Breakthrough in Roll-to-Roll Sensors: Faster, Smaller, and More Sensitive

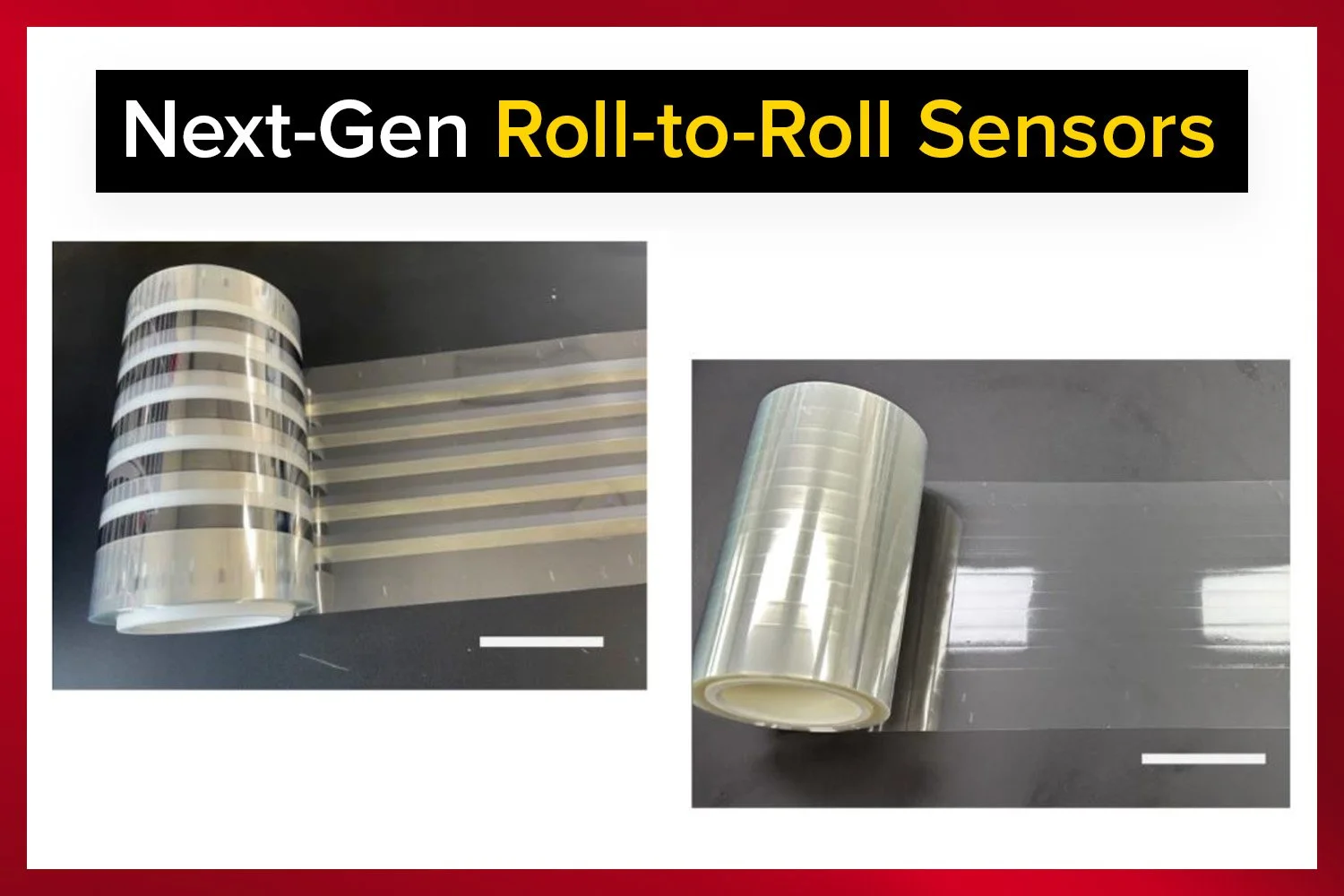

Can flexible touch sensors be both miniaturized and mass-produced?

That is the question driving a new research article titled “Enhancement of Roll-to-Roll Gravure-Printed Cantilever Touch Sensors via a Transferring and Bonding Method.”

From smartphones and wearables to biomedical monitoring devices, the demand for smaller and more sensitive sensors is exploding. The smaller the sensor, the more easily it can be integrated into lightweight and low-power systems. The challenge is how to produce such sensors at scale without compromising performance.

Traditionally, these sensors are fabricated through MEMS (microelectromechanical systems) processes. MEMS delivers excellent performance but is expensive and not well suited for mass production. Roll-to-roll gravure printing, in contrast, promises scalable and low-cost manufacturing on flexible substrates. Until now, however, it has been limited to thin, two-dimensional devices.

