R2R Hybrid Coater

From Precision Sheet Coating to Continuous Roll Processing,

One Integrated Platform for Total Thin Film Control

All In One Processing

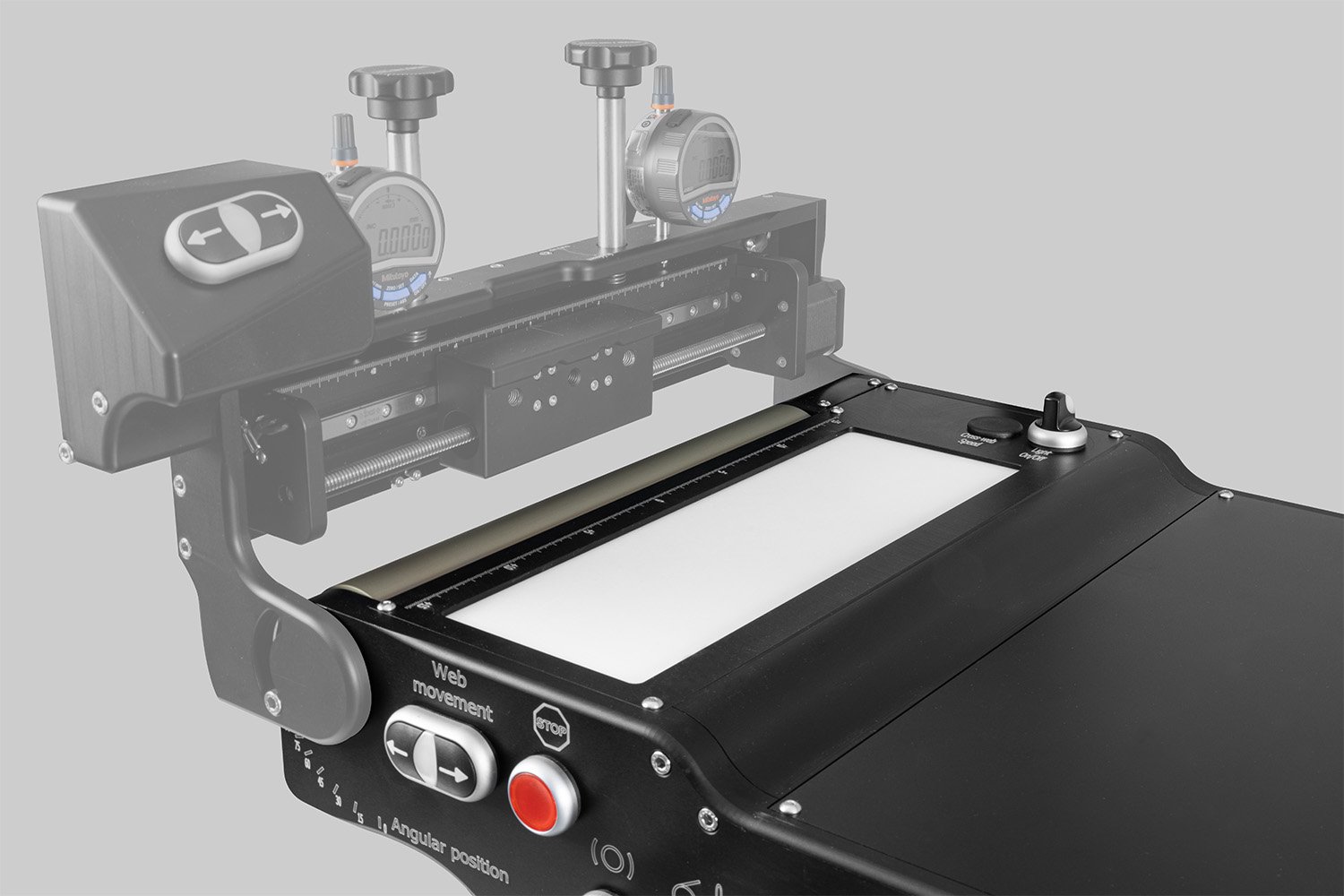

Discover the powerful combination of the Slot-die Coater and the Laboratory Roll-to-Roll Coater, an integration that offers unparalleled versatility for both research and production applications.

In advanced thin film manufacturing, continuous R2R processing offers high throughput and cost efficiency. However, some stages—such as quality inspection, patterning, or thermal treatment—may require stopping the roll to perform precise, controlled operations on a specific area of the substrate.

