Slot-Die Coating May Be the Future of Solar Manufacturing: Review Uncovers Key Strategies for High-Efficiency Solar Coating

Can Scalable Solar Tech Compete with Silicon?

A recent review titled "Organic and perovskite solar cells based on scalable slot-die coating technique: Progress and challenges" explores a pivotal question for the future of renewable energy. Can we produce high-performance solar cells at industrial scale both efficiently and affordably?

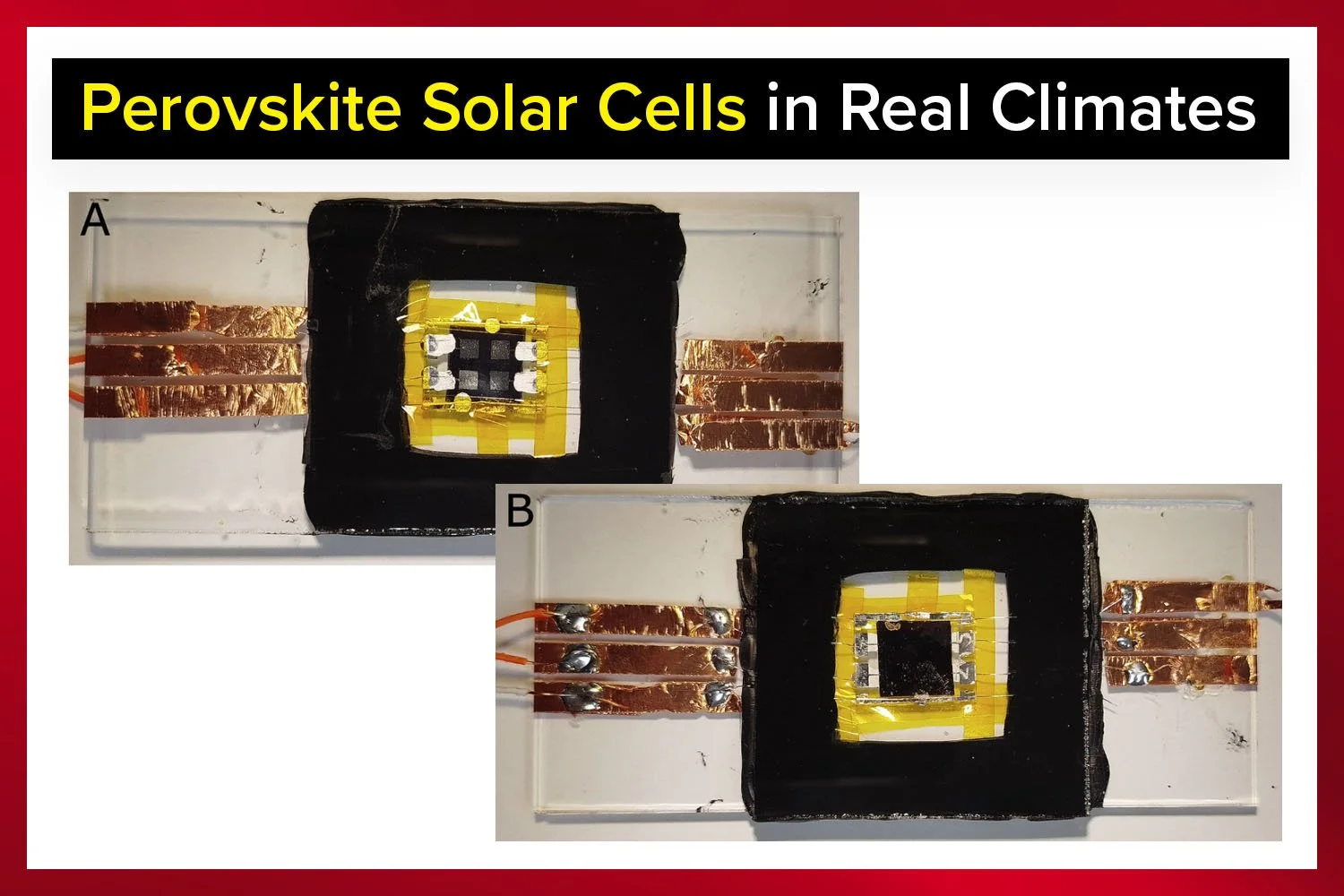

Silicon solar cells currently dominate the global photovoltaic market. They are known for their high efficiency and durability, but their manufacturing process is costly and material-intensive. Thin-film alternatives such as organic solar cells (OSCs) and perovskite solar cells (PSCs) offer lower-cost options and flexible applications. However, a significant barrier remains: how to scale up their production without compromising performance.

