R2R Battery Breakthrough: Scalable Zinc Anodes Achieve 99.9% Efficiency and 2700 h Lifetime

Can we finally build large zinc batteries that are safe, efficient, and affordable?

This is the central question behind the research article “Roll-To-Roll Coating to Processing Large-Area Zinc Anodes toward Fast and Dendrite-Free Deposition.”

Zinc batteries have been attracting attention for years as a safer alternative to lithium-ion. Zinc is abundant, inexpensive, and works well in water-based electrolytes, which reduces many of the fire and safety risks that plague lithium systems. In principle, zinc could be the backbone of large-scale energy storage, stabilizing renewable power on the grid or powering devices that demand long-lasting, low-cost batteries.

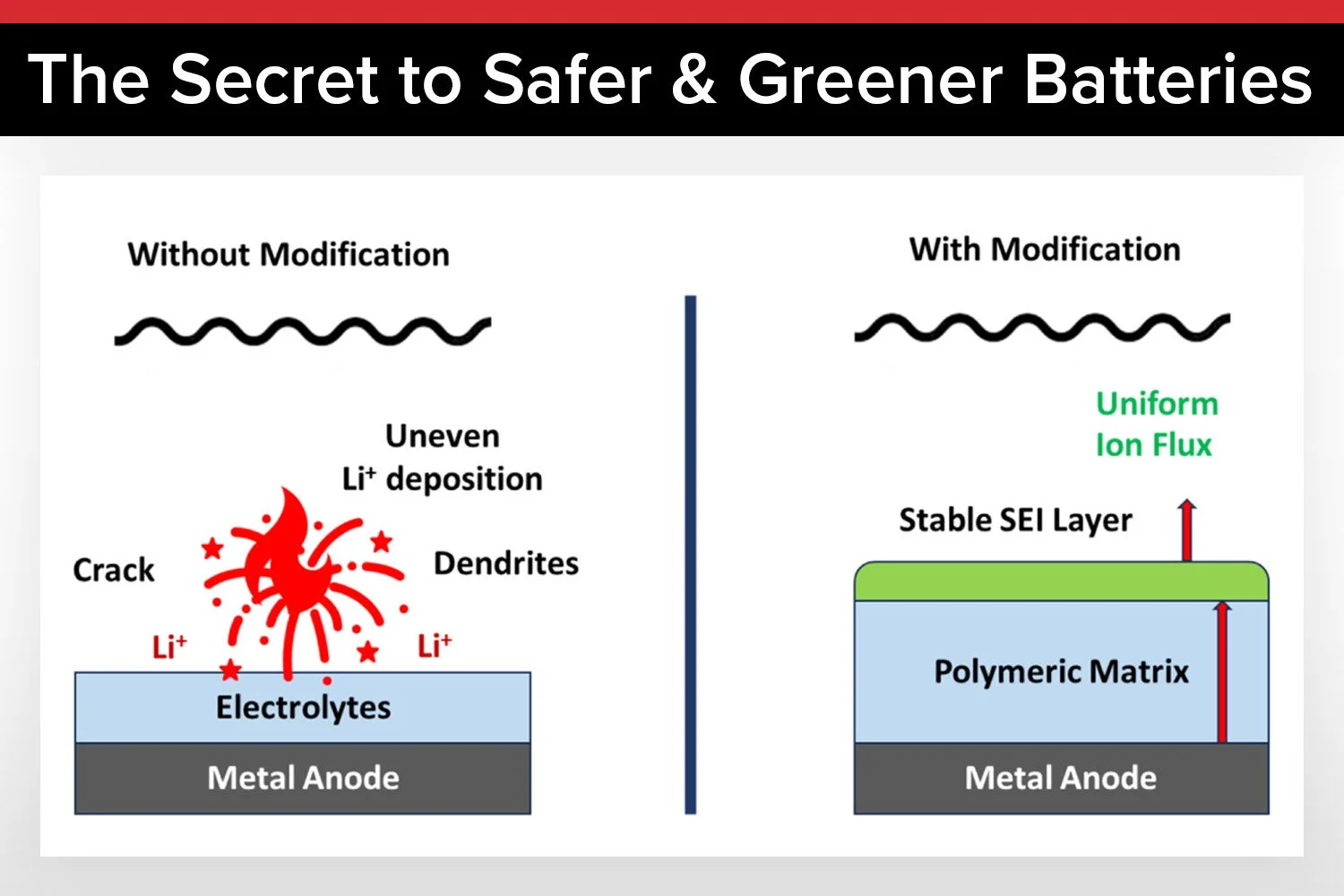

But there has always been a catch. Zinc anodes tend to grow dendrites, sharp metallic structures that shoot out during charging like microscopic tree branches. These dendrites don’t just look messy under a microscope, they pierce separators, trigger short circuits, and bring batteries to a premature end. Add to that the problems of corrosion and unwanted side reactions, and zinc’s potential has been left untapped.

