Slot-die Coating Optimization with AI: Machine Learning Unlocks New Efficiency for Batteries and Solar Cells

Can Machine Learning Unlock Smarter Coatings?

What if we could make the thin films used in batteries and solar panels not only faster, but more precise, more reliable, and less wasteful to produce? Roll-to-roll slot die coating is already one of the most important techniques in modern manufacturing, yet it still faces a stubborn problem: achieving perfectly uniform coatings is harder than most people realize.

A recent research article, “Surrogate-assisted optimization of roll-to-roll slot die coating”, published in Scientific Reports by a team from the University of Sheffield, shows that the key to better coatings may lie in artificial intelligence. By using machine learning to predict and optimize process conditions, the researchers achieved coatings that were more uniform than ever before. For industries that depend on thin films, such as energy storage and solar power, this work points to an important step forward.

Key Highlights

Roll-to-roll slot die coating is critical in the production of thin films for batteries, solar cells, and fuel cells.

Conventional optimization relies on trial and error and often leaves potential performance improvements untapped.

The study used Radial Basis Function Neural Networks (RBFNNs) to predict coating outcomes from experimental data.

An evolutionary algorithm, RVEA, was applied to find the best possible combinations of parameters.

Shim thickness and substrate velocity were identified as the most important factors for uniform coatings.

The optimized conditions produced the five most uniform coatings recorded in the study.

Performance was quantified through an increase in hyper-volume fraction from 0.68 to 0.84.

The approach is practical for industrial use, requiring only a few hours of computation and testing.

