Why Emerging Solar Cells Struggle to Scale: New Data Uncovers the Missing Link Between Solar Research and Industry

Why are game-changing solar technologies still struggling to reach the market?

Organic and perovskite solar cells have long been hailed as the future of lightweight, flexible, and efficient solar energy. Yet despite more than two decades of remarkable laboratory breakthroughs, these technologies remain largely confined to research labs.

A recent perspective article published in Advanced Energy Materials by Ümran I. Biçer and Frederik C. Krebs from infinityPV explores this issue head-on. Titled “Lost in Transition? Perspective on Research versus Commercialization of Organic and Perovskite Solar Cells,” it examines why industrial progress has lagged behind the accelerating pace of research.

Drawing from a bibliometric study of more than 28,000 scientific papers and data from over 100 companies, the authors reveal a widening gap between academic innovation and industrial adoption. Their work underscores the urgent need for stronger collaboration, standardization, and trust between research and industry to unlock the full commercial potential of emerging photovoltaics.

Key Highlights

Over 28,000 publications analyzed alongside 108 companies

Despite record lab efficiencies, commercialization remains slow

Lack of standardization and transparency prevents investor trust

China dominates both research output and company formation

Technology readiness (TRL) alone fails to capture market maturity

Perovskite-silicon tandem PV is emerging as a viable route to market

Few companies report revenue, reflecting early-stage markets

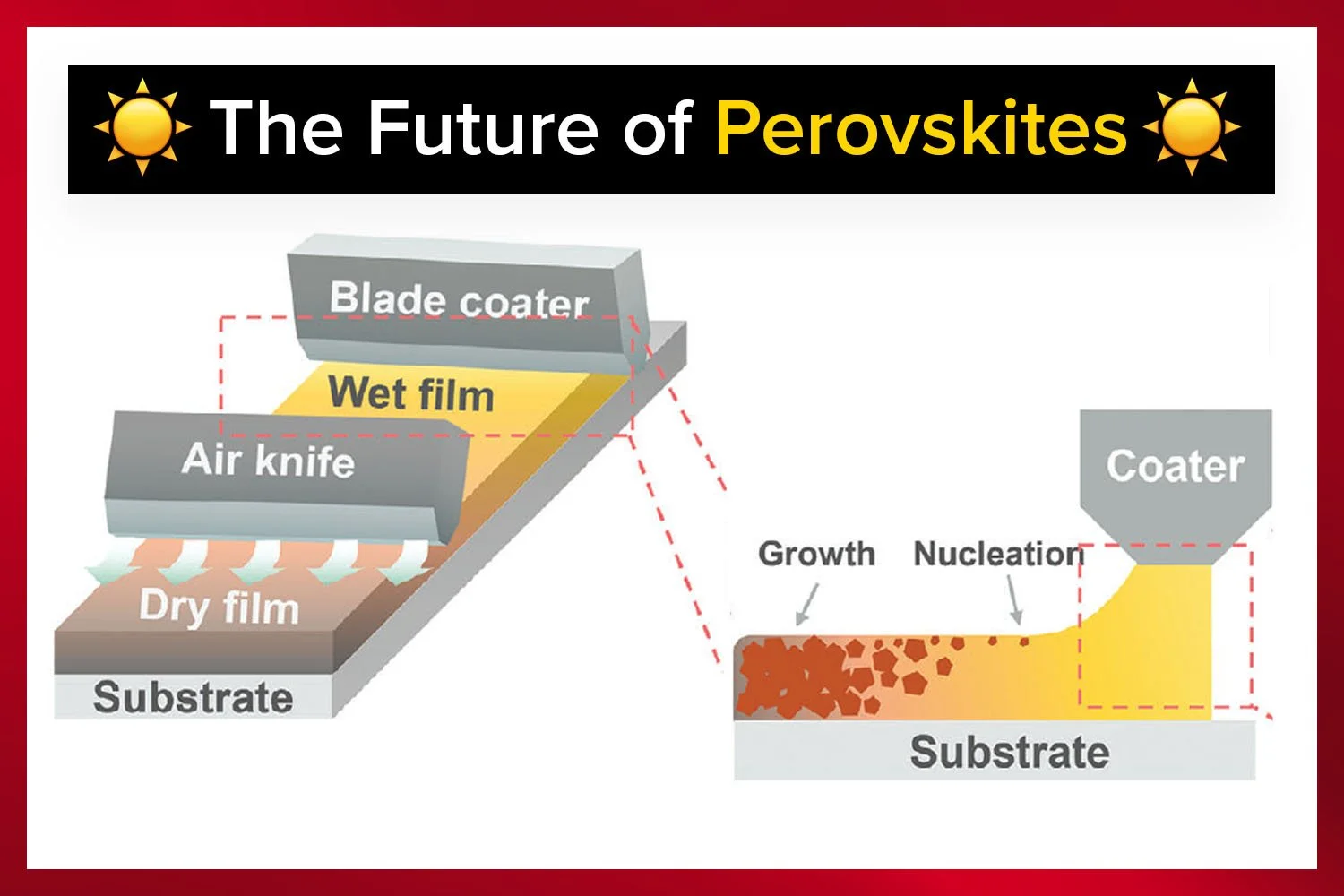

We believe perovskite solar cells can revolutionize renewable energy, but only if R&D bridges the gap between lab and industry. Success requires small-scale roll-to-roll platforms that replicate real-world conditions with precision.

What Are Organic and Perovskite Solar Cells and Why Do They Matter?

