What Are Perovskite Solar Cells? A Beginner’s Guide to Next-Generation Solar Technology

Solar technology is evolving fast, and one material is turning heads: perovskite.

Perovskite solar cells are on the rise, lately with their tandem application together with silicon (Si) solar cells, achieving efficiencies higher than conventional types. The excitement comes from their high efficiency, lightweight nature, and easy-fabrication features. This blog explains what perovskite solar cells are and why they’ve become a major focus in clean energy research.

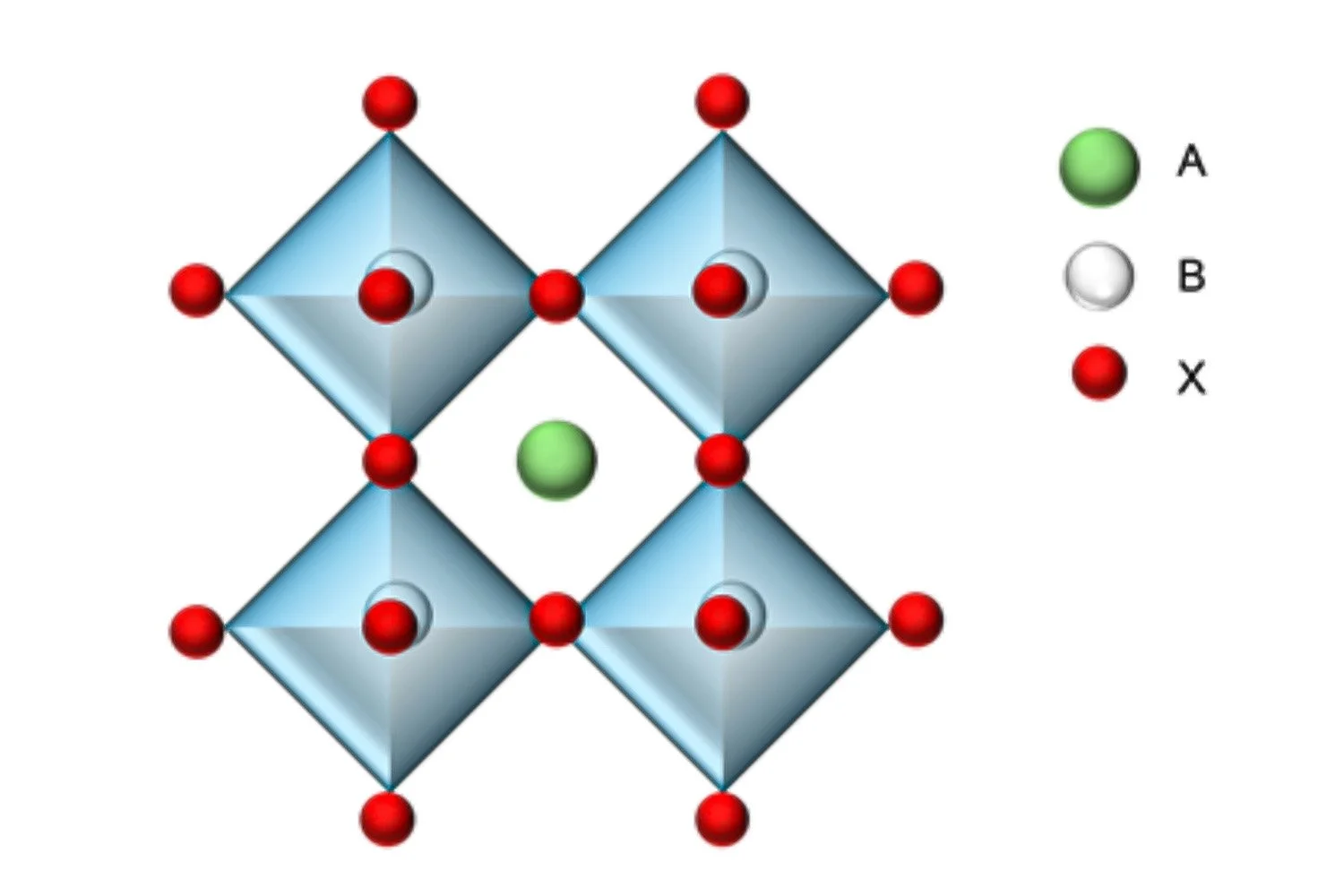

What is a Perovskite?

It is not the first time that perovskites have received this much attention. In fact, it goes back to 1839, when the mysterious mineral was found in the Ural Mountains and named after Russian mineralogist Lev A. Perovskite. The first perovskite discovered was calcium titanate, but scientists later discovered that many materials could form the ‘perovskite’ structure, which looks similar to a cube at the atomic scale.

