Roll-to-Roll Processing Produces Color Changing Dressings That Show Early Infection Signals

What if a wound dressing could tell you exactly how a wound is healing, in real time and without the need for lab tests. This is the idea at the center of the research article titled Roll To Roll Production of Smart Dressings for Wound Monitoring. Wound care remains a persistent challenge for healthcare systems around the world, especially for people suffering from chronic or slow healing wounds. Clinicians still rely primarily on visual assessment and lab cultures, both of which can be delayed or subjective. The article proposes a fundamentally different approach by developing wound dressings that incorporate printed color changing sensors. These sensors monitor pH, temperature, and humidity directly inside the dressing and provide a simple visual indication of how the wound is progressing.

What sets this work apart is the use of roll-to-roll screen printing to manufacture these sensors on real medical dressings at a practical production scale. Until now, most smart wound dressing concepts existed only as laboratory prototypes that could not be produced in large quantities. This study demonstrates that high throughput printing can deliver accurate and durable sensors on cotton, gauze, and nonwoven substrates. The work includes in vivo testing, successful blood repellent coatings, and clear evidence that sensor readings correlate with infection driven changes in wounds. The result is a convincing demonstration that printed biosensors can be produced at clinical scale and at a cost that would allow widespread adoption.

Key Highlights

First known demonstration of roll-to-roll production of smart wound dressings with integrated color changing sensors

Sensors track pH, temperature, and humidity on textile dressings in real time and historically

Production reaches more than ten impressions per minute with high precision

Uses biocompatible inks and includes a blood repellent antifouling coating

In vivo testing confirms clear detection of infection related changes

What is roll-to-roll processing, and why is it revolutionizing the way we make flexible devices?

What Smart Wound Dressings Are and Why They Matter

Modern healthcare has made remarkable progress, yet wound care remains surprisingly difficult. Chronic wounds affect millions of people each year and often require long treatment cycles. Traditional wound assessment methods can be limited because they do not provide continuous or quantitative information. Smart wound dressings aim to change this by embedding sensing materials that respond to biological changes. The appeal is straightforward. A wound dressing that shifts color based on infection, inflammation, or improper moisture balance can alert both clinicians and patients without the need for specialized equipment.

Colorimetric sensors are especially promising because they require no electronics. They are visible to the naked eye, inexpensive to fabricate, and well suited for disposable applications. The challenge has been the transition from small scale creation to full scale manufacturing. A dressing might work well when hand printed in a laboratory, but real medical products must be produced at high speed on large rolls of material. The research described in this article addresses exactly that gap.

