Wet Processing Center

Process foil with immersion, spraying, heating/cooling, agitation and electrochemical treatments in a fully enclosed, zero-emission system.

Precision Wet Processing for Roll-to-Roll Foil

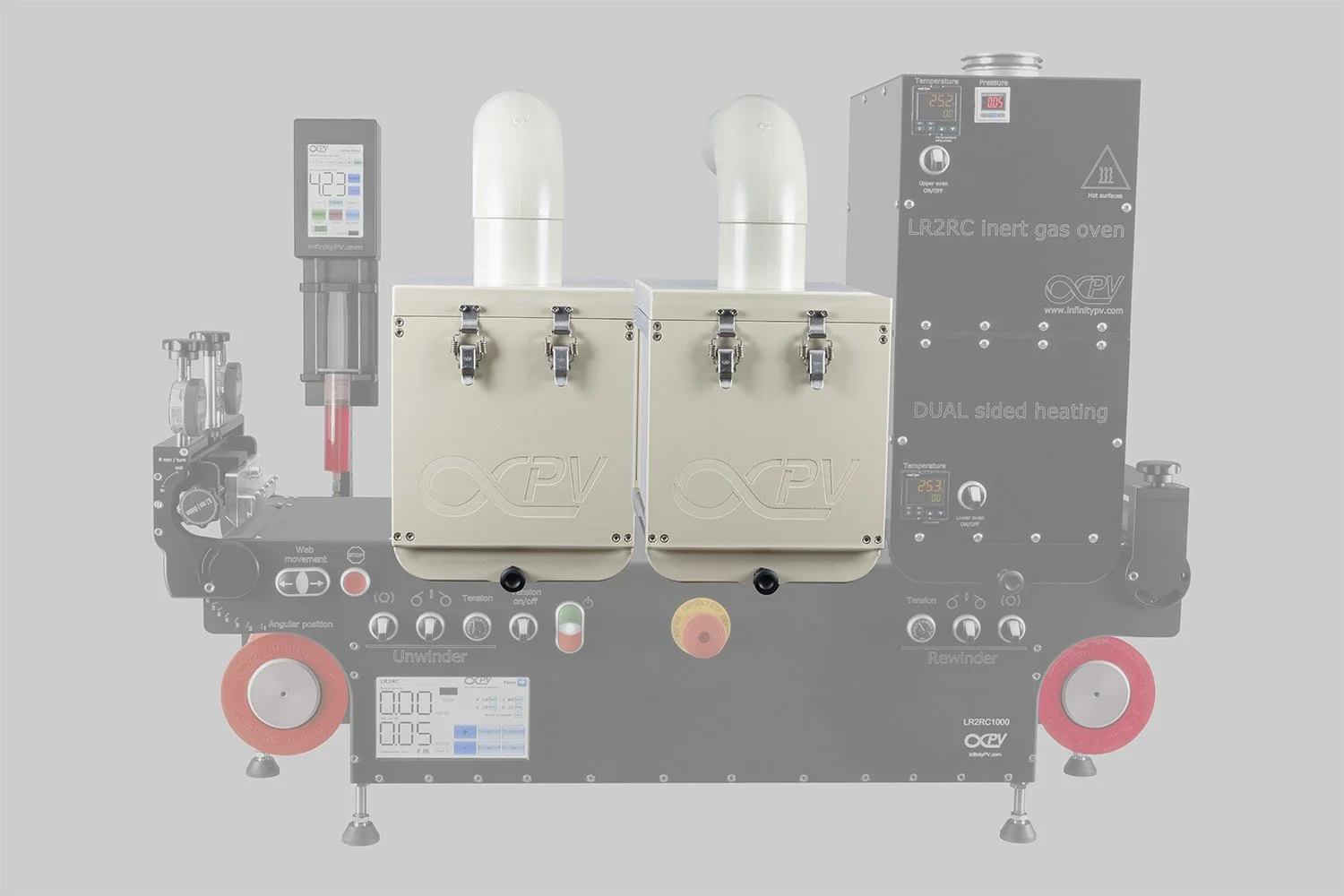

The Wet Processing Center is a component for the Laboratory Roll-to-Roll Coater that enables accurate roll-to-roll handling of foil in a fully enclosed, safe environment. Designed for research, prototyping, and pilot production, it supports immersion, spraying, and electrochemical treatments for thin-film technologies, printed electronics, solar cells, and other advanced materials.