The new study introduces a transferring and bonding method that makes it possible to build three-dimensional air-gap structures in roll-to-roll printed sensors. This avoids a common fabrication problem called “stiction” and results in devices that are both smaller and more sensitive than earlier versions. The work could accelerate the arrival of flexible, high-performance sensors in consumer electronics, healthcare, and the Internet of Things.

Key Highlights

Researchers combined roll-to-roll gravure printing with a transferring and bonding method to fabricate cantilever touch sensors

The new process avoids stiction issues, a long-standing challenge in air-gap sensor fabrication

Sensors were miniaturized to areas as small as 1.44 mm², about seven times smaller than earlier versions

SU-8 structural layers delivered sensitivities up to 67 times higher than epoxy-based controls

Printing speed was improved up to 22 times compared to previous methods

Response times remained stable across all sizes, around 280–310 ms

Hysteresis errors remain a limitation, but the new process opens paths to optimization

The method paves the way for flexible sensors in wearables, medical devices, and IoT systems

What is roll-to-roll processing, and why is it revolutionizing the way we make flexible devices?

What is Roll-to-Roll Gravure Printing and Why Does it Matter?

Roll-to-roll gravure printing is a manufacturing method where functional inks are continuously printed onto a flexible moving substrate. It is similar in principle to newspaper printing but with conductive and dielectric materials instead of ordinary ink.

The key advantage is scalability. Devices can be produced quickly and in large volumes at relatively low cost. This makes roll-to-roll particularly attractive for flexible electronics, where applications often require lightweight and low-power devices to be manufactured in bulk.

Until recently, the limitation has been complexity. Roll-to-roll printing has excelled at making thin-film devices such as organic transistors or capacitors, but it struggled with three-dimensional structures. Sensors with air gaps, which are critical for high sensitivity, were thought to require MEMS processes. The new method presented in this study challenges that assumption.

The Significance of the Study

Miniaturization is not only about saving space. It improves system integration, reduces cost per unit, and enables new applications. A smaller and more sensitive touch sensor can be embedded in smart textiles, compact medical monitoring devices, or distributed across surfaces for advanced user interfaces.

MEMS technologies remain the gold standard, but they are costly and less suited to flexible materials. The ability to fabricate miniature air-gap touch sensors with roll-to-roll methods bridges the gap between high performance and high volume manufacturing. This makes the research highly significant for industries looking to scale sensor technology into everyday products.

Simplified Explanation of the Methods

The researchers fabricated the sensors in two main parts and then brought them together.

For the lower part, they printed a silver bottom electrode, added a dielectric layer of barium sulfate, and created a spacer to form the critical air gap. For the upper part, they printed a sacrificial layer, added a stretchable silver top electrode, and then deposited the structural layer material. The sacrificial layer was dissolved in water, leaving behind a free-standing top structure.

The two parts were then aligned and bonded together. This transferring and bonding approach prevented the sticking problem that usually occurs when sacrificial layers are removed, allowing the sensors to be miniaturized far beyond earlier designs.

Four types of sensors were compared: SU-8 based sensors in small, medium, and large sizes, and epoxy-based sensors of large size used as controls.

Results and Performance

The team optimized the roll-to-roll process and achieved printing speeds more than twenty times faster than previously reported. The fabrication produced sensors in three sizes, down to just 1.44 mm², compared with earlier 10 mm² designs.

In terms of performance, the choice of material for the structural layer proved critical. SU-8 based sensors were dramatically more sensitive than epoxy-based sensors. Sensitivity describes how strongly the sensor responds to small applied forces. The SU-8 versions recorded sensitivities up to 67 times higher than epoxy-based versions of comparable size.

Hysteresis, which measures how much the sensor lags when pressure is applied and then removed, was higher for SU-8 sensors. While this is a limitation, the improvement in sensitivity is a major step forward, and the researchers note that choosing alternative polymers could reduce hysteresis in future iterations.

Importantly, the response time was not affected by miniaturization. Across small, medium, and large SU-8 sensors, the response time stayed around 280 to 310 milliseconds. This means shrinking the sensor did not slow it down.

Taken together, the results show that the new method can produce sensors that are smaller, faster to manufacture, and significantly more sensitive.

