Slot-die Coating on Clean Surfaces - How to Pristine Clean Surface Coat

Cleanliness is everything when it comes to advanced thin-film coatings. Whether you're fabricating medtech, multilayer perovskite solar cells, OLED displays, thin-film batteries, flexible electronics, or high-barrier packaging films, the surface you coat on can make or break the performance of the entire device. Even trace contaminants—like dust particles, oils from handling, or residual moisture from the air—can compromise adhesion, cause coating defects, or introduce inconsistencies in layer thickness.

This is where the concept of pristine clean surface coating enters the picture. By coating onto a freshly revealed surface that has never been exposed to the environment, you can dramatically reduce the risk of contamination and ensure the best possible conditions for high-quality film deposition. In this article, we’ll guide you through the process of pristine clean surface coating using a Laboratory Roll-to-Roll Coater, explain why it works so well for sensitive devices, explore complementary technologies like corona treatment, and help you evaluate whether it’s right for your application.

Let’s get started.

What is Pristine Clean Surface Coating?

Pristine clean surface coating refers to a method where a functional coating is applied immediately after a protective liner or carrier film is stripped away from a substrate. The key here is timing and process design. The coating happens on a surface that has never been exposed to the ambient environment, meaning no dust, no moisture, no oxygen, and absolutely no contact with any rollers, gloves, or machinery.

This approach is particularly valuable for multilayer device fabrication, where the performance of each layer depends not only on its individual quality but also on how well it interfaces with the layer below. Coating onto a truly clean, untouched surface enhances adhesion, reduces interface defects, and increases the reproducibility of the final device.

