Scalable Perovskite Solar Cells Achieve 24.6 Percent Efficiency: New Comb Nozzle Method Boosts Solar Film Uniformity

Introduction: A New Path to Large-Scale Solar Power

How do you take a solar cell that performs brilliantly in a research lab and make it in large quantities without sacrificing quality? A recent study titled "Spatially Regulated Gas Flow Control for Batch-Drying of Large Area Slot-Die-Coated Perovskite Thin Films" tackles this issue head-on. Conducted by researchers at the Karlsruhe Institute of Technology (KIT), the work introduces a new gas-assisted drying approach that dramatically improves how perovskite solar films are dried at scale.

This is a major step forward because bringing a technology from prototype to production is one of the hardest parts of innovation. In the case of perovskite solar cells, which are known for their high power conversion efficiencies, being able to scale production reliably could transform the solar energy market. The key lies in controlling the drying phase of the manufacturing process more precisely than ever before.

Key Highlights

Introduces a new 2D comb-nozzle (CN) drying method for large-area perovskite films

Achieves uniform drying across 100 cm² substrates with minimized edge defects

Boosts PCE85 yield from 62 percent using slot jet to 90 percent using comb nozzle

Enables high-quality slot-die coating in a scalable and roll-to-roll compatible way

Demonstrates champion perovskite/silicon tandem cells with 24.6 percent efficiency

Shows minimized grain size variability and pinhole formation

Employs a two-step deposition method for enhanced control over crystallization

Applicable to both 1.63 eV and 1.68 eV bandgap materials

Learn how to fabricate solar cells using slot-die coating and flexo printing on a Slot-die Coater.

What is Comb Nozzle Drying and Why Does It Matter?

