Slot-die Coating in Gloveboxes: Precision in Controlled Environments

Working in a Glovebox for Printed Electronics

Operating in a glovebox for the research and development of printed electronics, such as batteries, solar cells, fuel cells, pharmaceuticals, and more provides significant advantages. A glovebox maintains an inert atmosphere, typically filled with nitrogen or argon, which protects sensitive materials from moisture and oxygen. This controlled environment enhances material performance, longevity, and overall research quality.

Benefits of a Glovebox Environment

Protection from Contaminants: The sealed environment effectively minimizes exposure to dust, particulate matter, and volatile organic compounds, ensuring material purity and research integrity.

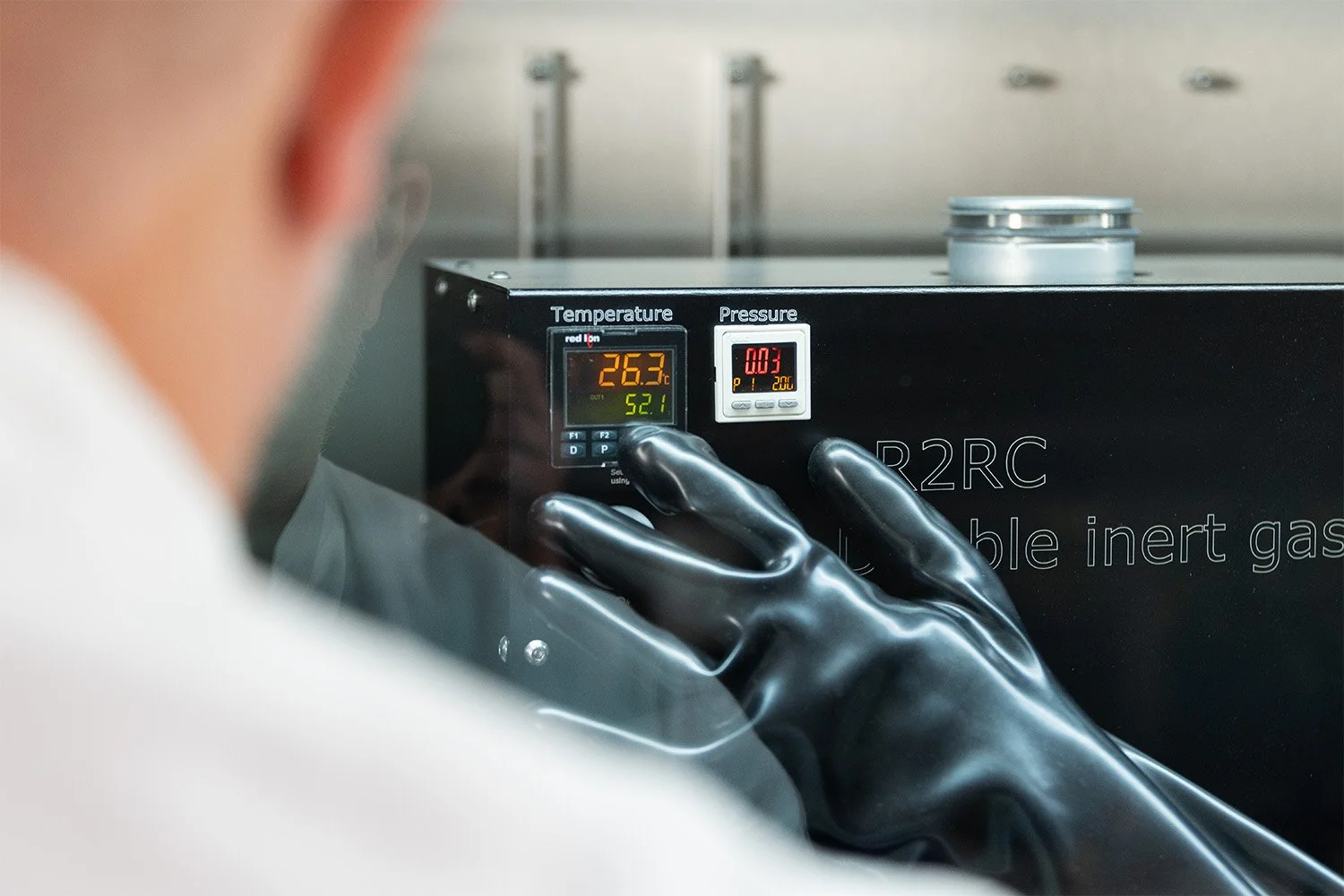

Stable and Controlled Conditions: Gloveboxes regulate temperature and humidity, offering stable conditions that promote reproducible results and optimal material performance.

Enhanced Safety: By preventing exposure to hazardous chemicals and reactive materials, gloveboxes create a safer working environment for researchers handling sensitive substances.

Precision and Handling: The enclosed workspace allows for meticulous alignment and handling of materials, minimizing degradation and improving the quality of printed thin films.