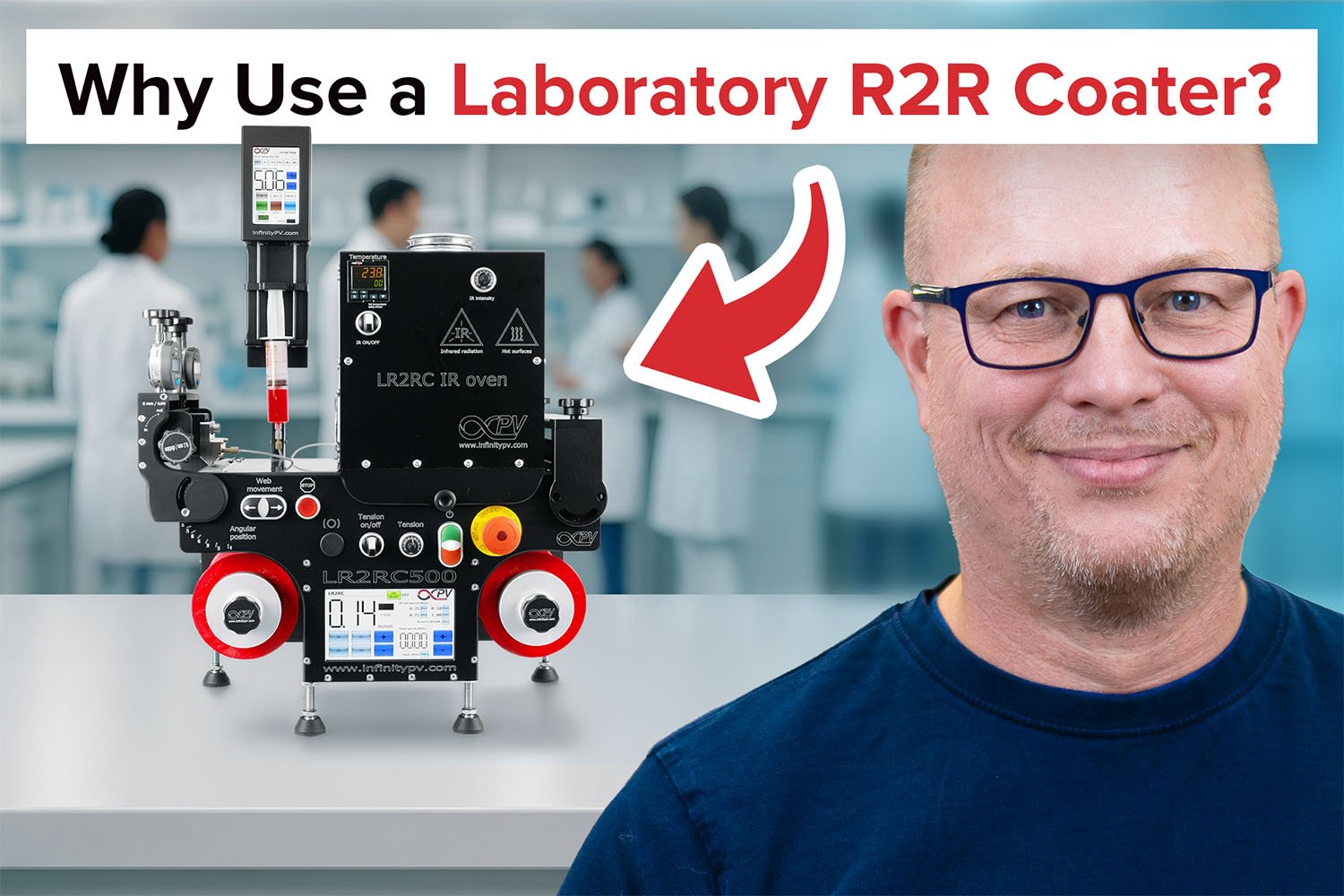

Researchers working in emerging fields like perovskite photovoltaics, organic electronics, printed sensors, and thin-film batteries have already recognized the value of pristine coating methods. The Laboratory Roll-to-Roll Coater is the ideal platform for this type of work because it offers precise control over web handling, slot-die coating, drying and curing, lamination, and rewinding—all within a modular, customizable setup.

Crucially, integrating coating processes within a cleanroom environment further enhances the benefits of pristine surfaces. Cleanrooms provide a tightly controlled environment with filtered air and minimized airborne particles, ensuring that the substrate remains free from contaminants throughout the process. When combined with the precise control of the roll-to-roll system, maintaining a cleanroom setting prevents particle deposition and environmental variability, resulting in higher quality, more reliable coatings—essential for sensitive electronic and biomedical devices.

The Laboratory Roll-to-Roll Coater is the ideal coating machine for scaling up to roll-to-roll processing of battery electrode materials or for testing and optimizing battery electrode slurries.

Step-by-Step: How to Perform Pristine Clean Surface Coating

The pristine coating process begins before any coating happens at all. The choice of liner materials, the design of the unwinding system, and the sequence of steps in the coating process all play critical roles in maintaining a pristine environment.

The first stage involves feeding a multilayer film into the coater. This film is typically composed of a functional substrate laminated with a protective liner—commonly made of PET or another stable, inert material. This liner has served as a protective layer, shielding the functional film from exposure during transport and storage.