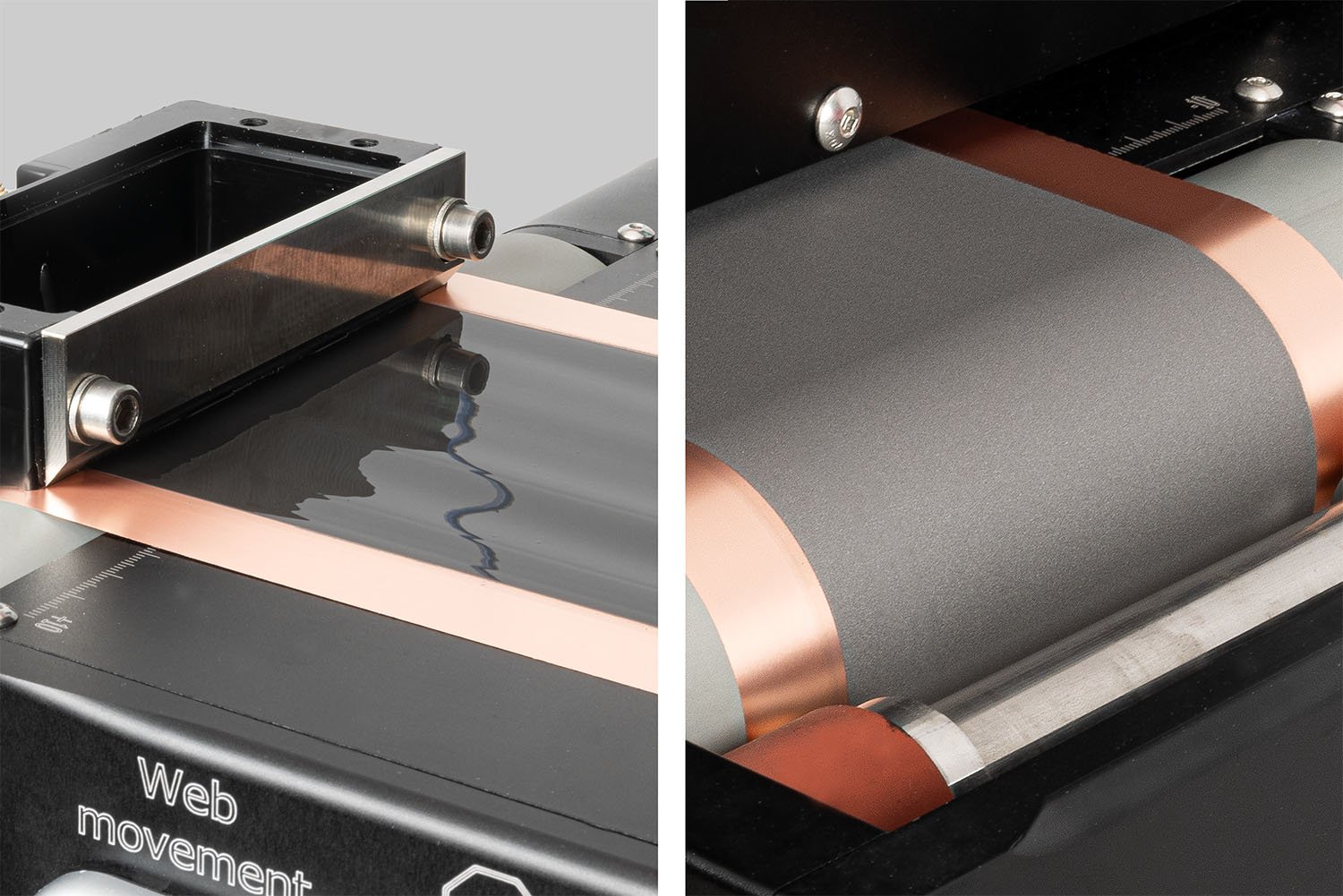

The Laboratory Roll-to-Roll Coater is the ideal coating machine for scaling up to roll-to-roll processing of battery electrode materials or for testing and optimizing battery electrode slurries.

What is Roll-to-Roll Slot Die Coating and Why Does it Matter?