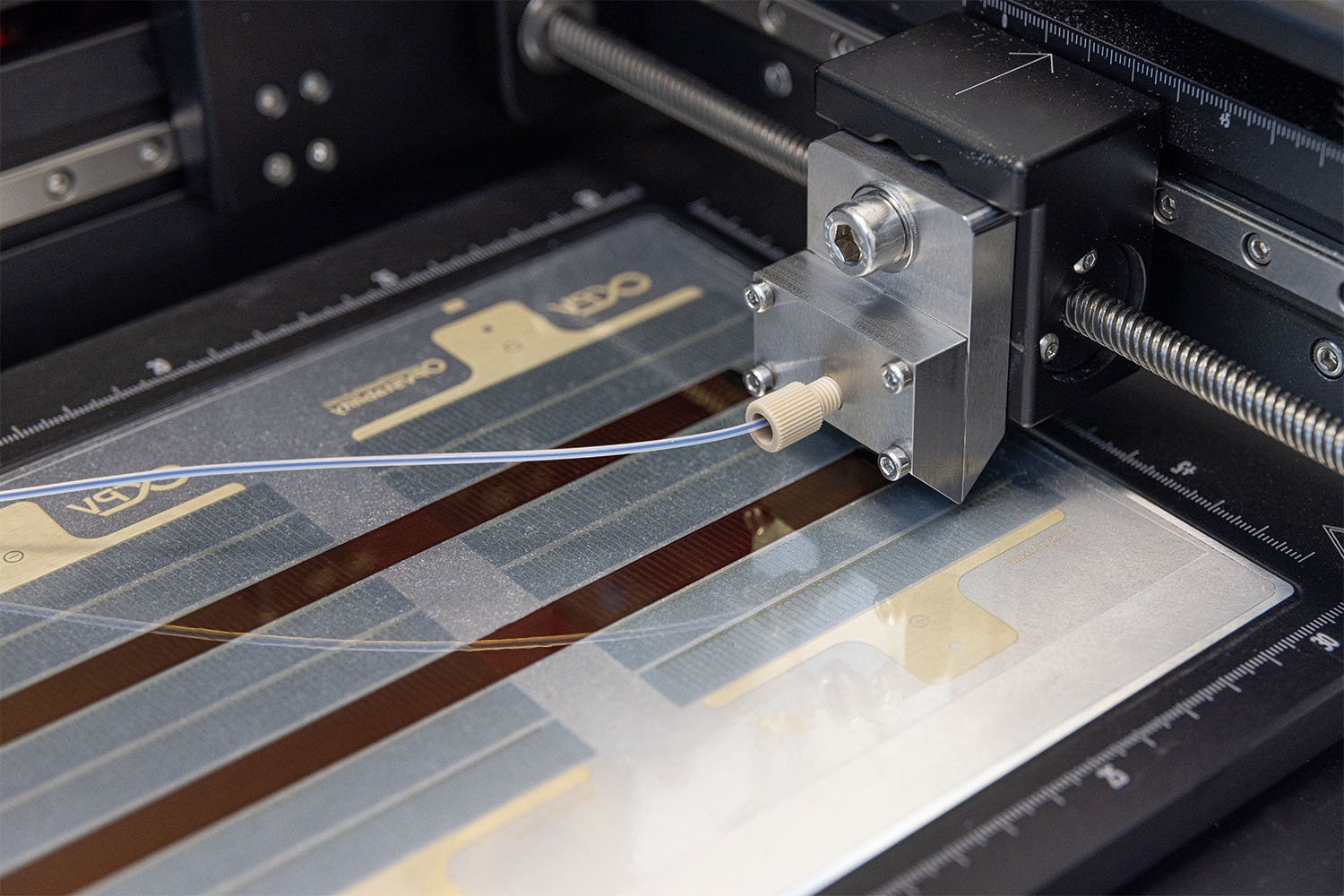

Dock the Slot-Die Coater onto the Laboratory Roll-to-Roll Coater platform and get the most advanced equipment in lab-scale thin film processing. The R2R Hybrid Coater merges the best of sheet coating and roll-to-roll coating into a single, innovative solution. This unique setup not only allows you to efficiently process large rolls of material but also offers the precision and control needed for detailed sheet applications.

What sets this system apart is the flexibility to operate the two pieces of equipment independently or together. This functionality provides total freedom in your research and processing, enabling you to tailor setups to meet specific project requirements.

