How Foil-Based Microchips Could Transform Neuroscience Using Roll-to-Roll Coating

Can Roll-to-Roll Manufacturing Revolutionize Brain-on-a-Chip Research?

How do you study the growth of neurons outside the human brain? Scientists have long used microfluidic devices—tiny lab-on-a-chip systems that recreate the microenvironments of living tissues—to observe how neurons grow, connect, and regenerate. But while these devices have opened new doors in neuroscience, their production has remained slow and costly.

A team of researchers from Joanneum Research, TU Wien, and TECNALIA set out to change that. Their study, “Roll-to-Roll (R2R) High-Throughput Manufacturing of Foil-Based Microfluidic Chips for Neurite Outgrowth Studies,” introduces a new way to produce neuron chips not one by one, but continuously, on flexible foil using industrial roll-to-roll (R2R) manufacturing. The method could bridge the gap between laboratory research and large-scale biomedical production, allowing brain-on-a-chip technologies to reach more labs and applications.

At a time when neurological disorders affect one in three people worldwide, the ability to produce microfluidic tools quickly and affordably could have far-reaching implications. It could accelerate research into Alzheimer’s, Parkinson’s, and other conditions where understanding neuron growth is key to finding new treatments.

Key Highlights

First demonstration of R2R UV-nanoimprinting for neuron microchips

Foil-based chips supported healthy neurite outgrowth

Bonding strength matched conventional PDMS-glass systems

Fluid flow enhanced neurite growth and reproducibility

Scalable process suitable for biomedical and organ-on-chip production

What is roll-to-roll processing, and why is it revolutionizing the way we make flexible devices?

What is Roll-to-Roll Manufacturing and Why Does it Matter?