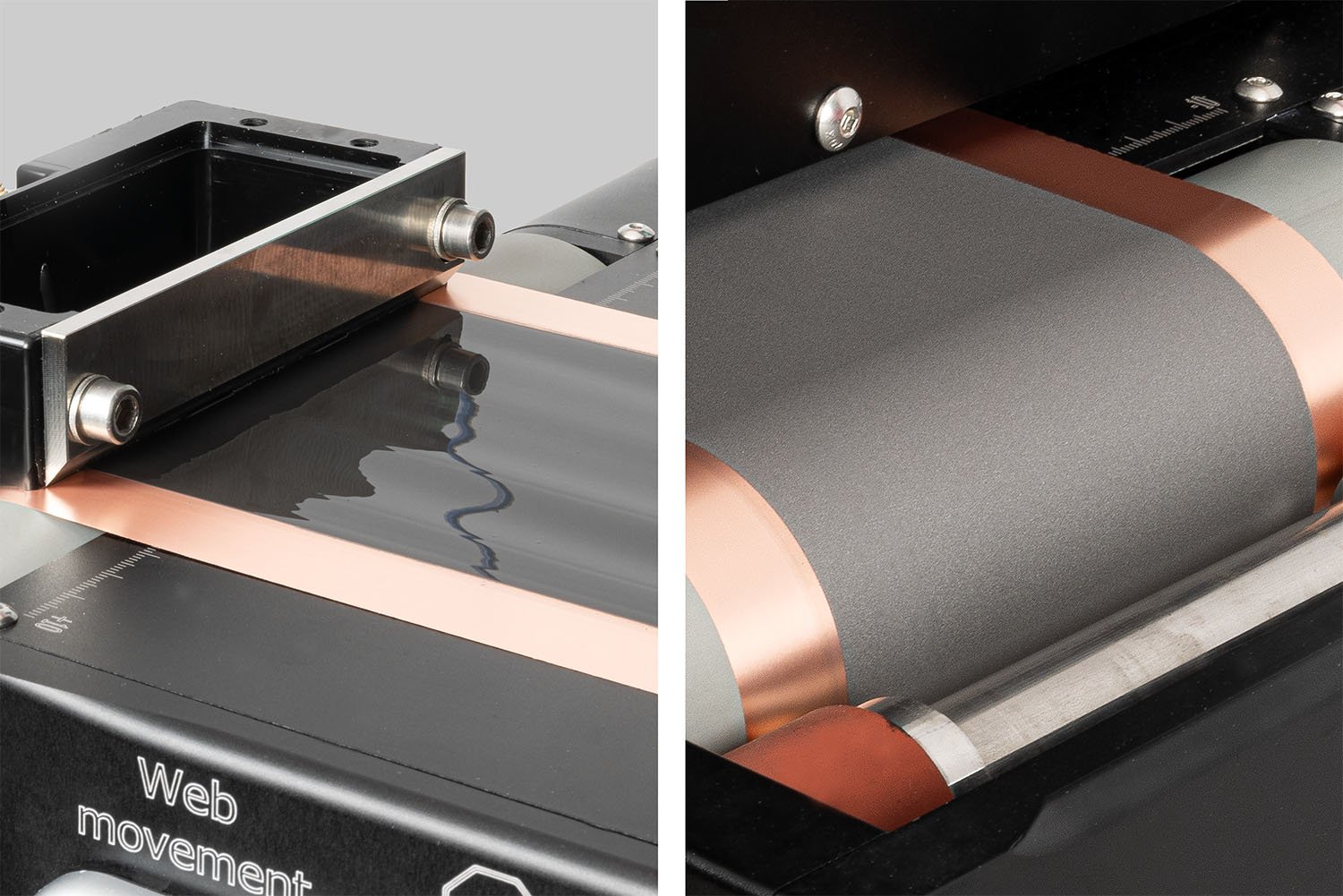

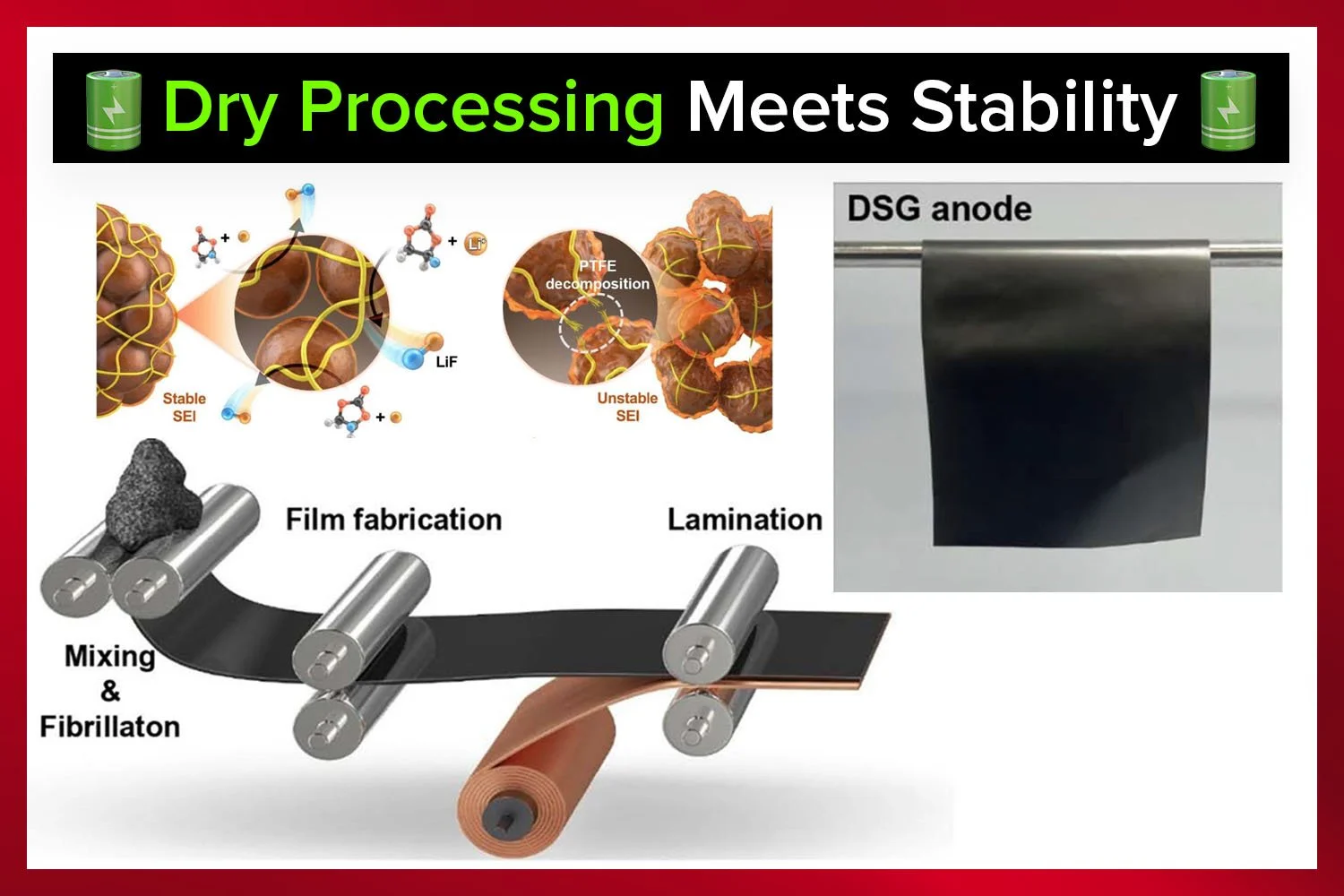

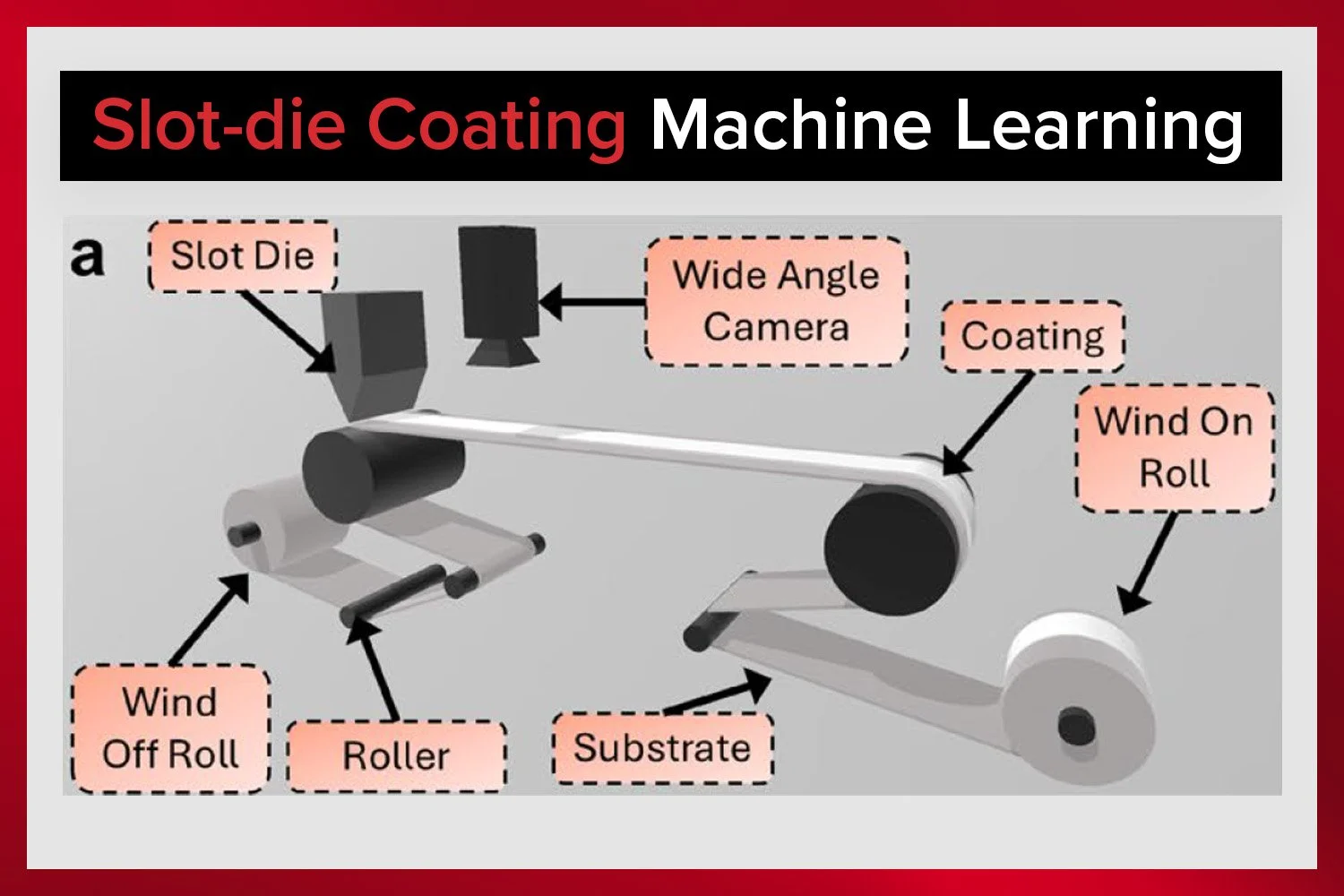

The new study takes on this long-standing challenge with a surprisingly straightforward solution: roll-to-roll coating. By adapting a manufacturing method already common in printing and electronics, the team has shown that it is possible to produce zinc anodes covered with an ultrathin protective nanofilm. The result is a battery that charges more smoothly, avoids dangerous dendrites, and lasts far longer than traditional zinc designs.

Key Highlights

Roll-to-roll method offers a low-cost and scalable way to fabricate large-area zinc anodes

A thin amorphous titanic oxide (ATO) nanofilm anchors directly onto zinc surfaces

Nanofilm promotes uniform zinc deposition, preventing dangerous dendrite growth

Achieved 99.9% Coulombic efficiency over 1500 cycles and lifetimes beyond 2700 hours

Strongly suppresses corrosion and hydrogen evolution, two key failure pathways

Demonstrated high performance in Zn||MnO₂ pouch cells, proving practical feasibility

Outperforms most reported methods in both capacity retention and cycling stability

Approach can be adapted to other oxides (e.g., SiO₂, Al₂O₃, ZrO₂) for broader applications