Immersion and Spray Processes

The system allows full liquid immersion for etching, washing, coagulation, imbibition, and ion or solvent exchange. Spray treatments apply liquids across foil surfaces while washings are recovered or safely discarded, offering controlled and efficient processing.

Electrochemical Treatments

Built-in electrochemical functionality provides heating, cooling, and agitation, while foils can be electrically connected with counter electrodes for various surface treatments.

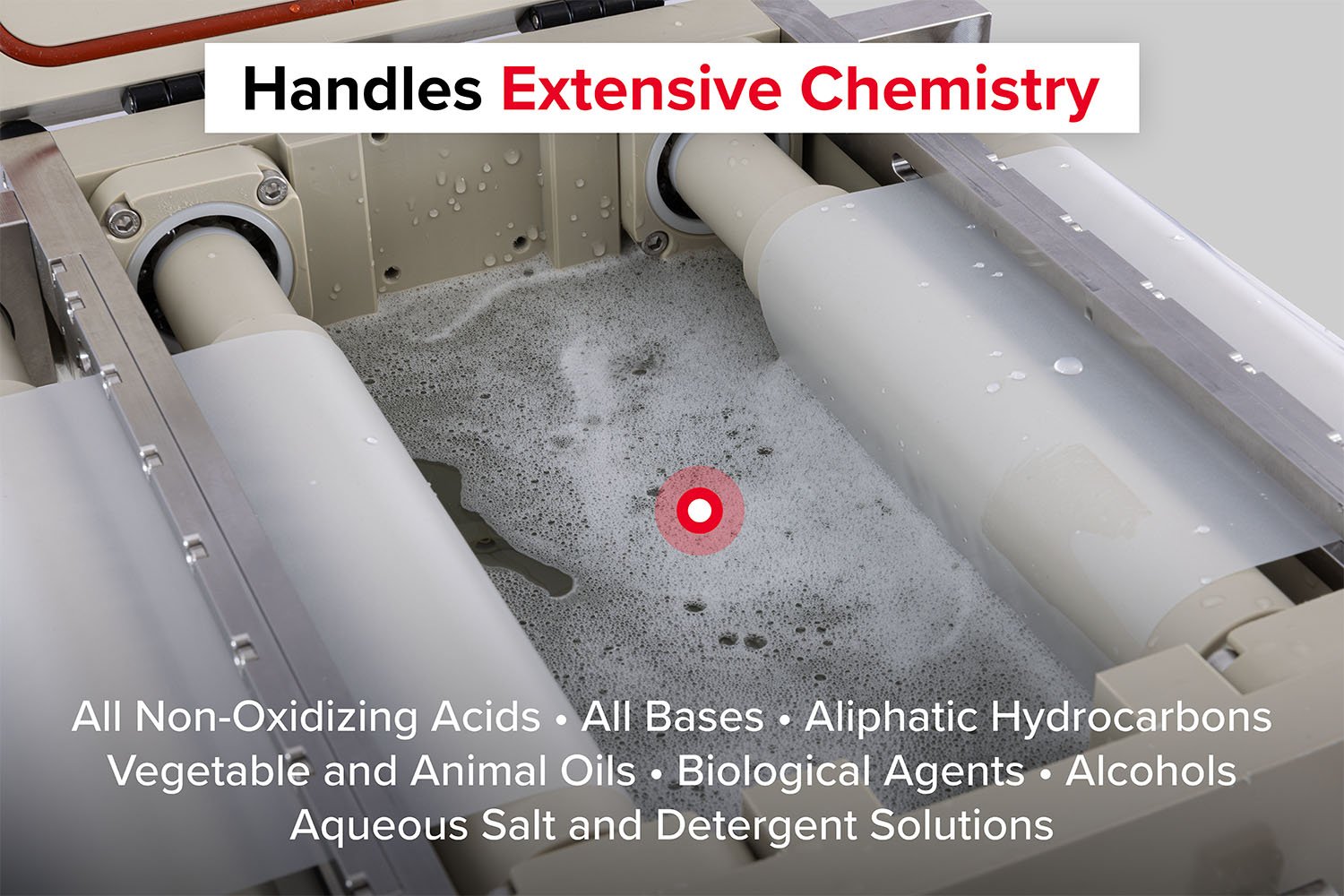

Handles Extensive Chemistry

All Non-Oxidizing Acids

All Bases

Glcohols

Gliphatic Hydrocarbons

Vegetable and Animal Oils

Biological Agents

Aqueous Salt and Detergent Solutions

Modular and Scalable Design

Processing tanks can be linked for sequential treatments such as etching, developing, stripping, and washing. Configurations include direct docking with the Laboratory Roll-to-Roll Coater (10 L) or stand-alone systems (50 L). Processing lengths range from centimeters to five meters, and a variety of rollers supports integration with ovens, coaters, knives, and laminators.

