First-Ever Printed Solar Cell Made from Fungus Using Slot-die Coating

A collaboration between the Department of Chemistry and Bioscience at Aalborg University and infinityPV is exploring a novel route toward sustainable printed solar cells by combining gene expression, biotechnology, and roll-to-roll coating technology. The idea is simple yet innovative: harness fungi that naturally break down decaying wood to produce complex organic molecules, then use those molecules as active materials in printed organic solar cells.

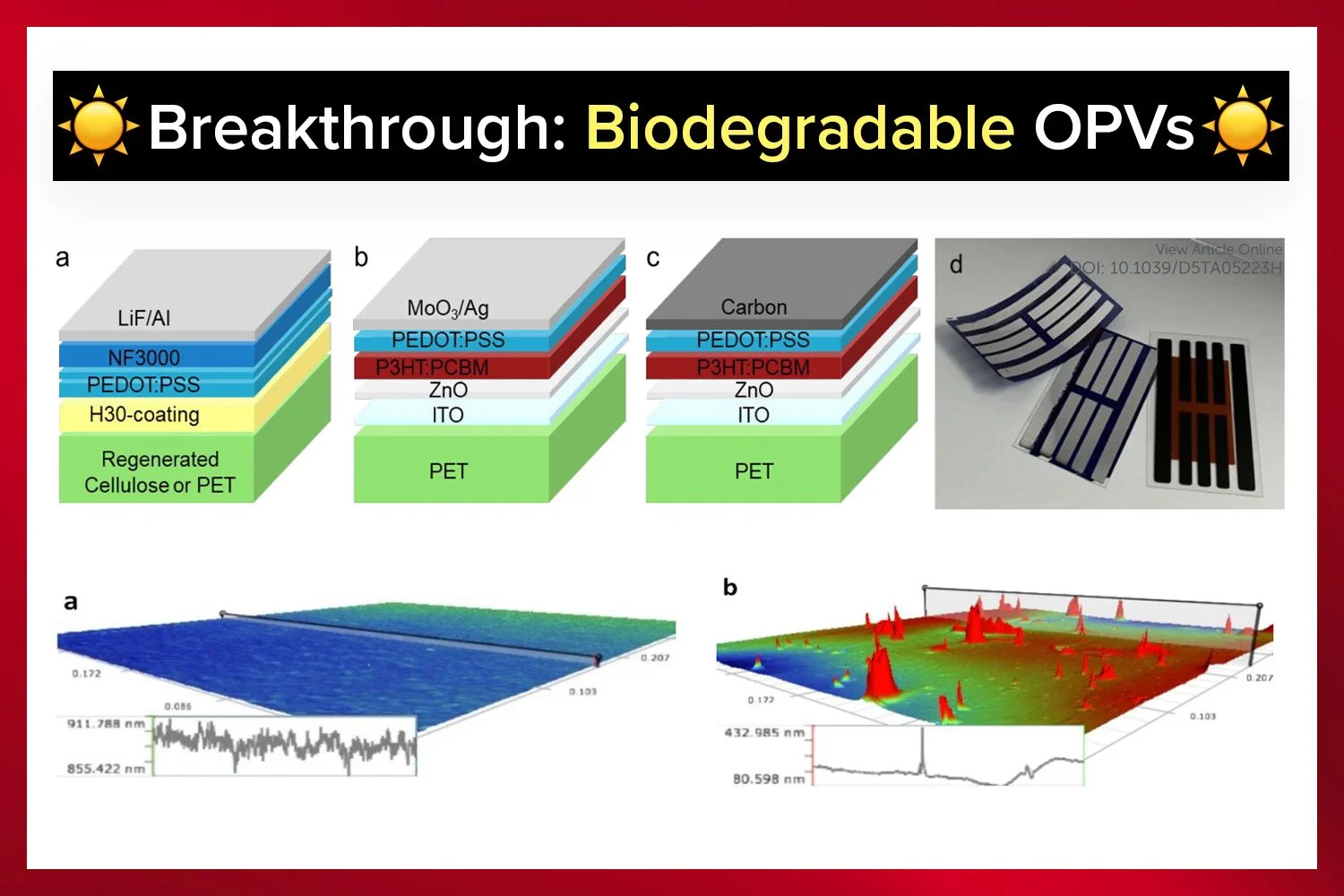

Among the most promising developments in organic photovoltaics today are small-molecule acceptors (SMAs). These materials have attracted attention for their high efficiency, which rivals that of silicon solar cells, and for their tunable properties. Their complex molecular structures require elaborate chemical synthesis and consistent reproducibility, both of which are essential for commercial applications. While most SMAs are synthetically produced, the increasing interest in understanding how their structure influences performance highlights a new opportunity. Small molecules derived from nature may offer similar advantages, along with benefits such as natural abundance, much lower production costs, and biodegradability.

This is where bio-derived materials like Xylindein come into focus. Xylindein is a pigment produced by Chlorociboria aeruginascens, a fungus known for staining decaying wood a distinct bluish green. Beyond its aesthetic appeal, Xylindein also possesses interesting electronic and photostability properties that make it a candidate for organic solar cells.

At Aalborg University, a team of seven students have already identified the genes responsible for the production of Xlindein in the fungus. Using cutting-edge gene editing methods and collaborating with experts in the field, they are currently working on transferring these genes from Chlorociboria aeruginascens to a fast-growing fungus that can be used as “production host”. This means that instead of having to mine solar cell materials from the ground as we do now - an unsustainable proces that results in water pollution and greenhouse gas emissions - we can produce the materials that we need in fungi, all locally here in Denmark.