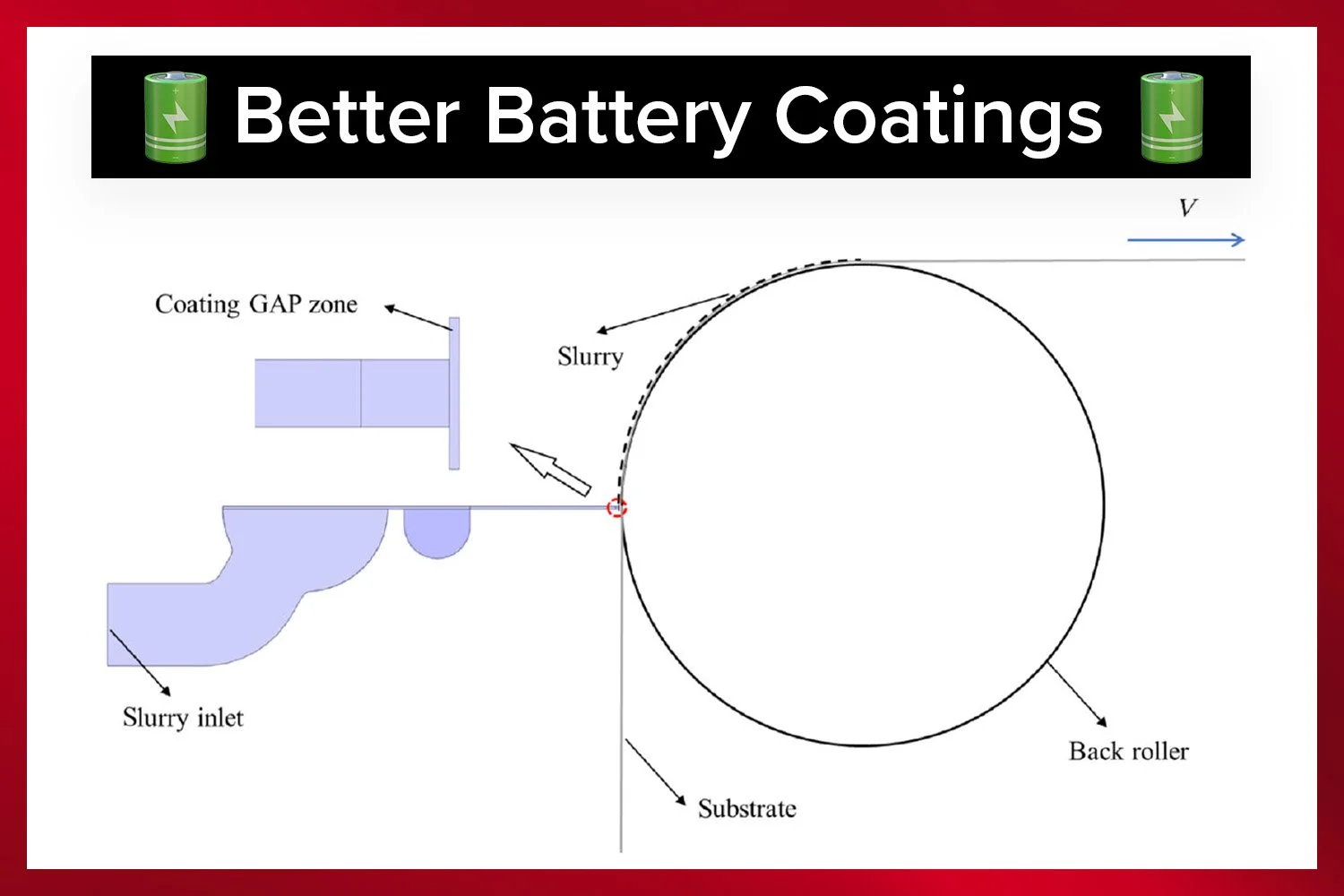

Slot-die coating is a critical step in manufacturing high-performance thin-film batteries.

What Is Roll-to-Roll Coating and Why Does It Matter?

If you’ve ever seen newspapers rolling off giant presses or thin plastic films being wound onto spools, you already have a sense of what roll-to-roll processing looks like. It is all about continuous, large-scale manufacturing. Instead of making one electrode at a time, you coat long sheets in a single flow, then cut or fold them into the shapes you need.

For zinc batteries, this is an especially powerful idea. Previous attempts at solving the dendrite problem have relied on complicated fabrication processes, thick protective layers, or exotic materials. These approaches often worked in the lab but were too expensive or fragile to ever scale up.

The roll-to-roll method described in this study flips the problem on its head. Rather than making protection an add-on process, it integrates it directly into a continuous coating step. The researchers used a simple liquid-air reaction to form a thin amorphous titanic oxide film, which naturally anchored itself to the zinc surface through chemical bonding. The result is a protective coating that is thin, uniform, strongly adhered, and crucially, easy to manufacture in bulk.

That combination of performance and scalability is what makes this work stand out. It is not just about making zinc better—it is about making zinc practical.

The Significance of the Study: Why Zinc Anodes Matter