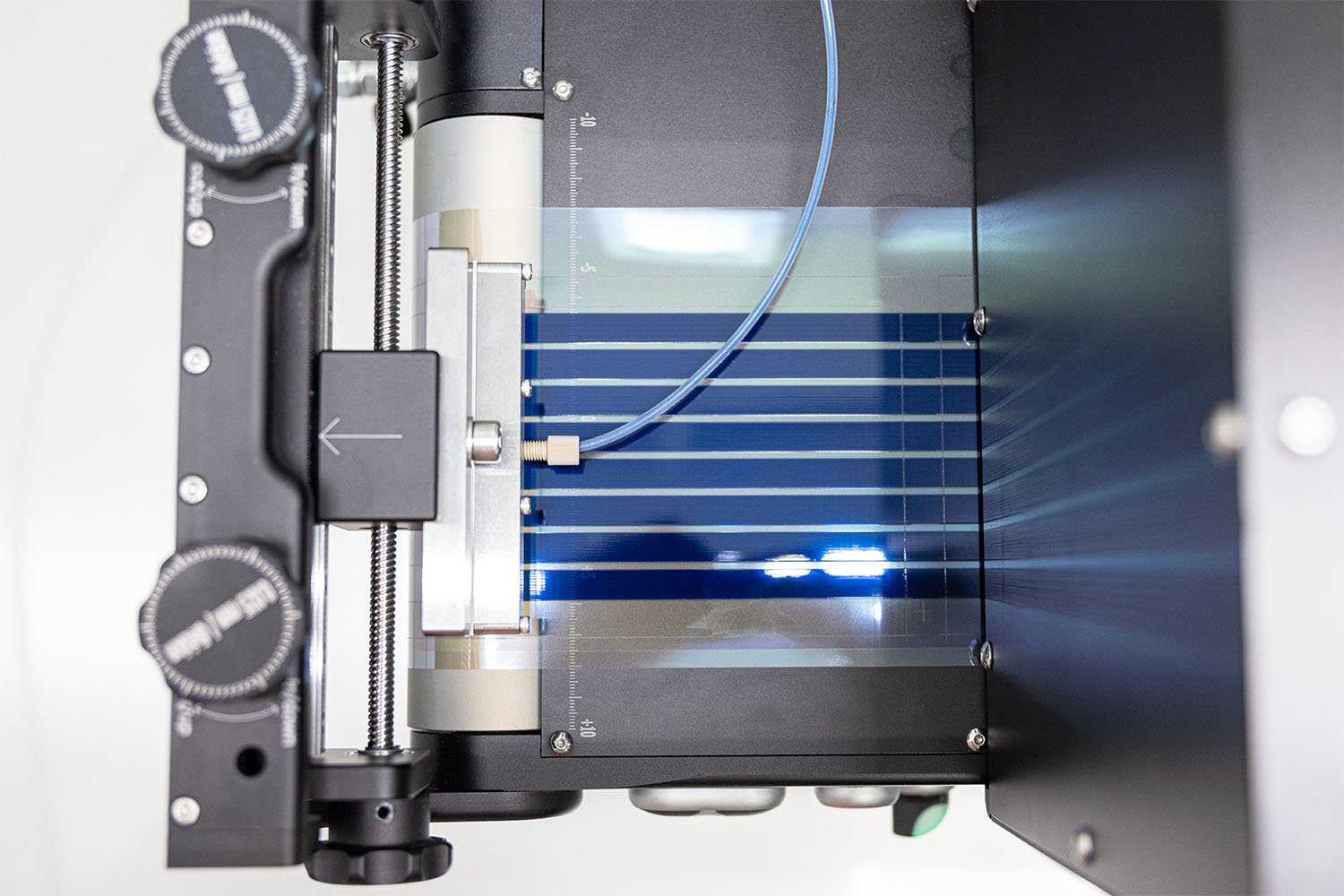

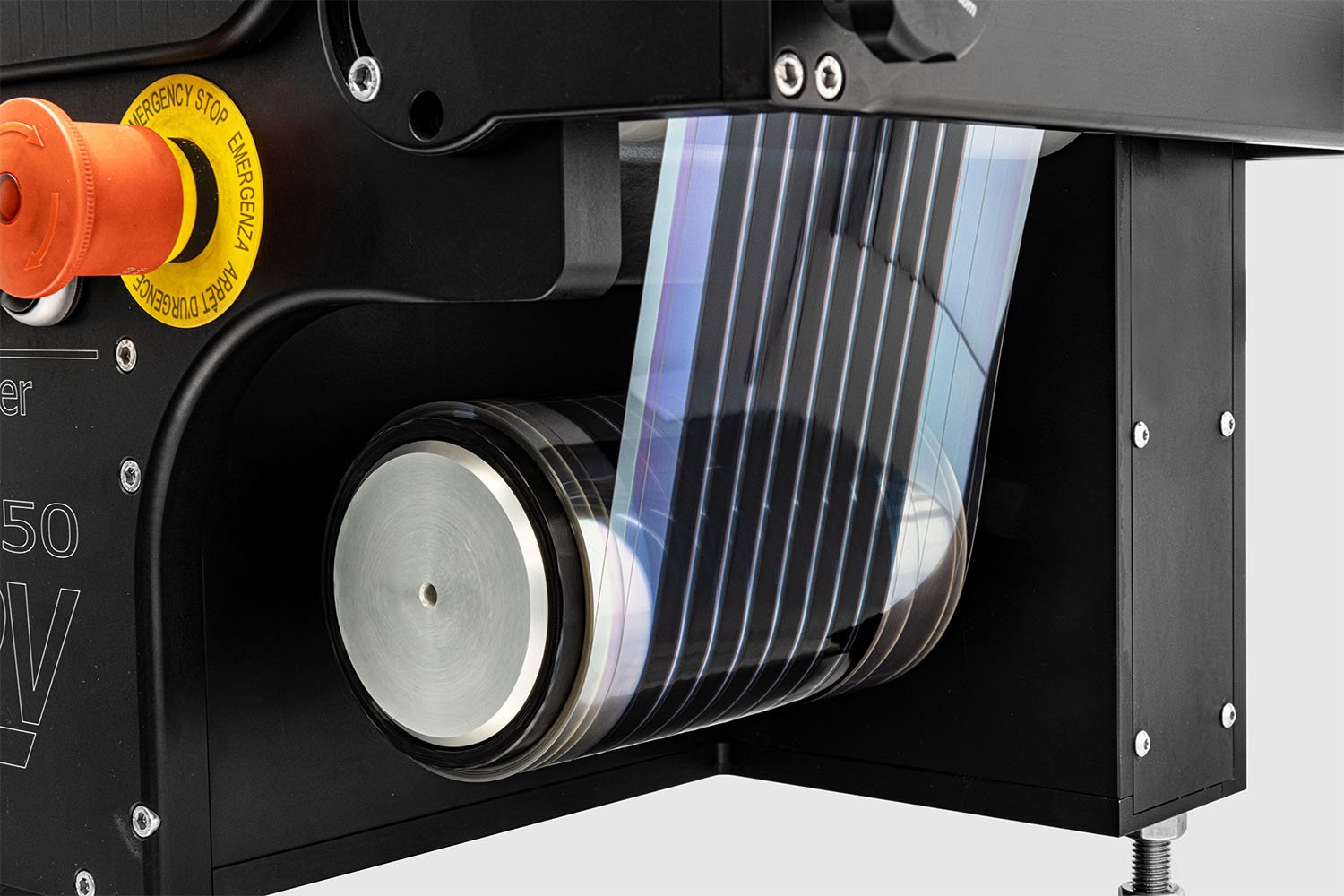

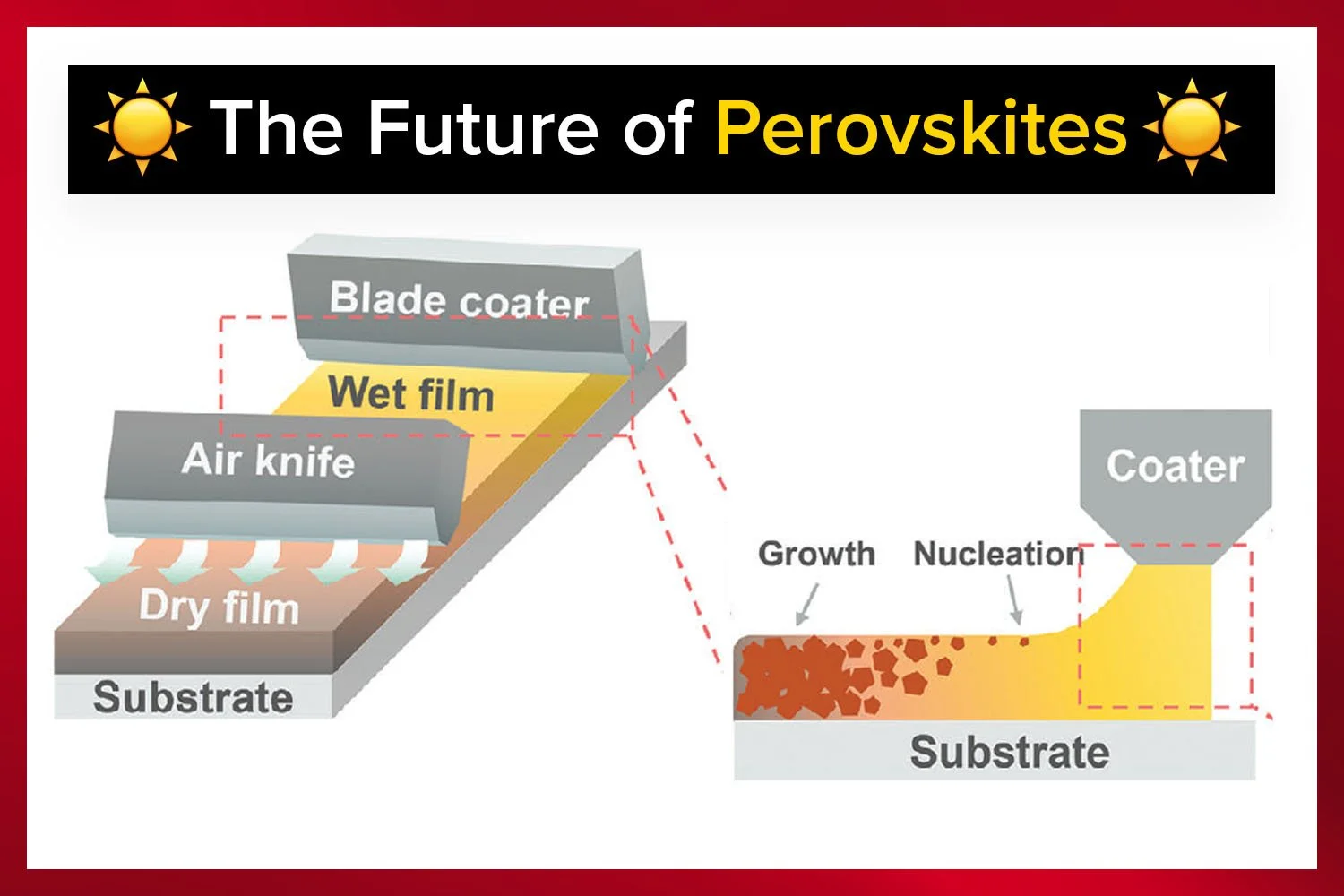

Slot-die coating is emerging as a transformative method that bridges the gap between lab-scale success and industrial scalability. This review details how slot-die coating enables better control over film formation, minimizes material waste, and integrates with roll-to-roll (R2R) production lines. The article also dives deep into the chemistry and physics behind slot-die processing and explains the optimization strategies that can make this technology commercially viable.