One of the most exciting features of perovskites is that their structure is highly tunable. The structure follows the general formula ABX₃, where 'A' and 'B' are cations of different sizes, and 'X' is an anion that bonds to both. By altering the A, B, or X components, scientists can fine-tune key properties such as bandgap, crystal stability, and light absorption behaviour, making them ideal for various optoelectronic applications. Beyond solar cells, this tunability gives rise to a wide range of other interesting behaviours: dielectric properties, electrical conductivity, optical properties, catalytic activity, thermal conductivity, and even magnetism. This diversity makes perovskites not only fascinating from a scientific standpoint but also promising for many types of advanced technologies.

What Makes Perovskite Solar Cells Special?

Perovskite solar cells stand out for their remarkable performance and versatility. They’ve shown a very fast rise in power conversion efficiency, going from 2% to over 20% in just a decade, challenging commercial silicon solar cells. Their composition and structure can be adjusted to absorb different parts of the solar spectrum, which opens the door to multi-junction or tandem solar cells, devices that combine multiple absorber layers to capture more sunlight. In these tandem setups, perovskites are often used as the top layer due to their tunable bandgap, enabling improved efficiency beyond what single-junction solar cells can achieve. This adaptability makes perovskites a highly promising material for next-generation solar technologies, already reaching a milestone of 30% efficiency in laboratory tests.

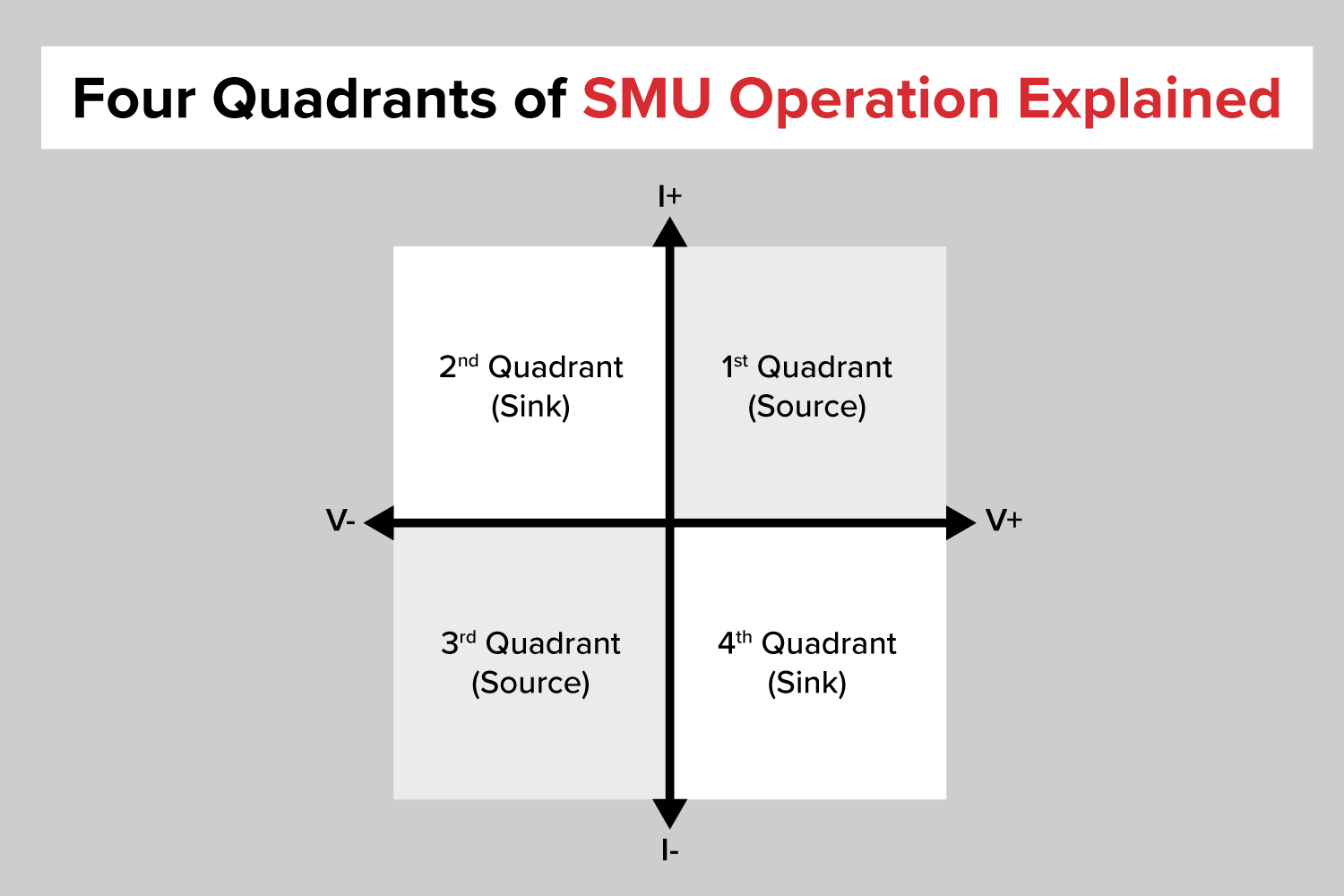

How Do Perovskite Solar Cells Work?

