What is a Solar Simulator? A Complete Guide to Artificial Sunlight for Photovoltaic Testing (Organic Solar Cells, Perovskites, and More)

The energy radiating from the Sun, solar radiation, is a powerful form of electromagnetic radiation. However, when it reaches Earth, it does not arrive uniformly. It strikes the surface at different angles, and along the way, it interacts with the atmosphere, scattering off clouds, dust, and air molecules. This scattering and diffusion transform the original radiation into a wide spectrum of energy, producing different colors (wavelengths) and brightness levels (illuminance).

Depending on geometric location, season, time of day, and weather, the nature of sunlight can vary dramatically.

For solar cell research, this variability presents both a challenge and an opportunity. To truly evaluate how well a device performs, researchers need a way to reproduce sunlight in controlled and consistent conditions. But how do you bring the Sun into a laboratory? This is where solar simulators come in.

What is a Solar Simulator?

A solar simulator is essentially an artificial sun. It is designed to mimic the intensity and spectrum of natural sunlight. By doing so, it allows researchers to measure photovoltaic performance under standardized conditions, making results both comparable and reliable across different labs and experiments.

Understanding Solar Simulator Standards

Recreating sunlight is not as simple as shining a bright lamp. The simulated light must mimic the characteristics of real sunlight as it reaches Earth’s surface.

A key concept here is Air Mass (AM). This refers to the path length sunlight travels through Earth’s atmosphere, which depends on the angle of the Sun in the sky. For example:

AM0: Sunlight outside Earth’s atmosphere (used in space applications).

AM1.0: Sunlight when the Sun is directly overhead.

AM1.5G: The most common standard for ground testing. Here, sunlight passes through an atmosphere 1.5 times thicker than the vertical path, representing average mid-latitude conditions.

AM1.5D: Also called as direct standard spectrum,

The “G” in AM1.5G stands for Global, meaning that it includes both direct sunlight and diffuse light scattered by the atmosphere. In contrast, AM1.5D refers only to direct radiation. AM1.5G and AM1.5D share the same angle of the incoming light, but differs in considerations of reflections or scattering.

This standard defines both the spectrum and intensity of light used in testing, ensuring that results from different laboratories can be compared fairly.

How Solar Simulators Are Classified

Solar simulators are graded based on how well they match sunlight in three aspects:

Spectral Match: How closely the light reproduces real solar wavelengths.

Spatial uniformity: How evenly the light is distributed across the test area.

Temporal stability: How consistent the light remains over time.

Each is rated as Class A+, A, B, or C, with A+A+A + being the highest performance, meaning the simulator excels in all three aspects.

Color temperatures are also a way to describe the color of the light. But how can light have a temperature? This phenomenon is based on how the light with different energy levels is perceived. As the energy levels of light increase, it is perceived as cooler colors. Usually expressed in Kelvin(K), color temperature describes how “warm” (more reddish/yellow) or “cool” (more bluish/white) a light appears. A spectrophotometer can measure Color Temperatures. Here are some examples to understand better:

| Color Temperature | Source/Description |

|---|---|

| 1,700 K | Match flame, sodium lamps (street lights) |

| 1,850 K | Candle flame |

| 2000 K | Incandescent (Tungsten) lamps |

| 2,000 - 3,000 K | Sunrise/Sunset |

| 2,700 - 3, 000 K | Soft/Warm White Fluorescent/LED Lamps (suitable for homes) |

| 4000 K | Neutral/cool white Fluorescent/LED Lamps (office lamps), Moonlight |

| 5,500 - 6,000 K | Daylight |

What Light Sources Power a Solar Simulator?

The light source is the heart of a solar simulator. Its spectral output and physical characteristics shape how accurately the simulator matches real-world conditions. Different technologies are used depending on the application:

Xenon arc lamps: Among the most widely used. Xenon lamps generate a broad spectrum that closely resembles natural sunlight (5500-6500 K), especially in the visible range (380-750 nm). They can achieve high irradiance, which makes them suitable for large-area testing. However, they also produce excess infrared radiation, which can overheat samples unless filters are applied. Their lifespan is relatively short compared to other sources, and replacement costs can be high.

Metal halide lamps: Known for long lifetimes and stability, these lamps provide strong emission in the UV and visible regions. However, their spectrum deviates more noticeably from the solar standard in the infrared region, which may limit their accuracy for some applications.

Tungsten-halogen lamps: These are highly stable and inexpensive, but their spectrum is biased toward the infrared region, making them more suitable for testing materials sensitive to near-infrared light rather than full-spectrum solar cell evaluation.

LED-based simulators: A newer and rapidly growing option. By combining LEDs of different wavelengths, manufacturers can closely replicate the solar spectrum and even tune the output to mimic various sunlight conditions. LED simulators are compact, energy-efficient, and have long operational lifetimes. They also generate little heat, which is helpful for delicate samples. Their main limitation is that LEDs still struggle to fully cover the deep UV and far-infrared regions, though multi-LED arrays are improving this.