Safe, Clean, and Durable Operation

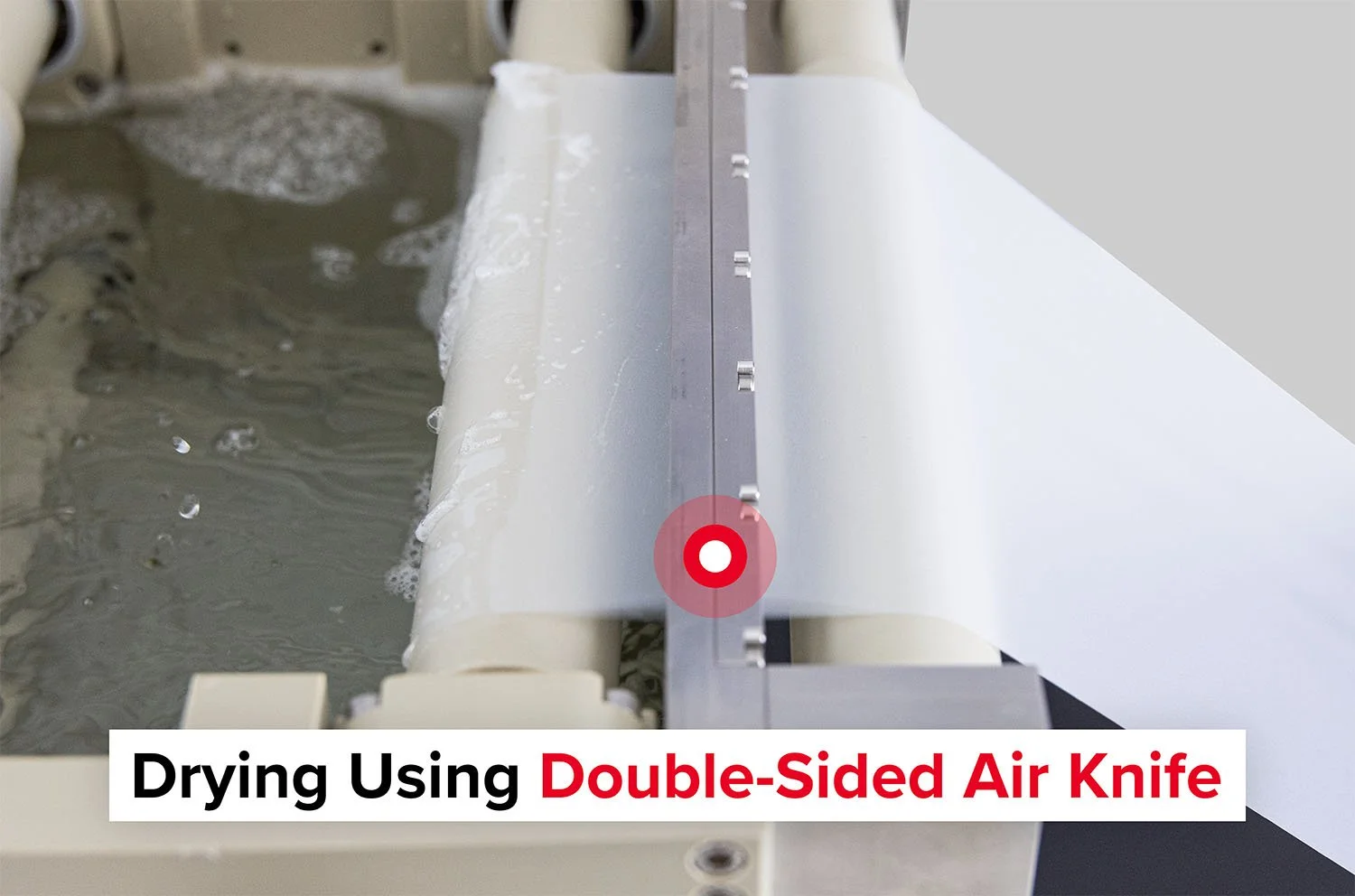

Closed-system operation ensures zero solvent or liquid emissions. Double-sided air knives enable rapid drying, and high-quality plastics, ceramics, and stainless steel (316L) ensure long-lasting chemical resistance.

Integration with the Laboratory Roll-to-Roll Coater

Designed to integrate seamlessly with the Laboratory Roll-to-Roll Coater, the Wet Processing Center provides a compact, versatile solution for lab and pilot-scale thin-film applications. Modular components allow customization for batteries, medtech, fuel cells, printed solar cells, sensors, and more, enabling optimized performance with flexibility and scalability.

Key Features

Immersion in liquid: Ideal for etching, washing, coagulation, imbibition, or the exchange of ions, solutes, and solvents.

Spray treatment: Apply liquids across foil surfaces while recovering or safely discarding the washings.

Electrochemical functionality: Heating, cooling, agitation, and electrical connection to the foil with counter electrodes for electrochemical surface processes.

Series connectivity: Multiple wet processing tanks can be linked for sequential treatments such as etching, developing, stripping, and washing.

Flexible configurations:

Direct docking on the Laboratory Roll-to-Roll Coater (10 L volume)

Stand-alone system (50 L volume)

Variable processing lengths: From a few centimeters up to 5 meters per tank.

