This Simple Change to Battery Manufacturing Makes a Big Impact: How Better Slurry Dispersion Can Boost Next-Gen Batteries

Can Better Mixing Make Better Batteries?

A recent study titled "High Shear Dispersion Techniques for Up-Scaling and Controllable Cathode Morphology in High Performance Li−S Pouch Cells" explores a seemingly minor yet surprisingly impactful aspect of lithium-sulfur (Li–S) battery production: the slurry mixing process.

This topic matters because Li–S batteries hold enormous promise thanks to their high theoretical energy densities and the use of abundant, low-cost materials like sulfur. However, practical deployment has been delayed by persistent issues such as limited cycle life and challenges with electrolyte efficiency. The researchers from Fraunhofer IWS and TU Dresden set out to address these limitations by focusing on one often-overlooked variable: the shear forces applied during cathode slurry preparation.

By comparing the effects of a conventional laboratory mixer with those of a high shear mixer, the study revealed that improved slurry dispersion results in more homogeneous cathodes, lower porosity, and significantly better battery performance. These improvements are especially evident when using lean electrolyte volumes in pouch cell formats, which are more relevant to commercial applications than traditional coin cells.

🔑 Key Highlights

High shear mixing creates more uniform and denser cathodes.

Improved electrode morphology leads to longer cycle life.

Pouch cells made with high shear slurry outperformed those prepared with low shear blending.

High shear mixing reduces surface roughness and internal resistance.

Controlling cathode porosity is especially important under lean electrolyte conditions.

The findings were validated across both coin and pouch cell formats.

The study examined two electrolyte systems: DME/DOL and HME/DOL.