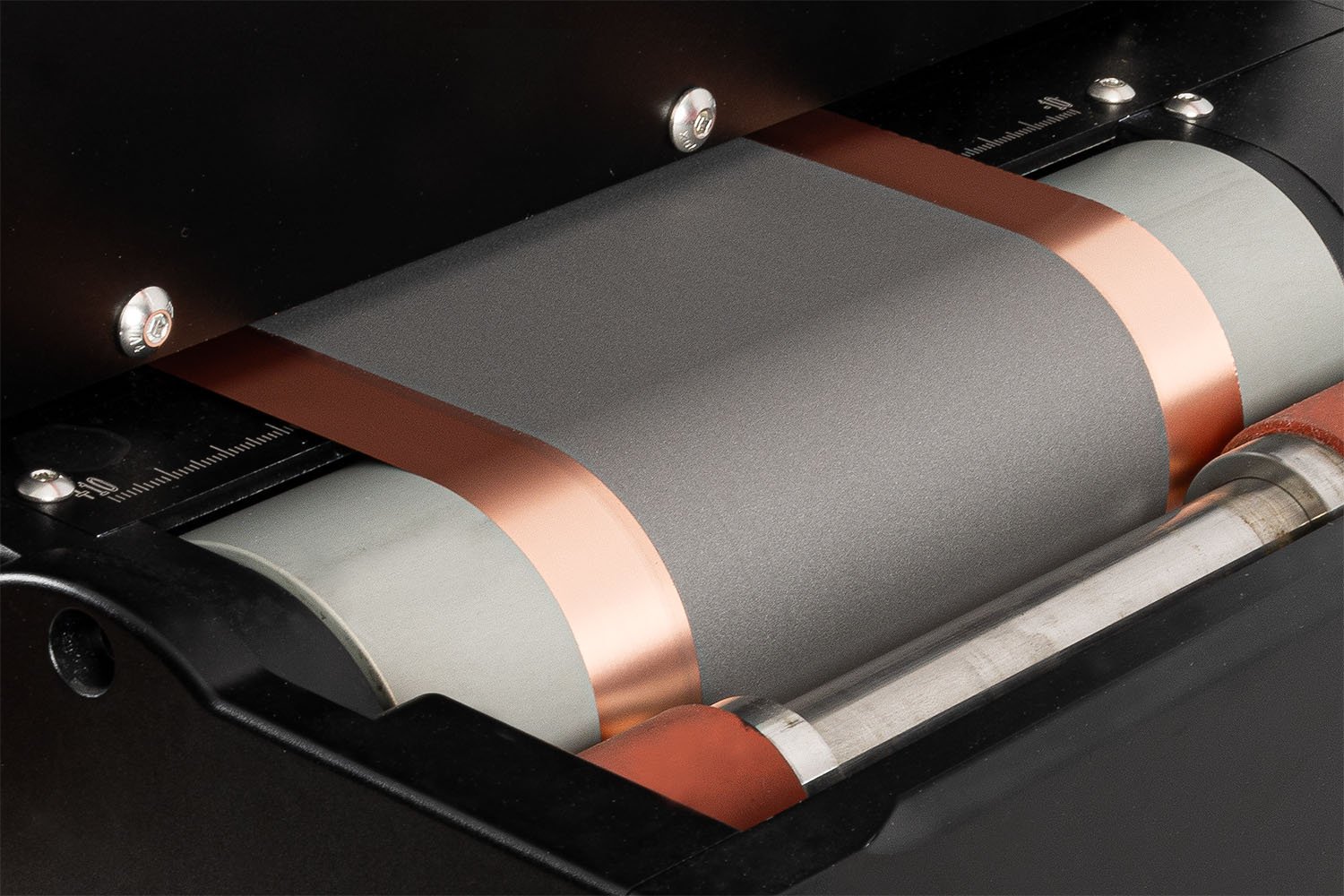

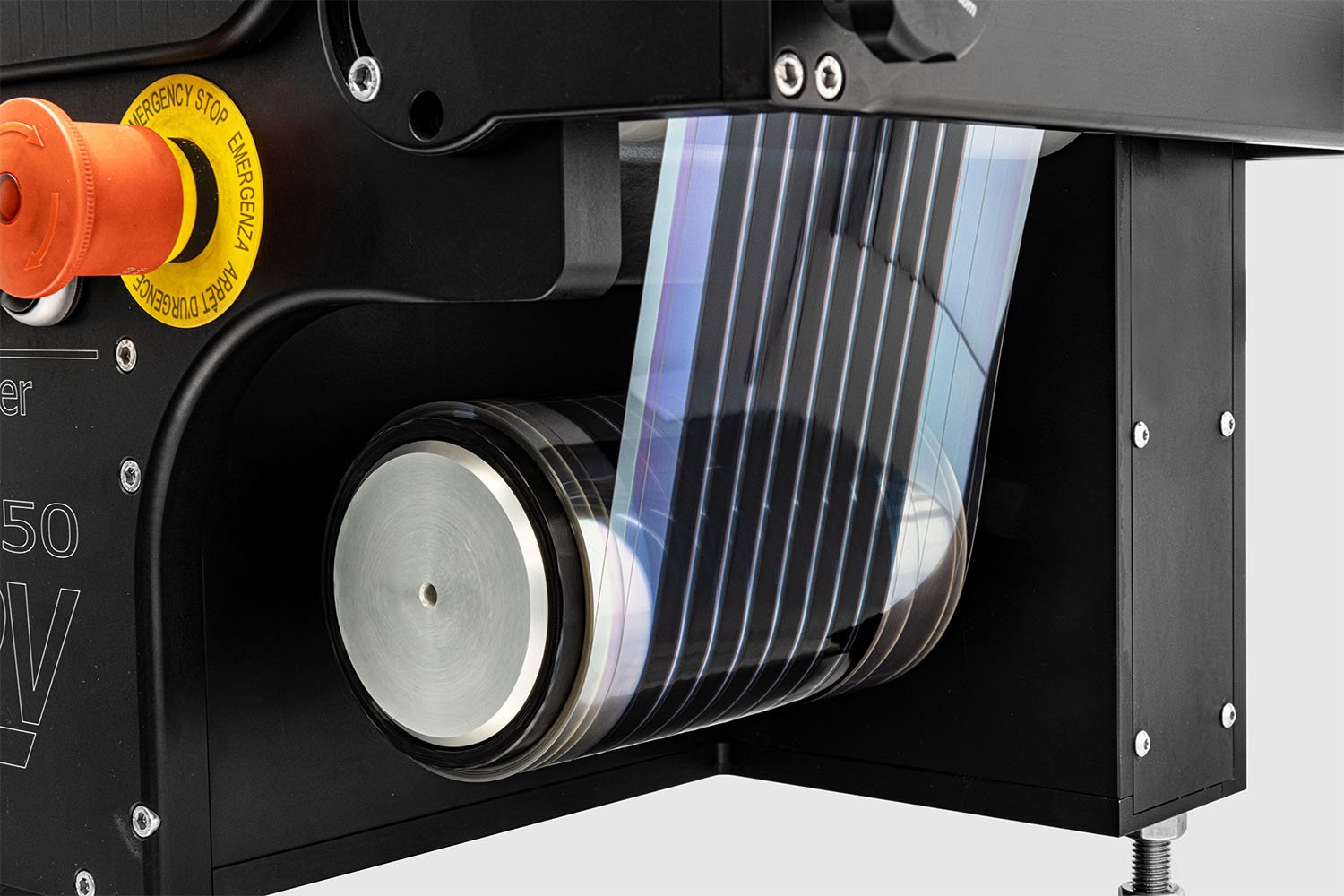

Inside the coater, the film reaches the Stripper Unit, where the liner is carefully peeled away. This exposes the underlying surface, which has been kept entirely isolated from air and mechanical contact. The peeling process is gentle and controlled to avoid static buildup or accidental scratching of the functional layer.