Key Highlights:

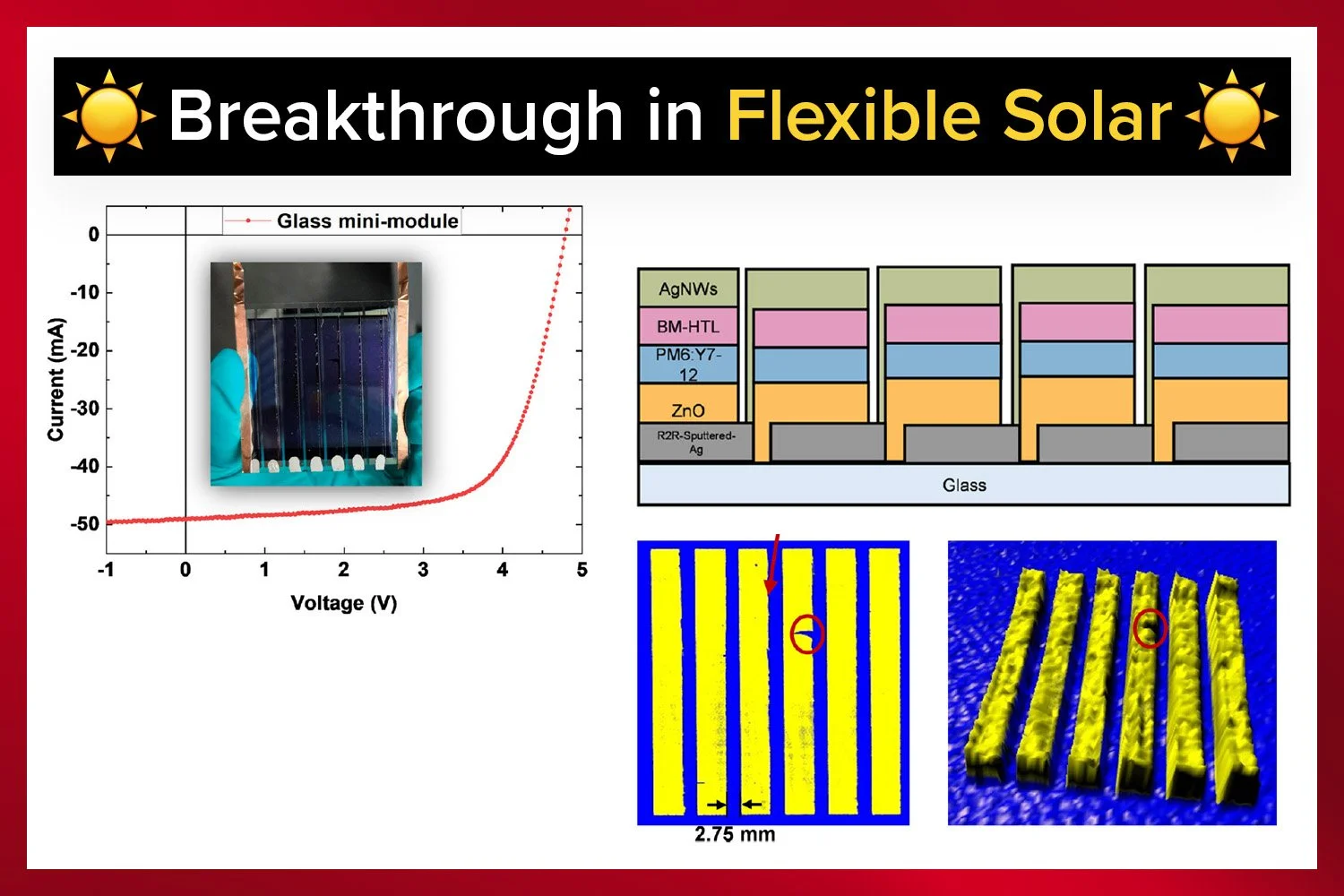

Slot-die coating supports scalable, high-throughput manufacturing of OSCs and PSCs

Organic and perovskite solar cells have reached record efficiencies of 19% and 26%, respectively