Solutions for Glovebox Applications

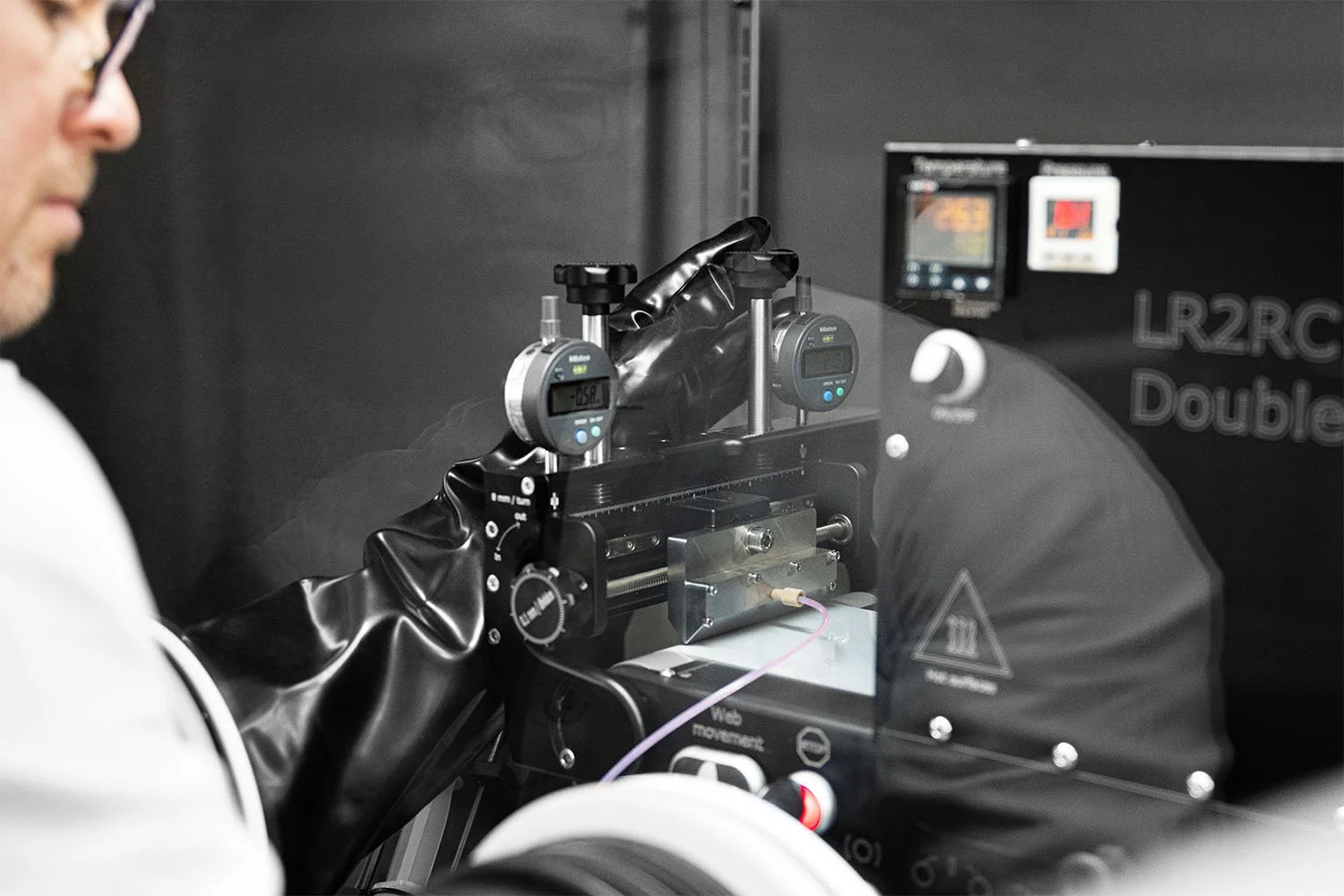

infinityPV slot-die coaters are specifically designed for seamless integration into gloveboxes, enabling high-precision coating in controlled atmospheres.

Compact and Glovebox Compatible Design: Our coaters fit within the limited space of gloveboxes while maintaining the flexibility required for experimental setups.

Operation in Inert Atmospheres: Compatible with nitrogen and argon environments, our slot-die coaters ensure sensitive materials remain unaffected by oxygen and moisture.

User-Friendly PC Control: Many of our models feature intuitive PC-based control systems, designed for remote operation and fine-tuned adjustments within confined spaces.

Automation and Reproducibility: The PC-controlled coating and printing platform enables process automation, ensuring consistency, reproducibility, and enhanced film quality.

Our technology allows researchers to achieve precise, uniform coatings while maintaining the benefits of a glovebox environment. Explore our solutions to optimize your glovebox research and production workflows.

Coating Equipment for Glovebox Applications

We enable precise coating in controlled environments with our advanced coating methods, perfect for research and development in glove box applications. Our slot-die coating systems are recognized for their precision and uniformity, making them ideal for sensitive material handling in glove box setups.

Slot-die Coater

We recommend choosing sheet-based processing, such as the Slot-die Coater, for lab-scale research, prototyping, and small-batch production. This method offers the flexibility to test formulations, adjust parameters, and produce precise coatings in limited quantities—ideal for early-stage development and specialized applications.

Laboratory Roll-to-Roll Coater

Choose Roll-to-Roll (R2R) Processing, such as the Laboratory Roll-to-Roll Coater, when you need to scale up lab-scale results for continuous, high-throughput production. While still on a laboratory scale, R2R processing ensures uniformity and consistency over long substrates, making it suitable for applications that will eventually transition to larger-scale manufacturing.

R2R Hybrid Coater

We recommend the R2R Hybrid Coater for researchers seeking maximum flexibility and performance in lab-scale thin film processing. This innovative system combines the precision of sheet-based coating with the efficiency of continuous roll-to-roll operation—making it ideal for everything from early-stage formulation to pilot-scale production.

Your Trusted Coating Partner

With decades of experience in printed electronics, our expert team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project.

Roll-to-Roll Coating? We got you covered.

Whether you're working within batteries, pharma and medtech, fuel cells, solar cells, or other thin-film technologies, we offer scalable Roll-to-Roll (R2R) equipment built for the lab. Our modular systems are designed for precision, repeatability, and flexibility, supporting everything from coating and drying to surface treatment and characterization.