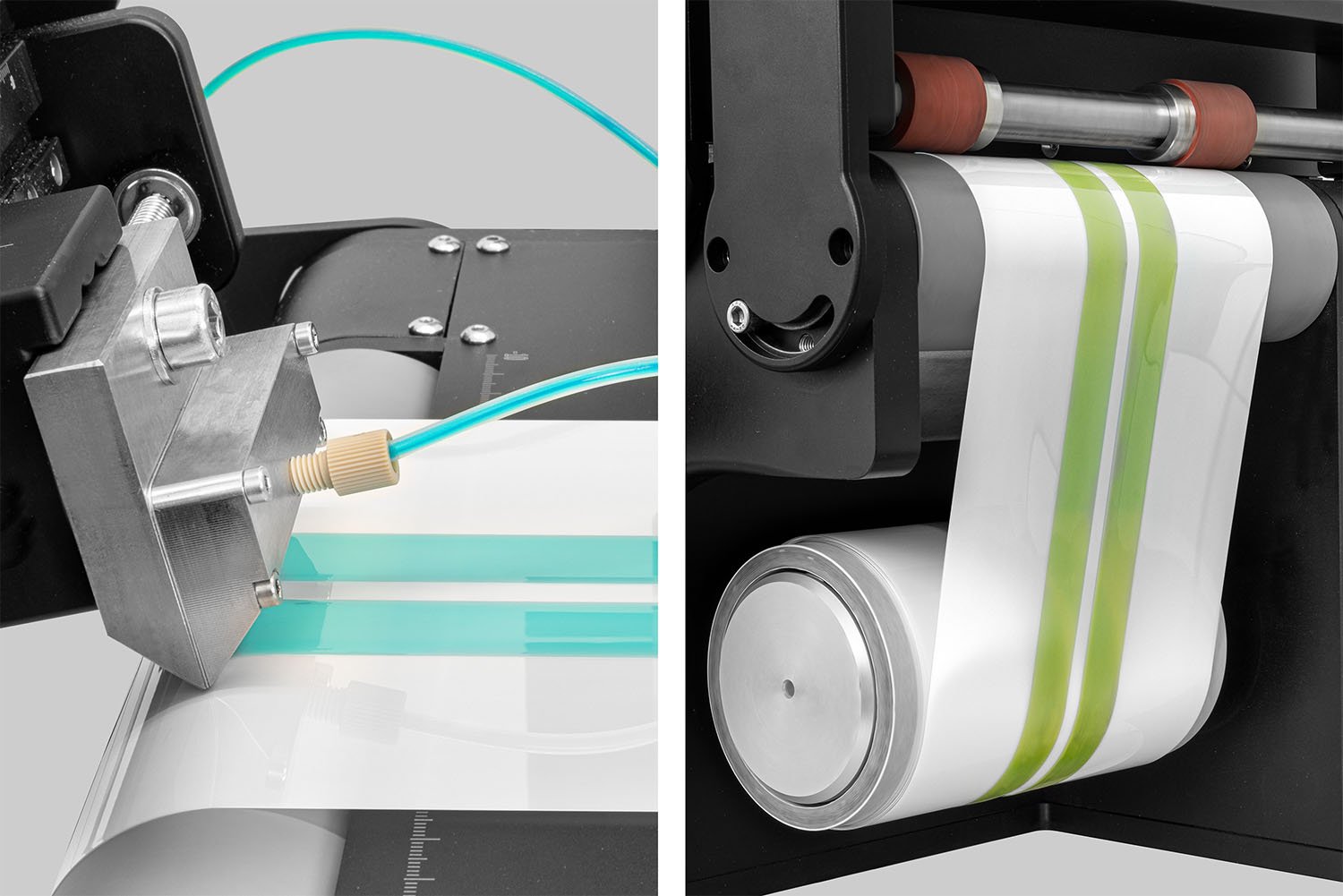

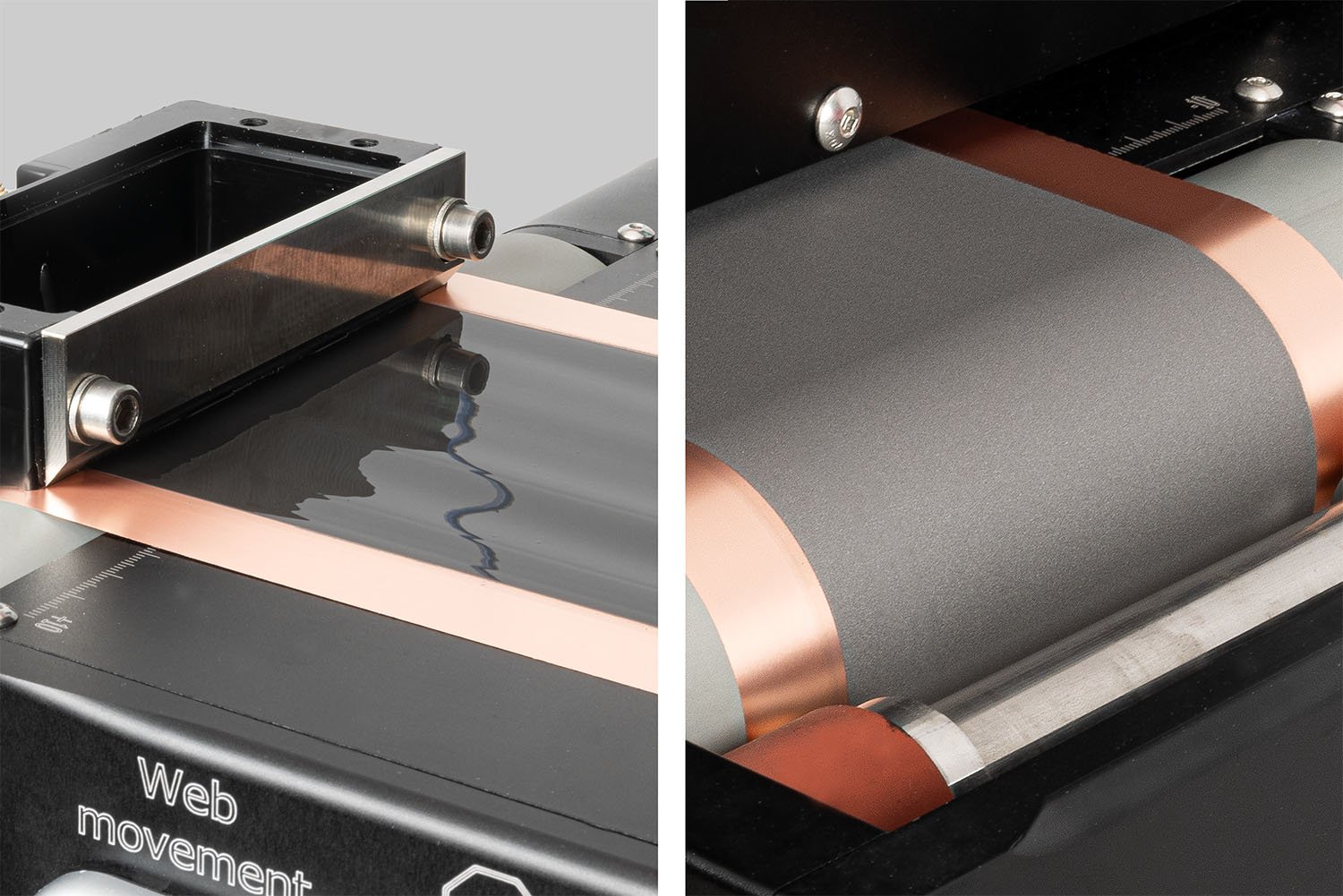

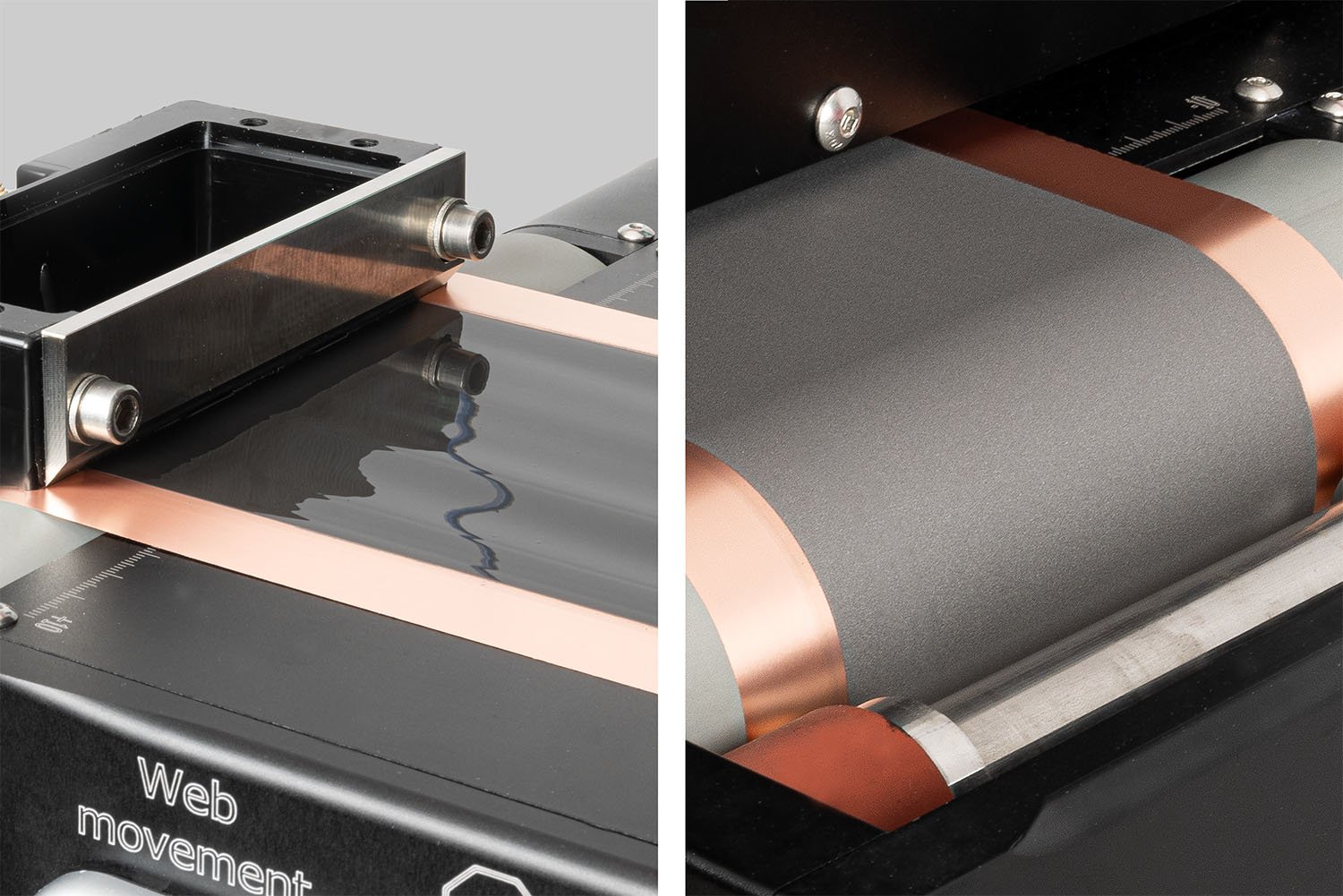

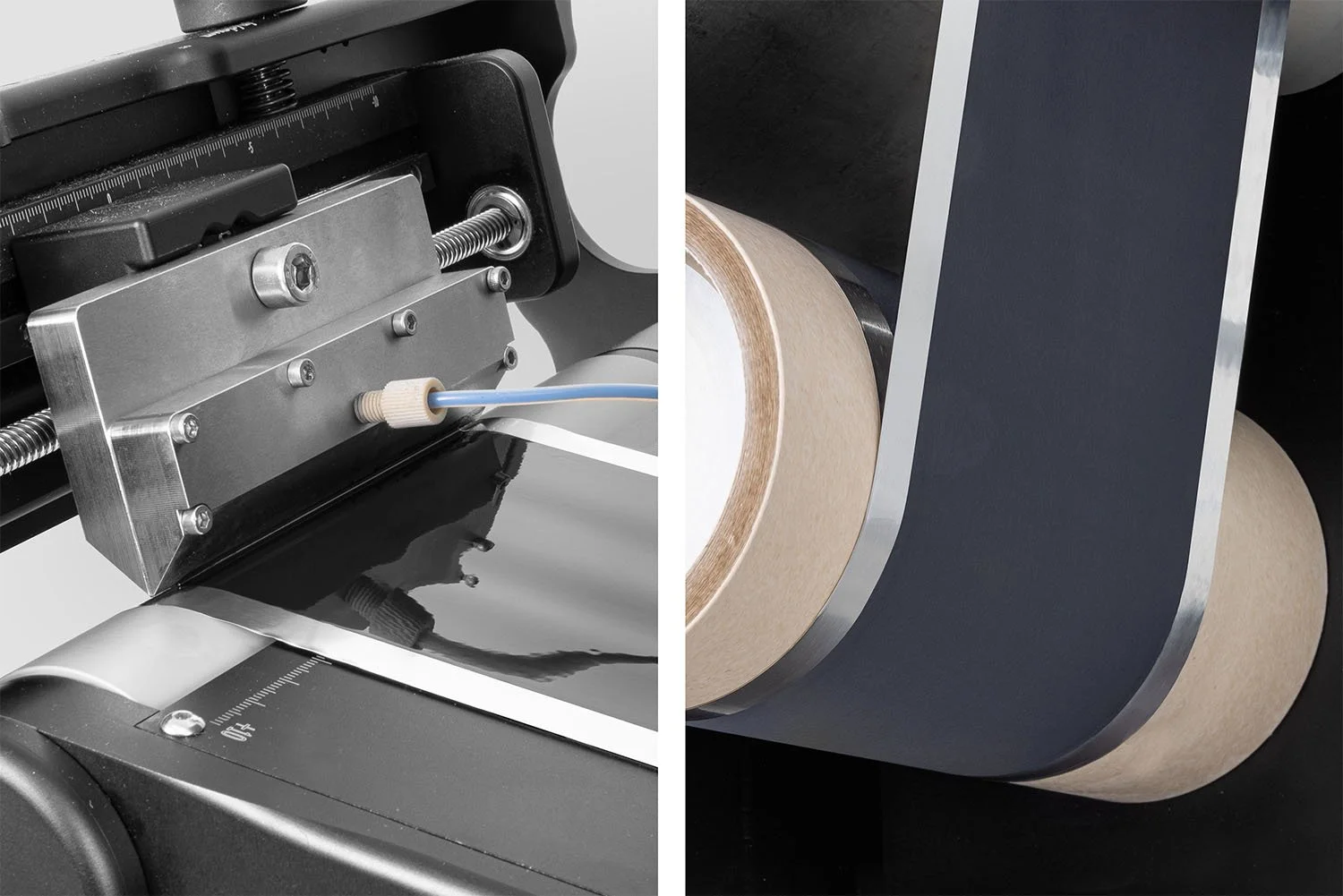

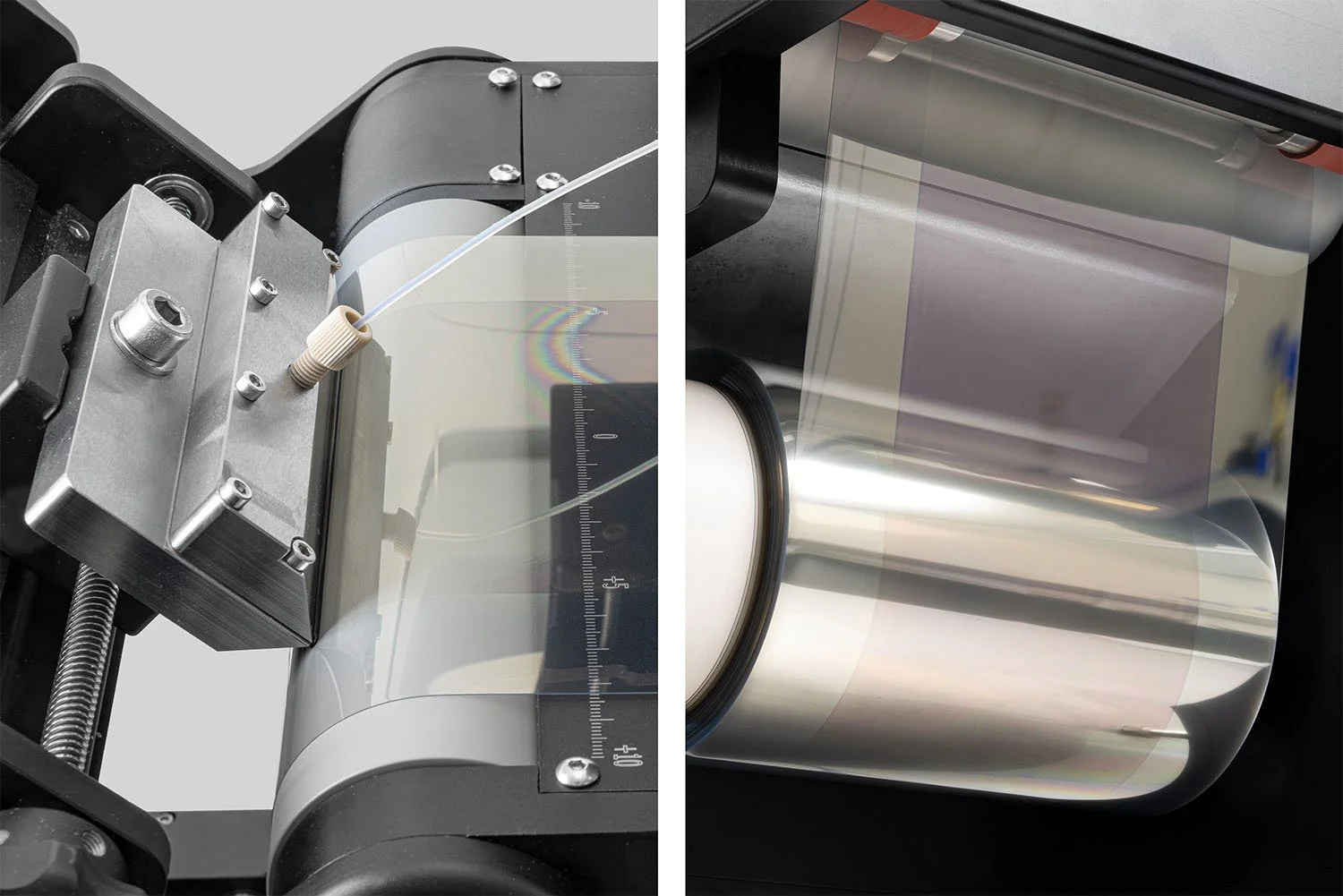

The Air Knife Pro for the Laboratory Roll-to-Roll Coater employs a high-speed air stream to form a thin, consistent curtain of air or gas, which can be precisely directed over the substrate. This facilitates the drying of surfaces or rapid quenching of coated thin films without any physical contact.

Micrometer screws with display ensure precise positioning of the air knife over the element. Adjustable angles and distances ensure effective drying or quenching while maintaining the integrity of the coating process.