Whether you’re developing cutting-edge materials or seeking to optimize existing processes, the R2R Hybrid Coater is your gateway to innovation. Transform your lab with the ultimate coating solution and stay ahead of the industry curve.

Key Features

Compact Size: Fits in laboratories, gloveboxes, or fume hoods without additional infrastructure.

Customizable: Choose from a variety of: lengths, coating widths, thin film processing options and numerous components.

Easy and Fast Exchangeable Modular Components: Includes printing and coating units, drying and curing systems, foil pretreatment, laminators, trimming knives, air knifes and more.

Modular Drying/Curing System: Accommodates various drying and curing methods including heated vacuum chuck.

Software Control Option: Advanced control options for precision and repeatability.

Web Tension Control: Ensures consistent quality across runs.

CE Certified - CSA/UL Compliant: Meets international safety standards.

How to Customize the R2R Hybrid Coater

Creating your custom R2R Hybrid Coater is simple. Start by configuring the Slot-die Coater to match your thin-film needs, then choose and configure the compatible Laboratory Roll-to-Roll Coater. Once ready, dock the Slot-die Coater on top for a fully integrated setup.

R2R Hybrid Coater

Dock the Slot-die Coater Pro onto the Laboratory Roll-to-Roll Coater platform and get the most advanced equipment in lab-scale thin film processing.

Components

After selecting your platform, it's time to choose from our array of components, ranging from slot-die heads to advanced laminators. Each component is engineered to enhance efficiency, consistency, and quality in your R2R system. Explore our offerings to tailor your coater platform precisely to your needs and unleash its full potential in revolutionizing thin-film production.