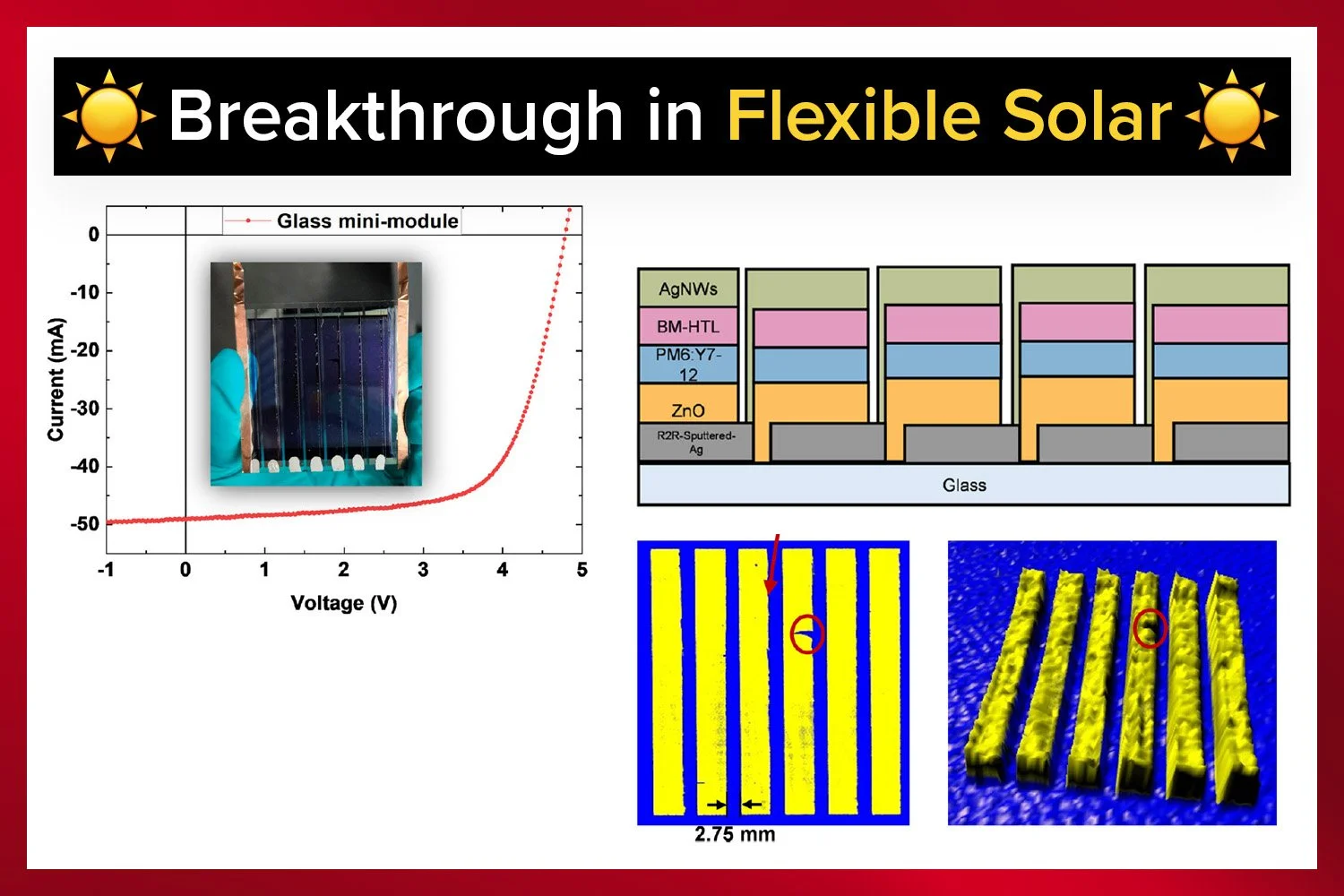

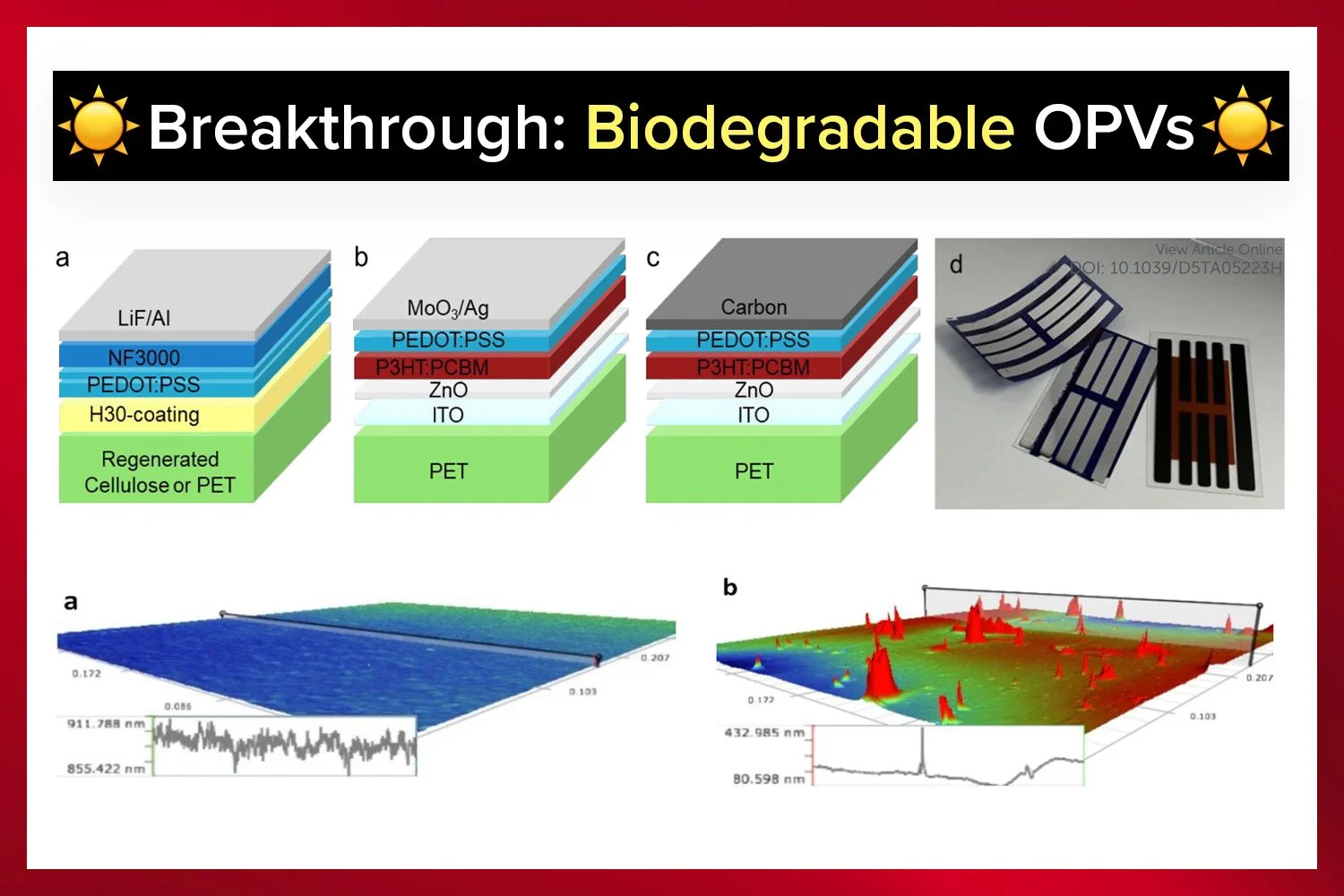

Organic solar cells (OSCs) and perovskite solar cells (PSCs) represent the forefront of emerging photovoltaic technologies. Unlike traditional crystalline silicon modules, these materials can be printed or coated in ultra-thin layers onto flexible substrates. This opens the door to new applications, from solar windows and lightweight rollable modules to powering wearables and indoor Internet-of-Things (IoT) devices.

The excitement around these technologies lies in their tunability. Scientists can fine-tune their chemical composition, structure, and fabrication processes to optimize performance for different environments. OSCs are primarily carbon-based polymers that convert sunlight into electricity, while PSCs use hybrid organic-inorganic crystals known for their strong light absorption and charge transport properties.

In the lab, PSCs have skyrocketed from below 4 percent efficiency to over 25 percent in less than a decade. OSCs, too, have surpassed 19 percent, with reports now approaching 20 percent. Both technologies are compatible with roll-to-roll manufacturing, making them suitable for large-scale, continuous production, which is key for future industrial scalability.

