Say Goodbye to Bubbles in LED: New Slot-Die Coating Technique Delivers Bubble-Free LED Films

Why Are LED Film Bubbles Still a Problem?

A recent study titled “Contact-Angle-Guided Semi-Cured Slot-Die Coating Eliminates Air Entrapment in LED Multilayer Films” takes a close look at a persistent issue in the production of polymer films used in LED devices: the formation of air bubbles. These bubbles are more than just a visual flaw; they negatively affect film quality, reduce uniformity, and harm optical performance.

So why is air entrapment particularly problematic in multilayer coatings, and what can be done about it? This study offers a clear explanation and presents a practical solution.

Through a combination of carefully controlled experiments and advanced computer simulations, the researchers demonstrated that modifying the coating process can significantly reduce air bubble formation. Their method involves semi-curing the base layer and carefully managing surface wettability during the coating step, guided by contact angle measurements.

Key Highlights

Air entrapment in multilayer LED films is a key cause of performance degradation.

Traditional “coat–dry–coat” methods often trap air at the interface between layers.

Surface wettability differences, especially lower contact angles, contribute to instability and bubble formation.

A semi-cured slot-die coating method is introduced to suppress air defects during multilayer application.

Partial curing improves wettability control, stabilizes fluid behavior, and minimizes air trapping.

Computer simulations revealed that vortex formation is the main mechanism driving air entrapment.

Incorporating temperature-dependent viscosity into simulations greatly improved accuracy.

The improved model reduced coating gap prediction error from 11.5% to 5 percent.

This method delivers more consistent and reliable multilayer films for LED manufacturing.

What Is Slot-Die Coating and Why Does It Matter?

