Roll-to-Roll Wet Processing Solutions

What Is Roll-to-Roll (R2R) Wet Processing

Roll-to-roll (R2R) wet processing is a continuous manufacturing technique in which flexible substrates—such as films, foils, membranes, or textiles—are processed in roll form through a sequence of baths containing solutions and solvents. This approach enables chemical treatments to be applied efficiently and consistently, supporting high-volume production while enabling the development of advanced materials and functional products.

Integrated and Scalable Processing Capabilities

R2R wet processing can also be combined with complementary methods such as slot-die coating, expanding its processing capabilities and allowing manufacturers to tailor material properties and performance. By integrating multiple steps into a continuous workflow, R2R wet processing supports precise control, repeatability, and scalability across a wide range of industrial applications.

Applications and Key Advantages of R2R Wet Processing

R2R wet processing is commonly used for the following operations and offers several key advantages:

Cleaning and surface preparation – washing and rinsing to remove impurities and residual chemicals

Chemical and material treatments – chemical reactions, electrochemical deposition, coating applications, and functionalization to impart specific properties such as antimicrobial, hydrophilic, or hydrophobic behavior

Patterning and surface modification – etching and patterning to create defined structures or designs

High-efficiency production – continuous processing, integration of multiple operations, and uniform treatment for consistent quality

Cost and resource efficiency – reduced labor, material waste, and energy consumption

Versatility and scalability – adaptable across materials and industries, from pilot to full-scale manufacturing

To learn more about R2R wet processing capabilities or to explore purchasing wet processing equipment tailored to your application, read more about our wet processing solutions.

Wet Processing Equipment for Advanced Materials

We provide precise wet processing solutions for flexible substrates, enabling researchers and manufacturers to develop and optimize advanced coatings, functional films, and high-performance materials. Our roll-to-roll and slot-die wet processing systems ensure uniform treatment and accurate chemical deposition, making them ideal for moisture- or oxygen-sensitive materials in controlled environments.

Laboratory Roll-to-Roll Coater

Choose Roll-to-Roll (R2R) Processing, such as the Laboratory Roll-to-Roll Coater, when you need to scale up lab-scale results for continuous, high-throughput production. While still on a laboratory scale, R2R processing ensures uniformity and consistency over long substrates, making it suitable for applications that will eventually transition to larger-scale manufacturing.

R2R Hybrid Coater

We recommend the R2R Hybrid Coater for researchers seeking maximum flexibility and performance in lab-scale thin film processing. This innovative system combines the precision of sheet-based coating with the efficiency of continuous roll-to-roll operation—making it ideal for everything from early-stage formulation to pilot-scale production.

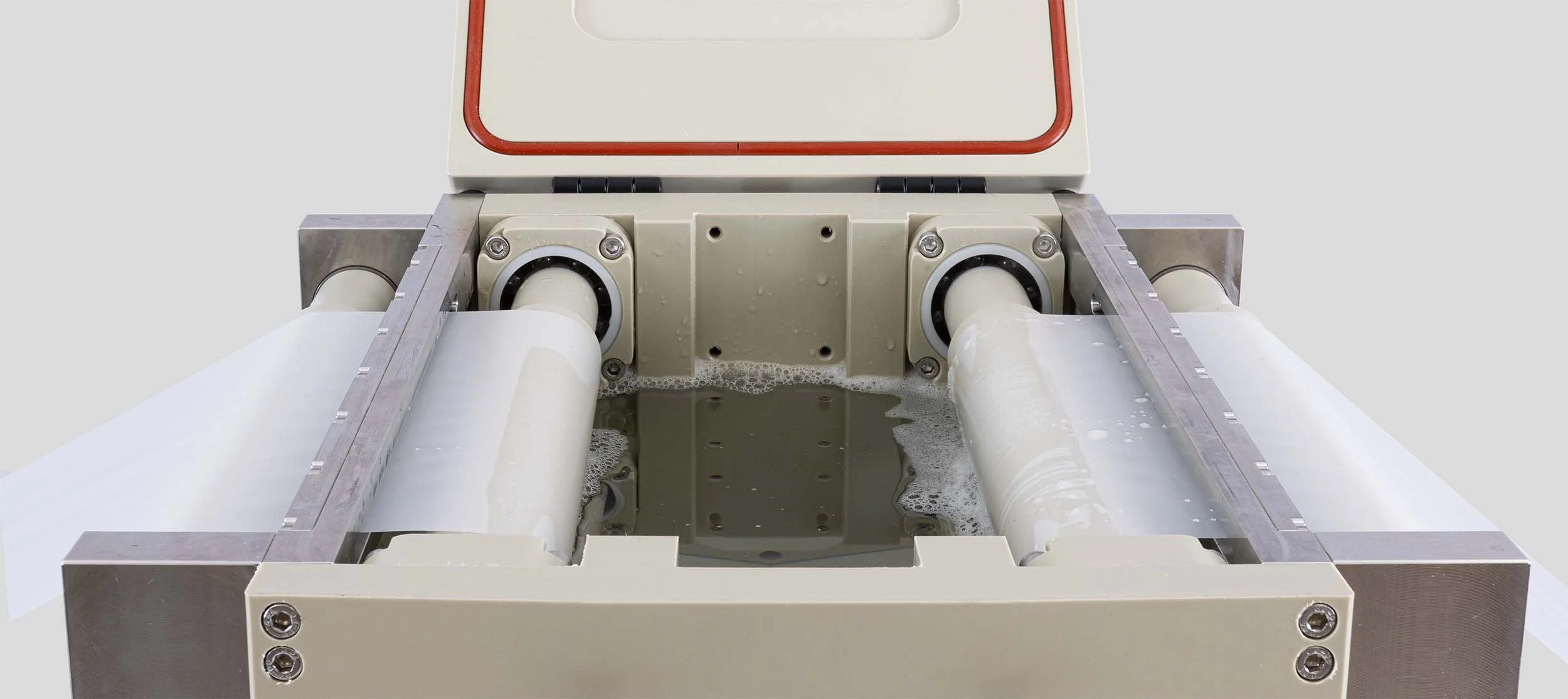

Wet Processing Center

A first-of-its-kind component for the Laboratory Roll-to-Roll Coater and R2R Hybrid Coater, enabling the processing of foil through immersion, spraying, heating/cooling, agitation, and electrochemical treatments—all within a fully enclosed, zero-emission system.

Transform Your R2R Coater Into a Web Washing Machine

Your Trusted Coating Partner

With decades of experience in printed electronics, our expert team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project.