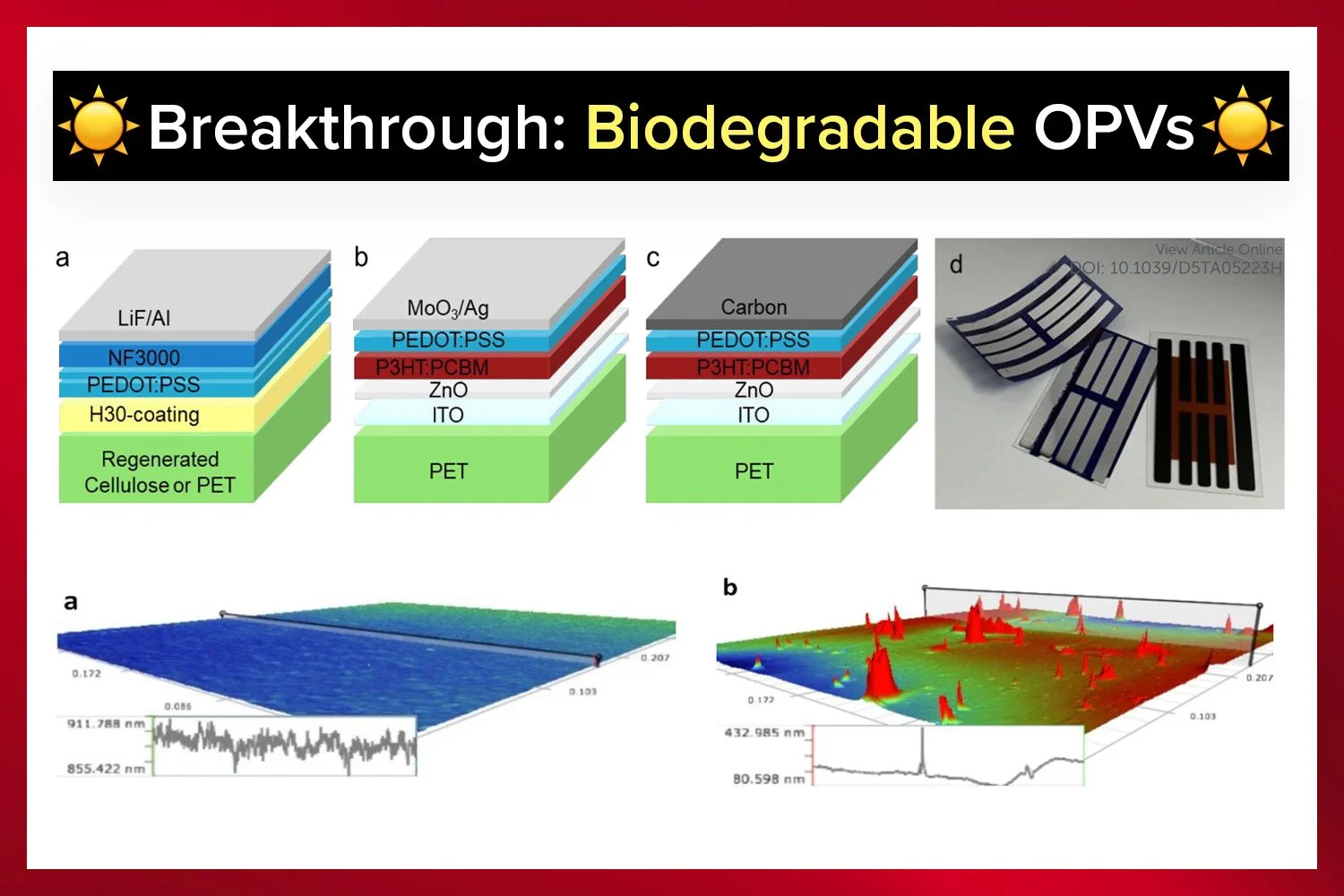

Film morphology and crystallization must be precisely controlled to avoid defects

Solvent selection, additives, and thermal conditions are critical optimization levers

Charge transport layers can also be slot-die coated to enhance device performance

Compared to spin coating, slot-die coating dramatically reduces material waste

Slot-die processes align with roll-to-roll manufacturing for flexible substrates

The technology is moving toward greener solvents and sustainable fabrication practices

Understanding Slot-Die Coating and Its Role in Solar Manufacturing

Slot-die coating is a precision coating technique in which a liquid ink is pushed through a narrow slit and deposited uniformly onto a moving substrate. By adjusting variables such as flow rate, substrate speed, and ink viscosity, researchers can finely tune film thickness and uniformity.

This technique is not only efficient in terms of material usage but also well-suited for integration into roll-to-roll production. Unlike spin coating, which wastes much of the solution through centrifugal force, slot-die coating applies only the necessary amount of material. This minimizes waste, reduces costs, and supports cleaner manufacturing processes.

