What is Battery Electrode Coating?

Battery technology plays a crucial role in powering modern life, from smartphones and laptops to electric vehicles and renewable energy storage systems. At the heart of every battery are its electrodes, whose performance and reliability directly affect the battery’s efficiency, lifespan, and safety. One of the key steps in manufacturing these electrodes is coating, a process that ensures the active materials are evenly distributed and firmly attached to the current collector. In this post, we will explore what battery electrode coating is, the different coating techniques, and the step-by-step process of preparing electrodes, with a focus on lithium-ion batteries as an example.

Batteries come in many sizes and shapes, are employed in a myriad of applications and are made from a variety of materials. Some of the most common are

Lithium-ion (Li-ion) batteries: Commonly used in consumer electronics and electric vehicles.

Lead-acid batteries: Utilized in automotive batteries.

Nickel-Cadmium (NiCd) and Nickel-Metal Hydride (NiMH) batteries: Found in a wide range of applications, including power tools and hybrid vehicles.

Solid-state batteries: Emerging technologies focusing on higher energy density and safety profiles.

Coating Methods

A critical component in all batteries are their electrodes, and depending on the type of battery, these can be manufactured in various ways, often involving techniques such as extrusion, casting, electrospinning, chemical vapor deposition, vacuum deposition, knife coating, doctor blade coating, tape casting, slurry coating and slot-die coating.

Knife Coating

Among these, the five latter techniques involve coating but four of them are basically different names for the same process* where a knife (or blade) is used to spread a fluid coating material uniformly onto a substrate. The knife is set at a specific angle and height, determining the thickness of the coating. For the sake simplicity “Knife coating” will be used as a common term in the rest of this text.

The difference mainly come from their areas of application. The naming “Knife coating” and “doctor blade coating” are typically used when creating very thin films, “Tape casting” or “Green tape casting” has its roots in the preparation of films from ceramic slurries whereas “Slurry coating” is a more general term for preparation of thin films from a slurry.

Slot-die Coating

Slot-die coating differs from the other coating techniques by allowing complete control of the layer thickness. Where the layer thickness in knife coating is a complex result of knife hight and angle combined with ink viscosity, sheer and ink thixotropy, the wet layer in slot-die coating is a direct result of ink being pumped at a specific pumping rate, though a slot with a specific width onto a substrate moving with a specific speed. In effect, the wet layer thickness, can easily and accurately be tuned “on the fly” simply by adjusting either the pumping rate or the speed at which the substrate is moving.

Preparing Battery Electrodes: Step by Step

Producing high-performance battery electrodes is a precise, multi-stage process. Each step plays a crucial role in ensuring the final electrode is uniform, mechanically stable, and electrochemically efficient. The preparation typically involves four main stages: slurry preparation, coating, drying or sintering, and post-processing such as calendaring and shaping.

Slurry preparation creates the functional mixture of active materials, conductive additives, binders, and solvents that will form the electrode.

Coating applies this slurry evenly onto the current collector using techniques like knife coating or slot-die coating.

Drying and sintering remove solvents and improve the electrode’s structural integrity, ensuring the layer is stable and defect-free.

Post-processing includes mechanical treatments like calendaring and shaping, which optimize thickness, density, and surface properties for use in a battery.

Together, these steps transform raw materials into a finished electrode ready for assembly, with each stage carefully controlled to maximize battery performance and reliability.

Slurry Preparation

The exact way of preparing the slurry for an electrode of course depends on the type of battery they are to be used for, and even for the same battery type there can be several ways of preparing the slurry. Although the slurry components can vary a lot, the general approach is often the same. In the following we will cover some of the Li-ion procedures/components as exemplification.

Components of the Electrode Slurry

The primary components of an electrode slurry consist of:

Active material: This is the primary component that undergoes oxidation/reduction during charge and discharge cycles.

Catode: For the cathode preparation, common materials used include lithium cobalt oxide (LiCoO₂), lithium iron phosphate (LiFePO₄), and lithium manganese oxide (LiMn₂O₄). The choice is influenced by factors such as capacity, voltage, stability, and cost

Anode: For the anode, the most common material is graphite. However, silicon-based materials, metal oxides, and lithium titanate (Li₄Ti₅O₁₂) are also being investigated to enhance energy capacity and reduce weight.

