How Public Funding Paved the Way for Printed Solar Cells, Slot-die Coating and Beyond

In the year 2000, research into organic solar cells began in Roskilde at the Risø Research Center. Thanks to continued public funding over the following 10 years, Danish expertise in functional organic materials for solar cells was established and developed, enabling production through printing under normal conditions—without expensive cleanrooms and vacuum facilities.

This investment was initially quite fundamental, even though the goal from the start was technical and scientific. The aim was organic materials for low-cost printed solar cells. The support was spread across many national, private, and international research councils, and the total public investment for the initiative, originating from the Risø Research Center, amounts to ~95 million DKK in funding for the period 2000–2025.

Although not all figures are available, it is estimated that the industrial turnover directly related to the public investment reached break-even around 2020. This means one can expect public funding to be matched by industrial turnover over a 20-year period.

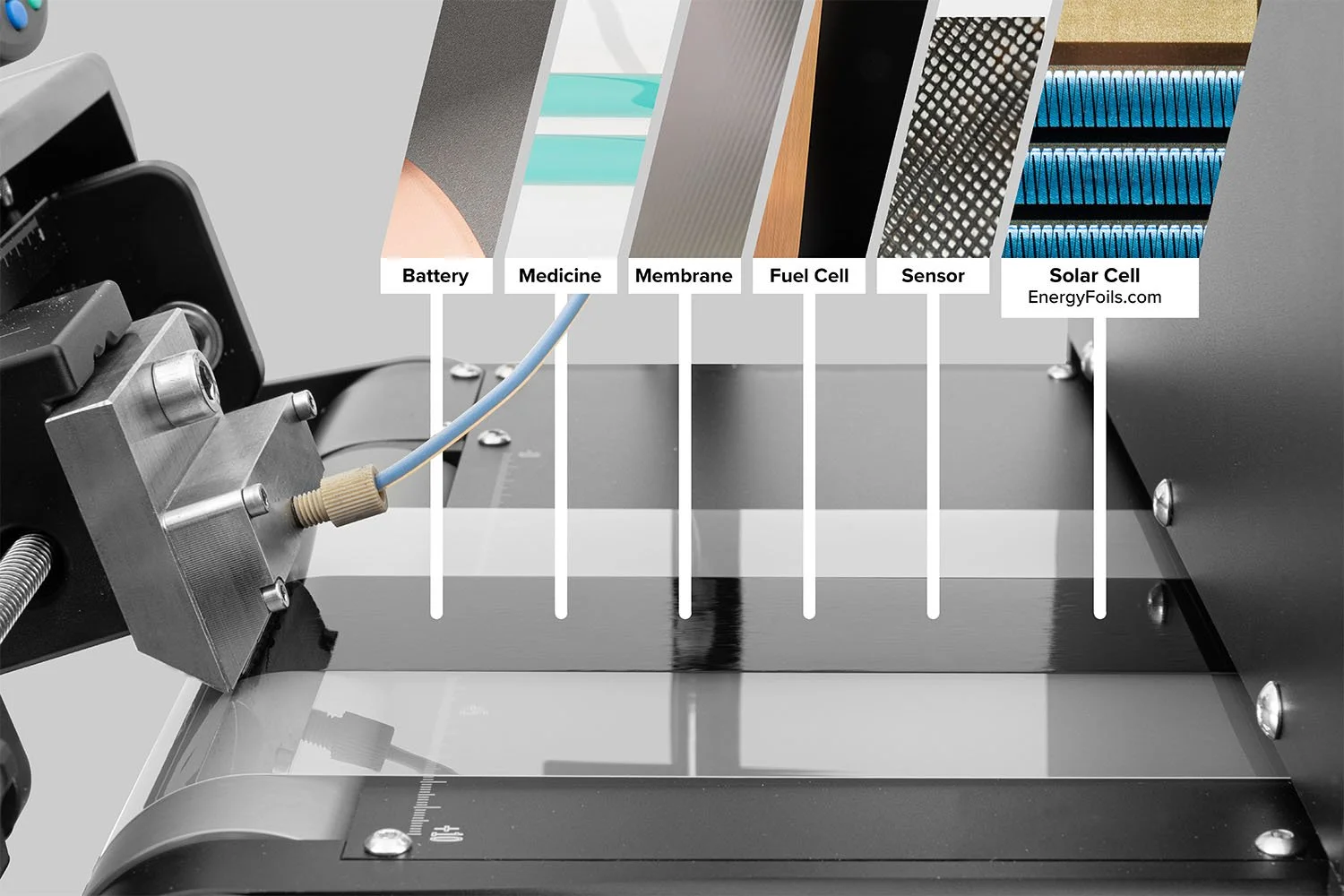

“infinityPV extended the slot-die coating method into many areas beyond solar cells. Among others: fuel cells and hydrogen technology, batteries for electric vehicles, sensors, membranes for water purification and separation technology, drug delivery, catalysis, and much more.”

– Frederik C. Krebs, CEO, infinityPV

Industrial Development

The major advancements within techniques, materials, measuring equipment, and manufacturing equipment attracted industrial attention from existing Danish companies, but also laid the foundation for new companies to be established.