Yet, as Biçer and Krebs point out, high laboratory efficiency alone does not guarantee market success.

Understanding the Research–Market Divide

The study identifies a critical disconnect between scientific progress and industrial outcomes. While research output continues to rise sharply, the number of companies actively producing devices remains limited.

This imbalance reveals what the authors describe as a "commercialization gap." Academic efforts often focus on efficiency and novel materials, but industrial priorities such as stability, reproducibility, cost, and lifetime are often underexplored. As a result, new devices that perform well in controlled lab conditions may not meet real-world reliability standards.

The article also draws attention to the importance of trust. Investors and policymakers are hesitant to support technologies that lack standardized testing, clear performance benchmarks, or long-term field data. Without shared standards, scaling from the lab to the market becomes a leap of faith.

Learn how to fabricate solar cells using slot-die coating and flexo printing on a Slot-die Coater.

Diving into the Methods: How the Analysis Was Done

To quantify this divide, the authors performed a bibliometric and industrial analysis covering more than 28,000 scientific papers and 108 companies across the organic and perovskite PV sectors.

Their dataset traced publication volumes, authorship, funding sponsors, and international collaborations, and compared these with business activity such as company formation, revenue reports, and technological focus.

Key patterns emerged:

China leads in both research output and company establishment, representing over 40 percent of OSC publications and more than 50 percent of PSC papers

Europe maintains strong innovation, particularly in organic PV and high-value patents, yet lacks equivalent industrial investment

The United States and South Korea show strong collaborative research networks but limited commercialization

This comprehensive approach offers a rare overview of how global research intensity correlates, or fails to correlate, with actual market development.