Conductive additives: These materials enhance the electrical conductivity of the electrode. Conductive additives should be chosen based on their conductivity and compatibility with the active material. Carbon black and graphene are commonly used conductive additives for Li-ion electrodes.

Binder: Binders hold the active materials and conductive additives together and adhere them to the current collector. The binder must provide both sufficient adhesion and mechanical stability. Polyvinylidene fluoride (PVDF) is a widely used binder in Li-ion battery electrodes. More environmentally friendly binders such as carboxymethylcellulose are also used.

Solvent: The solvent is used to dissolve the binder and create a workable slurry. Common solvents include N-methyl-2-pyrrolidone (NMP) and water, depending on the binder used.

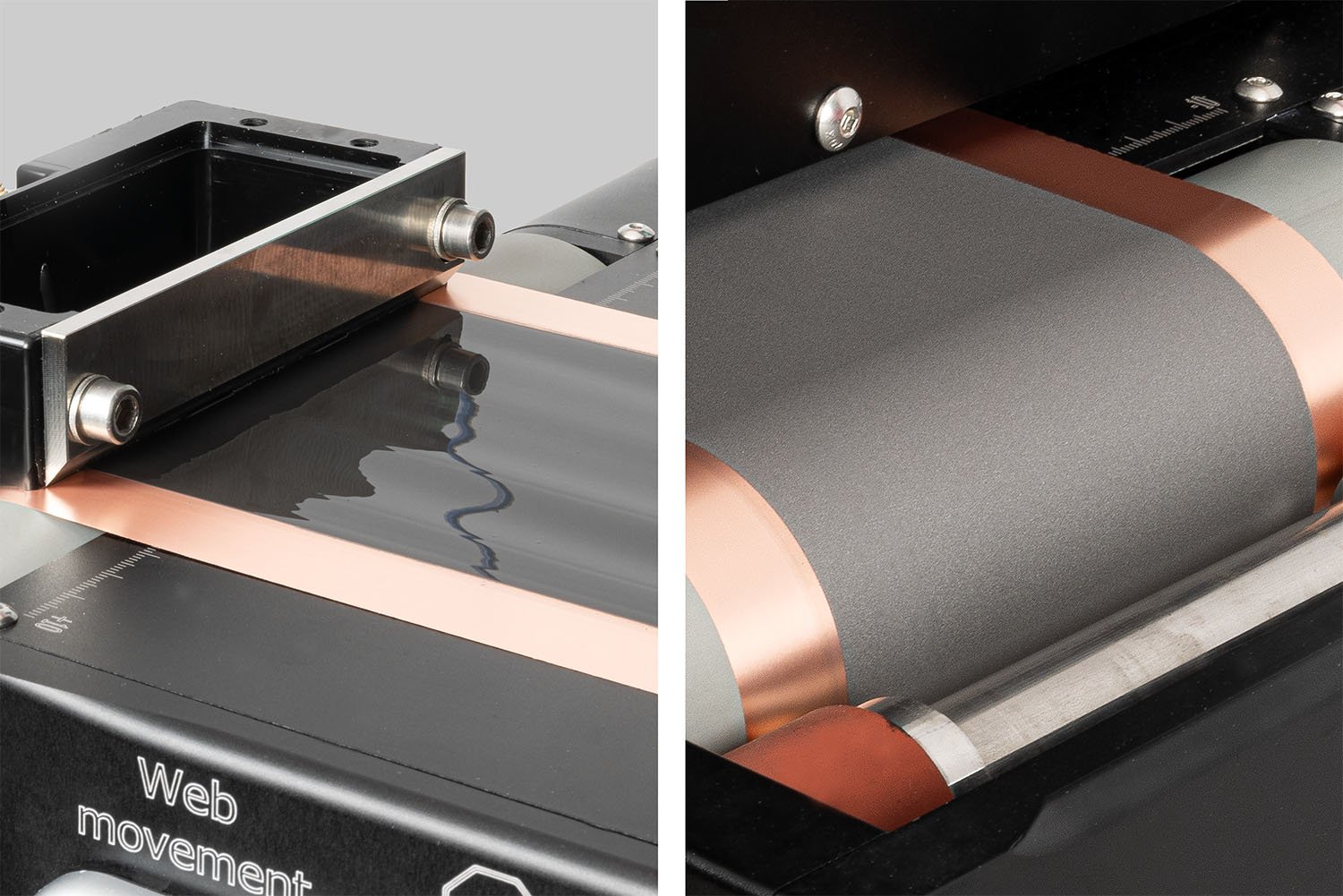

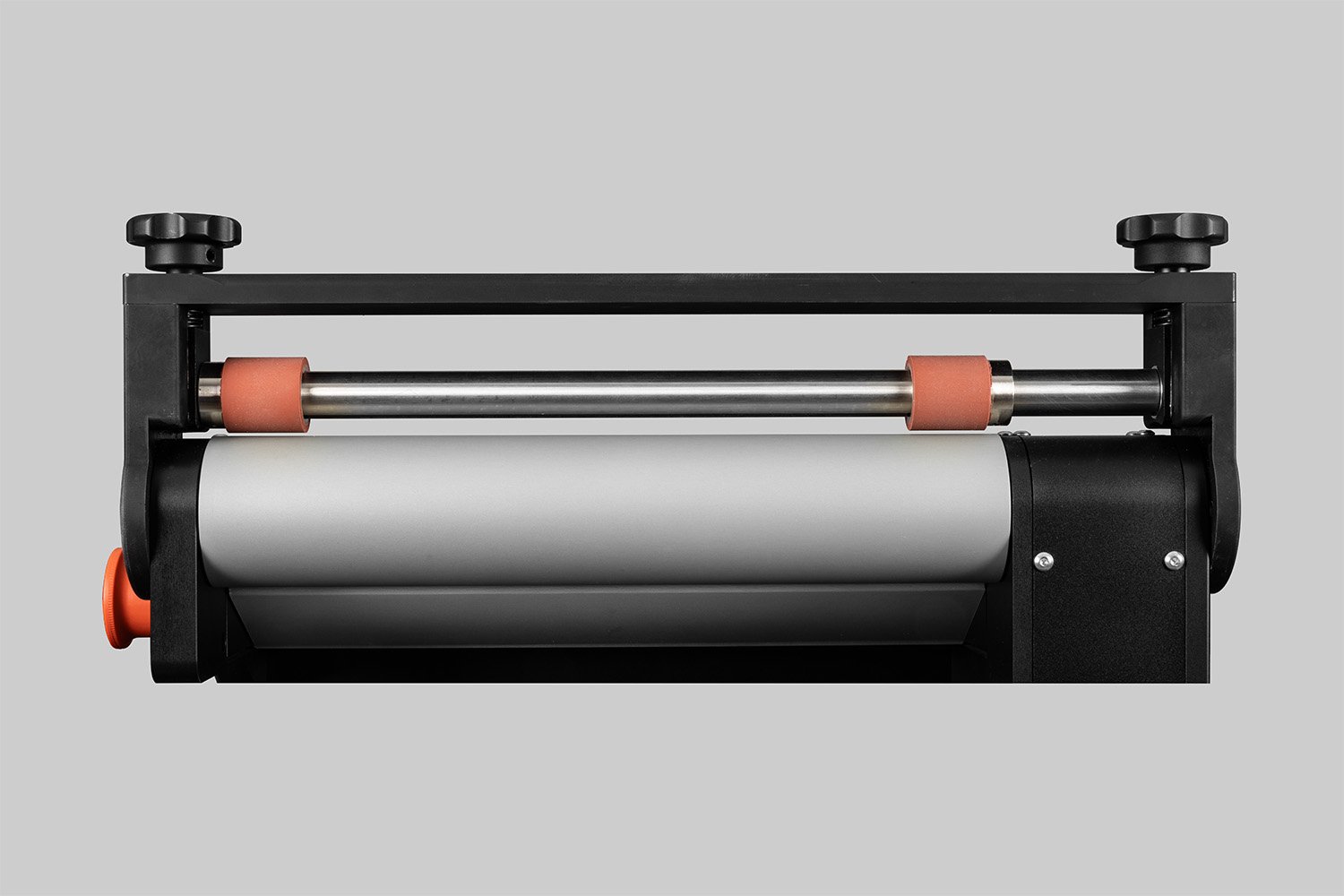

The Laboratory Roll-to-Roll Coater is the ideal coating machine for scaling up to roll-to-roll processing of battery electrode materials or for testing and optimizing battery electrode slurries.

Preparation Process:

The mixing process is critical for achieving a uniform slurry. The following steps are typically involved:

Dry mixing: Initially, the active material, conductive additives, and binder (in powder form) are mixed to ensure a homogeneous distribution of the components.