On this basis, infinityPV later founded a subsidiary within printed solar cells with a view to a future stock exchange listing, as the development and specialization of the slot-die coating method for producing well-defined thin flexible organic and inorganic films using the roll-to-roll method has proven to have vast industrial applications—far beyond what could have been foreseen when the research began 20 years earlier.

“infinityPV extended the slot-die coating method into many areas beyond solar cells such as fuel cells and hydrogen technology, batteries for electric vehicles, sensors, membranes for water purification and separation technology, drug delivery, catalysis, and much more,” says Frederik C. Krebs, CEO of infinityPV, who expects that public investment over a 40-year period will return tenfold.

When Technological Advances Pave the Way

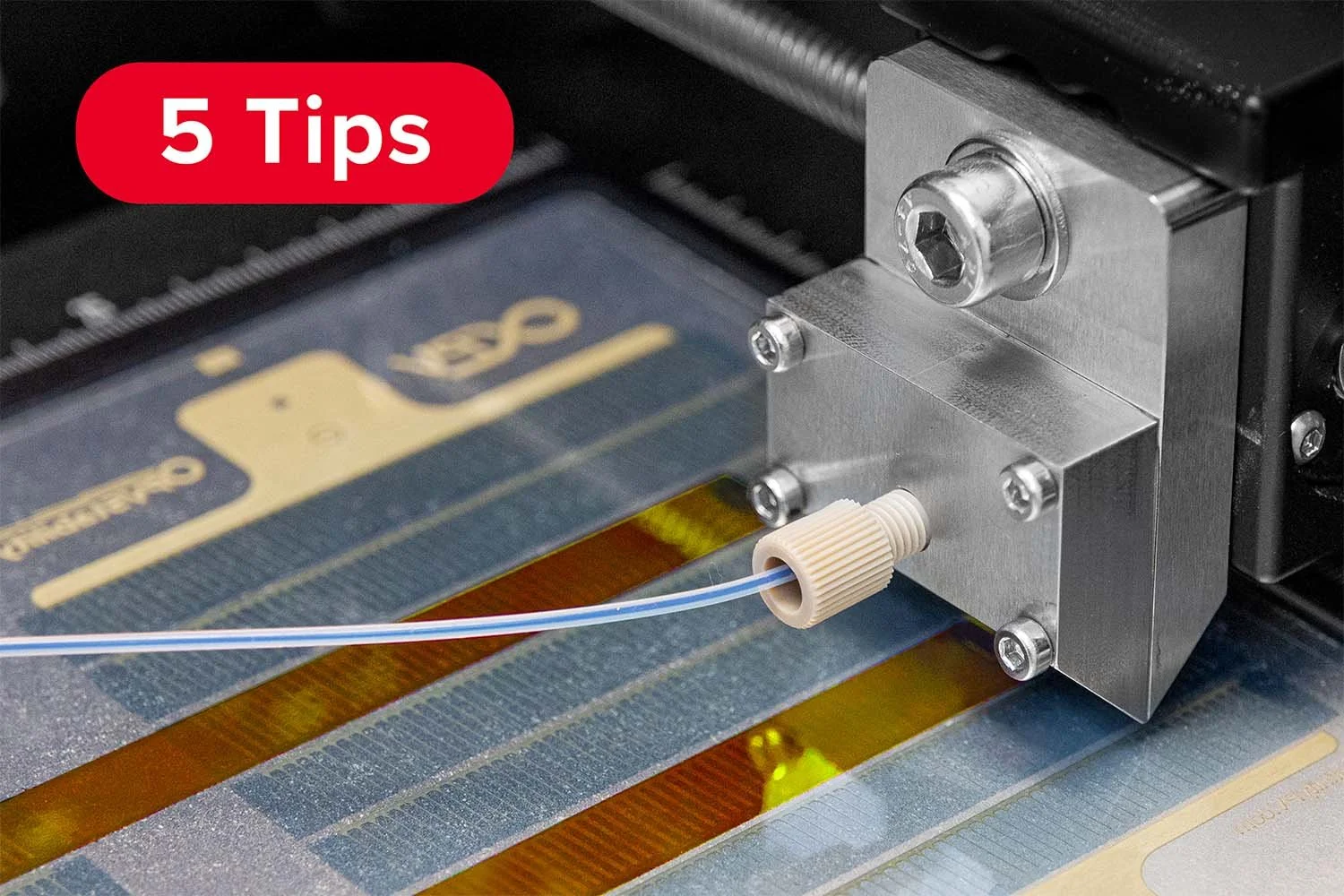

Quite simply, the need for a vacuum-free process for solar cell production resulted in the adaptation of a well-known method called slot-die coating. Slot-die coating is an age-old technique from around 1950, best known for its use in the photographic industry, where it was applied to produce thick multilayer films. It has proven particularly useful for producing thin functional films and can be controlled with precision down to just a few nanometers.

And hopefully, it gives food for thought that an idea so strong it secured public support guided researchers down a path. Along this very path, new foundations were created that could not have been foreseen. It proves that public support works—even if it is difficult to steer.

How Can We Help With Your Research?

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.