Why Roll-to-Roll Coaters Are Ideal for Scalable Slot-die Coating, Thin-Film Research and Pilot Production

Modular Laboratory Roll-to-Roll Coaters for Flexible Research

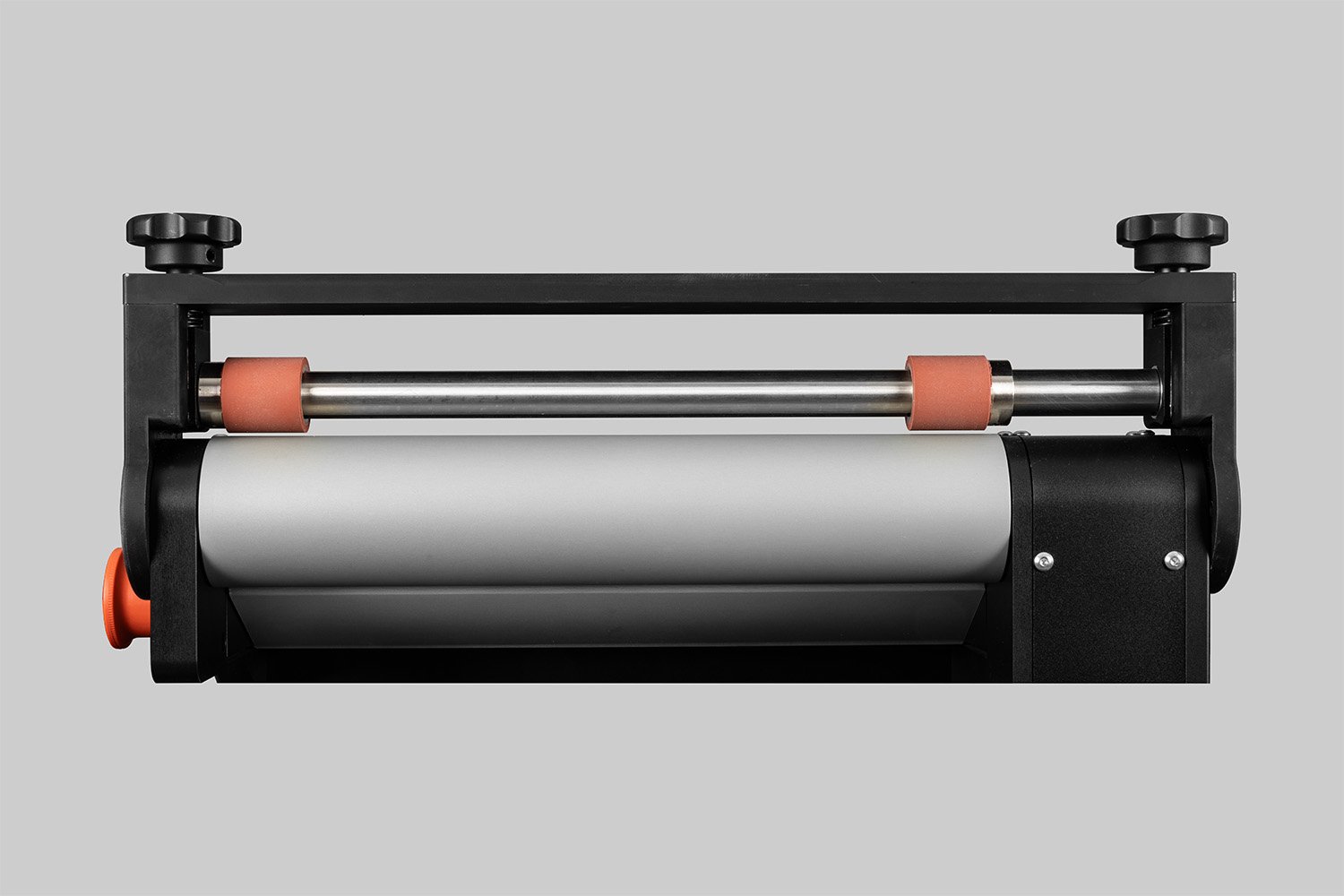

Laboratory Roll-to-Roll (R2R) Coaters with a modular design enable a high level of customization, with the option to add or modify functionality as research needs evolve. These systems make it possible to process hundreds of meters of foil using a compact footprint that fits into standard laboratories, gloveboxes, and fume hoods. By allowing tailored configurations from the outset—and upgrades over time—the modular approach helps reduce overall investment, downtime, and resource use.