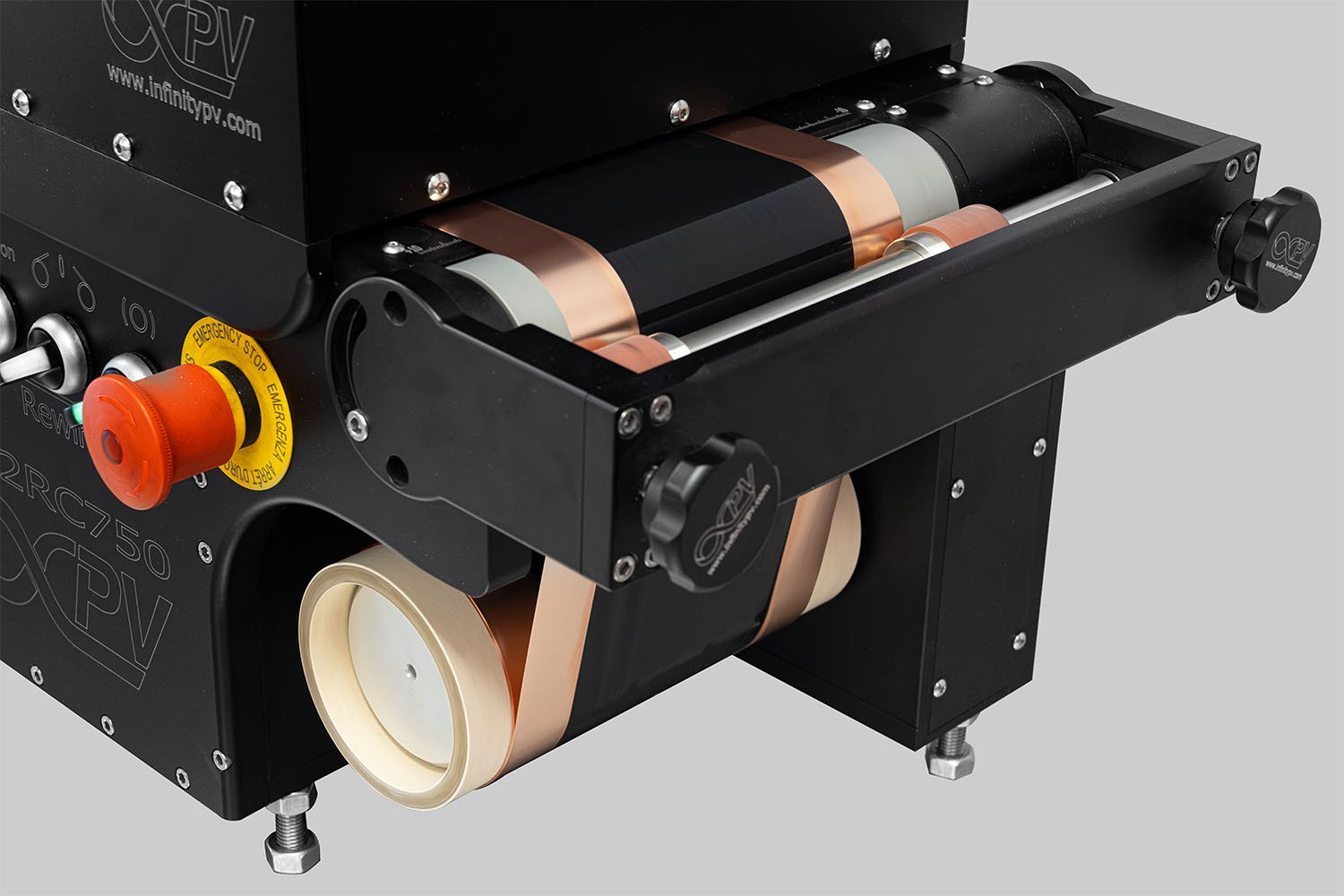

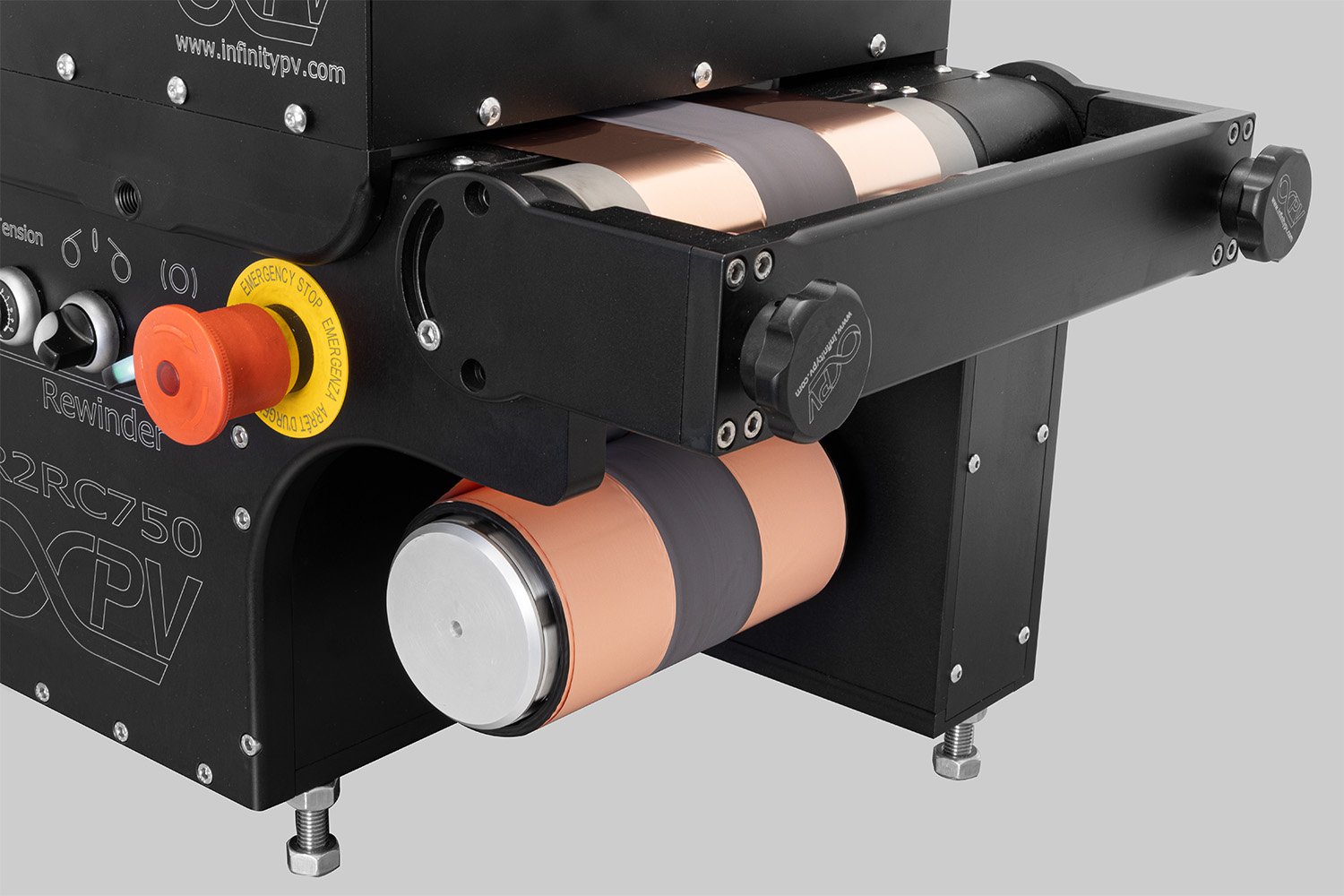