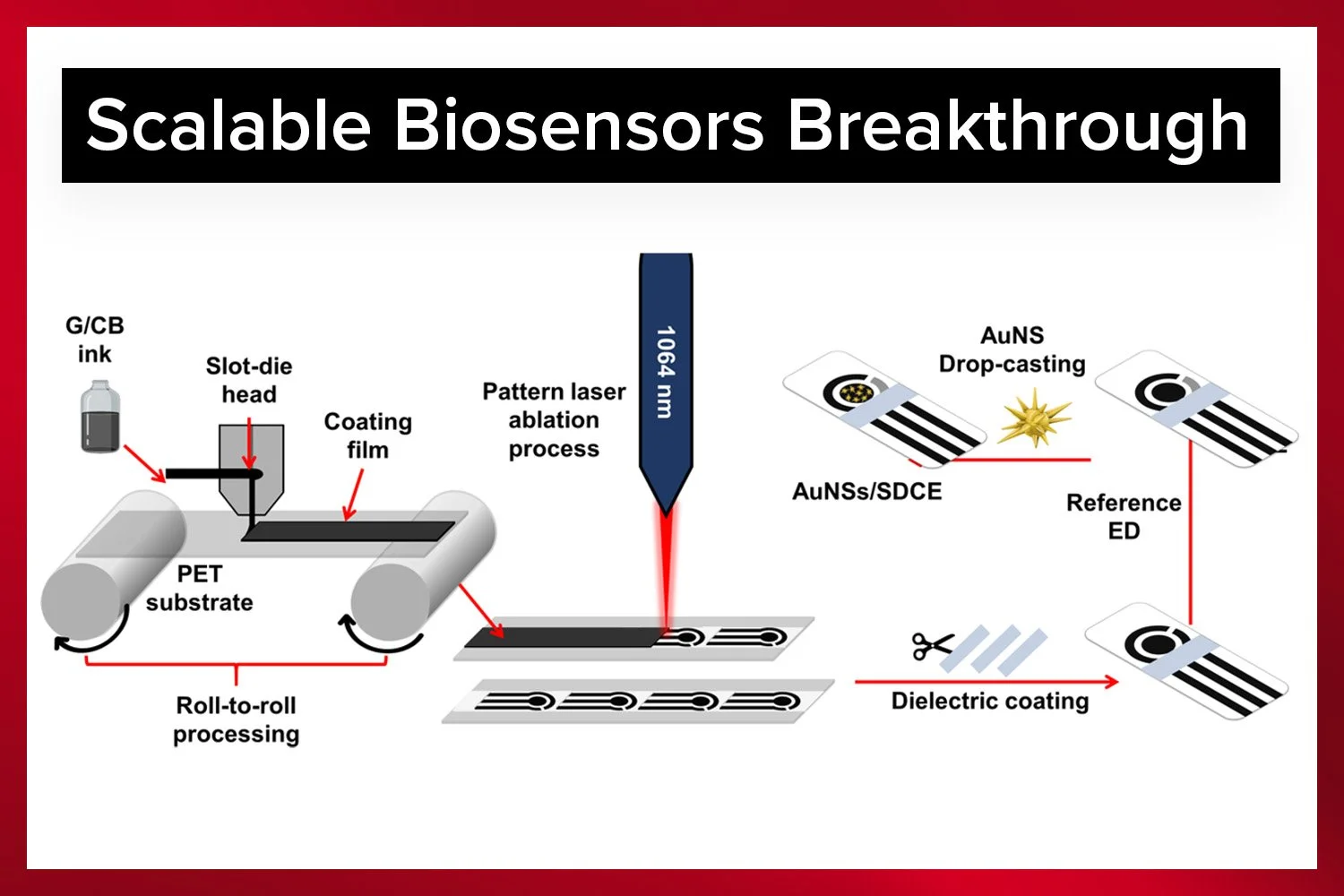

Roll-to-roll, or R2R, manufacturing is a continuous process where flexible films are unrolled, coated, imprinted, and re-rolled in a seamless sequence. It is a well-known technique in the electronics and packaging industries, but applying it to microfluidics represents something new.

In this study, R2R was used to create intricate networks of microchannels on transparent PET foils using a custom UV-curable resin called NILCure 31. These channels, only a few micrometers wide, were then sealed by laminating another layer of resin-coated PET on top. The result was a thin, transparent, and biocompatible chip that could guide neuron growth just like the more traditional PDMS-glass devices used in research.

The main advantage of R2R is scale. Instead of producing one chip at a time in a cleanroom, the process allows continuous production of hundreds or even thousands of chips per roll. It combines precision with throughput, reducing both cost and time. In the context of brain-on-a-chip research, this means that devices which once took hours to make could be mass-produced for use in diagnostics, education, or drug discovery.

The Significance of the Study

The core challenge the team addressed was scalability. Traditional microfluidic chips are often made with soft lithography, a technique that is well suited for prototyping but impractical for industrial use. By adapting R2R production to microfluidic applications, the researchers demonstrated a path forward for high-throughput fabrication of complex biological devices.

Beyond cost and speed, the R2R-produced chips met essential scientific standards. The PET foils retained their optical clarity, allowing for high-resolution microscopy, and the resin used in imprinting proved to be biocompatible. Bonding tests showed that the sealed foil layers were as strong and reliable as PDMS-glass devices, confirming their ability to withstand the pressures of fluidic flow without leaks or structural collapse.

The study highlights how industrial manufacturing techniques can support advanced biomedical applications. It shows that R2R can deliver microfluidic systems that meet research requirements while being compatible with automation and large-scale production. For organ-on-a-chip technologies—used to mimic tissues from brain to liver—this could be the missing link that enables wider adoption.

Discover how lab-scale slot-die coating improves pharmaceutical and medical device development through precise, uniform coatings for testing and prototyping.

How the Research Was Conducted

To explore the potential of R2R manufacturing, the researchers designed neuron-foil chips with two main regions: a soma compartment, where the neuron cell bodies are placed, and an axon compartment, where their extensions, or neurites, grow. These compartments were connected by microchannels only 5 micrometers wide and 10 micrometers high. Such narrow dimensions help guide neurites while preventing the larger cell bodies from passing through.