With this biotechnology-driven production method, the project envisions a future where solar power can be driven by truly sustainable and biodegradable materials, removing the need for unsustainable mining-practices and the polluting shipping required to transport these parts across the globe.

How to test solar cells using a source measure unit and solar simulator.

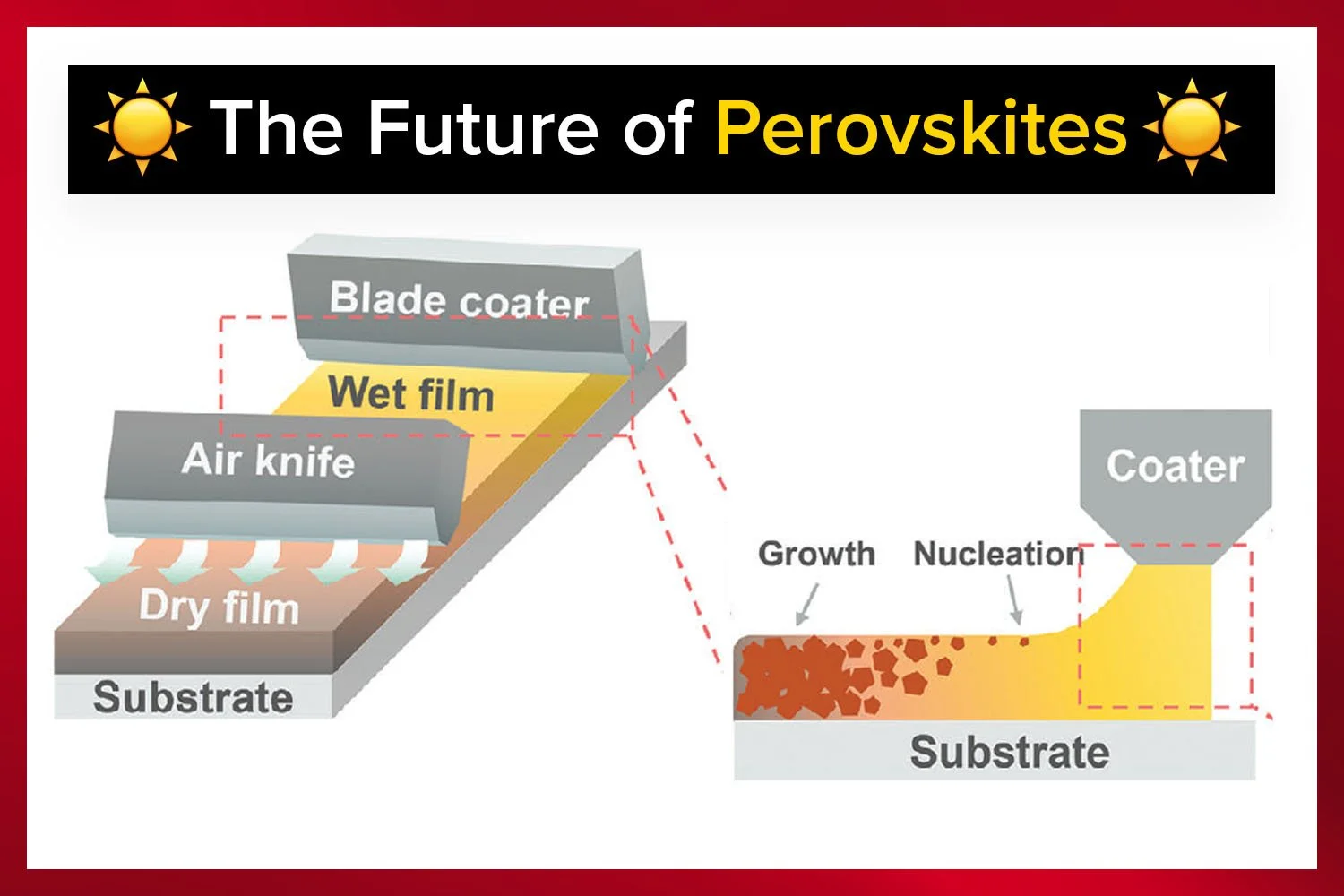

At Aalborg University they have already extracted the blue pigment from Chlorociboria aeruginascens for solar cell prototypes synthesis and at infinityPV, testing Xylindein in actual solar cell devices have commenced. Using our slot-die coating equipment and flexible electrodes, the first blends combining Xylindein with commercial donor and acceptor materials have been exploited. These experiments mark an important starting point, although several challenges remain, such as improving film quality and achieving better morphology.

The larger vision of the project is to establish a cost-effective, scalable, and environmentally responsible pathway for next-generation solar materials. Nature already offers synthetic machinery of high complexity enabling production of complex small molecules with desirable properties. This work points to a future in which bio-based flexible electronics can emerge from natural sources as well as from industrial labs.

About the Authors

The team from Aalborg University are a group working on Yinnovative and sustainable biotechnological production methods, transferring theoretical knowledge and lab-practices into products that can help make the world become more green. infinityPV is a Danish company pioneering slot-die coating and roll-to-roll processing, offering everything from advanced roll-to-roll manufacturing machinery to highly specialized test and measurement equipment, all engineered for flexible electronics.

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Customized for lab-scale research and development, this system facilitates the efficient application of battery electrode coatings.