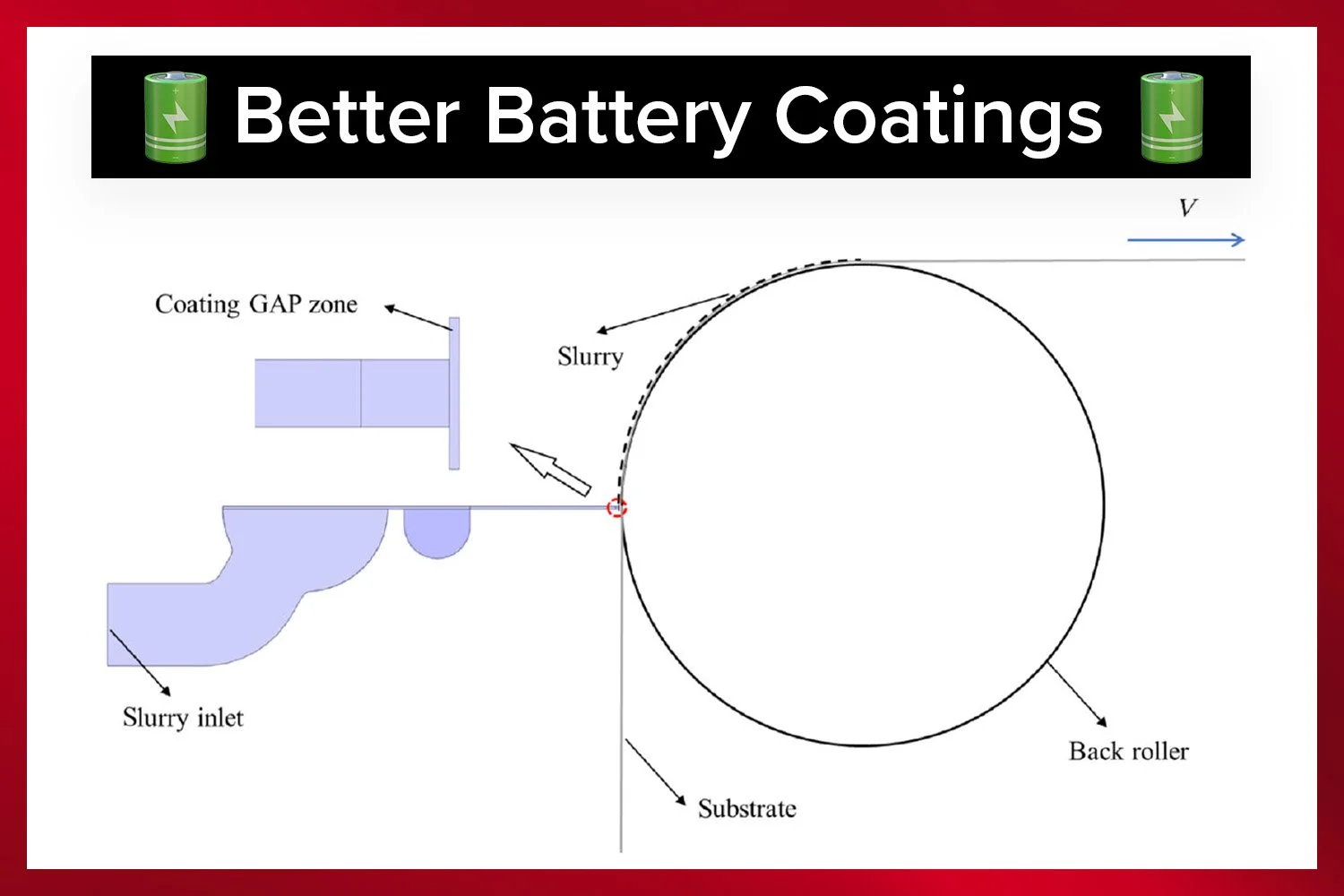

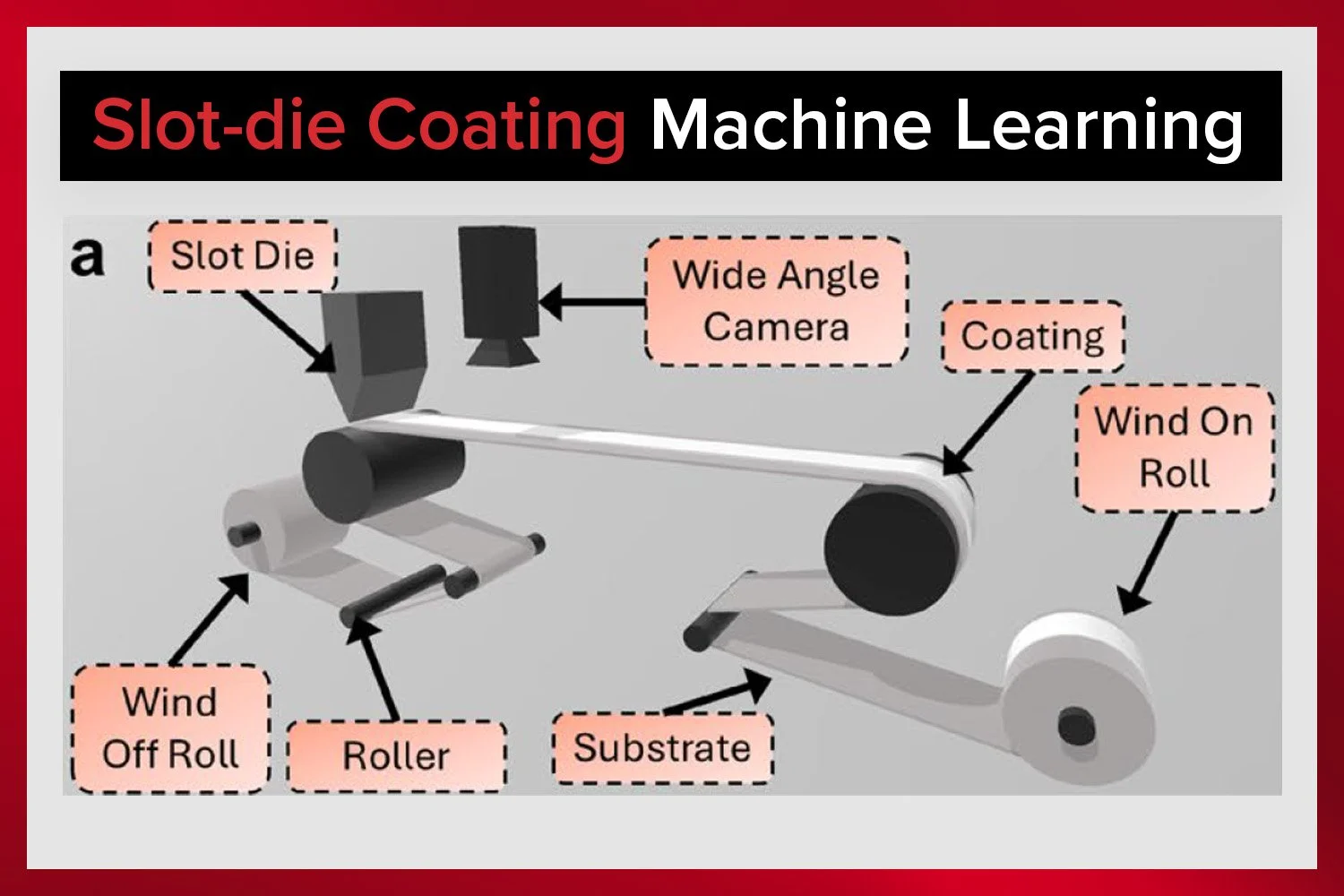

Slot-die coating on a roll-to-roll device was used to simulate industrial conditions.