Why This Research Matters for the Field

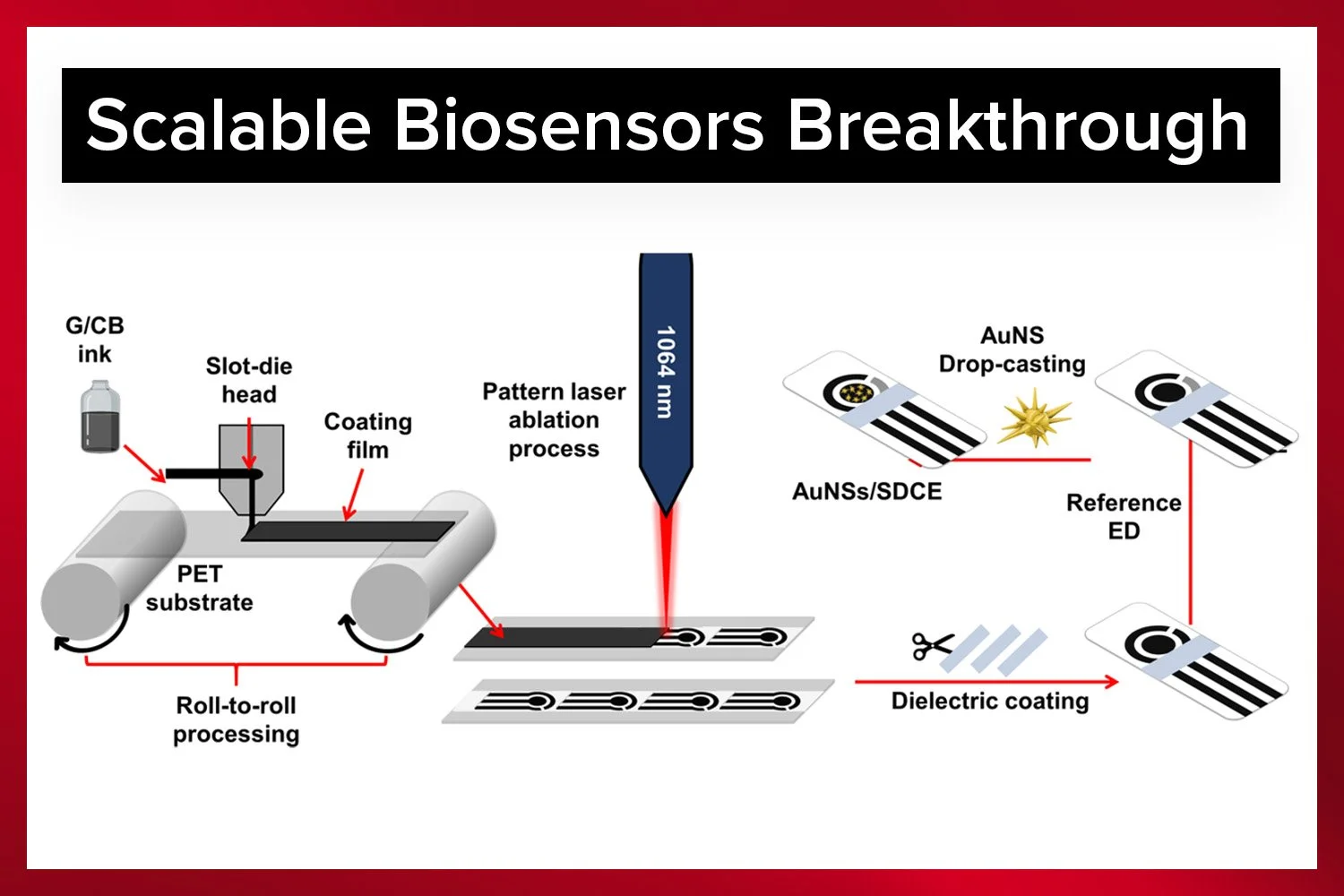

The most significant aspect of the work is not only the sensor design, but the full integration of the technology into a roll to roll manufacturing line. Roll-to-roll processing is an essential method in printed electronics and flexible device production because it supports continuous, low cost, and high throughput fabrication. Applying it to smart wound dressings shows that textile based biosensors can now be produced using the same industrial approaches used for printed solar cells or wearable devices.

This shift from prototype to scalable production is important for the future of clinical wound care. Hospitals and clinics require supplies that are consistent, affordable, and easy to deploy. A color changing dressing produced on a roll to roll line can meet these demands and can be tailored to different materials or sensor types. The work also demonstrates compatibility with porous substrates, something that had been difficult for many printed sensor systems. The ability to print high resolution structures on real medical fabrics greatly expands the potential applications.

Discover how lab-scale slot-die coating improves pharmaceutical and medical device development through precise, uniform coatings for testing and prototyping.

How the Sensors Work

The research team produced four different types of sensors, each designed for a specific measurement. These include two pH sensors, one reversible and one irreversible, a reversible temperature sensor, and an irreversible humidity sensor. Together they provide both real time and historical data on wound health.

The reversible pH sensor uses a chitosan based matrix that includes phenol red. The color transitions from yellow to red depending on acidity or alkalinity. This sensor responds rapidly and allows clinicians to see the current pH condition of the wound.

The irreversible pH sensor uses polydiacetylene vesicles. These materials undergo a permanent color change when exposed to elevated pH levels. This creates a memory effect that continues even if pH levels later return to normal. The benefit is the ability to track if the wound reached a concerning state at any point between dressing changes.

The temperature sensor is made from a silicone matrix mixed with thermochromic dyes. These dyes respond to temperature thresholds that correspond to inflammation. Because inflammation is one of the earliest signs of infection, temperature sensing is an important part of early detection.