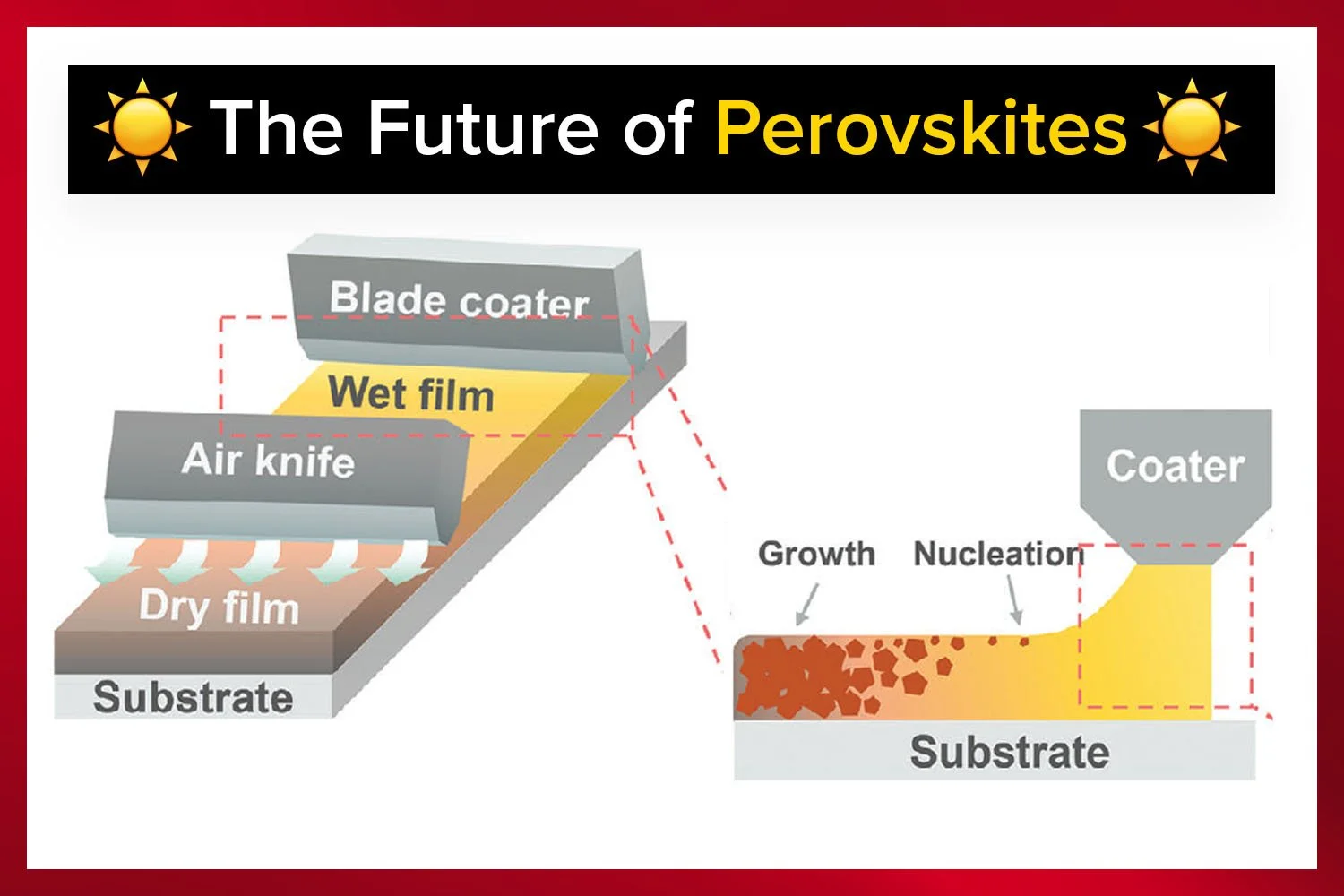

Drying is often taken for granted, but in the context of manufacturing perovskite thin films, it is one of the most sensitive and critical steps. Traditional methods rely on a single narrow gas jet that can cause inconsistent evaporation, especially at the edges of the substrate. This leads to defects that hurt the performance and reliability of the final device.

The comb nozzle drying system changes this entirely. Instead of one gas stream, it uses a grid of hexagonally arranged outlets, each paired with suction inlets. This allows a balanced and steady airflow over the entire surface of the coated substrate. It is like replacing a heat gun with a controlled convection system. The result is a much more uniform drying process.

This advanced drying system is used within a glovebox filled with inert gas, where it can precisely control factors such as drying height, temperature, and heat transfer. The fine-tuning of these parameters is crucial for consistent crystal formation in the perovskite layer.

The Significance of the Study: From Lab to Fab

In research labs, perovskite solar cells have reached efficiencies rivaling those of traditional silicon. But transitioning from small, high-performing cells to large-area modules remains a challenge. A major source of loss in upscaling has been uneven drying, leading to performance variability across the device.

This study offers a real solution. By achieving uniform drying across 100 square centimeters, the researchers could reduce edge defects and variability. Notably, when using the comb nozzle method, the performance loss during upscaling was only around 0.3 percent absolute. That is a small tradeoff for a big gain in manufacturability.

The method is also compatible with both standard bandgap materials and those with higher bandgaps. These higher bandgap perovskites are essential for tandem solar cells that stack perovskite layers on top of silicon to maximize energy conversion.

How to test solar cells using a source measure unit and solar simulator.

