Roll-to-Roll Slot-Die Coating: Full-Width, Lane, and Intermittent Coating Techniques Explained

The Importance of Patterned Coatings

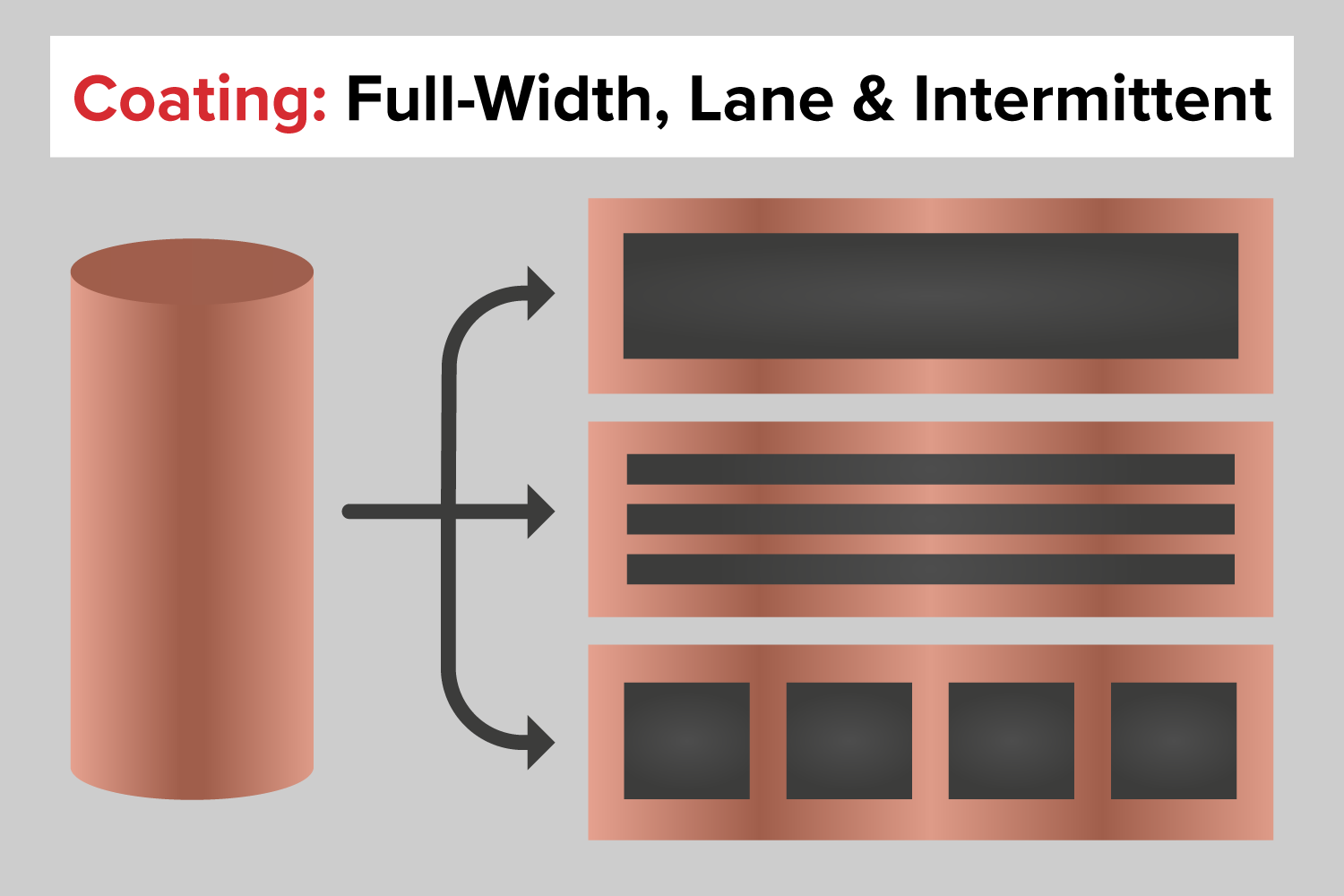

Roll-to-roll slot-die coating is a key process to high-volume thin film manufacturing. While traditional full-width coatings are widely used, many advanced applications now demand patterned deposition that reduces material costs, enables functional segmentation, and supports the production of next-generation devices. Two important approaches for achieving patterned coatings are lane coating and intermittent (patch) coating. Each brings distinct engineering challenges and requires specific solutions.

What is Roll-to-Roll Slot-Die Coating?

Slot-die coating is a pre-metered technique in which a liquid is pumped through a narrow slot in the slot-die and deposited directly onto a moving substrate. When integrated into roll-to-roll processing, this approach enables continuous coating of flexible substrates such as polymer films, metal foils, and paper.

The method provides excellent thickness control and coating uniformity. It is compatible with a wide range of functional fluids, including conductive inks, adhesives, and barrier materials. Because it scales efficiently from research to industrial production, roll-to-roll slot-die coating is widely used in the manufacturing of batteries, solar cells, medical devices, displays, and more.