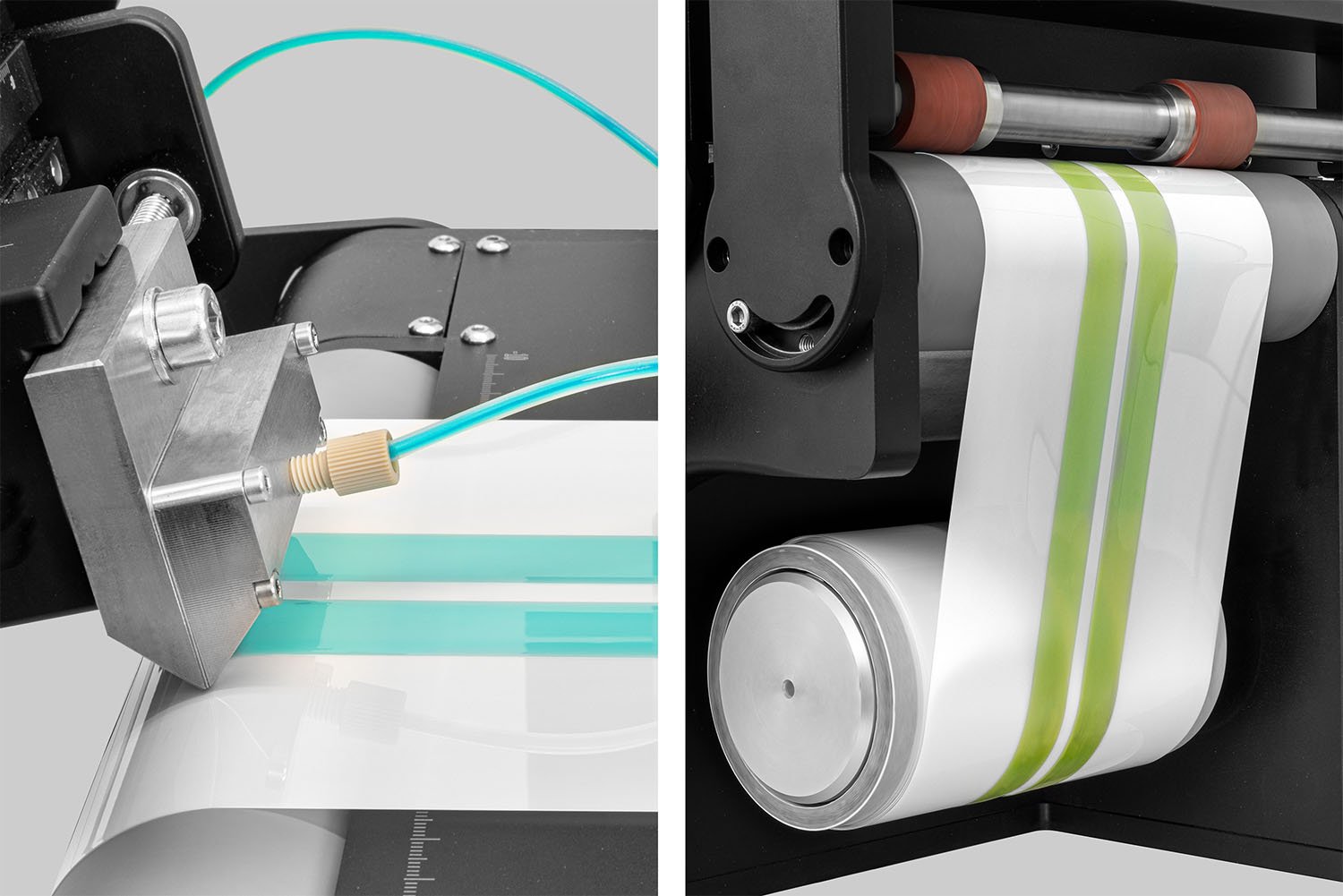

Technical Specifications

Two Sizes Available: Air Blade Width Up to 200 mm or 285 mm

PET Shim Included: Thickness of 120μm

Angle Adjustment Mount Included

Micrometer Screws with Display

Air/Gas Inlet for 8mm Outer Diameter Air Hose Included

Easy Assembly and Disassembly

Constructed with Anodized Aluminum

Compatible with the Laboratory Roll-to-Roll Coater

Air Knife Pro for the Laboratory Roll-to-Roll Coater

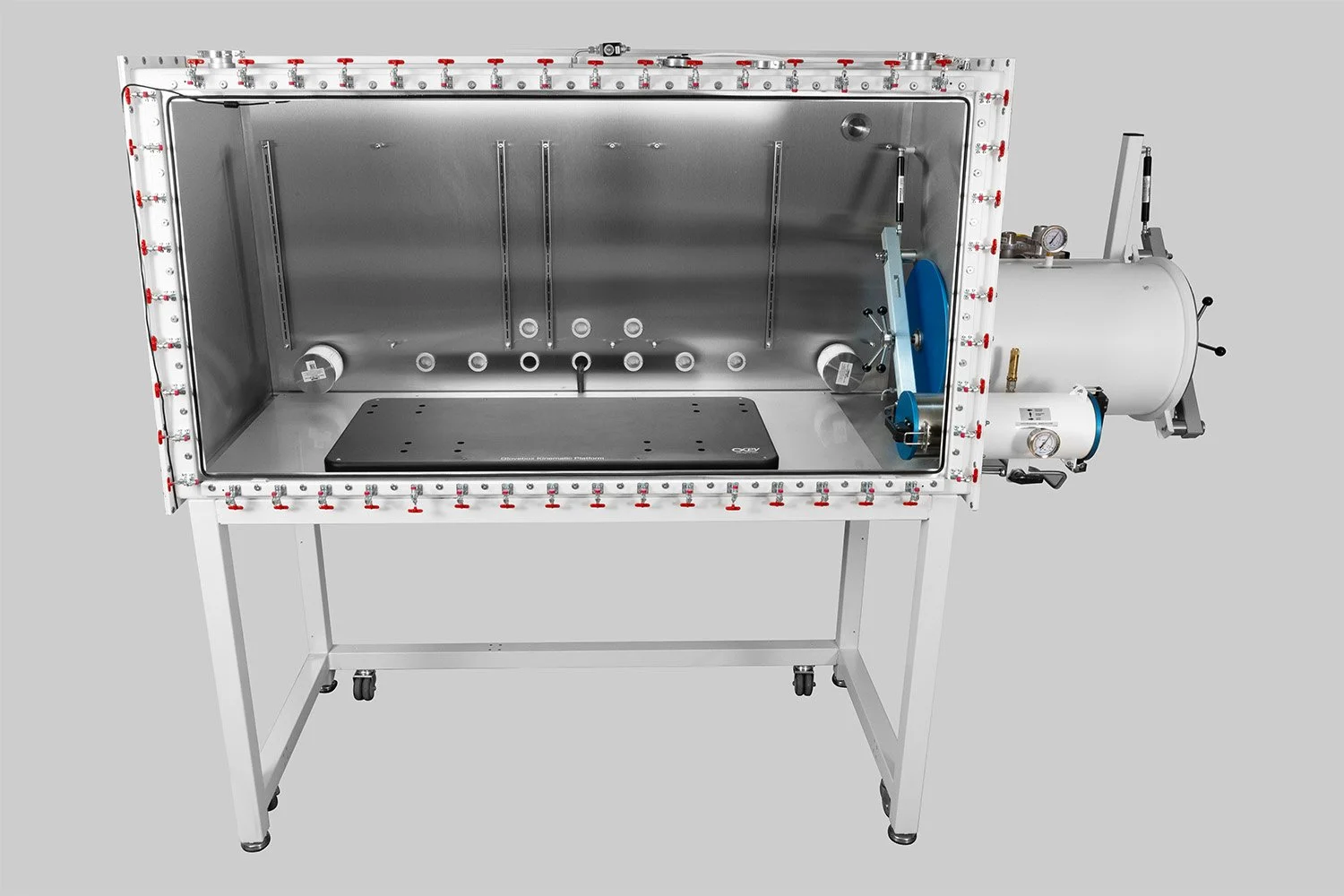