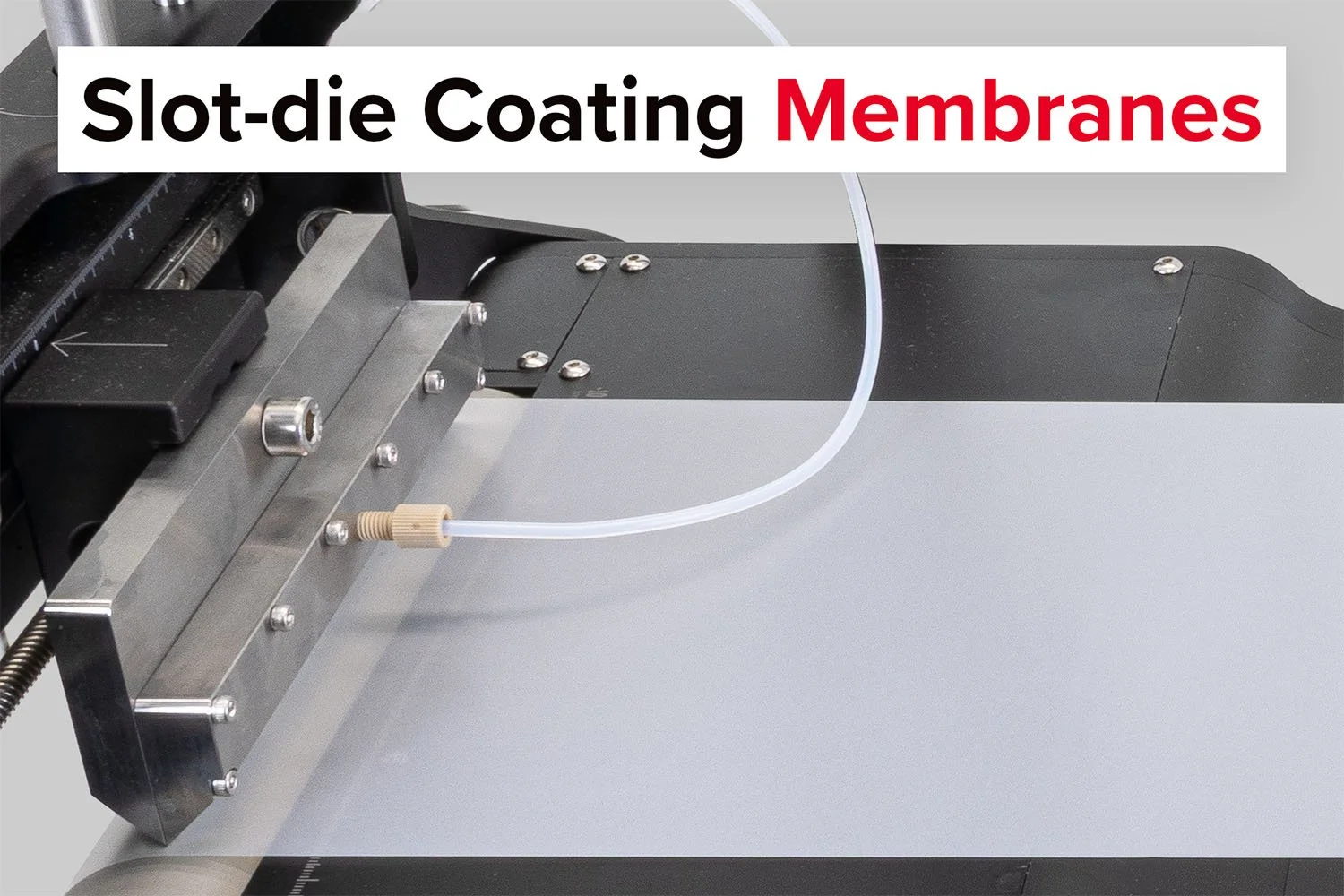

Immediately following the stripping step, the exposed substrate enters the slot-die coating zone. A precision-engineered slot-die head applies the desired coating solution—whether it is a conductive ink, a photoactive polymer, or a barrier formulation—directly onto the newly revealed surface. Because the coating happens instantly, there is no chance for contaminants to settle or react with the surface. This is the core advantage of the pristine coating method.

After deposition, the coated film continues into a drying and curing section, which may include infrared heating, hot-air drying, or ultraviolet (UV/UV-LED) curing modules depending on the chemistry of the ink. These systems are designed to remove solvents, initiate polymerization, or otherwise solidify the coating without introducing thermal or mechanical stress to the substrate.

Once the coating is dry and stable, the film reaches the lamination stage. Here, a second protective film—often similar in composition to the first liner—is applied over the freshly coated layer. Just like before, this second film is stripped immediately before application, so it also presents a pristine surface. This allows the newly coated layer to be encapsulated without exposure to rollers, fingers, or open air. This lamination can be permanent or temporary, depending on whether the device will be further processed, characterized, or stored for later use.

Finally, the laminated film is rewound and collected on a take-up roll. Because the coated surface was never exposed, the result is a pristine, encapsulated layer that is ready for high-performance applications or sensitive measurements.