To understand why this breakthrough is exciting, it helps to revisit why researchers care about zinc in the first place. Zinc offers a set of qualities that lithium, despite its dominance, simply cannot match. It is cheap and abundant, with global reserves far more evenly distributed than lithium. It is also inherently safer, especially when paired with aqueous electrolytes. That safety makes zinc batteries attractive for large stationary storage where the risk of fire must be minimized.

Yet zinc has its flaws. Dendrite growth disrupts ion flow and eventually leads to catastrophic failure. Corrosion generates unwanted by-products that slow down deposition. Hydrogen evolution wastes energy and builds pressure inside the cell. These combined effects sap efficiency and shorten lifespan, meaning zinc batteries have remained more a promise than a product.

By developing a roll-to-roll coating that addresses all three issues at once, this research demonstrates that zinc does not have to remain an underdog. Instead, it can move closer to fulfilling its potential as a safe, scalable, and sustainable energy storage solution.

Roll-to-roll processing is perfect for scaling up fuel cell production.

Diving Into the Methods: How the Coating Works

The beauty of this approach lies in its chemistry. The protective film is made of amorphous titanic oxide, or ATO, which forms through the hydrolysis of a titanium precursor. At the interface, the ATO bonds tightly to zinc through Lewis acid–base interactions, creating strong Zn–O–Ti linkages that prevent the layer from peeling away.