The humidity sensor includes hydrochromic polydiacetylene particles embedded in a silicone layer. It helps track wound moisture and exudate accumulation. Understanding moisture is important because both dryness and excessive fluid can hinder wound healing.

How Roll to Roll Processing Enabled Scalable Production

The study used a continuous roll to roll screen printing line with a vacuum conveyor that holds the dressing substrates in place. The system allowed multiple layers to be printed in sequence while maintaining registration accuracy. Each layer was dried or cured before the next one was applied.

Production speeds exceeded ten impressions per minute on fifty by fifty centimeter formats. The resolution reached approximately point four millimeters on challenging porous fabrics. This is notable because fabrics typically stretch or shift, which makes consistent printing difficult. The research succeeded in controlling these variables without losing image precision.

The overall cost of producing the sensing units is low enough to support disposable use. The printing sequence can also be modified to incorporate other sensing chemistries or to adjust the design for different dressing geometries. This flexibility makes roll to roll processing an excellent fit for rapid commercialization.

Learn the complete process of creating uniform thin films using a slot-die coater.

Keeping Sensors Clean with Antifouling Coatings

Blood and wound exudate can block the visibility of colorimetric sensors. To solve this, the researchers developed a hydrophobic antifouling coating that includes modified titanium dioxide particles with wax and ethyl cellulose. This mixture forms a micro and nano structured surface that resists wetting. Blood does not spread across the surface and instead forms droplets that slide away. As a result, the underlying sensors remain visible despite exposure to biological fluids.

The coating also maintains breathability and mechanical durability. Abrasion tests showed that the treatment remains effective after repeated contact and bending. For clinical use, this level of durability is essential.

Methods and In Vivo Validation

The research included a broad set of laboratory tests to confirm optical behavior, mechanical strength, and cell compatibility. Microscopy, spectroscopy, rheology, and contact angle measurements were used to characterize the sensors and coatings. Cell viability remained above eighty percent, which supports the dressing’s biocompatibility.

The most convincing evidence came from in vivo testing. The team used a fourteen day mouse model to compare infected and non infected wounds. The dressings were changed each day so that irreversible sensors could store a daily record of wound conditions. Infected wounds showed sustained changes in temperature, pH, and moisture, and these differences became clearly measurable within the first week. The results demonstrate that the printed sensors can detect clinically relevant changes and that they maintain clarity and function during real wound healing processes.

Achieve pristine, contamination-free coatings with the Laboratory Roll-to-Roll Coater.

Future Outlook for the Industry

The implications of this work extend beyond the single set of sensors described here. Once roll to roll production has been proven, a wide range of sensing chemistries could be integrated into textile dressings. Potential additions include markers for glucose, lactate, oxygen, or inflammatory cytokines. The manufacturing platform can also be adapted to different fabrics and dressing sizes.

Smartphones or clinical scanners could be paired with these dressings to support data collection and digital analysis. This would allow automated tracking of wound healing trajectories and could help clinicians make more timely decisions. The combination of printed sensors and digital monitoring fits naturally into the broader trend of personalized healthcare.

From an industrial perspective, the cost effectiveness and modularity of roll to roll printing provide a clear path toward commercialization. With further development, these dressings could become a routine part of modern wound care.

Conclusion

This research article demonstrates a major advancement in the field of wound monitoring. It shows that smart dressings with integrated color changing sensors can be manufactured at scale using roll to roll screen printing. The sensors measure pH, temperature, and humidity and remain visible due to an effective antifouling coating. Laboratory tests and in vivo studies confirm that the dressings can reliably detect infection related changes and support continuous evaluation of wound conditions. The work establishes a practical manufacturing route that brings sensor enhanced dressings much closer to widespread clinical adoption and positions roll to roll printed electronics as a key technology for the next generation of medical textiles.

Authors

Ziheng Wang

Yujin Ahn

Semin Kwon

Tianhao Yu

Yumin Dai

Julia Walsh

Joo Hun Lee

Sang Mok Park

Seul Ah Lee

Murtuza Peerbhai

Chandan K Sen

Hyowon Lee

Young L Kim

Hyunjoon Kong

Chi Hwan Lee

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.