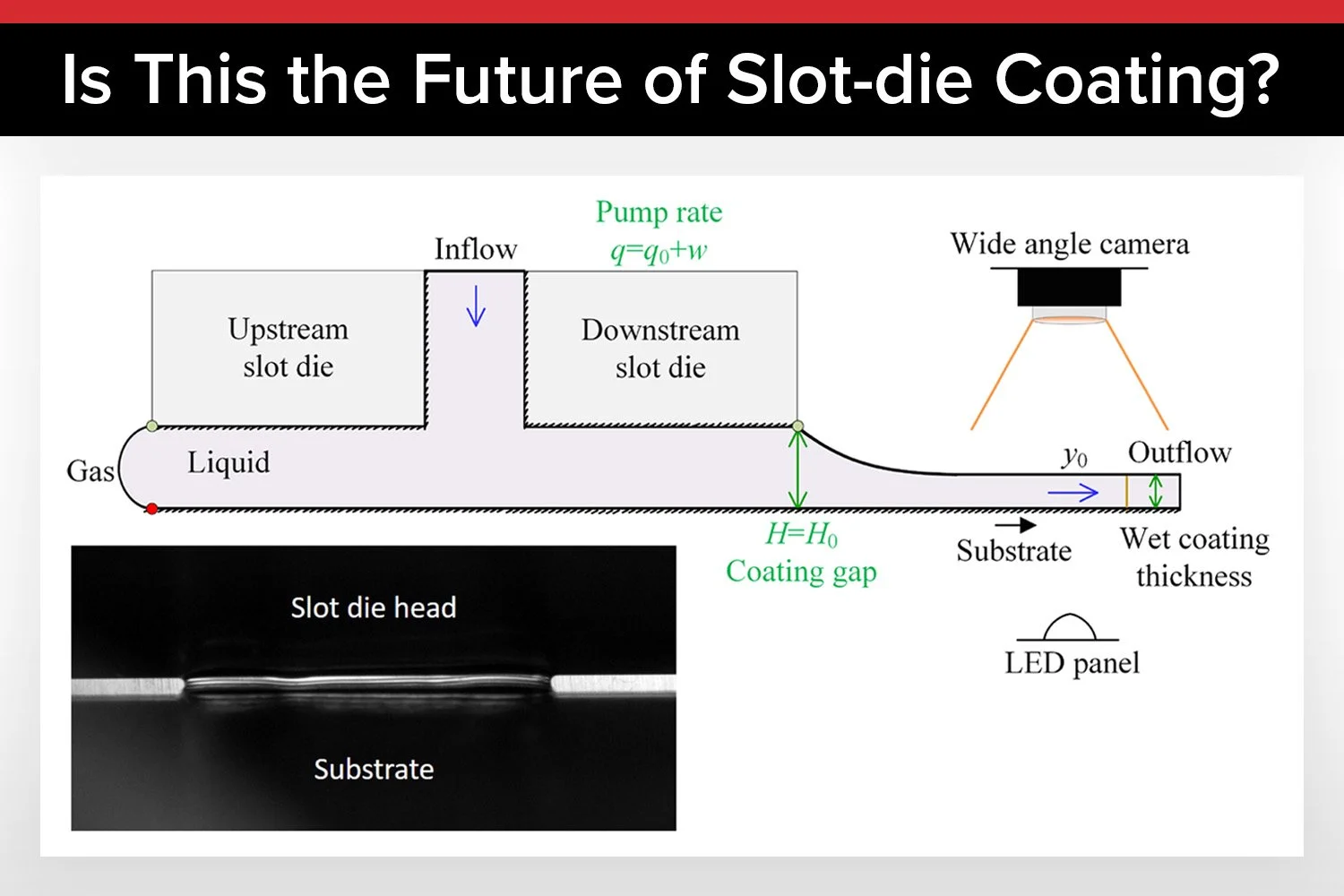

The Laboratory Roll-to-Roll Coater makes double-sided slot-die coating simple.

Future Outlook and Industry Relevance

The implications for industry are substantial. Wearable electronics are becoming more sophisticated and demand sensors that are lightweight, flexible, and able to detect small changes in pressure or touch. Roll-to-roll printed miniature sensors could make wearable health monitors more accurate while keeping them affordable.

Biomedical devices often need to detect delicate biological signals such as slight changes in pressure or motion. Miniaturized air-gap sensors with high sensitivity are well suited for this role. The roll-to-roll method offers a way to produce them in large quantities, lowering barriers for clinical adoption.

In the Internet of Things, embedding sensors into everyday objects requires low-cost production. Roll-to-roll printing, combined with the new bonding method, offers the scalability to make this feasible. Surfaces from household appliances to industrial machinery could be equipped with responsive, flexible sensors.

Looking further ahead, the study suggests that with automated micro-transfer equipment, it may be possible to fabricate sensors at the micro- and nanoscale. This would open the door to ultra-miniature devices for highly specialized applications, from medical implants to advanced robotics.

Conclusion

This study demonstrates how roll-to-roll gravure printing, combined with a transferring and bonding method, can overcome long-standing challenges in fabricating miniature touch sensors.

Key achievements include faster production speeds, miniaturization down to one-seventh the size of earlier designs, and sensitivity improvements up to 67 times compared to conventional controls. Response times remained consistent, confirming that performance is not sacrificed by scaling down.

Hysteresis remains a challenge, but the flexibility of the method means new materials can be explored to address it. The approach paves the way for flexible, high-performance sensors that can be produced at scale and integrated into future devices across wearables, healthcare, and IoT.

Authors

Sang Hoon Lee, University of California, Irvine

Jae Hak Shin, Konkuk University, Seoul

Sangyoon Lee, Konkuk University, Seoul

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.