Importantly, the coating is not thick or heavy. Atomic force microscopy showed it has a roughness of just 12.6 nanometers. That is thin enough to leave the zinc’s morphology intact but thick enough to make a big difference in performance.

Tests confirmed that the film changes how zinc interacts with its environment. Surfaces became more hydrophilic, allowing electrolytes to spread evenly and improving ion diffusion. The coating also acted as a shield, suppressing side reactions and corrosion that normally damage zinc anodes. In short, the ATO nanofilm created the conditions for zinc to deposit smoothly, rather than chaotically.

Performance Results: Batteries That Last Longer and Work Harder

The difference between bare zinc and coated zinc could not be clearer. Without the coating, zinc electrodes quickly sprouted dendrites, corroded, and failed after only a few hundred hours. With the ATO nanofilm, the same electrodes kept running for more than 2700 hours under similar conditions.

Efficiency improved as well. Coulombic efficiency, a measure of how much charge you can recover compared to what you put in, stabilized at 99.9% over 1500 cycles. Even under high-stress conditions with large current densities, the coated electrodes maintained stable performance for more than 1200 hours.

The coating did more than just extend lifespan. It made zinc batteries genuinely practical. In full-cell tests with manganese dioxide cathodes, the coated zinc maintained 95.6% of its capacity after 1000 cycles at high rates. Bare zinc, by contrast, managed only 40.5%. The coated electrodes also delivered higher capacities, faster ion transport, and better recovery after high-rate cycling.

Perhaps most strikingly, the researchers assembled pouch cells—devices closer to real-world battery packs—and showed they could power LED lights with ease. It was a small but powerful demonstration that this was not just a lab curiosity but a pathway to working technology.

Achieve consistent slurry coatings with ease using the Laboratory Roll-to-Roll Coater.

Future Outlook: From Lab Discovery to Industry Adoption

Scientific breakthroughs often stumble when it comes time to scale, but this work is built for scalability from the beginning. Roll-to-roll manufacturing is already standard in industries ranging from packaging to electronics. That means the infrastructure is there, ready to adapt to zinc batteries.

The researchers also highlight that their approach is versatile. While this study focused on titanic oxide, the method can be extended to other oxides such as silica, alumina, or zirconia. Each material could bring its own advantages, opening up a toolkit of coatings for different needs.

For the energy industry, the implications are clear. A scalable, cost-effective, and dendrite-free zinc battery could become a cornerstone of renewable energy storage. It could make large batteries safer for homes and businesses, while reducing reliance on lithium in markets where supply chains are fragile. The study suggests that the age of zinc batteries might finally be within reach.

Conclusion

This research presents a roll-to-roll coating strategy that transforms zinc anodes from fragile and failure-prone to stable and long-lasting. By applying a nanofilm of amorphous titanic oxide, the team achieved lifespans beyond 2700 hours, efficiencies of 99.9%, and strong resistance to corrosion and side reactions. The success in full pouch cells further underscores its practical value.

What makes this work truly important is not only its technical achievement but also its scalability. By choosing roll-to-roll processing, the researchers have aligned cutting-edge electrochemistry with a proven industrial manufacturing technique. The result is a pathway toward zinc batteries that are not just better, but actually deployable at scale.

For anyone interested in the future of energy storage, this marks an important step. Zinc batteries are safer, cheaper, and more sustainable than lithium-ion in many applications. With roll-to-roll coated zinc anodes, they now look more ready than ever to deliver on that promise.

Authors

Huanyan Liu

Huanhuan Sun

Wei Hua

Xiangjiang Liu

Wenbo Liu

Jian-Gan Wang

Get Professional Support for Your Battery Coating Needs

Need help with slot-die coating, coating machines, or any related applications? Contact infinityPV’s experts today for professional guidance and support.

The SDC Battery Coater Pro is specifically designed for researchers dedicated to developing and optimizing battery materials. It facilitates a seamless transition from research to commercialization. View video.