Full-Width Coating: The Baseline Process

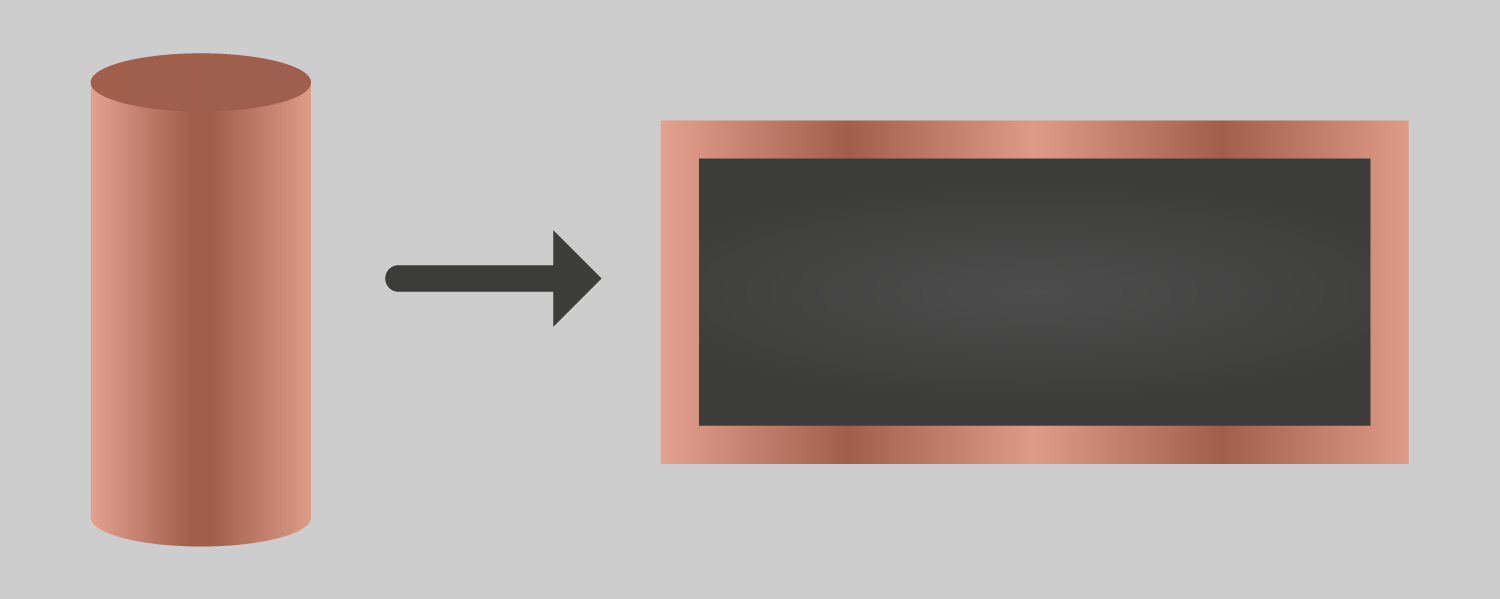

Full-width coating is the most common form of slot-die coating and serves as the foundation for roll-to-roll thin film production. In this approach, the coating material is distributed evenly across the entire width of the substrate, creating a continuous and uniform film.

The strength of full-width coating lies in its ability to deliver excellent thickness control, scalability, and reproducibility. It is widely used in industries such as packaging, barrier films, photovoltaics, and flexible electronics. Because the fluid is pre-metered and evenly delivered across the manifold, the process minimizes waste and produces highly uniform coatings, even at high web speeds.

However, the method applies material indiscriminately across the entire substrate. In applications where functional layers are required only in defined areas, or where costly materials must be conserved, full-width coating can be inefficient. These limitations have driven the development of patterned approaches such as lane coating and intermittent (patch) coating.

