How Better Slot-die Coating Control Leads to Better Lithium-Ion Batteries

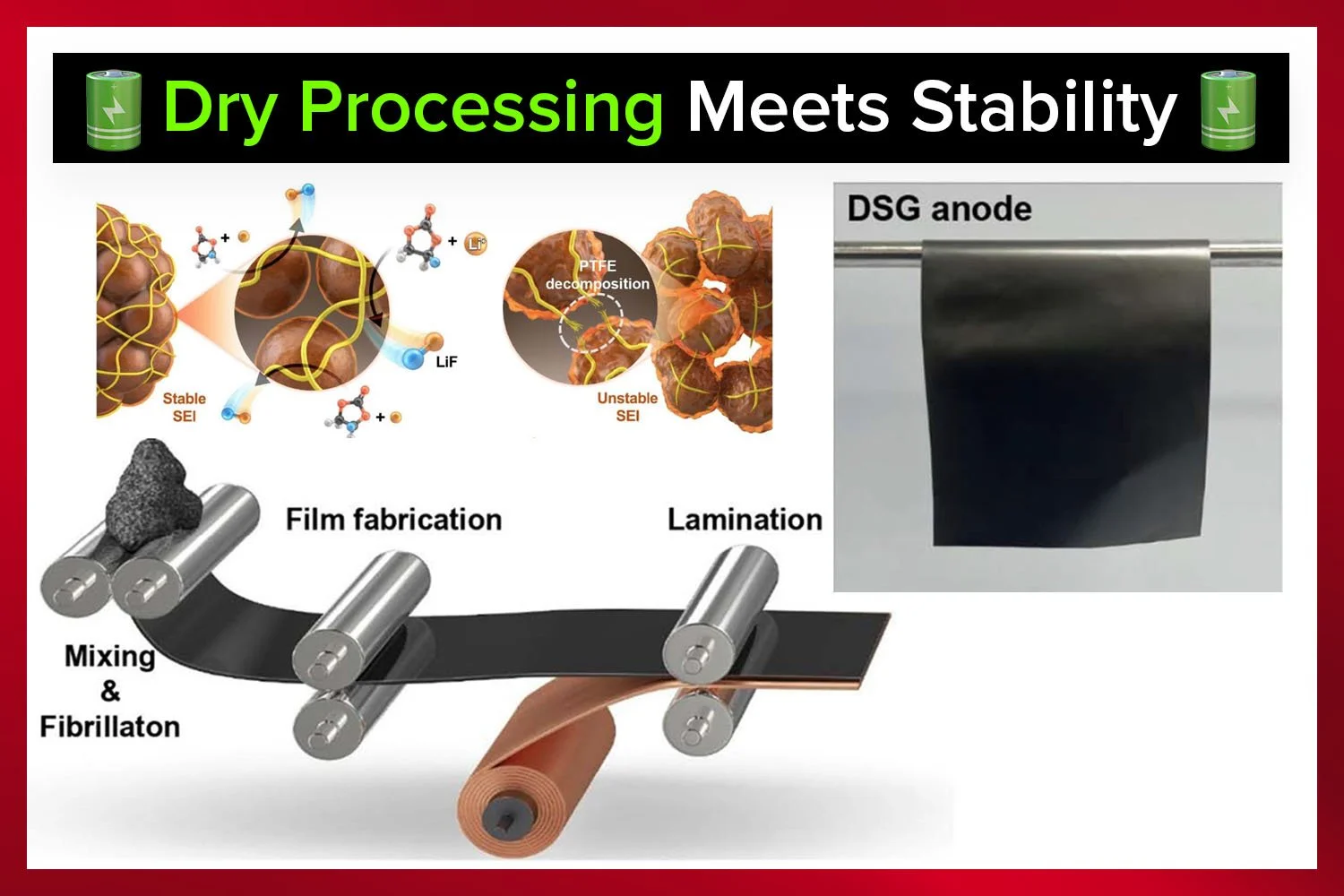

Modern lithium-ion batteries depend on an almost invisible layer. The electrode coating is only microns thick, yet it plays a decisive role in how much energy a battery can store and how long it lasts. Producing this layer evenly, at high speed and across wide substrates, is one of the most demanding steps in battery manufacturing.