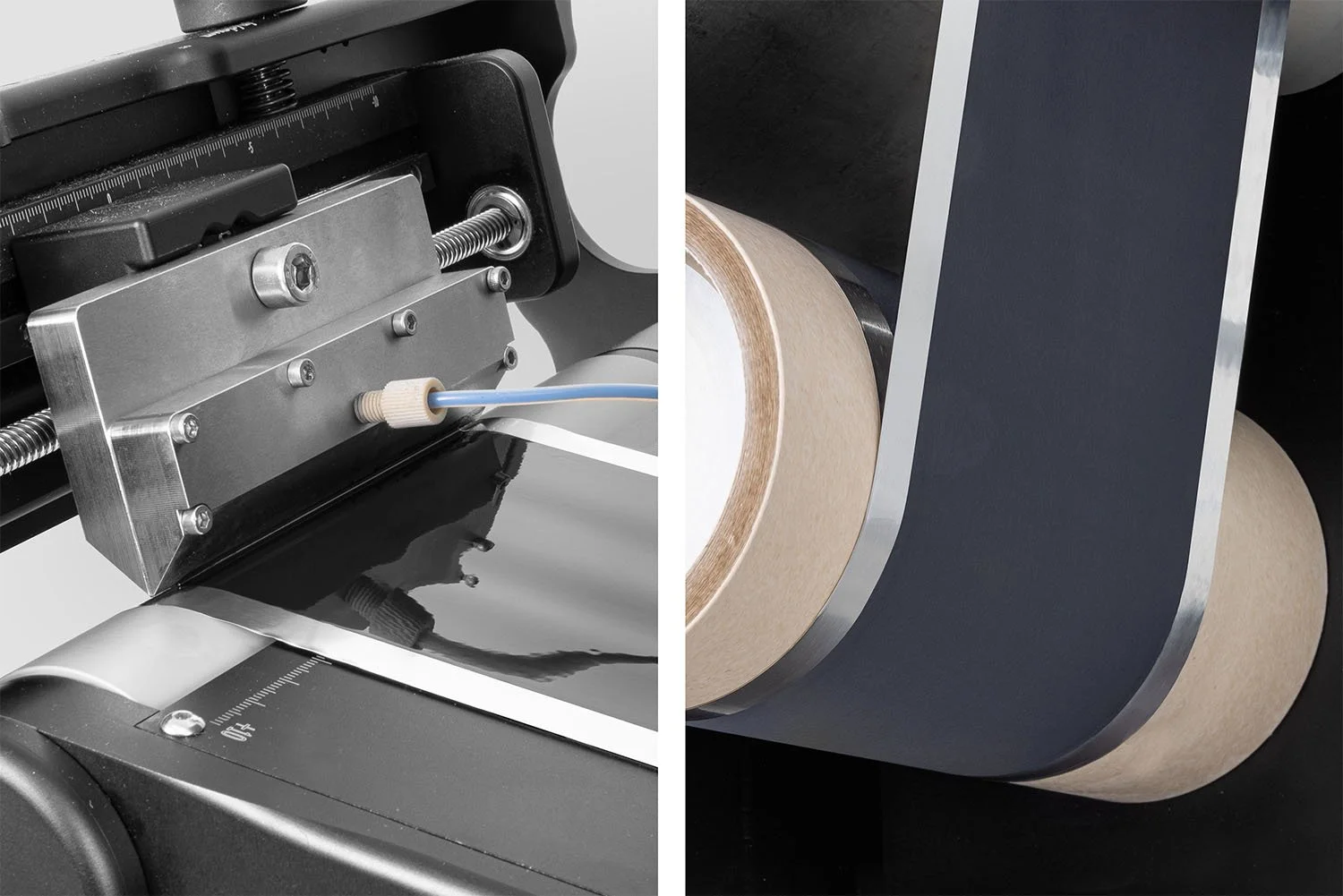

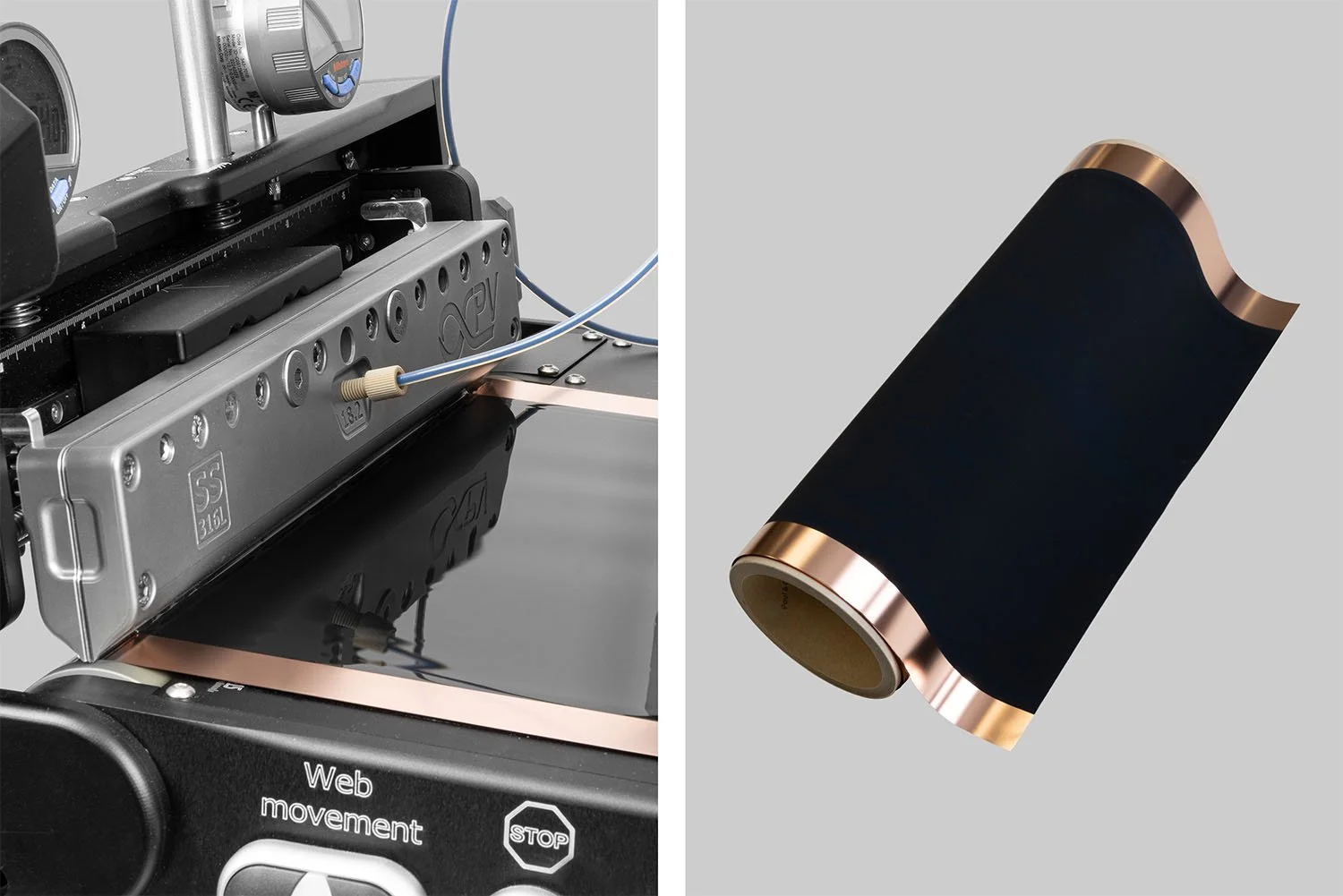

Slot-die Heads

Slot-die heads for high-quality coatings. Available in stainless steel, titanium, or PEEK, with widths from 40 mm to 305 mm, ensuring precise thin-film coating. View video.