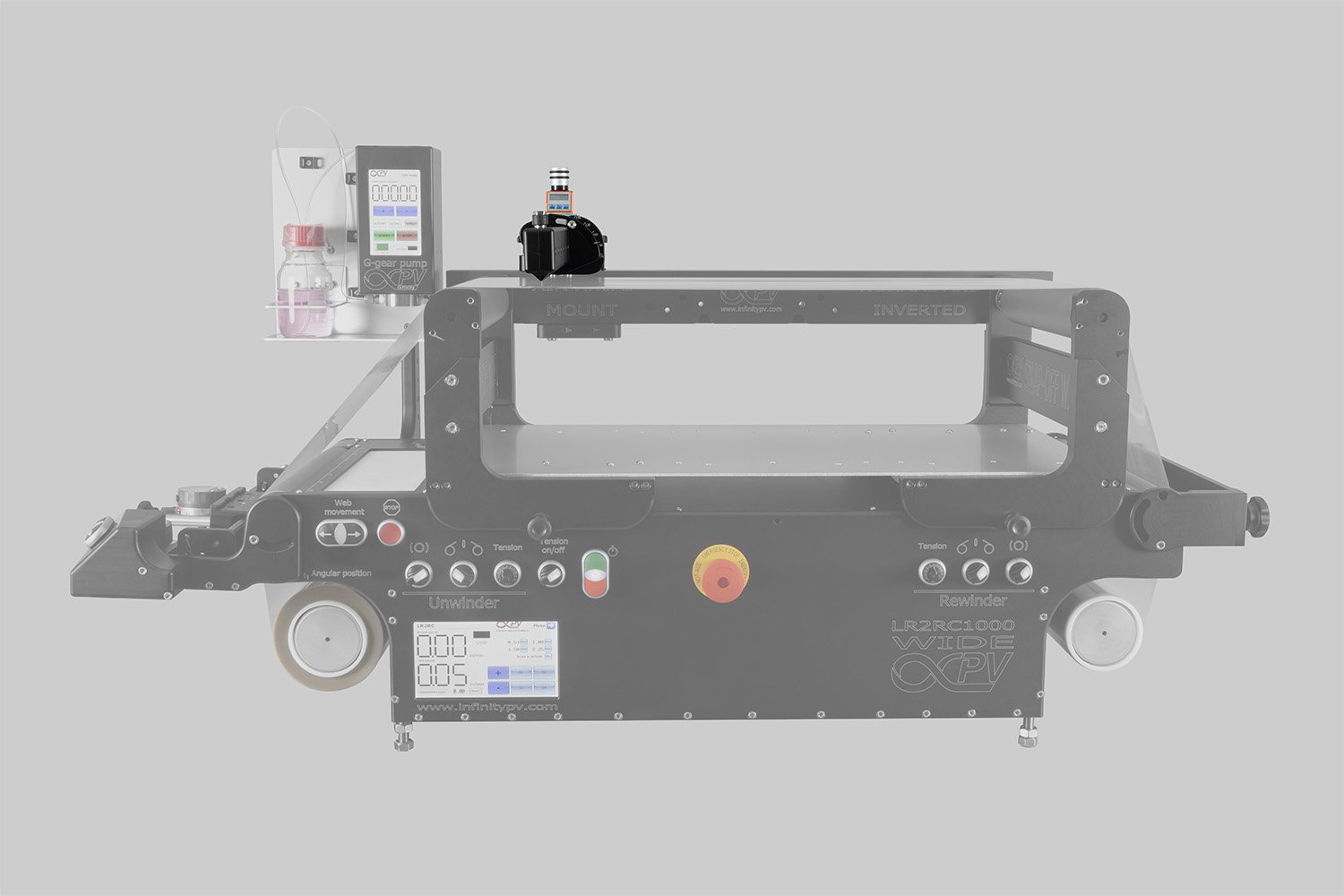

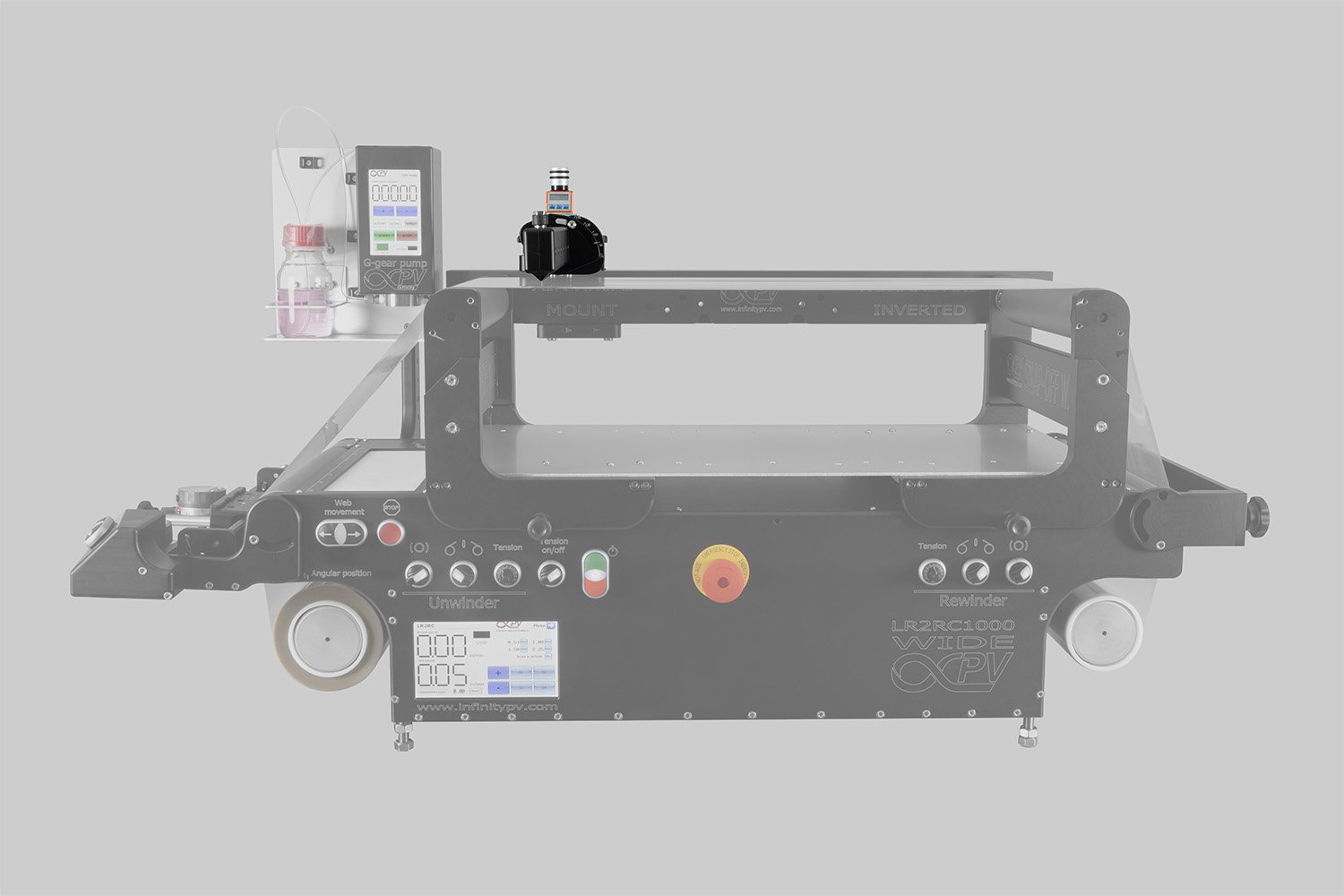

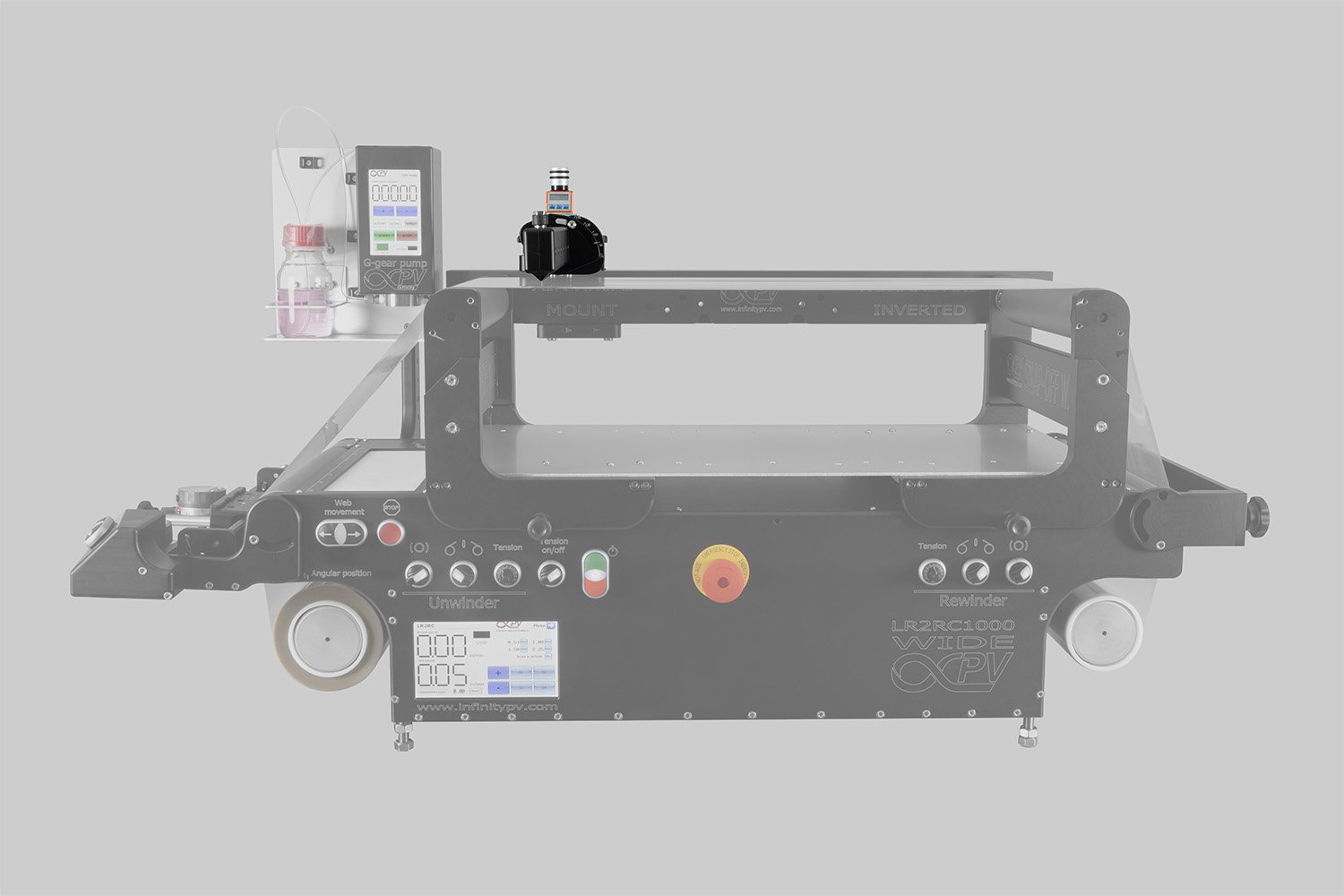

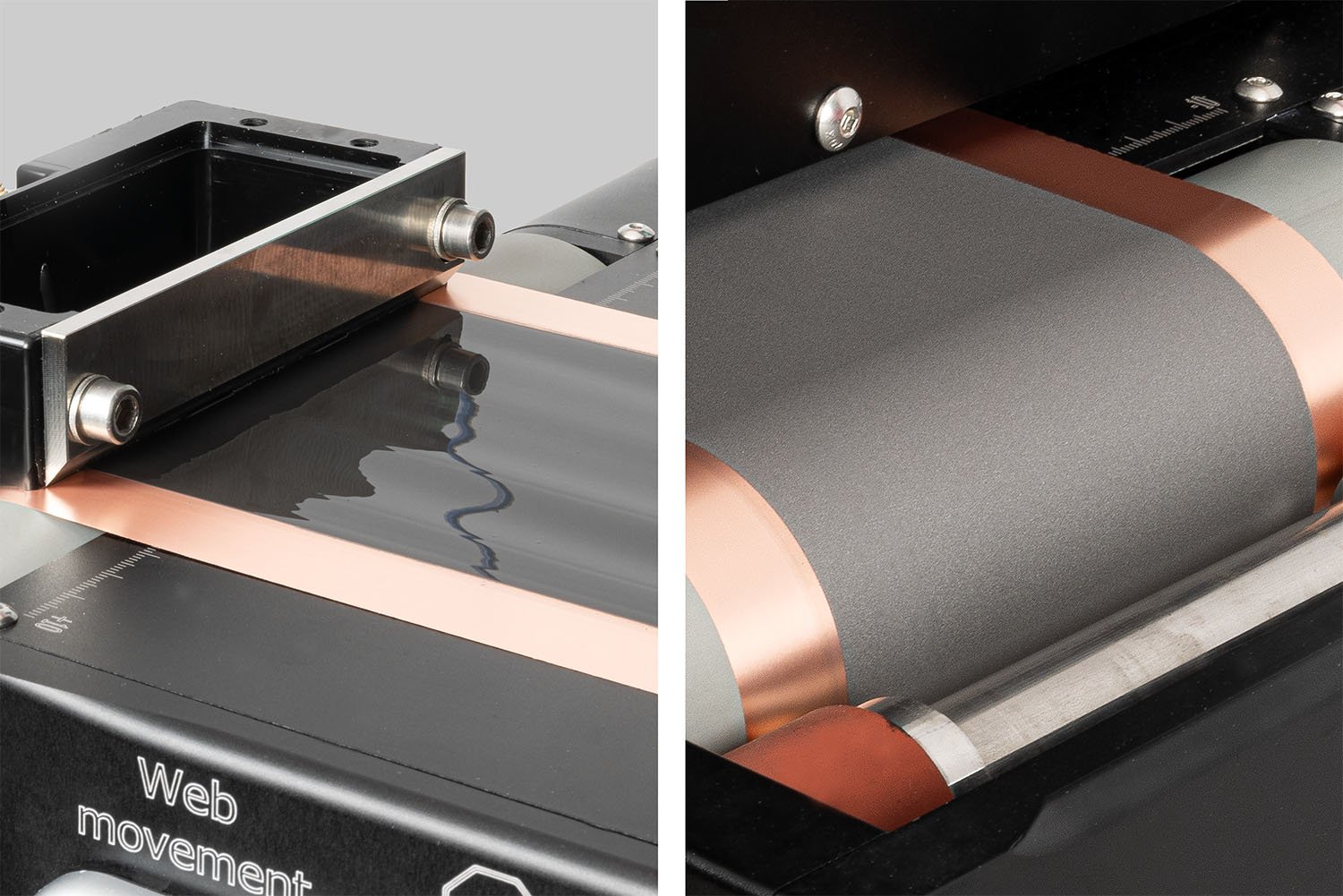

The Air Knife Pro is designed to seamlessly integrate with the Laboratory Roll-to-Roll Coater, a versatile and compact system for precise thin-film processing in lab and pilot-scale environments. Our modular components allow you to customize your coater for a wide range of applications including batteries, medtech, fuel