Wet mixing: The dry mixture is then combined with the solvent. This can be done using various mixing techniques, such as planetary mixers, high-shear mixers, or ball mills. The goal is to achieve a uniform dispersion of the active material and additives in the binder solution.

Viscosity control: The viscosity of the slurry can be a critical parameter that affects the coating process (especially for knife coating). It should be adjusted to ensure that the slurry can be easily applied to the current collector. This may involve adding more solvent or adjusting the mixing time.

Degasing: Air bubbles trapped in the slurry can lead to defects in the electrode. Degasing is performed to remove these bubbles, typically using a vacuum chamber and/or ultrasonic treatment. This step is essential for ensuring the integrity of the electrode during the drying and curing processes.

Coating of the Slurry

The coating step is typically carried out as described above using either knife coating or slot-die coating. Depending the need this can be carried out either on a sheet coater or a Roll-to-Roll (R2R) coater. The sheet coater handles sheets of substrates up to a given size, defined by the size of the machine outline, and allows for use of both flexible and rigid substrate. R2R coater handles rolls of substrate, the length of a coat only being limited by the length of the roll. Below is a summary of some of the characteristic of the two coaters. For more knowledge consult our guide about how to choose a slot-die coater.

| Roll-to-Roll | Sheet | |

|---|---|---|

| Substrate type | Flexible | Rigid and flexible |

| Coating size | cm² – m² | cm² – dm² |

| Drying (typical) | Heating from top/ all sides | Heating from the bottom |

| Additional post treatments | Many | Few |

| Upscaling potential | High | Low-Medium |

| Time to set up | Medium (only once per “run”) | Fast (every experiment) |

Drying

After coating, the electrodes must be dried to remove the solvent. This is typically done in an oven at controlled temperatures to ensure complete solvent evaporation without damaging the electrode structure. The drying process can significantly affect the electrode's microstructure and performance.

Following drying, a curing step may be necessary to enhance the adhesion of the binder and improve the mechanical properties of the electrode. This can involve heating the electrodes at elevated temperatures for a specified duration.