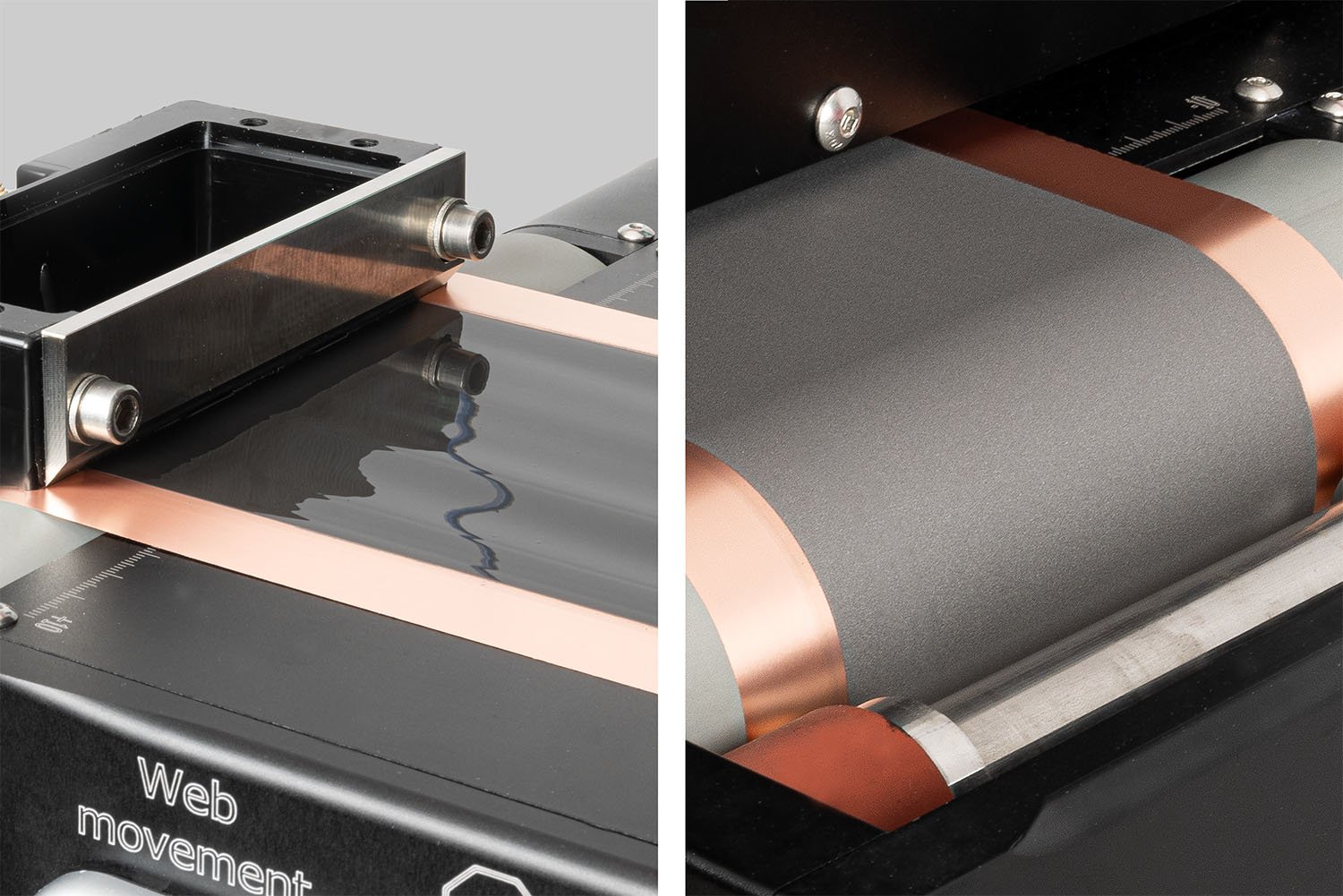

Slurry Coater

A vital tool for lab-scale production of advanced thin films, supporting critical applications like batteries, fuel cells, and printed solar cells. Watch video.