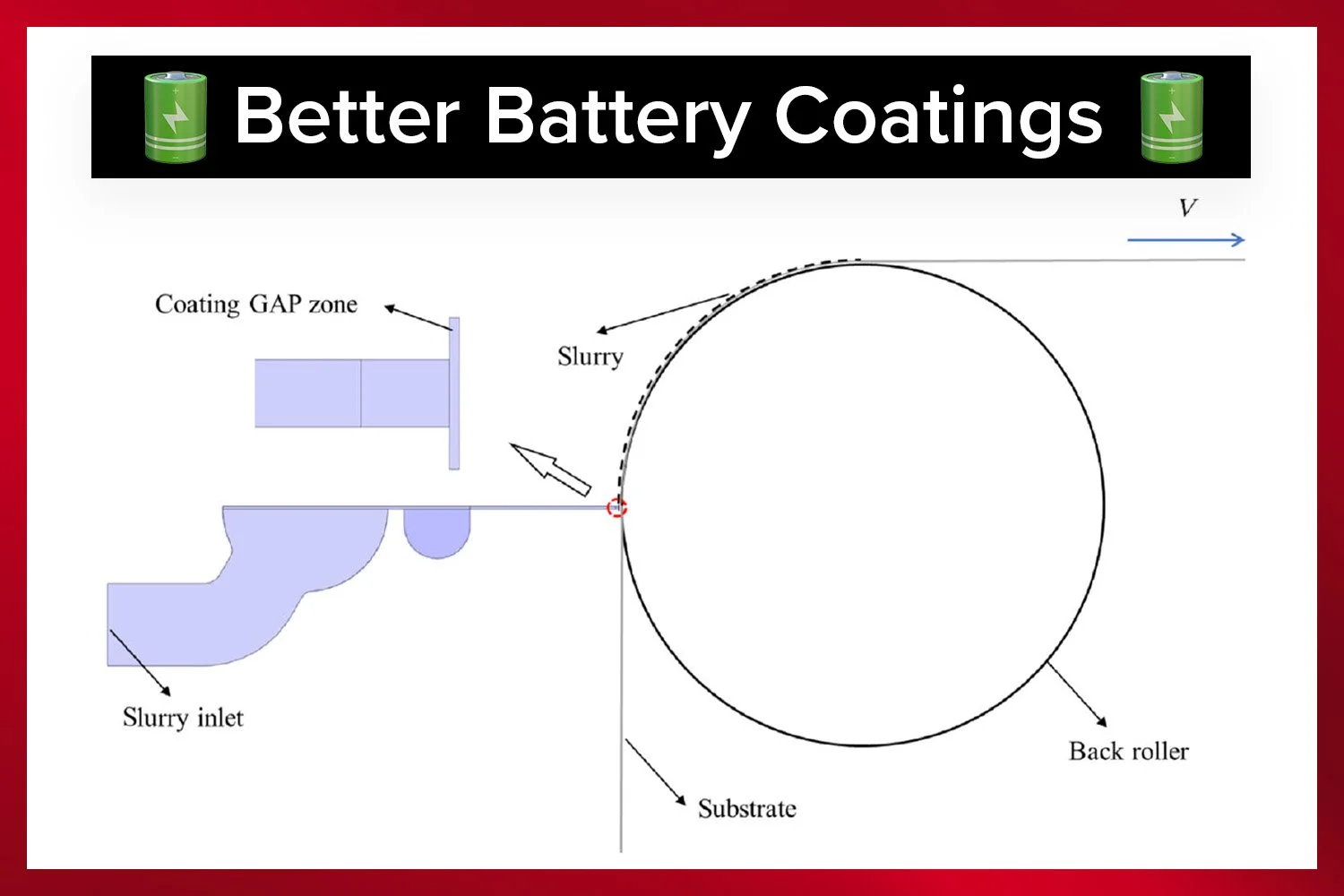

The research study “Numerical simulation of slot-die coating for lithium-ion battery electrode and investigation into wet film morphology” tackles this challenge head-on. Instead of relying solely on experiments and trial-and-error adjustments, the authors use detailed numerical simulations to understand what actually happens inside a slot-die coater and immediately after the slurry leaves the slot-die head.

Their findings show that many common coating defects can be predicted, explained, and even avoided by carefully considering die design, slurry properties, and the often-overlooked gap between the die and the moving substrate. At a time when battery production is scaling rapidly worldwide, this kind of insight is becoming increasingly valuable.