Lane Coating: Engineering Flow for Defined Coating Zones

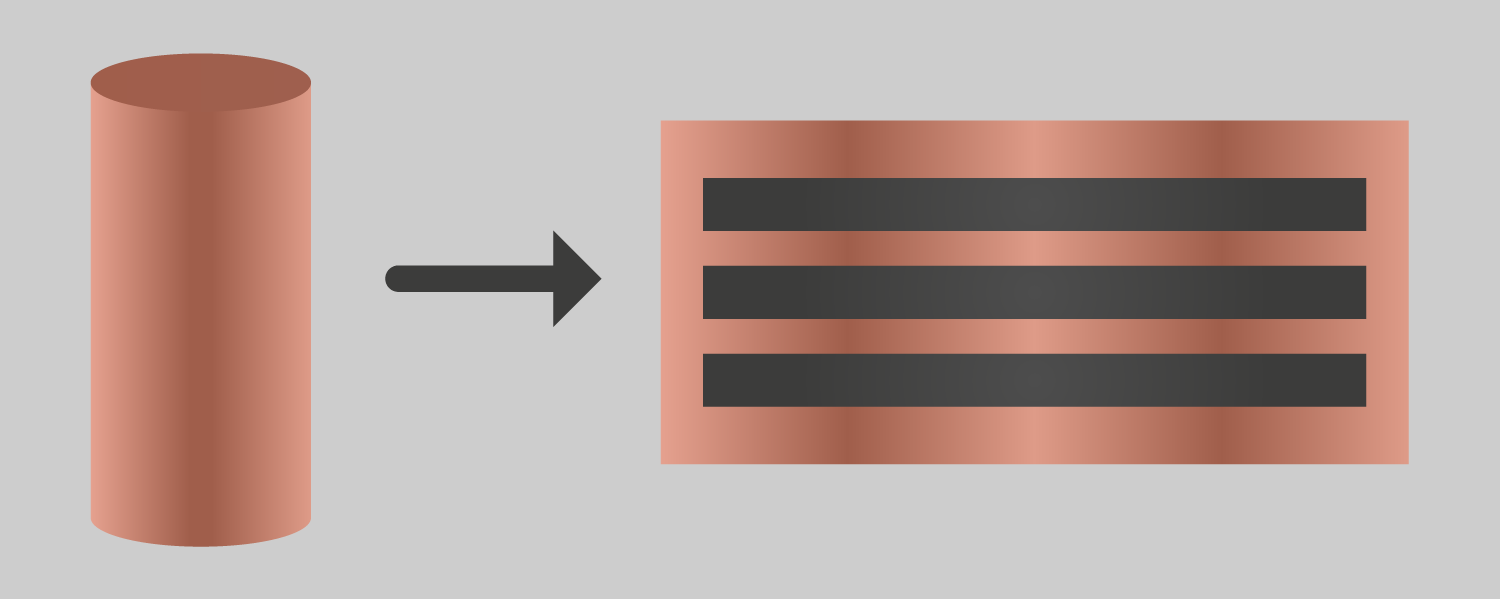

Lane coating is a technique where the coating material is deposited in longitudinal stripes or "lanes" along the substrate, separated by uncoated regions. This is essential for applications such as solar cells, battery electrode manufacturing, MedTech and specialized adhesive tapes.

The design of the slot die is crucial for lane coating. Uniform distribution of the coating fluid across the entire manifold width is essential, even when only specific sections are used for coating. Specialized shims or inserts within the die are designed to block flow in the desired uncoated areas. In fixed-lip dies, shims with "finger" geometries extend from the manifold to the die exit, preventing flow. The design must account for pressure drop and ensure consistent flow rates within the active lanes. Flexible-lip dies use deckle systems, clamped against the die face, to block flow. Adjustable screws control lip opening and ensure even pressure distribution. Precise correlation between screw spacing and deckle dimensions is critical. For narrow lane geometries, serrated lips, where the coating and non-coating regions are machined directly into the lip, offer high precision but require careful upfront planning as it is a permanent feature.

While internal die geometry governs the initial flow distribution, external flow dynamics significantly impact coating quality. At the edge of each lane, surface tension creates a meniscus. Understanding the fluid's surface tension, substrate surface energy, and contact angle is critical to preventing edge beading or striations. Air entrainment, especially at higher coating speeds, can also be a concern.

Intermittent (Patch) Coating: Precision Start-Stop Control

Intermittent coating (also called patch coating) deposits discrete areas of coating material onto the substrate. Unlike continuous coating, which covers the entire web, intermittent coating selectively applies material in defined regions. This technique is employed when: material cost reduction is paramount (especially with high-value materials); functional segmentation is needed (creating distinct functional zones); selective exposure is desired; direct processing is required (eliminating post-processing steps); substrate utilization is optimized; and sustainability considerations are important.

Start-Stop Challenges

Unlike continuous coating, which presents challenges related to maintaining consistent thickness and uniformity across the entire web, intermittent coating introduces complexities associated with the frequent start-stop cycles. The transient phases of starting and stopping the coating process are particularly critical, with defects like "head" (excess material at the start) or "tail" (streaking at the end) are common. Fast-acting valves are essential to minimize the transition time between flow and no-flow states. The valve's response time must be carefully synchronized with the substrate speed. Precise pressure regulation is required to maintain a consistent flow rate during the active coating phase, and minimizing the dead volume between the valve and the die is crucial to prevent drips or inconsistencies during shutoff.

The distance between the coating head and substrate influences the formation of the coating bead; therefore, precise positioning is required. As the liquid approaches the substrate, vapor molecules adsorb onto the surface, also affecting the coating process. The fluid's rheological properties (viscosity, elasticity, shear-thinning behavior) significantly influence the coating process, making it critical to understanding these properties for selecting appropriate operating parameters.

Conclusion: Toward High-Precision R2R Manufacturing

Roll-to-roll slot-die coating provides a scalable and cost-effective method for producing thin films. Although full-width coating remains a common approach, patterned methods such as lane coating and intermittent coating are expanding the range of applications. While full-width coating is common, lane and intermittent coating techniques enable advanced applications requiring precise material placement and patterned deposition. Lane coating relies on carefully engineered die geometries and flow control to create defined coating zones, while intermittent coating focuses on precise start-stop control to deposit discrete patches of material. Achieving high-quality results with both methods demands a comprehensive approach that integrates advanced die design, precise process control, and a thorough understanding of fluid dynamics and rheology.

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.