Post Processing

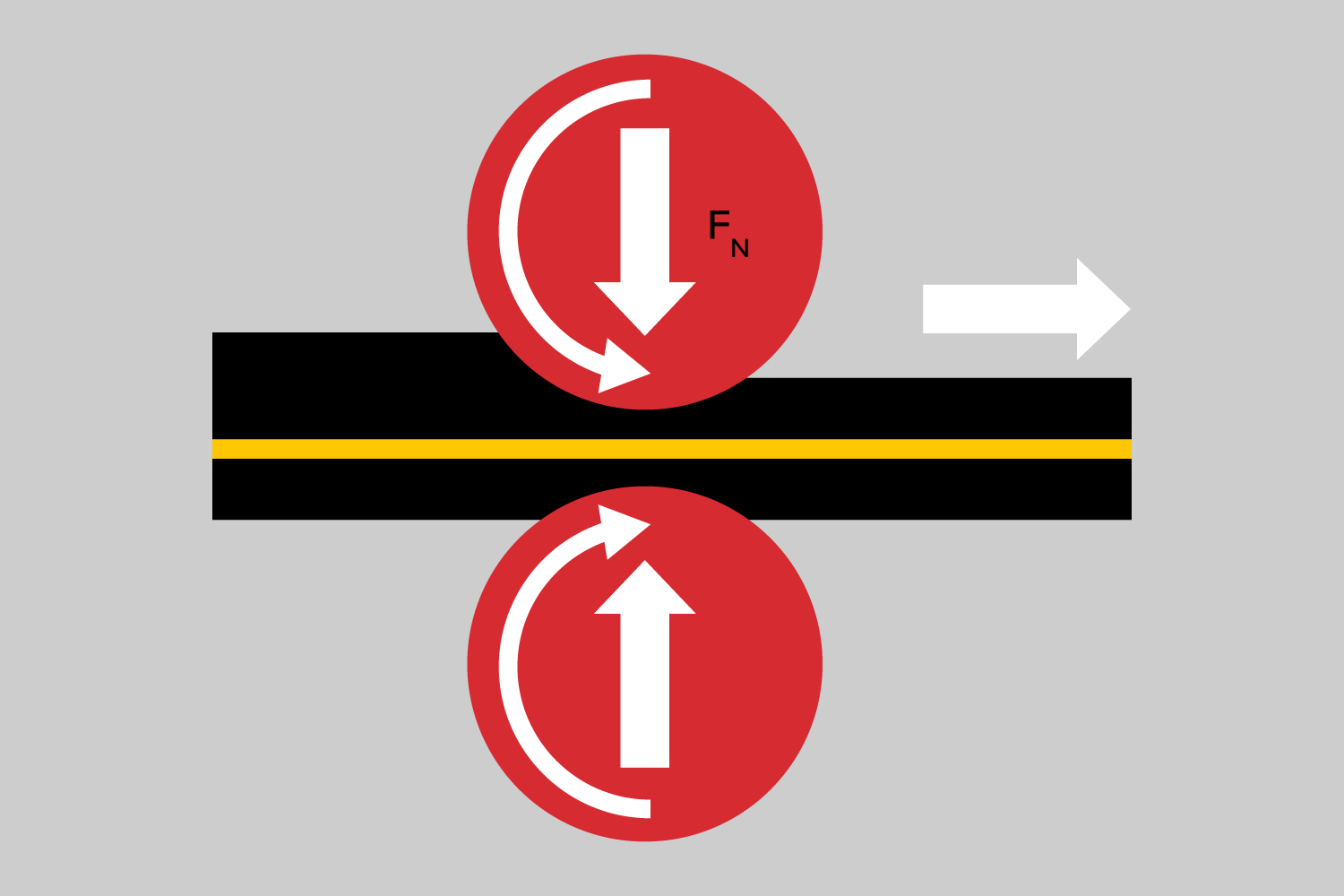

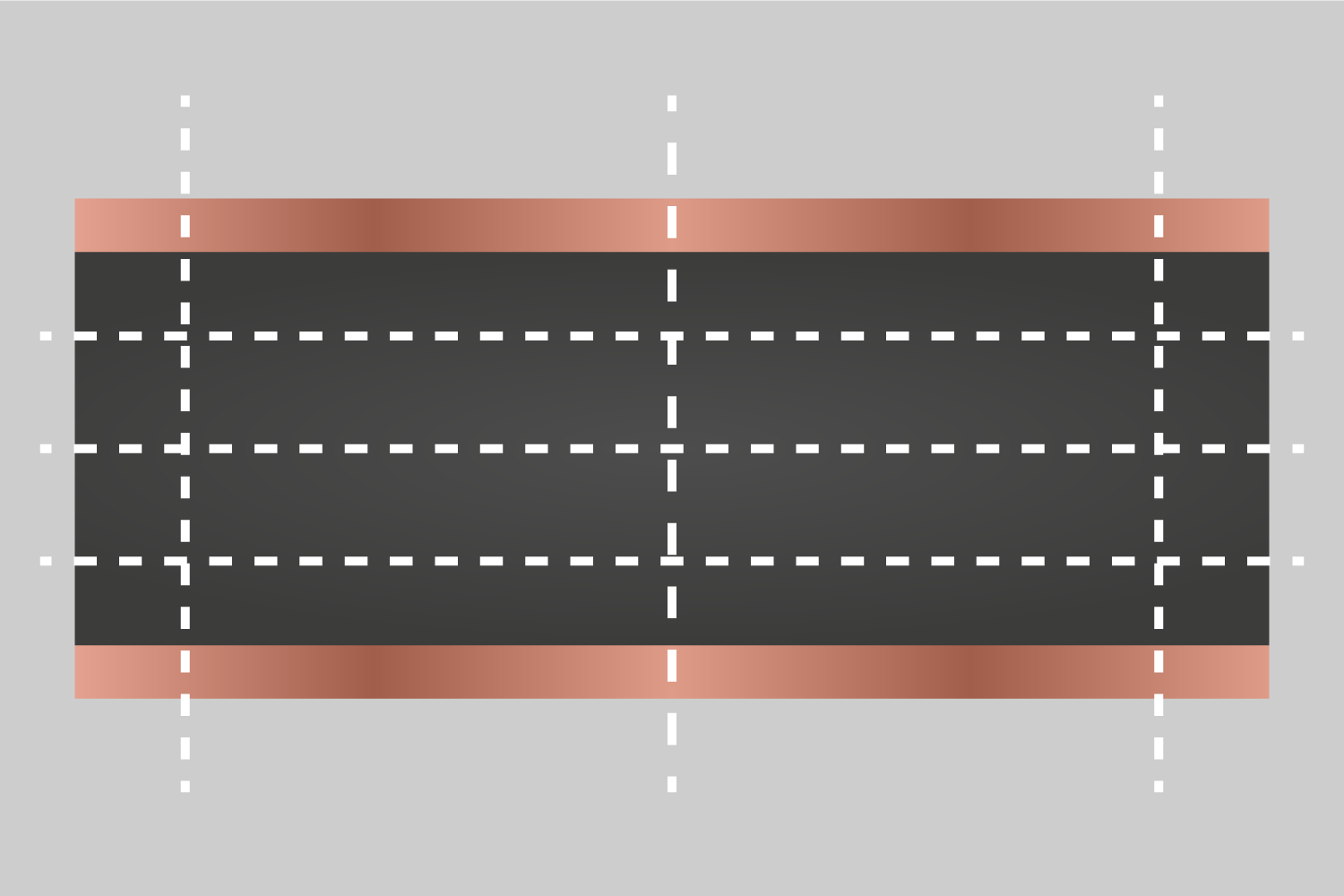

After finalising the drying step, calendering can be a critical manufacturing process in the production of coated battery electrodes. This technique involves passing the coated electrodes through a series of pressure rollers to achieve uniform thickness, density, and surface characteristics. The calendering process can significantly influence the mechanical and electrochemical properties of the electrodes, ultimately affecting the performance of the battery.

As a last step, the electrode typically needs to be cut/stamped/stencilled into a shape that can be used in a device.

Conclusion

Battery electrode coating may seem like a small part of the manufacturing process, but it has a major impact on battery performance, reliability, and