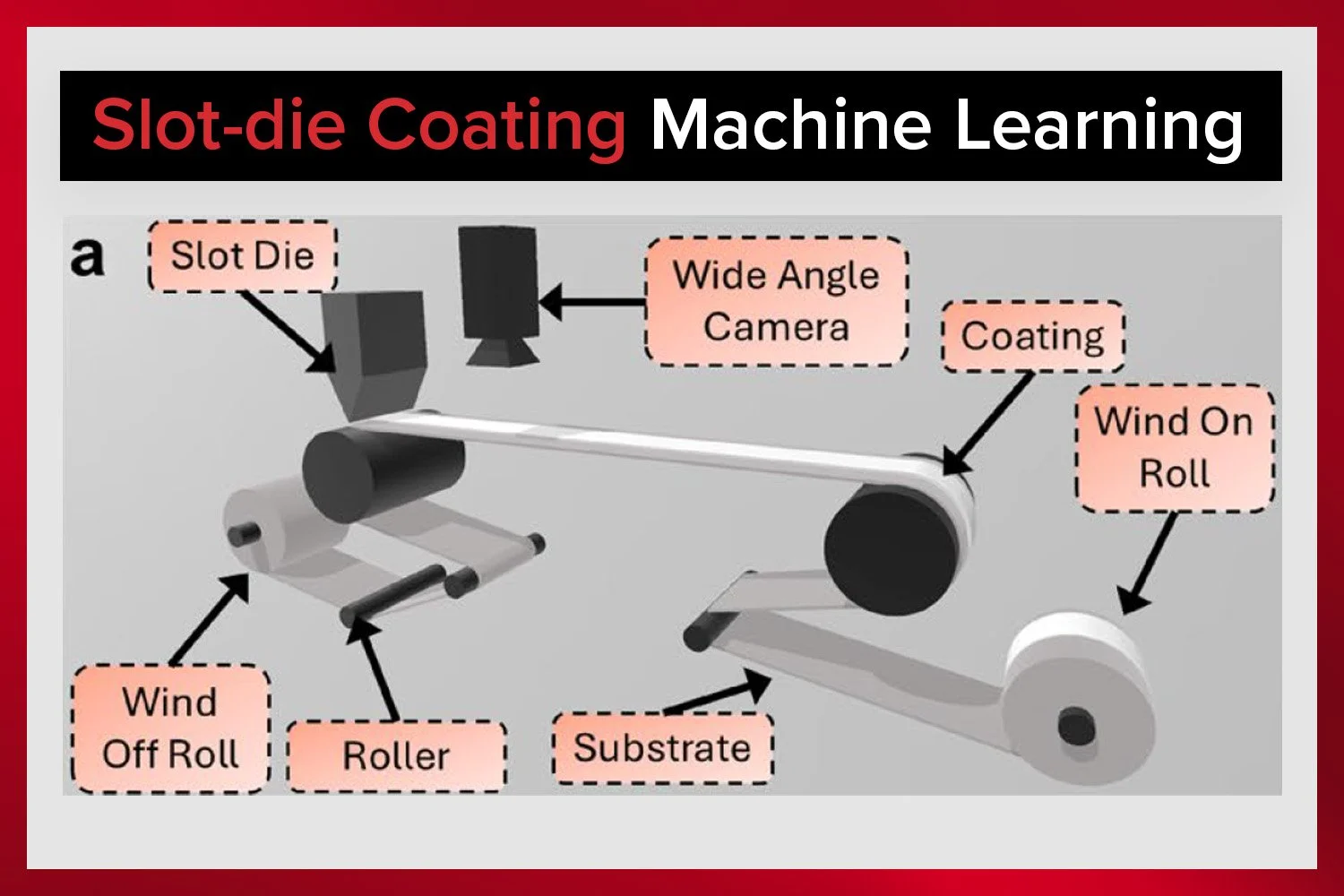

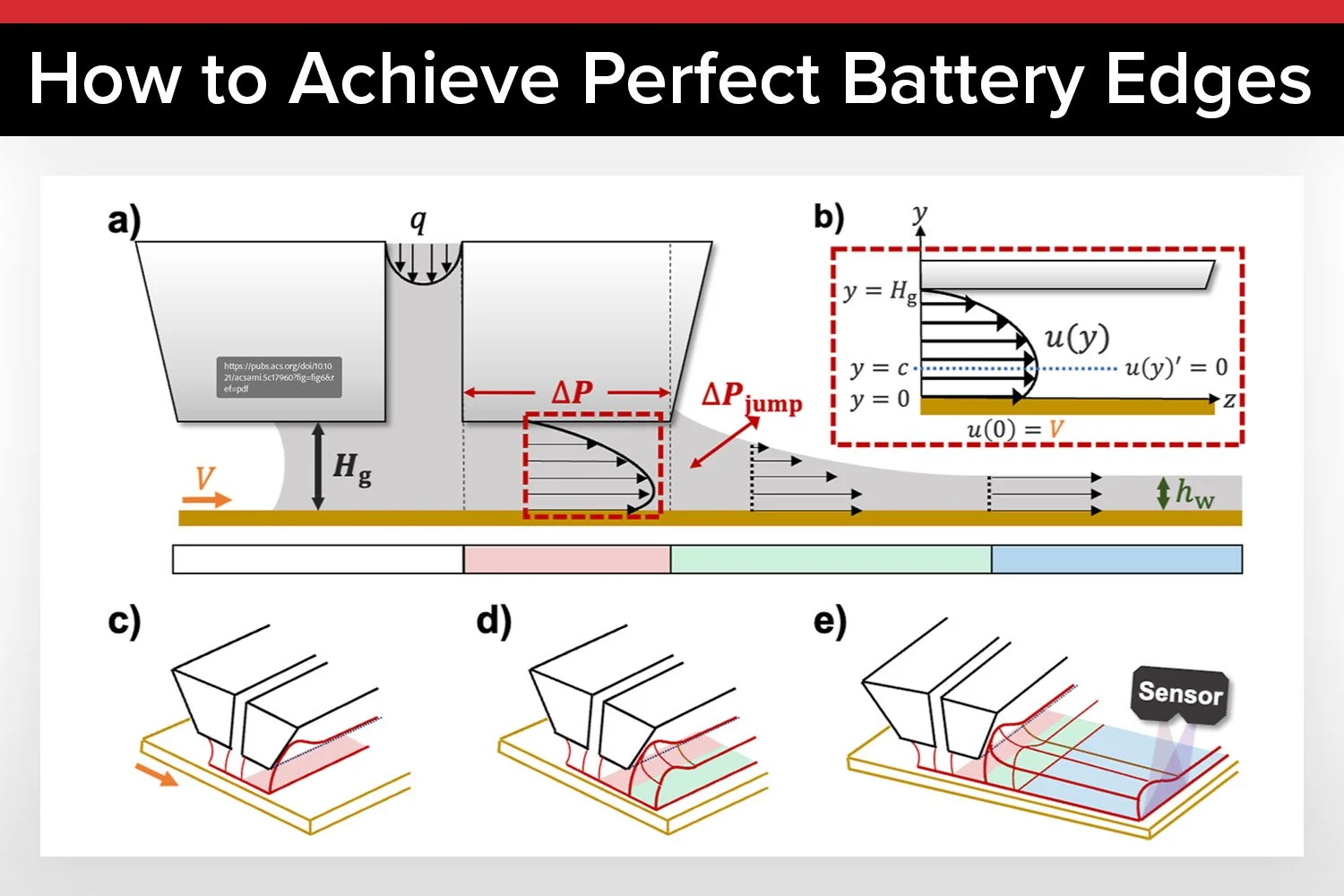

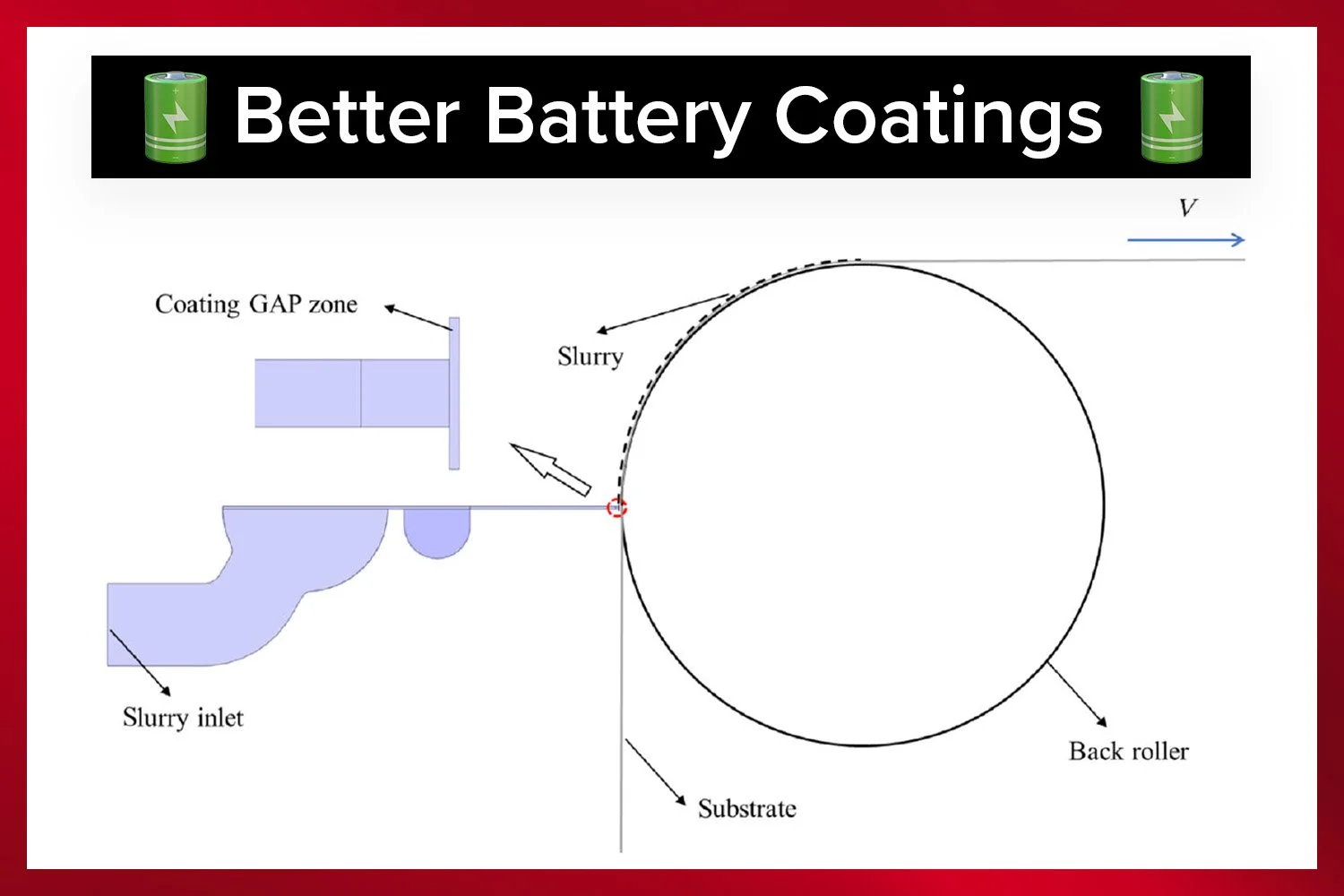

Slot die coating is a continuous process where a liquid solution is pumped through a precisely engineered slit onto a moving substrate. By controlling settings such as the speed of the substrate, the distance between the die and the surface, the composition of the liquid, and the thickness of the shim inside the die, manufacturers can determine the final properties of the film.