The Technology Readiness Trap

Emerging photovoltaics are often evaluated using the Technology Readiness Level (TRL) scale, originally developed by NASA to measure technological maturity. However, Biçer and Krebs argue that TRL alone does not capture economic or industrial viability.

To complement TRL, newer metrics such as Technology Performance Level (TPL) and Technical Bankability Level (TBL), developed by institutions like NREL and DNV, better reflect investment risk and long-term reliability.

The authors emphasize that emerging PV technologies frequently become "lost in transition" between TRL 4 and 6, the stages where validation and demonstration occur. Many promising technologies fail here, a phenomenon often called the "Valley of Death." Bridging this gap requires not only scientific progress but also institutional coordination, policy incentives, and open industrial standards that foster trust and scalability.

How to test solar cells using a source measure unit and solar simulator.

Lessons from the Industry: Successes and Setbacks

The article reviews the industrial evolution of both OSC and PSC companies.

Early organic PV start-ups such as Konarka attracted significant investment but failed to achieve long-term viability due to poor stability and limited efficiency. These early setbacks created skepticism among investors, a reputation that still lingers today.

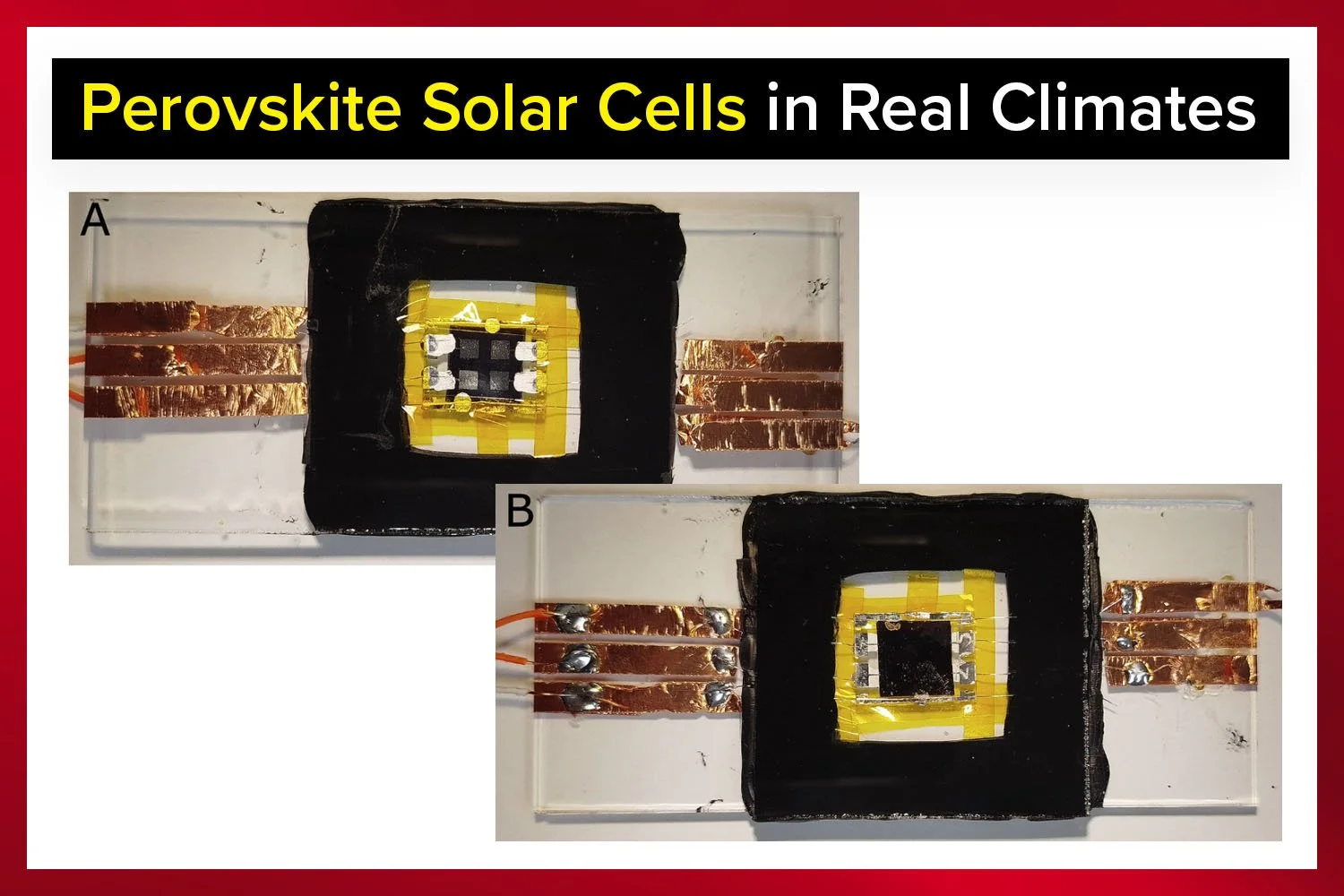

Perovskite solar cells, however, have experienced a more cautious rise. Since 2015, the focus has shifted toward perovskite-silicon tandem cells, combining the flexibility of perovskites with the proven reliability of silicon. This hybrid strategy has drawn major industrial players and spurred large-scale factory projects, including a 1 GW perovskite module plant recently commissioned in China.

Despite these positive signs, financial transparency remains low. Roughly 70 percent of companies analyzed publish no revenue data. This opacity reflects a young market dominated by prototypes, pilot lines, and research collaborations rather than mass-produced commercial products.

Building the Bridge: Collaboration, Standards, and Trust

For emerging PV to transition from lab success to commercial stability, Biçer and Krebs outline several essential actions:

Standardization and Certification – Achieving international standards such as IEC 61215 and 61730 for outdoor modules and IEC TS 62607-7-2 for indoor light conditions marks a major step forward. Companies like Heliatek, Renshine Solar, and GCL have recently obtained such certifications, signaling industrial maturity.