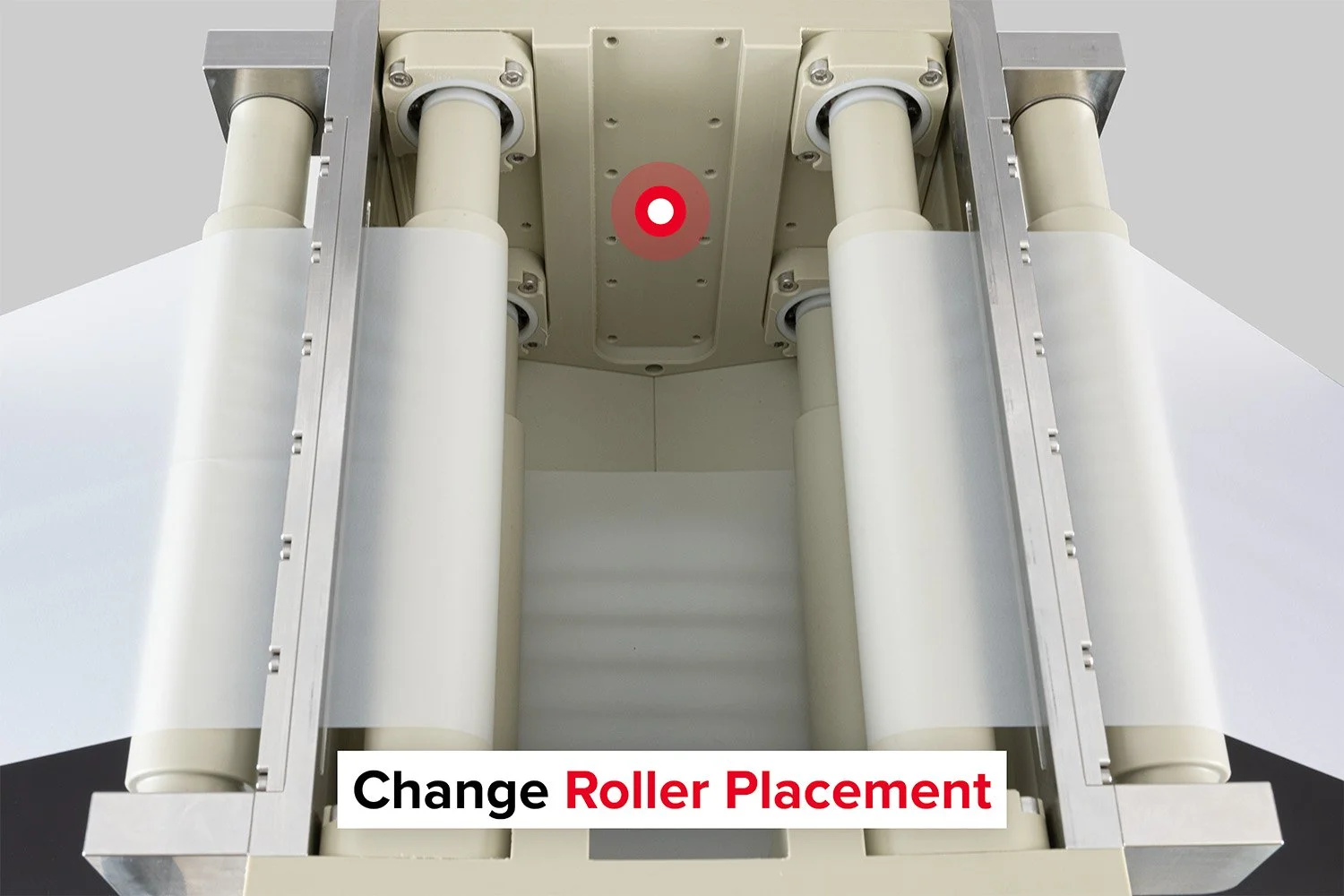

Roller variety: Extensive options for foil handling, including auxiliary rollers for integration with ovens, coaters, knives, and laminators.

Closed system operation: Zero emission of solvents or liquids, ensuring safe and clean processing.

Enhanced drying: Double-sided air knives at entry and exit for rapid solvent removal.

Durable construction: Manufactured from high-quality plastics, ceramics, and stainless steel (316L) for longevity and chemical resistance.

Wet Processing Center

Wet Processing Components

The essential part of the Wet Processing Center is the tank that holds the liquid, the rollers and all the auxiliary products such as stirring, cooling, heating, circulation, ventilation in a pseudo sealed container.

The Infeed-Outfeed Rollers can be designed as self-centering or straight and can be electrically connected to circuitry for electrochemistry or electrically insulating. The rollers feature 316L stainless steel bearing holders, equipped with either stainless steel or ceramic bearings.

In the Wet Processing Center, handling foil immersed in liquid requires that the rollers and their bearings are also submerged. Our chemically inert immersion rollers provide reliable and smooth foil transport while fully immersed, ensuring safe and efficient operation.

Blowing air or inert gas onto both sides of the foil, directed toward the Wet Processing Tank, effectively prevents emissions from escaping. This creates a pseudo-enclosed environment that is safe, contained, and adaptable for various processing needs.

The electric heating coil enables precise temperature elevation during wet processing, which is often critical to achieving optimal results. It is constructed with Teflon lines and stainless-steel heating elements, ensuring reliable performance, durability, and efficient heat transfer.

Wet processing of foil by immersion in liquids requires effective mixing and precise control of the intended contact time. Mechanical stirring is the most efficient method to achieve these objectives.

Enhance your thin-film drying process with the compact Dual-Sided Inert Gas Oven. Featuring precise PID temperature control and flexible gas flow options, it's ideal for fast, consistent drying in research and pilot runs.

We Are Ready to Help You

With decades of experience in printed electronics, our team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project.