Perovskite solar cells follow the general solar cell working principle as light absorption, charge separation, charge transport, and charge collection. As the photons of sunlight hit the perovskite layer, they generate excited charge carriers, which are electrons and holes. These charge carriers are separated and directed by special transport layers. While electrons move toward the electron transport layer (ETL), holes move toward the hole transport layer (HTL). Through these transport layers, the charge carriers reach the respective positive and negative electrodes and travel through an external circuit, creating electric current.

A typical perovskite solar cell consists of several stacked layers:

A transparent conducting substrate (like glass or plastic coated with indium tin oxide)

An electron transport layer

The perovskite light-absorbing layer

A hole transport layer

A metal electrode, often gold or silver

Depending on the device design, the perovskite absorber layer can be deposited in two main structures: planar or mesoporous.

In planar structures, the perovskite is coated as a flat, smooth layer. This type is simpler to make and often used in lab-scale devices with high efficiency. In mesoporous structures, a sponge-like scaffold, usually made of titanium dioxide (TiO₂), is first deposited. The perovskite is then filled into this scaffold. This design helps improve contact between layers and supports better charge separation and transport. Both structures are solution-processable, meaning they can be made using spin coating or printing techniques. The choice between them depends on the desired performance, stability, and manufacturing method.

What is roll-to-roll processing, and why is it revolutionizing the way we make solar cells?

How Are Perovskite Solar Cells Made?

One of the key advantages of perovskites is that they are solution-processable, meaning they can be dissolved in a liquid and deposited onto surfaces using simple methods. Unlike silicon, which requires melting, at high temperatures and slicing solid crystals, perovskite layers can be printed or coated onto flexible substrates at low temperatures.

Laboratory-scale methods often use spin coating, where a solution is spread evenly across the surface of a substrate by spinning it at high speeds. Other scalable methods include slot-die coating, inkjet printing, and spray coating, all of which are compatible with roll-to-roll manufacturing. This opens exciting possibilities for high-throughput production of flexible solar modules.

The simplicity of these fabrication methods is one of the reasons perovskite solar cells are being explored for wearable electronics, building-integrated photovoltaics (BIPV), and indoor energy harvesting.

Scaling up perovskite solar cells from lab-scale devices to industrially relevant sizes brings several challenges, especially related to efficiency and stability. Lab-scale perovskite solar cells have been extensively studied, with record power conversion efficiencies typically achieved in devices with active areas below 1 cm² under controlled laboratory conditions. However, translating these results to larger areas is far more complex. Achieving smooth and uniform thin films becomes harder, and larger active areas tend to show more resistance and defects, which can limit charge transport and reduce efficiency.

Overall, stability suffers much more than efficiency during upscaling. Larger-area devices tend to degrade several times faster than small-area ones, even under identical conditions. On the path to commercialization, modules must demonstrate optimal performance under long-term outdoor conditions, including exposure to heat and humidity. Another important discussion related to scaling up is the use of lead salts, which raises environmental and health concerns. Although the amount of lead used in perovskite solar cells is very small compared to what is used in lead-acid batteries or even in some silicon solar cell production, the lead in perovskite solar cells is in a water-soluble form, making it a potential environmental hazard.

Learn how to fabricate solar cells using slot-die coating and flexo printing on a Slot-die Coater.

Conclusion

Perovskite solar cells represent a new era in solar energy technology. With their tunable structure, impressive efficiency, and potential for printable production, they offer exciting alternatives to conventional silicon panels. Their versatility also enables tandem cell designs, pushing solar performance even further. While perovskites still face challenges, such as improving their long-term stability and scaling up manufacturing, the progress so far has been remarkable. Early-stage industrialization is already underway, while academic research continues to thrive. As an emerging technology, perovskite solar cells are set to shine in the coming decade.

About the Author

Ümran Işıl Biçer is a Marie Curie PhD fellow at infinityPV, contributing to the Marie Skłodowska-Curie EIFFEL project. She received her bachelor’s degree from Middle East Technical University in Turkey and completed her master’s through the Erasmus Mundus MaMaSELF program, studying at Ludwig Maximilian University of Munich and the University of Montpellier, with her thesis conducted at the University of Helsinki. She is pursuing a PhD in the development of non-fullerene acceptors for organic solar cells, focusing on scalable roll-to-roll printing methods to improve solar cell efficiency and stability.

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Related Articles

Related Products

Laboratory Roll-to-Roll Coater

A compact and modular high precision roll-to-roll slot-die coater that transforms the way thin functional films are printed and coated.

LR2RC500 Bundle

Probably the world’s most compact R2R slot-die coater. A compact, fully integrated R2R coater that fits on a workbench, in a fume hood or a glovebox.

Compact solar simulator (390–700 nm) with six tunable LEDs, Class A uniformity, and excellent temporal stability. Ideal for small to medium solar cells and controlled illumination experiments.