Shared Infrastructure – Establishing open pilot lines and collaborative manufacturing facilities can accelerate technology transfer and de-risk scale-up.

Cross-sector Collaboration – Partnerships among universities, start-ups, and established manufacturers can help translate research knowledge into reproducible industrial processes.

Transparent Reporting – Public disclosure of performance and durability data will strengthen investor confidence and allow fair benchmarking.

Without these foundations, emerging PV will continue to thrive on paper but stall in practice.

Join our hands-on Printed Electronics Workshop and gain practical experience in every step of printed solar cell manufacturing, from ink preparation to testing and final integration

The Future Outlook: Where Do We Go from Here?

According to the authors, the future of solar technology is not about one winner. Instead of viewing silicon, organic, and perovskite technologies as competitors, the industry should see them as complementary tools for different applications.

Perovskite-silicon tandems are likely to dominate the push toward high-efficiency modules, while organic solar cells will thrive in flexible, lightweight, and semi-transparent use cases such as building-integrated PV, agrivoltaics, and indoor electronics.

To ensure that these technologies do not remain "lost in transition," policymakers and funding bodies must recognize their potential and provide coordinated support. A fraction of the investment historically poured into crystalline silicon could catalyze the next wave of solar innovation.

Conclusion

This perspective by Ümran I. Biçer and Frederik C. Krebs highlights a pressing challenge in renewable energy innovation: bridging the research-to-market gap. Emerging photovoltaic technologies have advanced scientifically at an extraordinary pace, yet their industrial growth remains constrained by fragmentation, lack of trust, and insufficient standardization.

The solution lies in collaboration, openness, and shared industrial responsibility. By focusing on scalable processes, transparent certification, and realistic market pathways, the solar industry can unlock the potential of organic and perovskite photovoltaics, not as experimental alternatives but as vital players in the global energy transition.

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Compact solar simulator (390–700 nm) with six tunable LEDs, Class A uniformity, and excellent temporal stability. Ideal for small to medium solar cells and controlled illumination experiments.