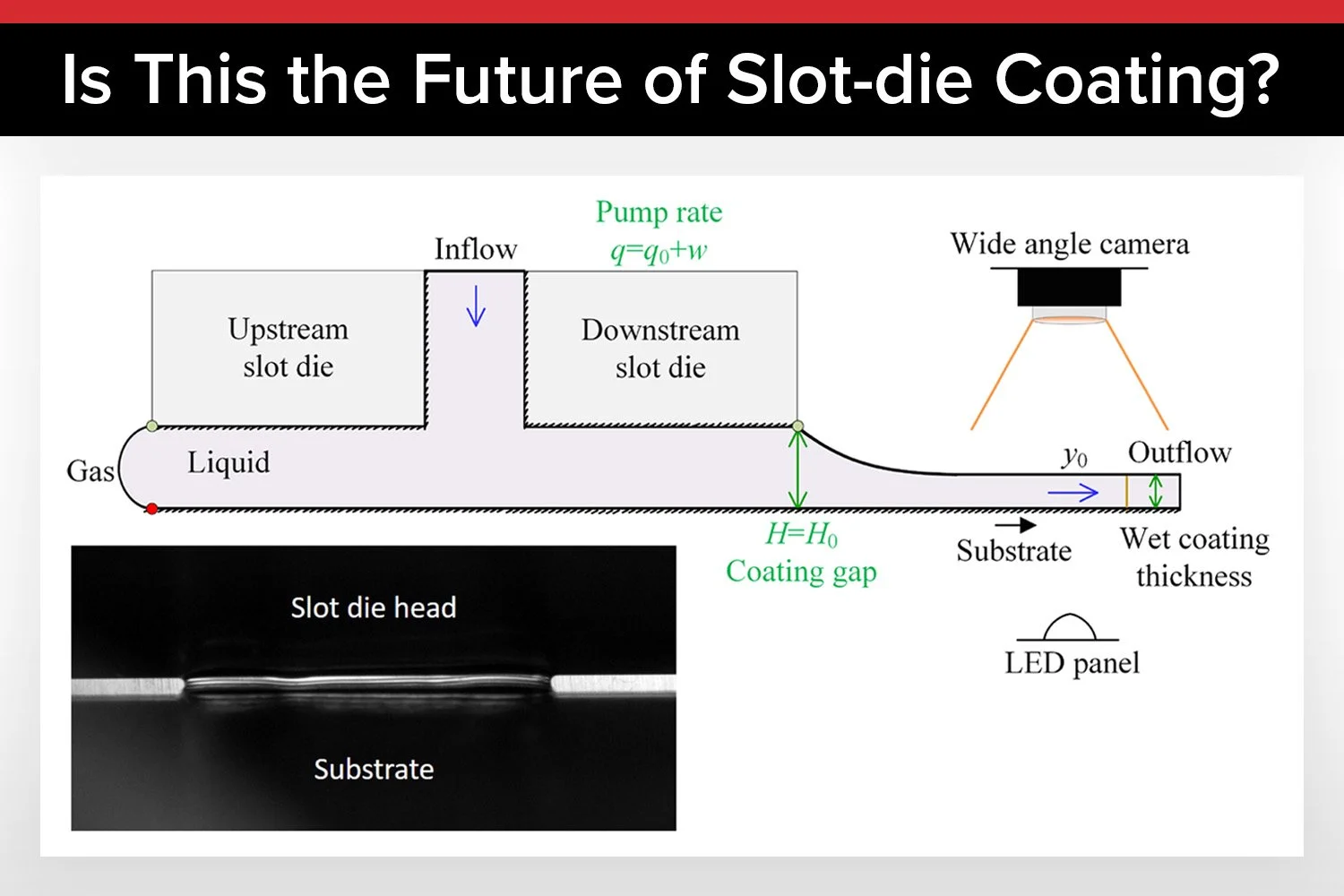

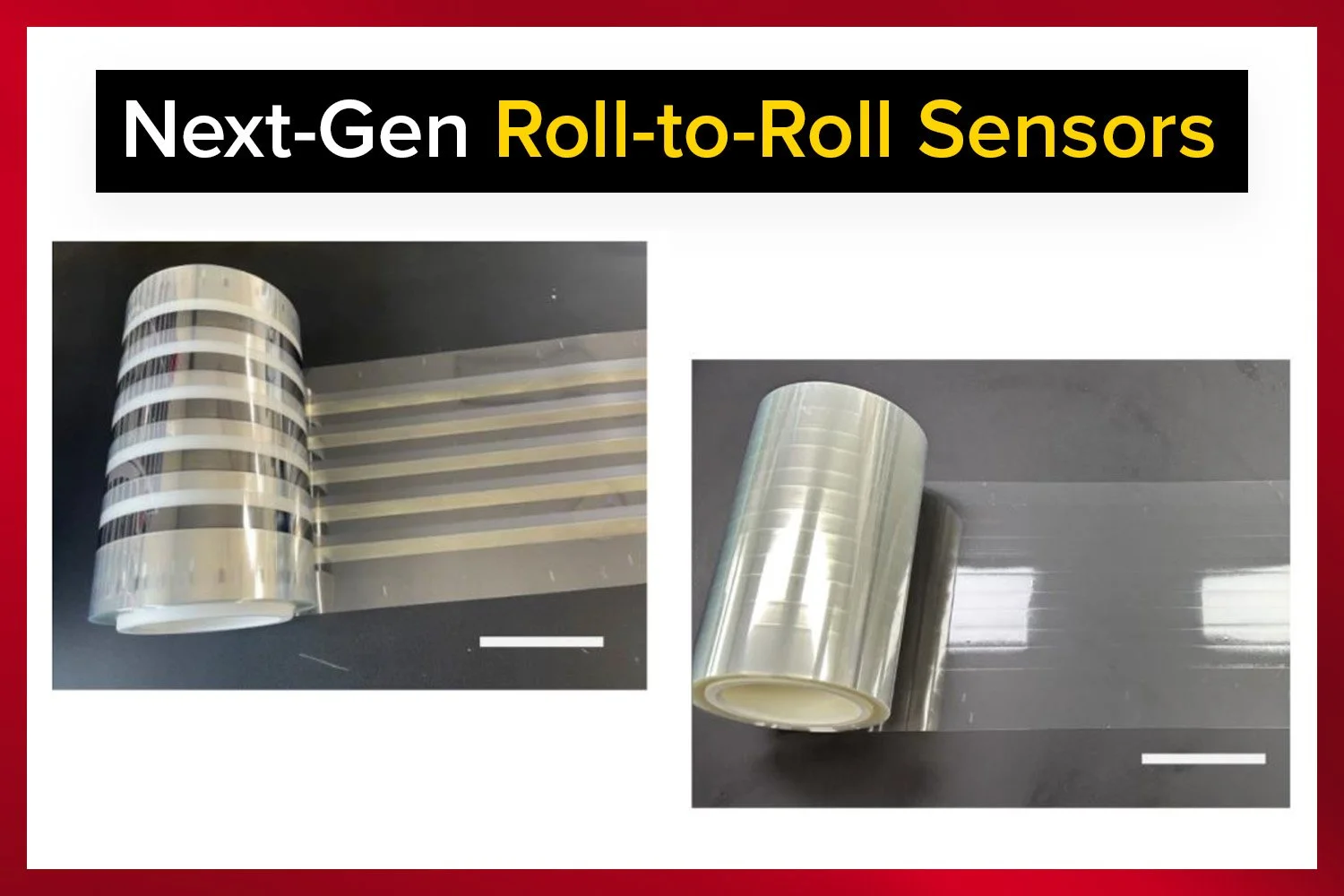

Slot-die coating is a technique used to apply thin films with high precision, especially in roll-to-roll manufacturing settings. It allows for uniform film thickness, minimal material waste, and compatibility with large-scale production.

In single-layer applications, the coating fluid spreads over a substrate that is typically clean and uniform. However, in multilayer systems, each new liquid layer is applied over a cured solid layer, which changes the way the liquid behaves. This difference can cause instability at the interface, especially if the surface of the cured layer does not promote smooth fluid spreading. These disruptions make it easier for air to become trapped beneath the liquid, leading to bubbles and other coating defects.