Key Highlights

A validated numerical model captures slurry flow from the die inlet all the way to the coating gap

The simulations predict inlet pressure and wet film uniformity with less than 5 percent deviation from experiments

Three dominant wet film defect types are identified and explained

Die geometry and slurry viscosity are shown to be decisive for coating quality

The study provides practical guidance for improving lithium-ion battery electrode coating

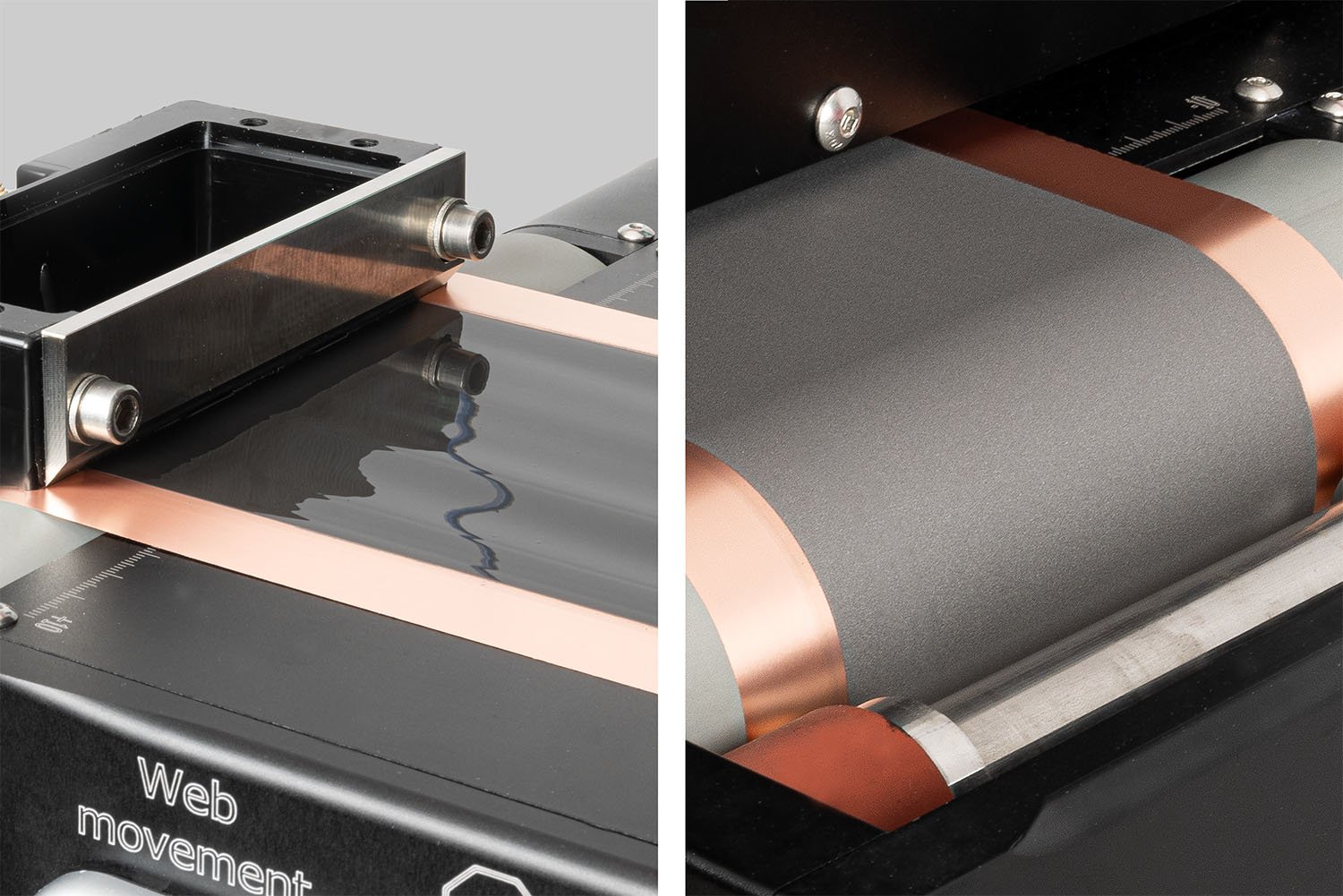

Slot-die coating is a critical step in manufacturing high-performance thin-film batteries.