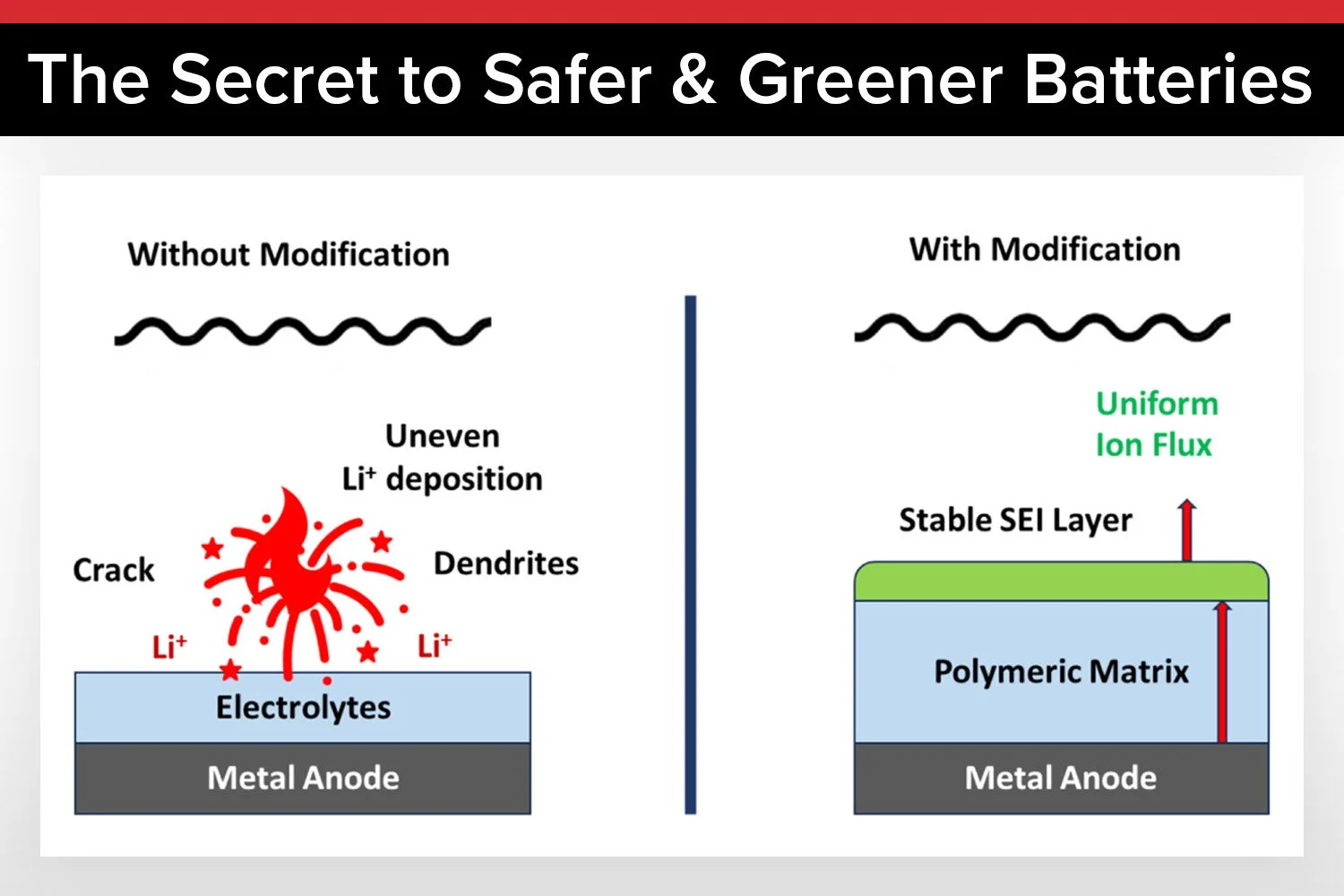

This technique is widely used in large-scale production because it is fast, efficient, and can be tailored to different applications. Its importance spans several industries. For example, in lithium-ion batteries, the thickness and uniformity of electrode coatings determine how much energy the battery can store and how reliably it performs. In solar panels, uneven coatings can reduce efficiency and shorten device lifetimes. Even minor variations matter, because they directly affect product quality, yield, and cost.

Although slot die coating is often assumed to give perfect control of thickness, the reality is more complicated. Variations can and do occur, even when the process is running within its accepted operating window. These small deviations can significantly impact performance. Traditionally, the only way to optimize production has been through trial and error. Engineers test different settings, observe the results, and gradually move toward acceptable performance. This approach is slow, consumes material, and rarely finds the true optimum.

The Significance of the Study: Why Machine Learning is Key

The Sheffield study addresses a long-standing gap in the field. While theoretical models exist to predict whether coatings will fail entirely, no accurate models have been available to describe how small changes in parameters affect quality inside the safe operating range. Without such models, companies have relied on experience and repeated testing rather than systematic optimization.

Machine learning provides a way out of this cycle. Instead of relying on incomplete theory, machine learning uses real experimental data to learn how the system behaves. The method can identify subtle patterns that are difficult for humans to detect. By applying this approach, the researchers showed not only how to improve coatings but also which parameters matter most.

Shim thickness and substrate velocity were found to have the strongest influence on uniformity, while the coating gap played a lesser role. These insights are valuable because they highlight parameters that are slow and difficult to adjust experimentally, making them hard to explore through traditional methods. With a machine learning framework, such relationships become clearer, and optimization becomes much more efficient.

Achieve consistent slurry coatings with ease using the Laboratory Roll-to-Roll Coater.

Diving Into the Methods: How the Study Was Done

The team began by creating a structured dataset of 81 experiments. Each experiment used different values of shim thickness, coating solution composition, substrate velocity, and coating gap. By systematically varying these inputs, they ensured the data captured a wide range of possible behaviors.

They then used Radial Basis Function Neural Networks, a form of artificial intelligence that is particularly good at modeling complex and nonlinear relationships. This model was trained to predict two outputs: the thickness of the coating and its uniformity. The training results showed that the model could predict outcomes with an error rate of less than 11.5 percent, which is a high level of accuracy for such a complex process.