Learn the complete process of creating uniform thin films using a slot-die coater.

The Role of Slot-die Coating in Achieving Uniformity

Slot-die coating is the technique of choice in pristine surface processes because of its precision, flexibility, and compatibility with a wide range of coating materials. Unlike spray or spin coating, slot-die deposition involves no material waste and provides excellent control over layer thickness, width, and wet film behavior.

When combined with the pristine surface approach, slot-die coating allows researchers to explore complex multilayer stacks without worrying about defects from previous handling steps. The technique is scalable, meaning that methods optimized on a laboratory roll-to-roll system can later be transferred to pilot or production-scale systems with minimal adjustments.

To get the most out of slot-die coating on pristine surfaces, it’s important to carefully match ink rheology, substrate wetting behavior, coating gap, and web speed. Fortunately, a Laboratory Roll-to-Roll Coater provides the fine control necessary to tune these parameters in real time.

Complementary Surface Treatments: When to Use Corona

While pristine coating avoids surface contact and contamination, there are situations where corona treatment can complement the process. Corona treatment is a method of increasing the surface energy of films, particularly polymers like PET, polypropylene, and polyethylene. By exposing the film to a high-voltage electrical discharge, the corona process introduces polar functional groups to the surface, improving wettability and adhesion.

In pristine coating workflows, corona treatment is most useful when preparing liner materials that will later be stripped to reveal the pristine surface. Applying corona treatment to these liners ensures that the functional film beneath them adheres evenly during lamination, without voids or non-uniform bonding. This is particularly important in applications where coating uniformity must be preserved during liner removal or when lamination occurs at lower temperatures.

Corona units like the LabelTEC system can be integrated directly into the roll-to-roll process, allowing inline treatment just before or after key steps. However, it’s important to note that corona-treated surfaces are not pristine in the same sense as untouched surfaces. Therefore, corona is best used to prepare or functionalize liners, not as a replacement for pristine coating techniques.

Surface treatment technologies like plasma and corona are crucial for enhancing the adhesion of inks, coatings, and adhesives, particularly when working with non-porous materials like plastics and polymers. Read our article here.