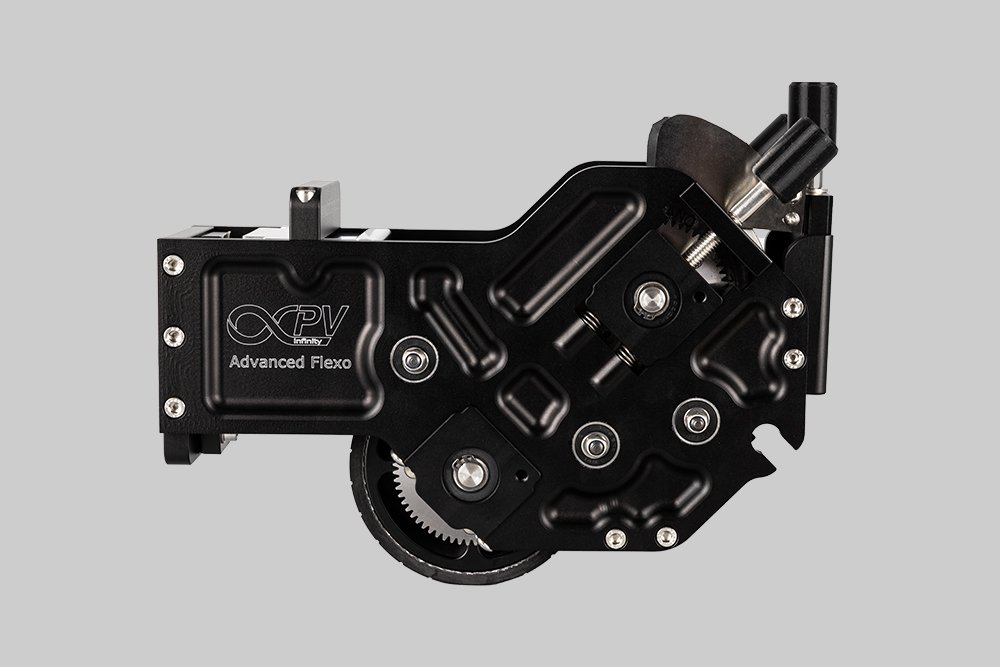

In this context, a modular design refers to systems built around interchangeable components. Each component performs a specific task and can be replaced with an alternative module to support different processes. This flexibility allows the same R2R platform to adapt to a wide range of experimental requirements without the need for a complete system replacement.

With a Laboratory Roll-to-Roll Coater, you can swap components as needed.

Broad Application Range and System Capabilities

Laboratory R2R Coaters are used in a wide variety of research fields, including:

They are well suited for both laboratory-scale experiments and pilot-scale development, supporting process exploration as well as early-stage scale-up.

Roll-to-roll coaters primarily scale with the width of the substrate, while the length of the coating is limited only by the length of the roll.