What Is Slot-Die Coating and Why It Matters

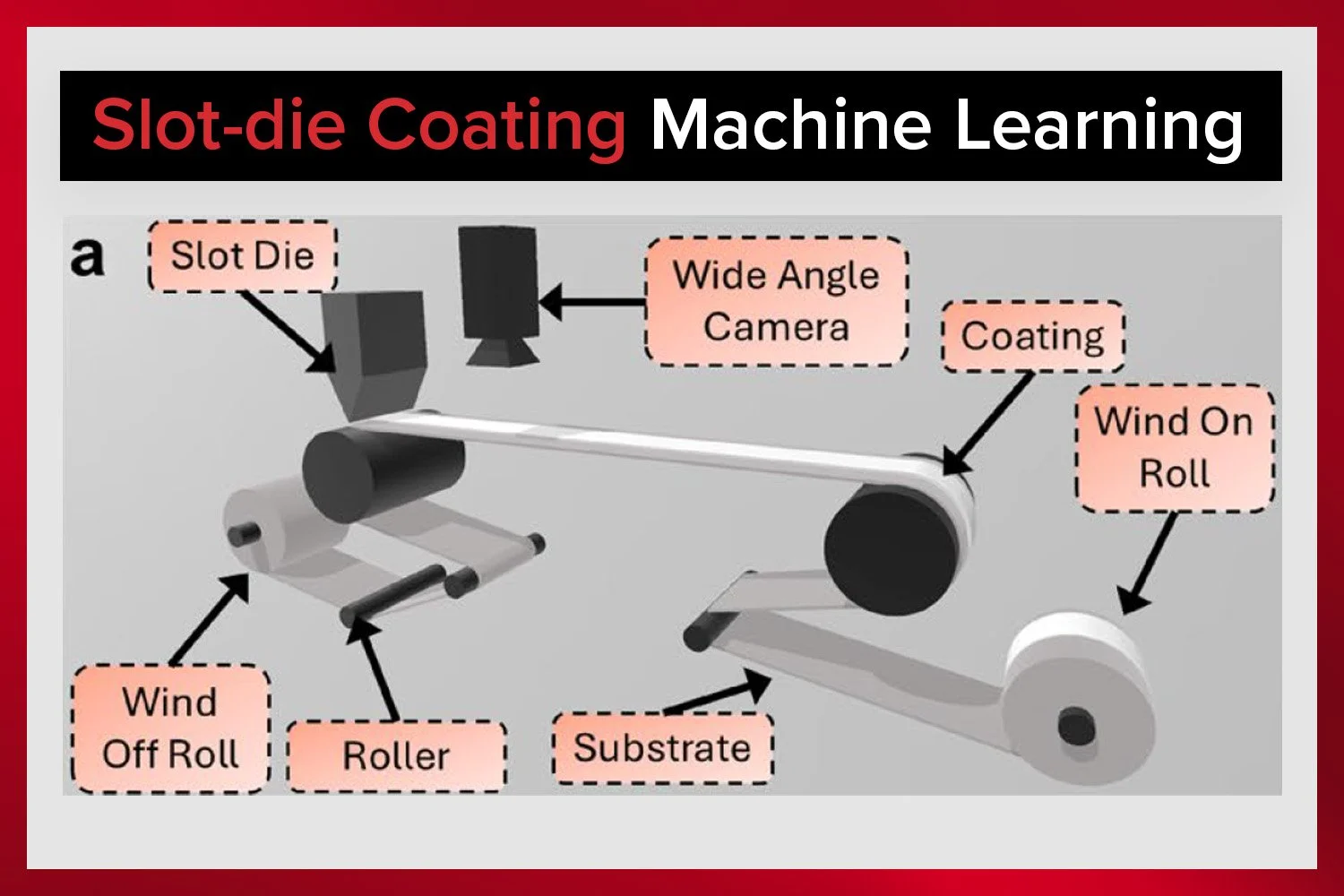

Slot-die coating is a cornerstone technology in roll-to-roll manufacturing. It allows a controlled amount of liquid to be deposited onto a moving substrate, making it especially suitable for battery electrodes, where thickness accuracy and uniformity are critical.

In theory, slot-die coating offers excellent control and scalability. In practice, however, coating lithium-ion battery slurries is far from simple. These slurries are dense, particle-loaded, and non-Newtonian, meaning their viscosity changes with shear. Small disturbances in flow can quickly translate into thickness variations across the coated width.

Those variations may look minor at first glance, but they can lead to uneven drying, local differences in electrode density, and ultimately degraded battery performance. Understanding how and why these defects form is therefore essential for reliable battery manufacturing.

Why This Study Is Significant

Many previous simulation studies stopped at the die lip. They treated the outlet as a boundary and ignored what happens in the narrow gap between the die and the moving substrate. In real coating processes, that gap strongly influences the final wet film.

This study explicitly includes the coating gap in the simulation domain. By doing so, it connects large-scale flow inside the die with micron-scale flow at the point where the slurry becomes a film. That alone marks a major step toward more realistic modeling.