Diving Into the Methods: How It Was Done

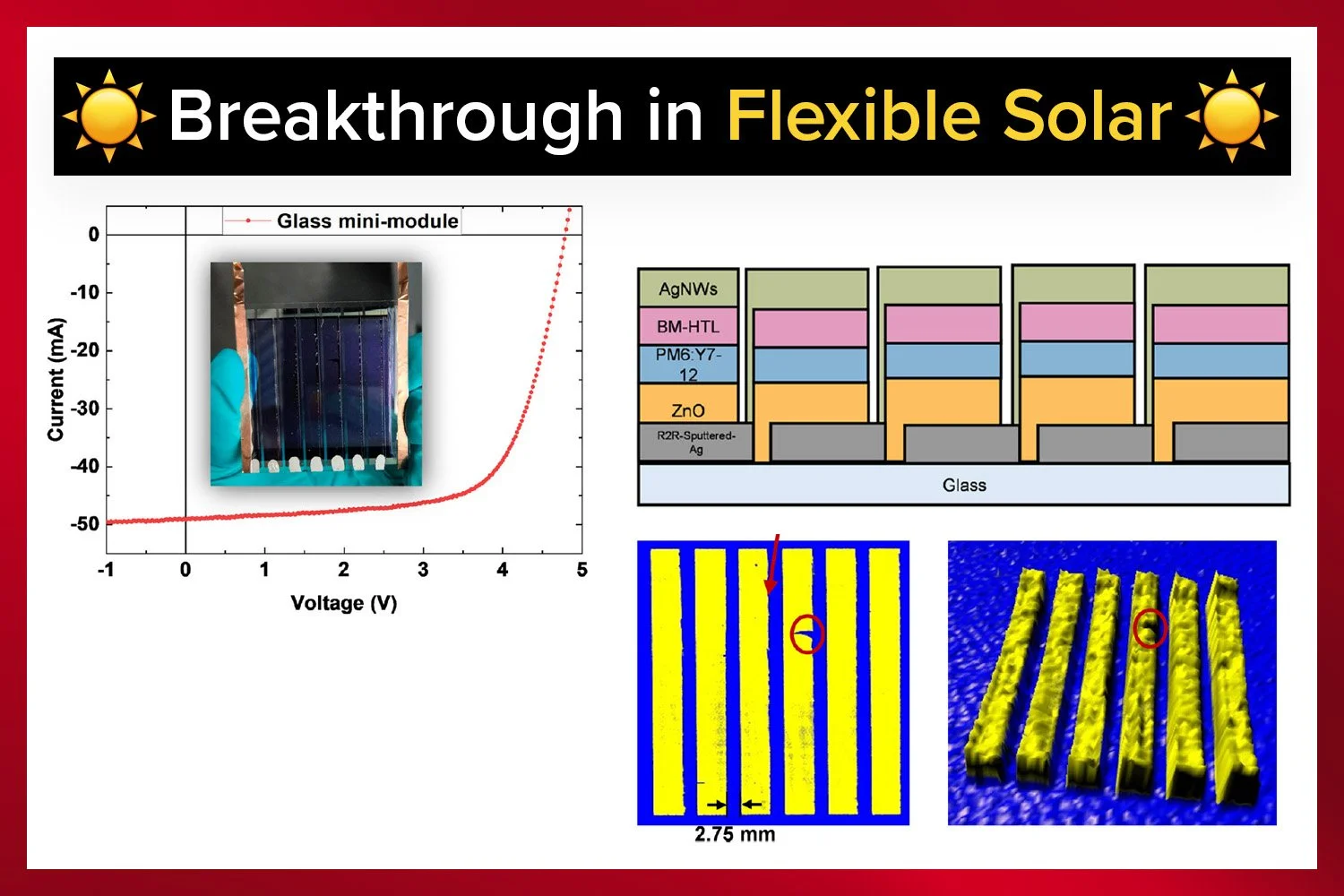

The process begins with a two-step slot-die coating technique. Slot-die coating plays a central role in this study as it is the method used to deposit the perovskite precursor layers onto large-area substrates. It is a pre-metered coating technique, meaning the amount of solution delivered to the substrate is precisely controlled. This makes it especially suitable for roll-to-roll production where consistent film thickness and uniformity are crucial.

In the first step, an inorganic precursor solution containing lead iodide and lead bromide is deposited onto the substrate using the slot-die coater. In the second step, an organic solution containing formamidinium iodide and formamidinium bromide is applied in a similar fashion. Slot-die coating allows both layers to be applied with a high degree of uniformity across the entire substrate.

The drying phase begins immediately after the second layer is applied. To evaluate the new method, the team compared two setups: the conventional slot jet and the new comb nozzle system. The comb nozzle features a 20 by 20 centimeter hood with carefully arranged gas outlets and suction inlets.

Researchers fine-tuned variables such as gas flow rate, nozzle height, and drying temperature. These adjustments were used to optimize how the solvent evaporated and how the perovskite crystals formed. As a result, they produced films with improved grain structure, fewer pinholes, and consistent thickness.

From Drying Control to Device Performance

Better drying control directly translates to better-performing solar cells. With the comb nozzle system, solar cells showed improved average efficiencies compared to those dried using the traditional slot jet method. Moreover, there was a noticeable reduction in the number of defective areas on each substrate.

When scaled into mini-modules, the films maintained high performance. These modules reached up to 17.9 percent efficiency. That is just a 6 percent relative drop from the best-performing small-area cells, which is quite low given the challenges involved in upscaling.

The study confirmed that the consistency of drying, achieved through comb nozzle control, leads to predictable and repeatable results. This is essential for manufacturing.

Join our hands-on Printed Electronics Workshop and gain practical experience in every step of printed solar cell manufacturing, from ink preparation to testing and final integration

The Industrial Outlook: Ready for Tandem Cells

Industrial applications require not just high performance but also stability and reproducibility. This is particularly important for tandem cells, which use a wide-bandgap perovskite top layer to maximize energy capture when combined with a silicon bottom cell.

The comb nozzle technique was successfully applied to these higher-bandgap films, delivering solar tandem devices with power conversion efficiencies up to 24.6 percent. The uniformity across all 16 devices tested was impressive, and performance was consistent even near the edges of the substrates.

This outcome confirms the technique's readiness for industrial implementation. It provides a practical path forward for companies looking to commercialize perovskite and tandem solar technologies.

Conclusion: A Step Closer to Scalable Perovskite Solar Modules

Drying has often been an overlooked stage in thin-film solar cell production, but this study makes it clear that drying is just as critical as material composition or deposition methods. With the comb nozzle system, the researchers have developed a tool that brings industrial-grade precision to one of the most complex aspects of perovskite film processing.

This innovation enables consistent and scalable production of high-quality perovskite films. It helps bridge the gap between lab-scale performance and industrial manufacturing. For the solar industry, this is more than just a technical improvement. It is a gateway to broader adoption of tandem solar cells and a future where efficient, affordable solar energy is accessible at scale.

Authors

Kristina Geistert

Ronja Pappenberger

Philip Scharfer

Philipp Cavadini

Wilhelm Schabel

Faranak Sadegh

David B. Ritzer

Bahram Abdollahi Nejand

Ulrich W. Paetzold

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Customized for lab-scale research and development, this system facilitates the efficient application of battery electrode coatings.