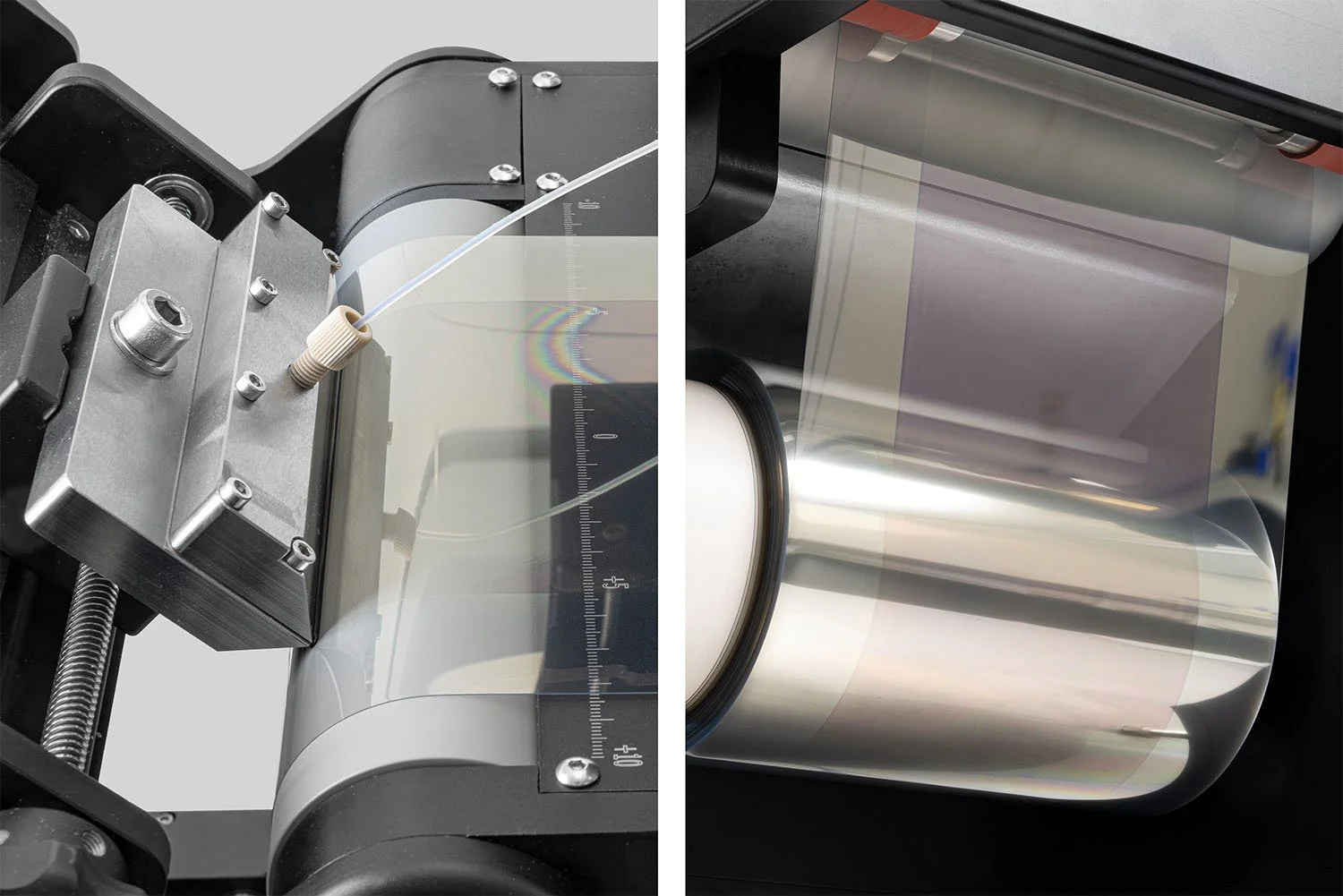

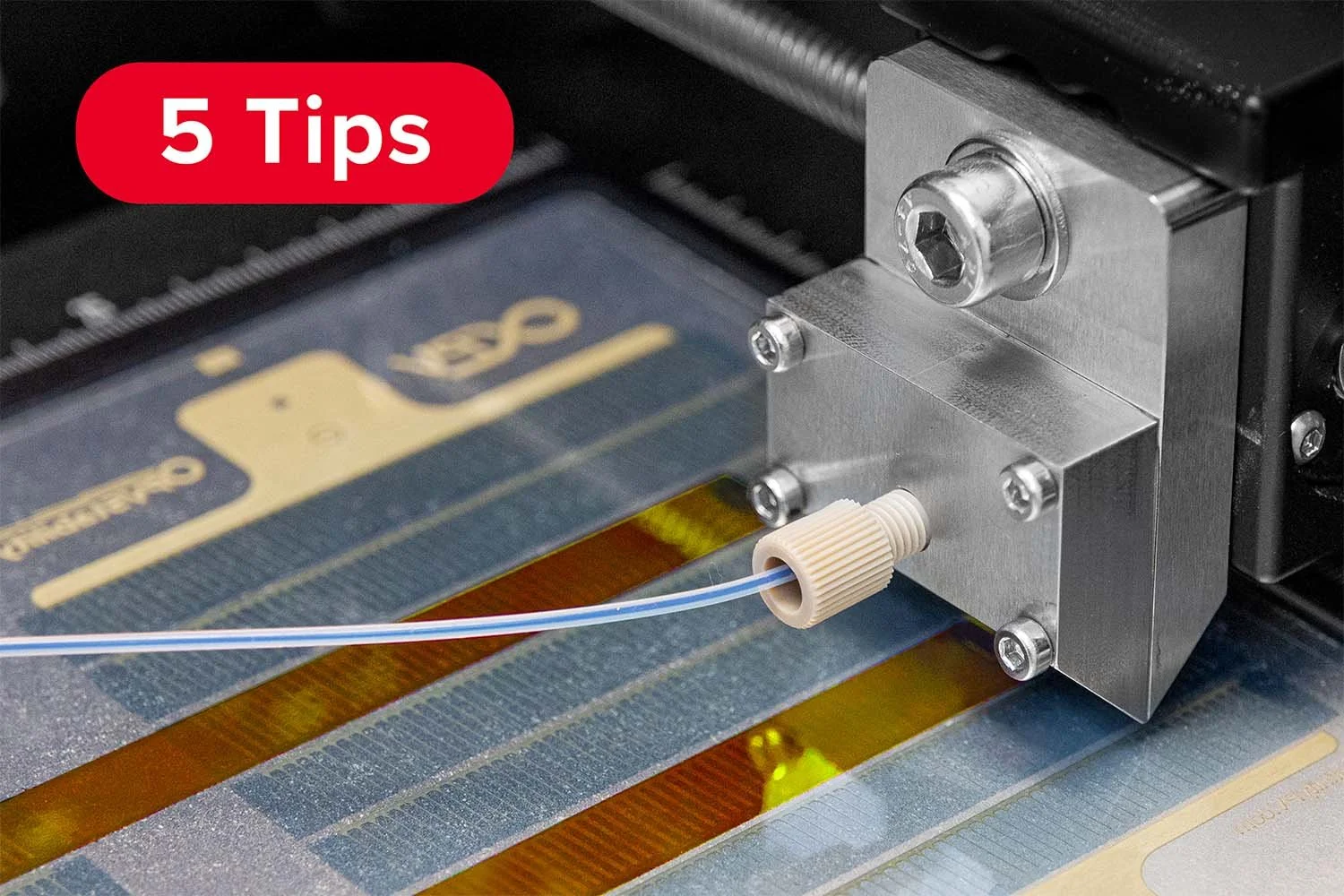

The systems are available in multiple lengths and widths, enabling integration into diverse laboratory environments. Their modular architecture supports a broad selection of technologies for coating, printing, drying, washing, and curing. Typical components include slot-die heads, air knives, slurry coaters, flexographic printers, laser scribers, laminators, and a range of pumps and ovens.

Optional surface treatments, such as plasma or corona treatment, can be integrated prior to coating. Larger systems may incorporate multiple coating stations for inline processing, and a Wet Processing Center can be added when washing or chemical treatment of the foil is required. Together, these options create a highly adaptable platform that can be reconfigured quickly to support new materials, processes, or research directions.

Plasma or corona treatment can be integrated prior to coating.

Configuring the System: From Essential Needs to Future Readiness

Designing a customized R2R system begins with defining the required machine size based on essential process needs. This involves determining the minimum number of modular components required to carry out the intended workflow. A simple process—such as coating followed by drying—may require only one modular unit, with the oven counted as the modular component and the coating setup typically integrated into the base system.

More advanced workflows may involve additional steps, such as lamination combined with UV curing after coating and drying. In such cases, two modular units may be sufficient if the processes are carried out sequentially. However, efficiency considerations often lead to inline processing, where all steps are completed in a single run. A fully inline configuration—combining coating, drying, lamination, and UV curing—requires additional modular units but significantly reduces handling time and increases throughput.