The Significance of the Study: Why Bubble-Free LED Films Matter

LED polymer multilayer films offer significant advantages in terms of performance and design flexibility. By using multiple layers instead of a single, mixed layer, manufacturers can prevent particles from settling over time, ensure more consistent performance, and achieve finer control over light emission properties.

These films also enable better control of color rendering and energy efficiency by allowing designers to precisely place and tune the behavior of fluorescent particles within each layer. This level of control is essential in today’s lighting systems, where uniform brightness, color stability, and long-term reliability are increasingly important.

However, air bubbles threaten to compromise these advantages. Defects introduced during manufacturing can disrupt optical pathways, scatter light unevenly, and even shorten the lifespan of devices. For manufacturers seeking to deliver high-quality, high-performance LED products, solving this problem is essential. This study’s proposed solution addresses that need directly.

Learn the complete process of creating uniform thin films using a slot-die coater.

Diving Into the Methods: How They Tackled the Problem

The research team used KER-2600 silicone gel as their model coating fluid. This transparent, thermally stable silicone material closely mimics the behavior of actual LED encapsulant polymers, making it a strong substitute for experimental purposes.

They mixed the gel with fluorescent particles to replicate real production conditions and conducted high-speed imaging experiments to observe how the liquid spread across cured and uncured surfaces.

To quantify the surface interaction, they used the sessile drop method. In this test, a droplet is placed on a surface, and the angle it forms at the contact point—known as the contact angle—is measured. A smaller angle indicates better spreading and stronger adhesion.

For the simulations, they used COMSOL Multiphysics to create a two-dimensional model that captured how the fluid moved and interacted with the substrate. This model accounted for key parameters such as viscosity, surface tension, and flow speed. Later, they updated the model to include changes in viscosity as the material heats and cures, which proved crucial for improving the model’s predictive power.

What They Found: A Deeper Look at the Results

Contact angle measurements showed that the surface of a fully cured polymer film has a significantly lower contact angle than the original bare substrate. While this might suggest better wetting, the results demonstrated that a lower contact angle actually increases the likelihood of air entrainment.

This occurs because the low-angle surface encourages uneven spreading, especially at the front of the moving liquid, also known as the upstream meniscus. These instabilities can create small vortices, which trap air as the liquid moves across the surface.

The researchers compared this effect in single-layer and multilayer coatings. While single-layer coatings remained smooth and defect-free, multilayer coatings consistently produced trapped air bubbles at the interface. The difference was directly linked to how the cured bottom layer influenced the liquid flow behavior of the new top layer.

Choose the right slot-die head for your application Read our guide to understand which slot-die head is right for you.

Preparation of Bilayer Polymer Films Using the Semi-Cured Method

To reduce these instabilities, the team introduced a controlled partial curing step. Instead of fully drying the bottom layer, they allowed it to reach a semi-cured state before applying the next layer. This change in surface properties helped balance the fluid forces and reduce the risk of trapping air.

As curing time increased, the contact angle of the surface also increased. This meant that the top layer had a more stable platform to spread across. However, there was an optimal range. If the curing time was too short, the bottom layer remained too wet and unstable. If it was too long, the increased rigidity reintroduced flow problems.

The researchers identified a sweet spot that allowed for better control over the allowable coating gap—the space between the die and the substrate—and minimized air bubble formation. They defined this as the coating window.

Initially, their simulations overestimated how much gap could be tolerated before defects appeared. However, by incorporating temperature-dependent viscosity into their model, they achieved a much more accurate prediction of coating limits. This allowed them to fine-tune the process more effectively.

The updated model showed a close match to experimental data, especially in predicting the lower limits of the coating window. This improvement supports the idea that modeling real-world curing effects is essential to accurately simulating and controlling the slot-die coating process.

Future Outlook and Industry Relevance

This work is particularly relevant to industries focused on high-performance LED devices, optical films, and multilayer coatings. The proposed method does not require specialized equipment or new materials. It simply adjusts the timing and control of the curing process to enhance film quality.

As roll-to-roll manufacturing continues to expand into optoelectronics and advanced display systems, having a reliable, defect-free coating process becomes increasingly important. This study offers a practical solution that manufacturers can adopt with minimal disruption and high potential for improved outcomes.

What is roll-to-roll processing, and why is it revolutionizing the way we make flexible devices?

Conclusion: A Small Change With a Big Impact

The research demonstrated that a modest process adjustment—partially curing the bottom film layer—can have a major effect on the quality of multilayer coatings. By preventing air from becoming trapped between layers, this method improves uniformity, enhances optical performance, and increases production reliability.

Combined with updated simulation techniques that account for curing-related viscosity changes, this study provides a valuable roadmap for optimizing multilayer film fabrication. It is a compelling example of how detailed analysis and thoughtful process design can solve persistent manufacturing challenges.

Authors

Zikeng Fang

Jiaqi Wan

Chenghang Li

Henan Li

Ying Yan

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.