Applications of Pristine Clean Surface Coating

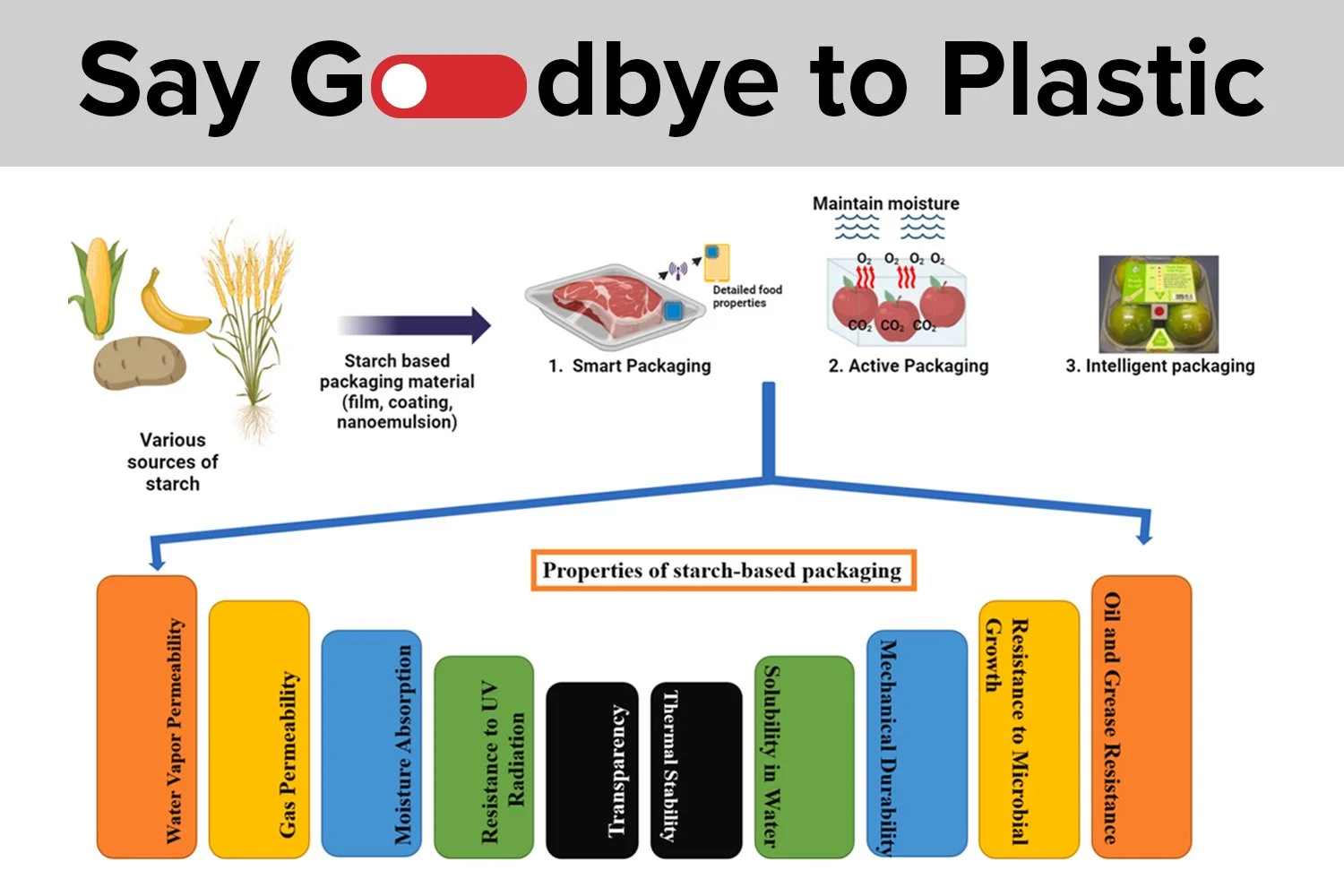

The list of use cases for pristine surface coating is rapidly growing, particularly in fields that demand extreme control over interfaces and film quality. Some of the most promising areas include:

Medtech: In medical device manufacturing, pristine surface coatings are vital to ensure biocompatibility, sterility, and minimal particle shedding. Coatings applied to implantable devices, diagnostic tools, and surgical instruments help prevent microbial contamination, reduce adverse tissue reactions, and improve device longevity. The ability to deposit ultra-clean, uniform coatings enhances the safety and performance of medtech products, meeting stringent regulatory standards and ensuring patient well-being.

Perovskite Solar Cells: These devices are highly sensitive to moisture and oxygen. Coating photoactive and transport layers onto pristine surfaces reduces defects and increases efficiency and reproducibility.

OLED Displays: Uniform emission and long device lifetime depend on clean interfaces between functional layers. Pristine coating enables the deposition of emissive and charge transport layers without contamination.

Flexible Sensors: When manufacturing stretchable or bendable sensors, mechanical and chemical integrity of the coating is crucial. Pristine surfaces improve adhesion and reduce variability.

High-Barrier Films: Packaging and encapsulation layers benefit from pristine coating by eliminating pinholes and defects that can compromise barrier performance.

Electrochemical Devices: Batteries, supercapacitors, and fuel cells require consistent layer thickness and adhesion between electrodes and separators. Coating onto fresh, clean surfaces improves electrochemical performance.

Weighing the Pros and Cons

To help decide whether pristine clean surface coating is right for your application, consider the following comparison:

| Advantages | Challenges |

|---|---|

| Ensures ultra-clean surface for optimal adhesion | Requires use of additional liner materials |

| Reduces defects from dust, particles, and roller marks | Demands precise coordination between stripping and coating |

| Enhances reproducibility and yield in sensitive devices | Lamination step must be finely tuned to avoid bubbles |

| Compatible with slot-die, drying, and lamination steps | Slightly more complex setup compared to conventional coating |

For many researchers, the benefits far outweigh the challenges, particularly when working with delicate device layers where even minor contamination can cause major issues.