Equally important is validation. The authors compare simulated inlet pressures and wet film profiles with experimental measurements and find very close agreement. This gives confidence that the model does not just look good on screen, but actually reflects industrial reality.

Learn why laboratory R2R coaters are an essential starting point for thin-film batter coating.

Understanding Wet Film Morphology

A central focus of the study is wet film morphology. This term describes how the thickness of the freshly coated film varies across the width before drying begins.

The simulations reveal that most coating outcomes fall into a small number of characteristic patterns. Uniform films are the goal, but three types of nonuniformity appear repeatedly in practice.

Edge bulges occur when excess slurry accumulates near the edges of the coating. Central bulges show the opposite behavior, with the thickest region in the middle. Edge trailing appears as thinning or instability near the edges, often accompanied by waviness.

By clearly defining and visualizing these patterns, the study makes it easier to link specific defects to their underlying causes.

How the Simulations Were Performed

This work is an original research study based on computational fluid dynamics simulations. The authors construct a detailed three-dimensional model of a slot-die coating head, including the inlet channel, main manifold, slit channel, die lips, and the coating gap.

The slurry is modeled as a shear-thinning, non-Newtonian fluid, which reflects the real behavior of battery electrode formulations. Flow is assumed to be laminar, which is appropriate for the velocities and dimensions involved.

To ensure reliability, the model is tested against multiple experimental coating cases. In all cases, the predicted inlet pressures and wet film unevenness closely match measured values. This validation step is crucial, as it confirms that the simulations can be used not only for explanation, but also for process optimization.

Achieve consistent slurry coatings with ease using the Laboratory Roll-to-Roll Coater.

How Die Design Shapes the Coating

One of the clearest messages from the study is that slot-die geometry matters deeply. Features that might appear secondary can strongly influence flow stability and film uniformity.

The presence of an auxiliary manifold, for example, plays a key role in suppressing edge bulges. By redistributing pressure and smoothing velocity profiles before the slit exit, it prevents excessive flow toward the edges.

The geometry of the slit exit also matters. Expansion angles and depths influence shear stress and velocity homogeneity as the slurry leaves the die. Adjusting these parameters can significantly reduce edge trailing defects.

Die lip thickness is another stabilizing factor. Thicker lips tend to dampen velocity fluctuations and improve overall uniformity, especially in the central region of the coating.

The Role of Slurry Properties and Process Conditions

Hardware alone does not determine coating quality. Slurry rheology and operating conditions are just as important.

The study shows that higher slurry viscosity generally improves wet film uniformity. More viscous slurries resist sudden velocity changes and are less prone to forming bulges or thinning regions.

Pressboard dimensions inside the die also influence pressure distribution. Smaller pressboards help avoid localized high-pressure zones that can drive unwanted flow patterns.

Together, these results highlight an important reality of roll-to-roll coating. Optimal performance comes from aligning formulation, die design, and process settings, rather than tuning any single factor in isolation.

The Laboratory Roll-to-Roll Coater makes double-sided slot-die coating simple.

Relevance for Industry and Future Outlook

As demand for lithium-ion batteries continues to grow, manufacturers face increasing pressure to scale production while maintaining tight quality control. Numerical simulation offers a powerful way to meet this challenge.

Models like the one presented in this study can reduce dependence on costly trial-and-error experiments. They make it possible to test design changes and process adjustments virtually, before implementing them on the production floor.

In the future, similar approaches could be extended to multilayer coatings, coupled drying simulations, and emerging battery chemistries. As digital tools become more integrated into manufacturing workflows, simulation-driven process design is likely to play an even larger role.

Conclusion

This study demonstrates how detailed numerical simulation can bring clarity to one of the most critical steps in lithium-ion battery manufacturing. By modeling the full slot-die coating process, including the coating gap, the authors provide a realistic picture of how wet film defects form and how they can be mitigated.

The identification of edge bulges, central bulges, and edge trailing, along with their links to die geometry, slurry viscosity, and process parameters, offers practical value for both researchers and industry engineers. Beyond its specific findings, the study underscores the growing importance of simulation as a tool for improving roll-to-roll coating quality and manufacturing efficiency.

Authors

Ningbo Li

Ruolan Jiang

Haobo Cao

Peng Wang

Bing Dong

Dongxu Han

Yujie Chen

Jun Yang

Dongliang Sun

Get Professional Support for Your Battery Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

The SDC Battery Coater Pro is specifically designed for researchers dedicated to developing and optimizing battery materials. It facilitates a seamless transition from research to commercialization. View video.