Air Knives

Air knives for all needs. The Standard Air Knife for efficient drying and quenching, and Air Knife Pro for controlled, repeatable results.

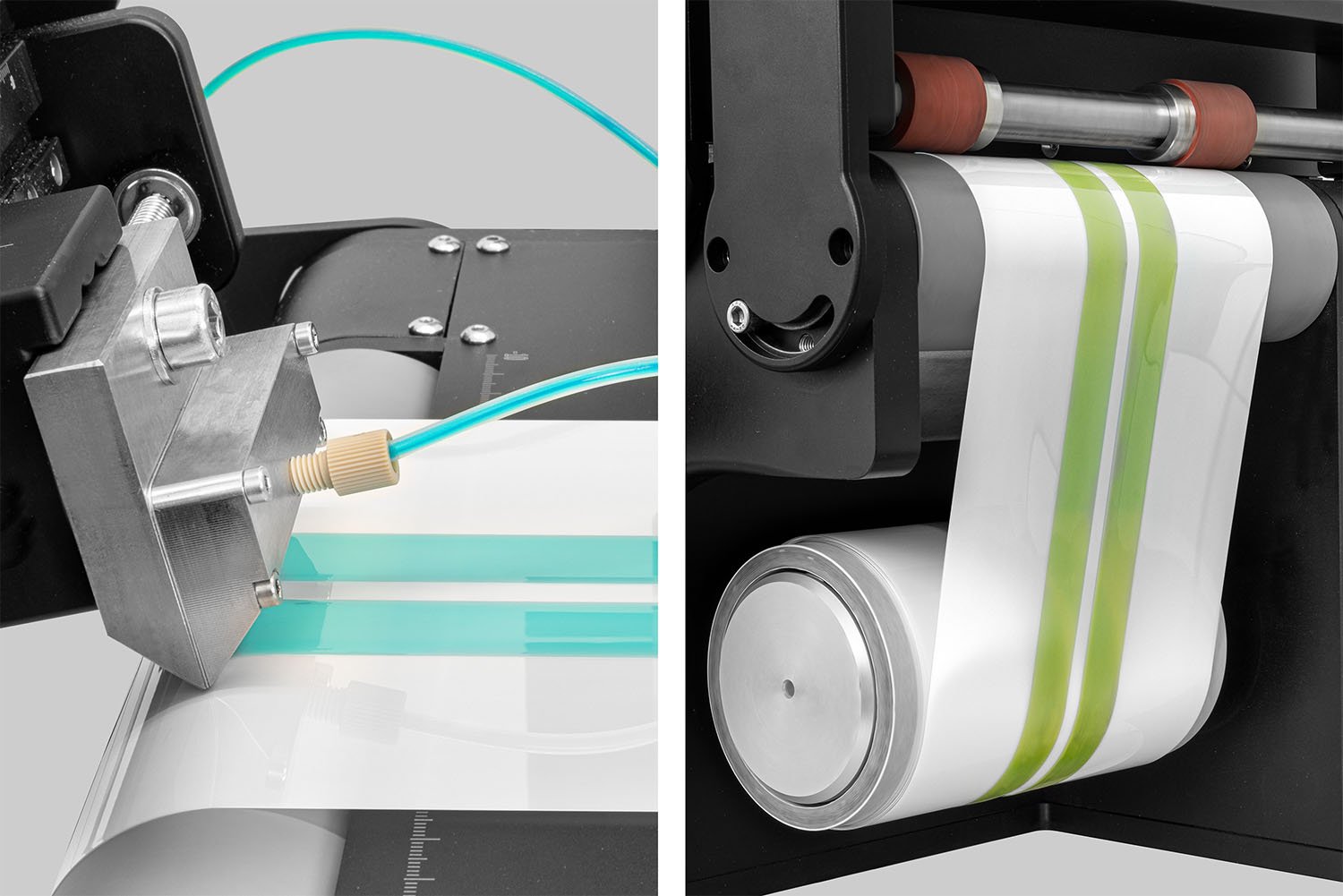

Roll-to-Roll Laminator

A laminator designed for thin-film encapsulation with various adhesives, featuring precise tension control and customizable web width. Watch video.