Each type has its strengths and limitations, and the choice depends on whether the goal is research, industrial testing, or large-scale evaluation.

| Light Source | Color Temp / Spectrum | Lifespan | Spectrum Adjustment |

|---|---|---|---|

| Xenon Arc | ~6000 K; good UV-vis; IR 800-1000 nm | 200-1,500 h | Filters only |

| Metal Halide | 3,000-20,000 K; visible spectrum | 6,000-15,000 h | Filters only |

| Tungsten-Halogen | ~3,400 K; IR-heavy | Varies by usage | Filters only |

| LED-Based | 3,000-10,000 K (tunable); 350-1100 nm (tunable); high match | 25,000-50,000 h | Individual LED Adjustment |

| Light Source | Pros | Cons | Bulb Cost |

|---|---|---|---|

| Xenon Arc | High irradiance; good spectral match | High cost/maintenance; Explosion Risk; IR emission; short life | ~$500-$3,000 |

| Metal Halide | Stable; efficient; safer than xenon | Limited IR/UV; light spreads; aging issues | ~$30-600 |

| Tungsten-Halogen | Inexpensive; effective IR source | Poor visible/UV match; best as supplemental light | ~$50-$7,000 |

| LED-Based | Energy-saving; tunable; low maintenance | Limited UV/IR; higher upfront cost; cooling required | ~$150-3,000 |

When comparing light sources, it is also important to consider the spectral mismatch. A lamp having the right color temperature or appears like sun does not necessarily mean every photovoltaic device will respond. This response depends on the respective absorption spectrum, e.g. silicon solar cells have strong absorption at near-infrared region, so a simulator with excess IR such as Tungsten-Halogen based ones can overestimate their efficiency. On the other hand, organic and perovskite solar cells rely more on the visible and UV regions, so a simulator lacking UV may underestimate their performance.

This mismatch can also affect comparisons across laboratories. For example, two labs using different sources might report slightly different efficiencies for the same device. That’s why many simulators are calibrated with filters and reference cells to correct for spectral mismatch. Keeping this factor in mind ensures that test results are fair, accurate, and comparable across different PV technologies and testing setups.

Application Areas for Solar Simulators

Solar simulators are used across a wide range of applications, not just in photovoltaics. Their ability to reproduce sunlight under controlled conditions makes them powerful tools for testing, research, and product development. Some key fields include:

Energy Science: Perhaps the most well-known application. Solar simulators are indispensable for testing the performance of solar cells, as well as exploring next-generation energy technologies like water splitting.

Material Science: New materials, plastics, and coatings are often exposed to simulated sunlight to study durability, weathering, and photocatalytic properties. This is critical in developing advanced materials for electronics, sensors, and energy devices.

Biotechnology & Medical Research: Controlled sunlight exposure is used in studies ranging from skin cancer research and sunscreen development to broader photobiology investigations. Accurate simulators ensure that biological effects can be studied in repeatable conditions.

Environmental Engineering: Solar simulators are applied in testing photodegradation, photo-oxidation, and pollution reduction processes. For example, they help researchers evaluate how contaminants break down under sunlight or how water treatment systems perform.

These applications show how solar simulators extend far beyond energy, supporting innovation in biotechnology, medicine, materials, and environmental solutions.