scalability. From slurry preparation and uniform coating to drying, curing, and post-processing, each step is carefully designed to optimize the structure and electrochemical behavior of the electrodes. As battery technologies continue to advance, especially with the growth of electric vehicles and next-generation energy storage, innovations in electrode coating methods will remain a critical area of research and development. These improvements will help create batteries that are more efficient, durable, and sustainable.

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

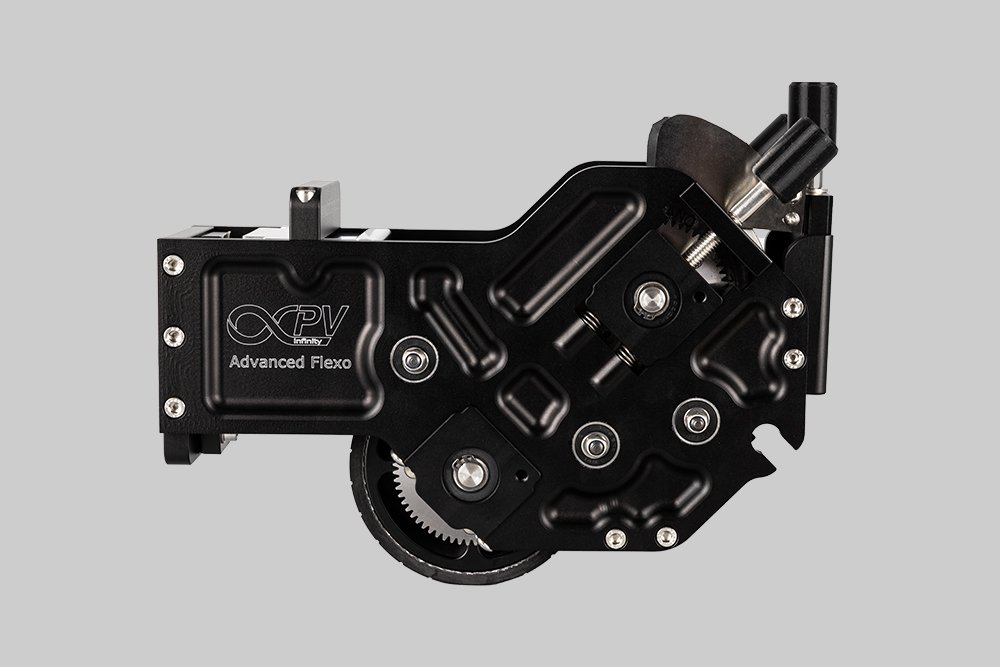

The SDC Battery Coater Pro is specifically designed for researchers dedicated to developing and optimizing battery materials. It facilitates a seamless transition from research to commercialization. View video.