Stripper Unit

The Stripper Unit allows for removal of a protective liner or other foil just before the coating or printing station. It comes with compressed air spindles, tension control and automation of nip engagement. Watch video.

Rollers

The Laboratory Roll-to-Roll Coater features 60 mm anodized aluminum rollers, durable and cost-efficient for 95% of applications. With low runout, they ensure experimental success. For specific needs, we offer POM or PEEK rollers for insulation or chemical resistance and stainless steel for extreme corrosion resistance.

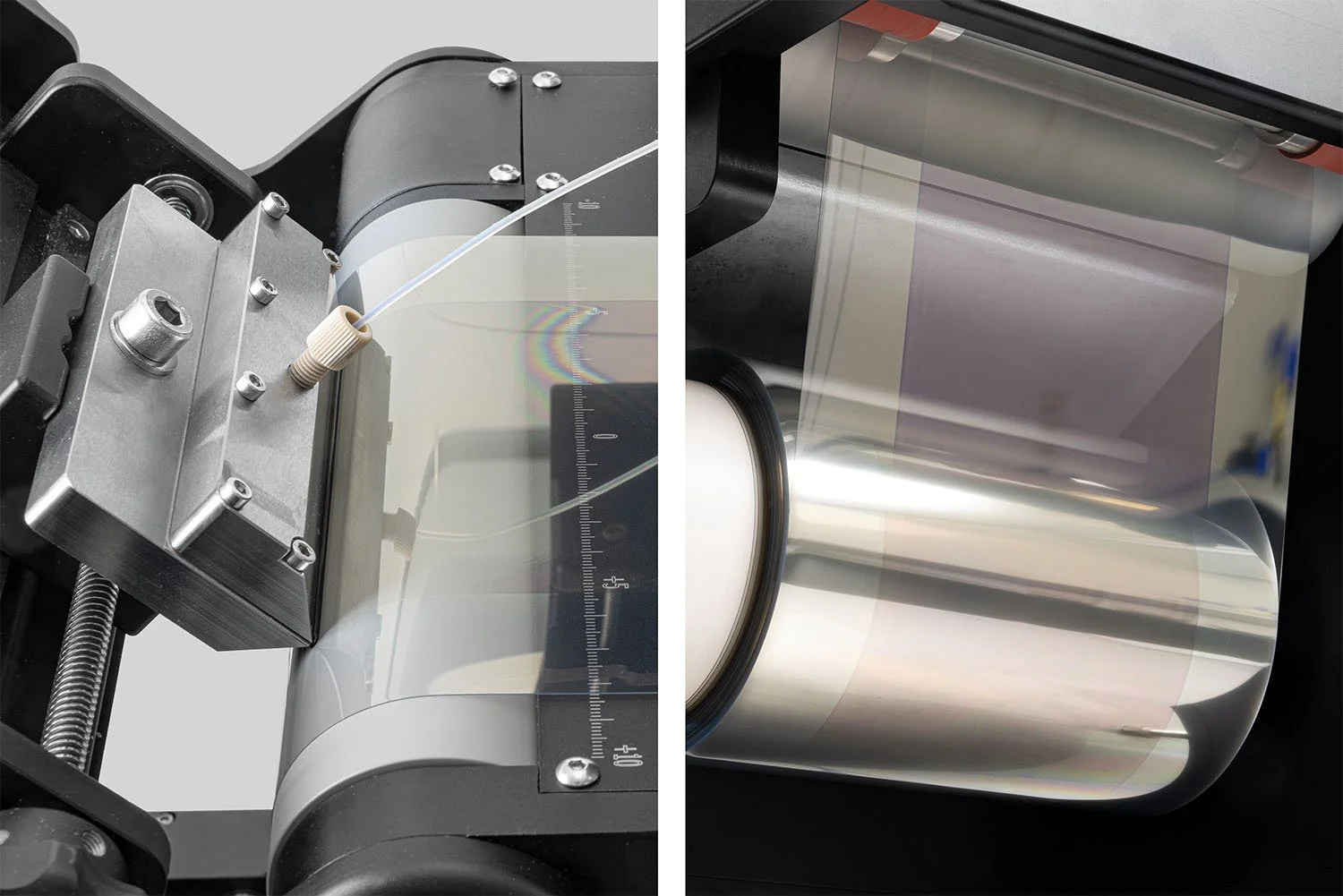

Inspection Table

Inspection Table that enables inspection on transparent substrates directly after coating or printing. Ideal for visual checks or camera systems, it fits LR2RC750, LR2RC1000, and LR2RC1500 platforms and can be added during purchase or retrofitted later. Watch video.