Two designs were tested: one with straight channels and one with angled channels meeting at 70 degrees. The team used a custom-built roll-to-roll UV nanoimprinting system to fabricate the chips. During production, a thin layer of UV-curable resin was slot-die coated onto a PET substrate, pressed against a nickel mold, and cured under UV light to create the channel structures. The second PET layer was laminated on top using controlled pressure and UV curing to seal the channels. Laser cutting was used to shape the final chips, which were fitted into standard 96-well plates for cell culture experiments.

The chips were then tested with glioblastoma cells (U87-MG), chosen for their known neurite-forming behavior. Cells were grown under both static and dynamic conditions, with some chips placed on a rocking platform to simulate gentle fluid flow. Over several days, the researchers used fluorescence microscopy to observe cell attachment, neurite extension, and overall chip performance.

From Manufacturing to Biology: What They Found

The roll-to-roll process produced microchannels that were consistent, smooth, and free from air bubbles—an important factor for both fluid flow and cell health. Microscopy confirmed that the channels had the correct dimensions and that lamination did not cause any collapse. Bonding strength tests further showed that the PET-resin seal held up well against the pressures involved in liquid handling.

When cells were cultured on the chips, both the straight and angled designs successfully supported neurite outgrowth. Under static conditions, neurons grew into the channels as expected, but results varied between replicates. When dynamic flow was introduced, the picture changed. Fluid flow through the microchannels led to a more consistent pattern of growth and increased the average neurite length by almost half compared to static conditions.

Interestingly, the geometry of the microchannels also made a difference. Angled channels produced longer neurites—about 36 percent longer on average—suggesting that the shape of the channel walls influences how neurons orient and extend. These findings echo previous research showing that microenvironmental design, including flow direction and wall angles, can affect cellular alignment and morphology.

Achieve pristine, contamination-free coatings with the Laboratory Roll-to-Roll Coater.

Looking Ahead: The Future of R2R Microfluidics

This work does more than present a new fabrication technique. It lays the groundwork for a future where microfluidic systems for biological research can be produced at the same scale as consumer electronics. By using industrial roll-to-roll machinery, laboratories could gain access to consistent, ready-to-use devices, accelerating both experimentation and product development.

In neuroscience, these chips could become essential tools for studying how neurons respond to injury, grow across gaps, or react to new drugs. They may also help develop disease models that better mimic the human brain, reducing dependence on animal testing. Beyond neural applications, the same principles could apply to other organ-on-a-chip technologies, from heart tissue to liver models, and even integrated biosensors.

The researchers also noted some challenges ahead. The PET material exhibited autofluorescence under certain wavelengths, which could interfere with imaging, though this was mitigated with stronger fluorescent dyes. Future work may explore new materials or coatings to overcome this limitation and further refine imaging quality.

Conclusion

The study demonstrates that roll-to-roll manufacturing can produce microfluidic neuron chips at industrial scale without compromising performance. The foil-based design is transparent, biocompatible, and strong enough to support both static and dynamic cultures. It allows neurons to grow and connect in ways comparable to traditional devices, while offering the benefits of automation and scalability.

By proving that large-scale, high-throughput production of complex biological chips is possible, this research opens the door to broader adoption of microfluidics in biomedical research and industry. It suggests a future where brain-on-a-chip technologies can be as readily available as standard lab equipment, helping scientists everywhere study the complex behavior of neurons more efficiently and affordably.

Authors

Nihan Atak

Martin Smolka

Anja Haase

Alexandra Lorenz

Silvia Schobesberger

Stephan Ruttloff

Christian Wolf

Ana Ayerdi-Izquierdo

Peter Ertl

Nerea Briz Iceta

Jan Hesse

Martin Frauenlob

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.