Prediction alone is not enough, however. To find the best possible settings, the team combined their model with an optimization algorithm called RVEA (Reference Vector Guided Evolutionary Algorithm). RVEA explores trade-offs between competing objectives. In this case, the two competing goals were achieving the target coating thickness and maximizing uniformity. The algorithm generated a Pareto front, which is a set of conditions where no improvement in one property can be achieved without worsening the other.

Finally, they validated the results experimentally. The algorithm suggested new operating parameters, which were tested in the lab. The validation experiments produced coatings with improved properties, including the five lowest uniformity values recorded during the entire study.

What Did They Find?

The results confirmed that there is a trade-off between thickness accuracy and coating uniformity. In other words, it is not always possible to achieve both the exact target thickness and the smoothest possible coating at the same time. The RBFNN model captured this trade-off accurately and provided guidance on how to balance the two.

The optimized settings identified by the algorithm led to coatings that were far more uniform than those obtained through traditional parameter selection. The improvement was quantified using hyper-volume fraction, a common measure of performance in multi-objective optimization. This value increased from 0.68 in the initial experiments to 0.84 in the optimized set, a clear indication of progress.

While the predictions for thickness were less reliable, likely because of the limitations of the small-scale laboratory equipment, the improvements in uniformity were consistent and significant. Importantly, the computational requirements were modest, and the experimental validation was fast, meaning the approach could realistically be applied in an industrial setting.

The Laboratory Roll-to-Roll Coater makes double-sided slot-die coating simple.

Why This Matters for Industry

For industries producing lithium-ion batteries, solar panels, or fuel cells, this work demonstrates a path toward better performance and reduced costs. More uniform coatings mean higher-quality products, fewer defects, and less waste. Because thin-film production is often scaled up to hundreds of meters of material per day, even small improvements in efficiency and yield can translate into significant savings.

Equally important, the study shows that machine learning can deliver practical results in just a few hours. Instead of lengthy optimization campaigns, manufacturers could use real-time data and AI models to adjust their processes quickly. This represents a shift from reactive trial-and-error adjustments to proactive, data-driven control.

Looking Ahead: The Future of AI in Roll-to-Roll

The study is a strong proof of concept, but it also points to further opportunities. With larger datasets and industrial-scale equipment, machine learning models could become even more accurate. Additional process parameters, such as substrate treatments or die design variations, could be included to create a more complete picture.

One exciting prospect is the integration of machine learning into live production lines. In this scenario, data would be collected continuously, the model would update in real time, and the system could adjust its own parameters to maintain optimal conditions. Such an approach could revolutionize not only slot die coating but roll-to-roll processing as a whole.

Your coating process is only as good as the slot-die head that delivers it. Our guide helps you evaluate your needs and choose the right slot-die head for optimal quality, efficiency, and cost-effectiveness. Read the selection guide here.

Conclusion

The University of Sheffield’s research shows that machine learning can fundamentally improve how we approach roll-to-roll slot die coating. By replacing trial and error with a systematic, data-driven approach, the team achieved coatings with record-breaking uniformity. The combination of Radial Basis Function Neural Networks and evolutionary optimization offers both deeper insight into the process and immediate practical benefits.

For the industries that depend on thin films, this represents a clear step toward smarter manufacturing. The results suggest that the future of roll-to-roll processing will be not only faster and more efficient but also more intelligent.

Authors

Christopher Passmore – University of Sheffield

Kai E. Wu – University of Sheffield

Jonathan R. Howse – University of Sheffield

George Panoutsos – University of Sheffield

Stephen J. Ebbens – University of Sheffield

Get Professional Support for Your Battery Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

The SDC Battery Coater Pro is specifically designed for researchers dedicated to developing and optimizing battery materials. It facilitates a seamless transition from research to commercialization. View video.