Knife Cutter

Knife Cutter for precise foil handling offers ultra-durable carbide cutters and adjustable cutting positions. Precision-ground stainless steel rollers ensure gentle handling and chemical resistance, making it safe and efficient. Watch video.

Foil Turner

Foil turner that enables seamless inline processing on both sides of the foil, ideal for double-sided slot-die coating in batteries, fuel cells, membranes, and more. Watch video.

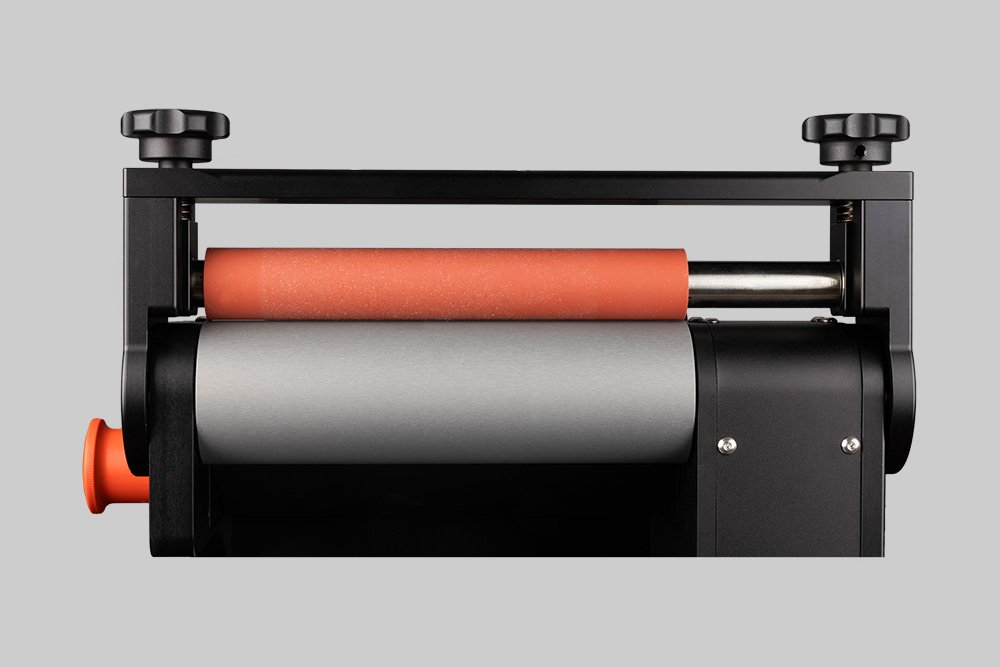

Nip Rollers

The Nip Rollers offer flexibility with multiple configurations. The Manual Nip Roller features a full rubber roller with manual control of nip pressure and tilt, while the Adjustable Nip Roller include adjustable rollers, automated nip engagement, pressure, and pressure points. It's perfect for simple manual packaging with minimal effort.

Spindles

Spindle options include the LR2RC500 with adjustable cones for core width, diameter, and position (35 mm to 90 mm inner diameters), and the LR2RC750, LR2RC1000, and LR2RC1500 platforms with automatic compressed air spindles for 3-inch core diameters, ensuring efficient handling for larger setups.

We Are Ready to Help You

With decades of experience in printed electronics, our team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project. Contact us to discuss how we can support your solar cell development.

Which Slot-die Head Do YOU Need?

Your coating process is only as good as the head that delivers it. Whether you’re developing batteries, solar cells, fuel cells, pharmaceuticals, or something else, selecting the right slot-die head is critical for quality, efficiency, and cost-effectiveness. In our guide, we break down how to evaluate your needs and help you understand which size and material slot-die head suits your application best.

Related Products

Slot-die Heads

Discover our versatile range of slot-die heads tailored to meet diverse application needs.

Ovens

The Laboratory Roll-to-Roll Coater accommodates various oven systems designed for the efficient drying and UV-curing of processed thin films.