The controlled deposition also means that slot-die coating is ideal for forming consistent, defect-free films across large areas. This level of control is essential for fabricating high-efficiency solar devices, where even minor inconsistencies can significantly impact performance.

The Broader Significance of Slot-Die Coating in Solar Research and Industry

The review emphasizes that slot-die coating is not simply a production method but a gateway to the industrialization of next-generation solar technologies. It highlights how recent scientific advances have addressed several critical challenges, especially in forming high-quality active layers and charge transport layers over large areas.

Given the global urgency to deploy renewable energy, scalable solutions are now more important than ever. Solar cells based on perovskite and organic materials can be manufactured at lower temperatures and on flexible substrates. This enables applications in portable electronics, building-integrated photovoltaics, and more. Slot-die coating allows researchers to translate laboratory breakthroughs into commercially relevant modules that can be fabricated continuously and at scale.

Learn how to fabricate solar cells using slot-die coating and flexo printing on a Slot-die Coater.

Optimizing Slot-Die Coating: Solvents, Additives, and Drying Techniques

The review details various strategies researchers are using to optimize the performance of slot-die-coated films. One major focus is solvent and additive engineering. The rate at which a solvent evaporates influences how donor and acceptor materials in the film organize themselves. For example, slower-evaporating solvents give molecules more time to form stable morphologies, which leads to higher device performance.

Additives can be used to fine-tune the drying kinetics and influence phase separation, domain purity, and crystallization. These parameters directly affect the morphology of the active layer and therefore the efficiency of the solar cell.

Thermal processing, particularly hot slot-die coating, is another strategy for managing film quality. Heating the substrate or coating head ensures more consistent drying, reduces ink gelation, and improves film uniformity. This is especially important for non-halogenated solvent systems that are environmentally safer but often more challenging to work with.

From Morphology Control to Device Architecture: How It All Comes Together

The review also delves into the theoretical underpinnings of slot-die coating. A proper balance between viscous forces, surface tension, and flow rate defines what is known as the "coating window." Operating within this window is crucial for achieving uniform films without defects. Too much or too little of any one parameter can result in dewetting, streaking, or other coating issues.

Advanced studies using in situ X-ray scattering techniques have revealed the crystallization behavior and domain formation during the slot-die process. These insights are helping researchers fine-tune coating parameters and design ink formulations that naturally self-assemble into optimized structures.

The review also discusses innovations in sequential deposition and ternary blends, both of which allow for better phase separation and higher efficiencies. In sequential processing, donor and acceptor materials are deposited in layers rather than mixed together, giving more control over morphology.

The Commercial Path Forward: Slot-Die in the Roll-to-Roll Ecosystem

As solar manufacturing shifts toward flexible substrates and continuous production lines, slot-die coating finds a natural home in the roll-to-roll ecosystem. The review outlines how this compatibility offers both economic and environmental benefits. Reduced material waste, lower energy requirements, and compatibility with green solvents make this approach ideal for large-scale deployment.

However, challenges remain. Ensuring long-term stability, reducing the use of toxic materials, and maintaining performance across large areas are ongoing concerns. The review highlights promising solutions, such as encapsulation techniques, improved transport layers, and robust new donor and acceptor materials.

With continued research and interdisciplinary collaboration, the vision of high-efficiency, low-cost solar energy using scalable, sustainable methods appears increasingly within reach.

Conclusion

Slot-die coating is a critical enabler for transitioning organic and perovskite solar cells from research labs to real-world applications. This review article underscores how the method's precision, efficiency, and compatibility with roll-to-roll manufacturing make it an ideal choice for scaling up next-generation photovoltaics.

By addressing technical challenges in morphology control, solvent selection, and device architecture, researchers are paving the way for mass production of solar cells that are not only efficient and lightweight but also environmentally sustainable. This represents a significant step forward in our global push toward clean and affordable energy.

How to test solar cells using a source measure unit and solar simulator.

Authors:

Reza Keshavarzi

Farzaneh Hajisharifi

Zahra Saki

Mirkazem Omrani

Reza Sheibani

Niloufar Afzali

Mojtaba Abdi-Jalebi

Luigi Vesce

Aldo Di Carlo

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Customized for lab-scale research and development, this system facilitates the efficient application of battery electrode coatings.