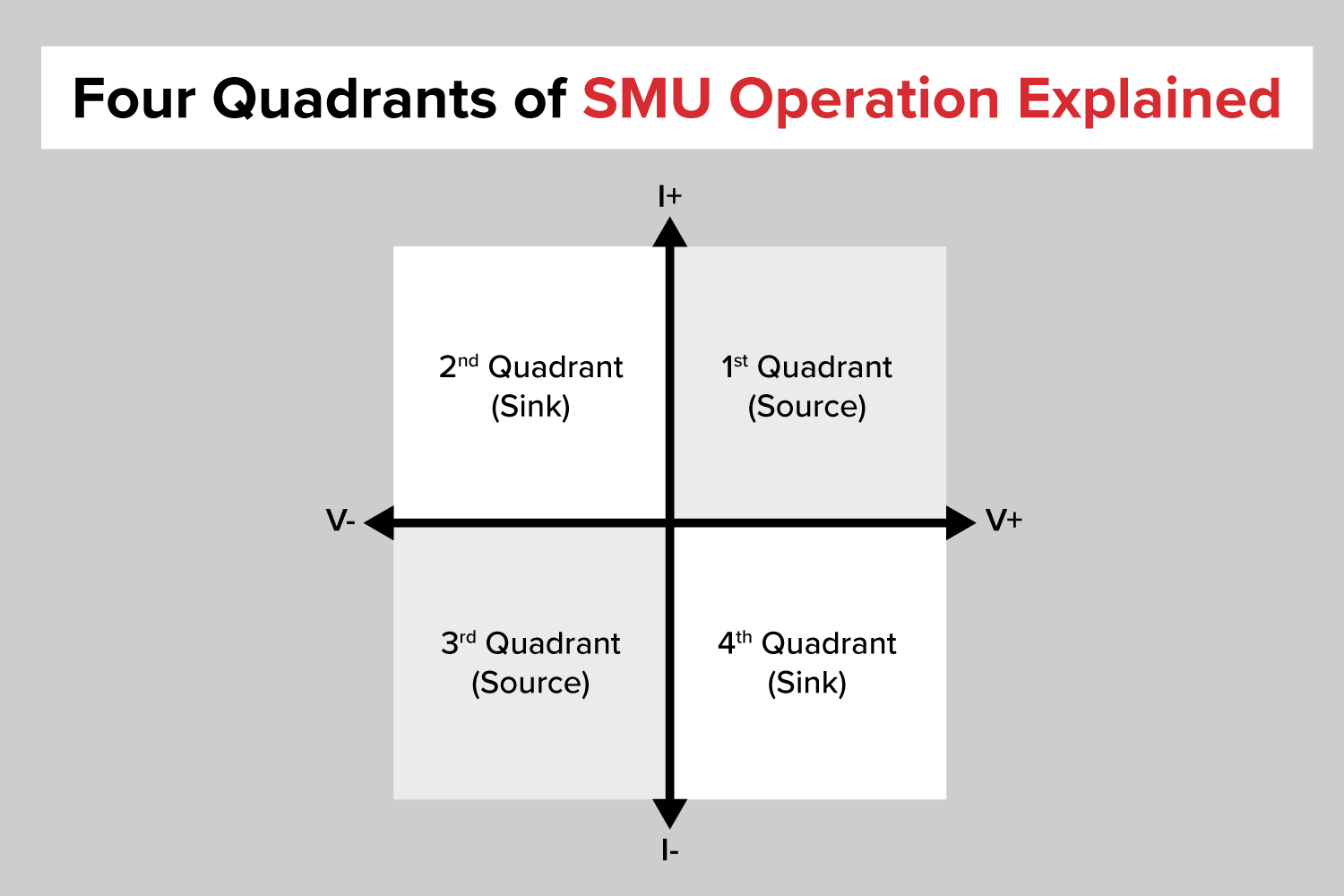

Using a solar simulator and SMU to test solar cells

How to Choose a Solar Simulator?

Choosing a solar simulator starts with knowing exactly what you need it for. Different applications, whether solar cells, medical research, material testing, or indoor photovoltaics, have very different light requirements. The best way to decide is to ask the right questions:

What sunlight conditions am I trying to simulate? (e.g., AM1.5G for terrestrial solar, AM0 for space, or specific indoor light sources such as LED or fluorescent).

What size is my target sample? (a single small device, or a full solar module or large-area material sample).

How sensitive is my device to certain wavelengths? (do you need extra UV for skin research, or accurate IR coverage for materials testing?).

How long will the test run? (short flash tests for industrial production, or stable long-term illumination for research and degradation studies).

What is my budget and maintenance tolerance? (LED-based simulators may have higher upfront costs but lower maintenance, while xenon arc lamps require more frequent replacements).

Do I need tunability? (being able to adjust the spectrum or intensity is valuable for advanced R&D, less critical in routine quality control).

Answering these will help to align the choice of a simulator based on the need, application, and resources.

Conclusion

Solar simulators allowing us to test, compare, and improve technologies without relying on daylight. Because sunlight itself is so dynamic and variable, simulators provide the stability and control needed to translate lab results into real-world performance. Whether the goal is advancing renewable energy, developing new medical treatments, or ensuring the durability of next-generation materials, choosing the right solar simulator is crucial. By matching light source, spectrum, and testing conditions to the specific application, researchers and industry professionals can be confident that their results are accurate, repeatable, and relevant to real-world scenarios.

About the Author

Ümran Işıl Biçer is a Marie Curie PhD fellow at infinityPV, contributing to the Marie Skłodowska-Curie EIFFEL project. She received her bachelor’s degree from Middle East Technical University in Turkey and completed her master’s through the Erasmus Mundus MaMaSELF program, studying at Ludwig Maximilian University of Munich and the University of Montpellier, with her thesis conducted at the University of Helsinki. She is pursuing a PhD in the development of non-fullerene acceptors for organic solar cells, focusing on scalable roll-to-roll printing methods to improve solar cell efficiency and stability.

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Related Articles

Related Products

Laboratory Roll-to-Roll Coater

A compact and modular high precision roll-to-roll slot-die coater that transforms the way thin functional films are printed and coated.

LR2RC500 Bundle

Probably the world’s most compact R2R slot-die coater. A compact, fully integrated R2R coater that fits on a workbench, in a fume hood or a glovebox.

Compact solar simulator (390–700 nm) with six tunable LEDs, Class A uniformity, and excellent temporal stability. Ideal for small to medium solar cells and controlled illumination experiments.