cells, printed solar cells, sensors and more. Built for easy installation and interchangeability, these components help you optimize performance while maintaining flexibility and scalability.

Applications

Learn More About Slot-die Coating

Learn how to choose the right slot-die coater for your needs. Compare sheet vs. roll-to-roll (R2R) systems, understand substrate compatibility, drying methods, treatment options, and scalability to make informed coating decisions.

Learn the key differences between roll-to-roll (R2R) and sheet coating techniques. Discover their advantages, challenges, and ideal applications to choose the right coating method for your lab or production needs.

Discover how pristine clean surface coating eliminates defects by applying functional layers onto untouched substrates. Ideal for medtech, solar cells, OLEDs, and advanced electronics.

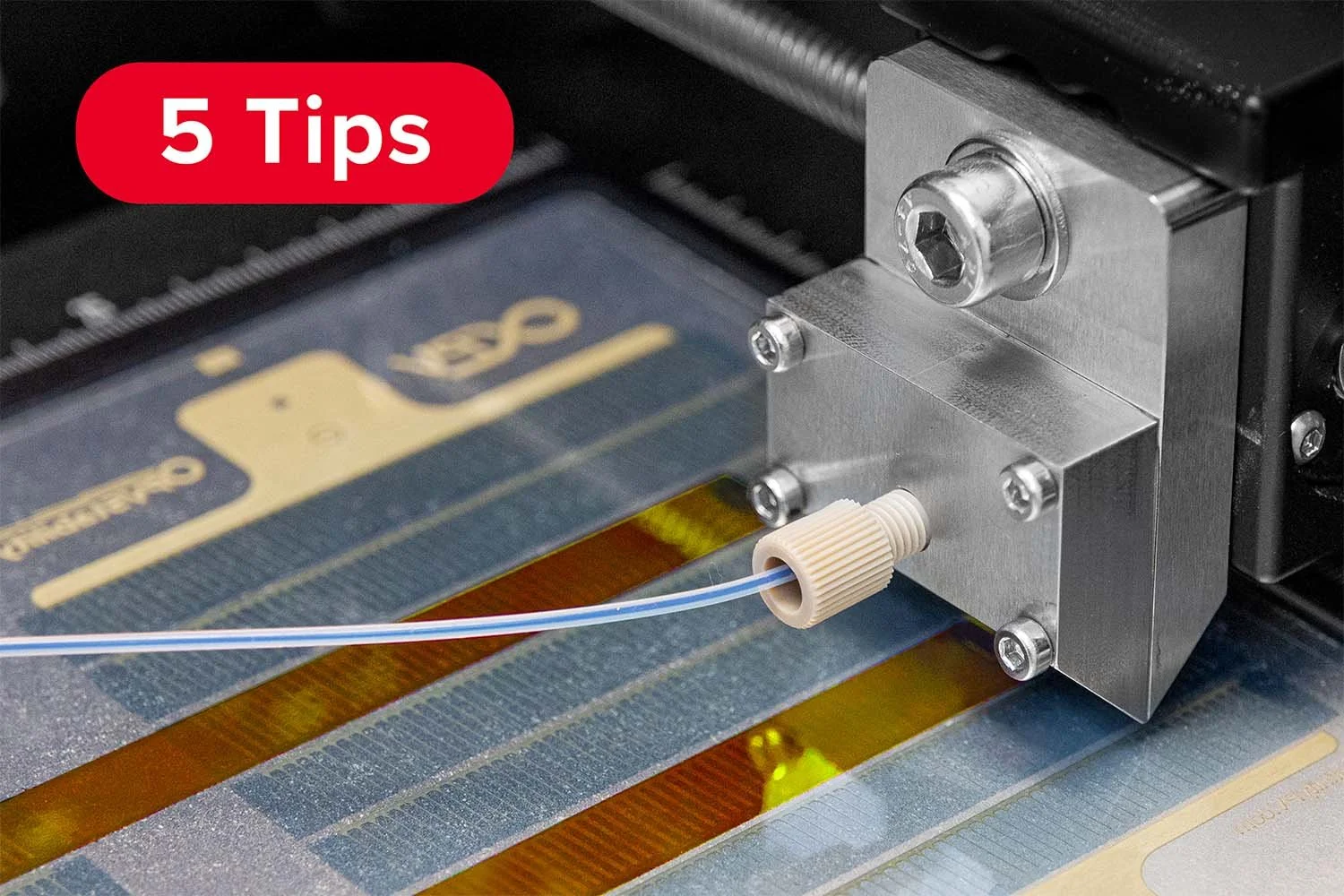

Master slot-die coating with these 5 helpful tips. Avoid common pitfalls, improve coating precision, and ensure smooth, consistent results. Perfect for beginners and experienced professionals alike.

Choosing the right pump for slot-die coating is crucial for achieving precise and consistent results. Our guide covers various pump types, including syringe, gear, and peristaltic pumps, and explains how each contributes to efficient ink delivery, ensuring high-quality coatings for applications such as solar cells, batteries, and printed electronics.