Future requirements should also be considered during the planning phase. Higher coating speeds, for example, may demand increased drying capacity, which in turn requires additional oven modules. Anticipating such developments when selecting the base system can avoid costly redesigns and limitations later on.

Controls, Accessories, and Day-to-Day Operation

Once the system size has been defined, configuration is completed by selecting the preferred control method—manual or PC-controlled—and choosing the appropriate accessories. These may include syringe pumps, air knives, precision micrometer adjustments, slitters, foil strippers, and specialized oven technologies.

System setup is designed to be fast and intuitive. Modular units are placed on the coater, the foil is threaded, and processing can begin immediately. Reconfiguration is equally efficient. Exchanging one module for another—for example, replacing an inert-gas oven with an IR oven—requires minimal downtime and no permanent system modifications.

Long-Term Value Through Retrofitting

A key benefit of the modular approach is the ability to retrofit the system as new process requirements emerge. Instead of investing in a completely new R2R coater, functionality can be expanded or modified by adding or replacing individual modules. This significantly reduces the initial investment, as only the modules required at present need to be purchased. At the same time, selecting a sufficiently sized base system remains essential to ensure compatibility with future expansions.

For those seeking a deeper understanding of the system’s versatility, a comprehensive animation is available that highlights key features and configuration possibilities.

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.