It’s easy to build your own roll-to-roll coater. Choose a platform. Select components. Get a quotation. Start here.

Building Your Own Pristine Coating Line

Thanks to the modular nature of the Laboratory Roll-to-Roll Coater, it's possible to assemble a fully functional pristine coating system tailored to your specific research or development goals. From web handling to coating, curing, and lamination, each module is engineered for precision, reproducibility, and scalability.

You can integrate components such as:

A Stripper Unit for controlled liner removal

A slot-die head for precision coating

A drying or curing oven (IR, hot-air, or UV)

A laminator for encapsulating the coated surface

Optional corona treatment units for surface activation

Whether you're building a new lab line or upgrading your existing equipment, infinityPV can help configure the exact setup you need.

Conclusion: Clean Surfaces, Better Results

Pristine clean surface coating is not just a technique, it’s a mindset. It reflects the understanding that the quality of a thin film is only as good as the surface it’s deposited on. By using a Laboratory Roll-to-Roll Coater with the right modules and workflow design, you can coat onto untouched surfaces with unparalleled precision. This approach is ideal for anyone working in next-generation electronics, energy devices, and thin-film research where cleanliness, reproducibility, and performance are critical. Interested in learning more? Our team is always ready to help you bring pristine precision to your lab.

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Related Articles

Related Products

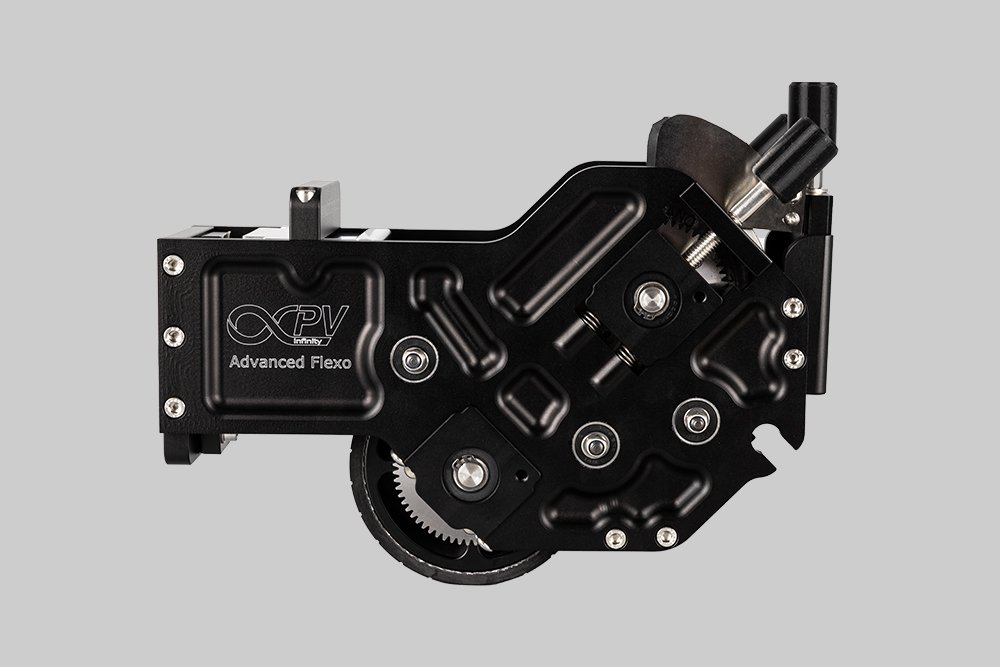

Laboratory Roll-to-Roll Coater

A compact and modular high precision roll-to-roll slot-die coater that transforms the way thin functional films are printed and coated.

LR2RC500 Bundle

Probably the world’s most compact R2R slot-die coater. A compact, fully integrated R2R coater that fits on a workbench, in a fume hood or a glovebox.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.