The Laboratory Roll-to-Roll Coater is the ideal coating machine for scaling up to roll-to-roll processing of battery electrode materials or for testing and optimizing battery electrode slurries.

What is High Shear Dispersion and Why is it Important?

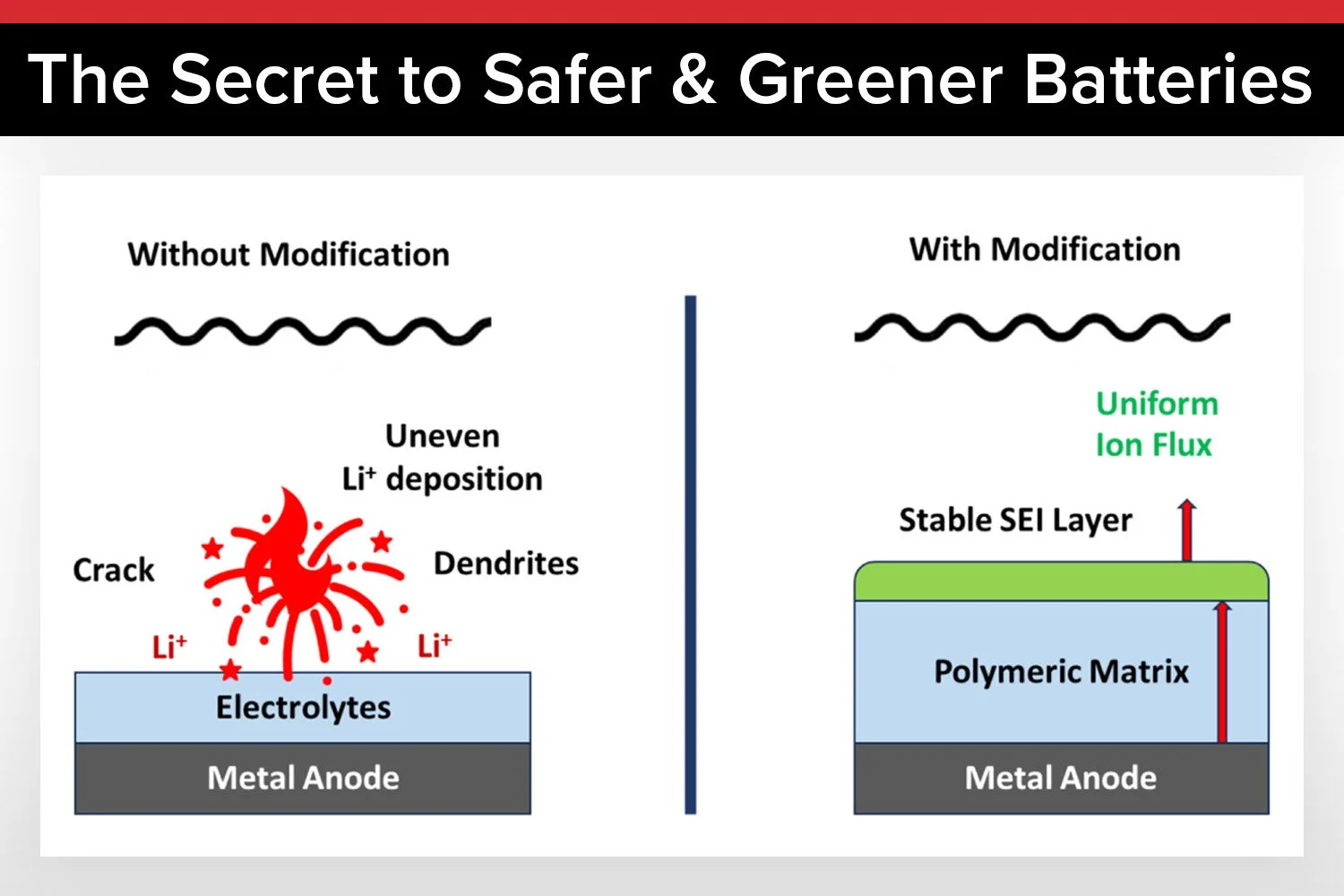

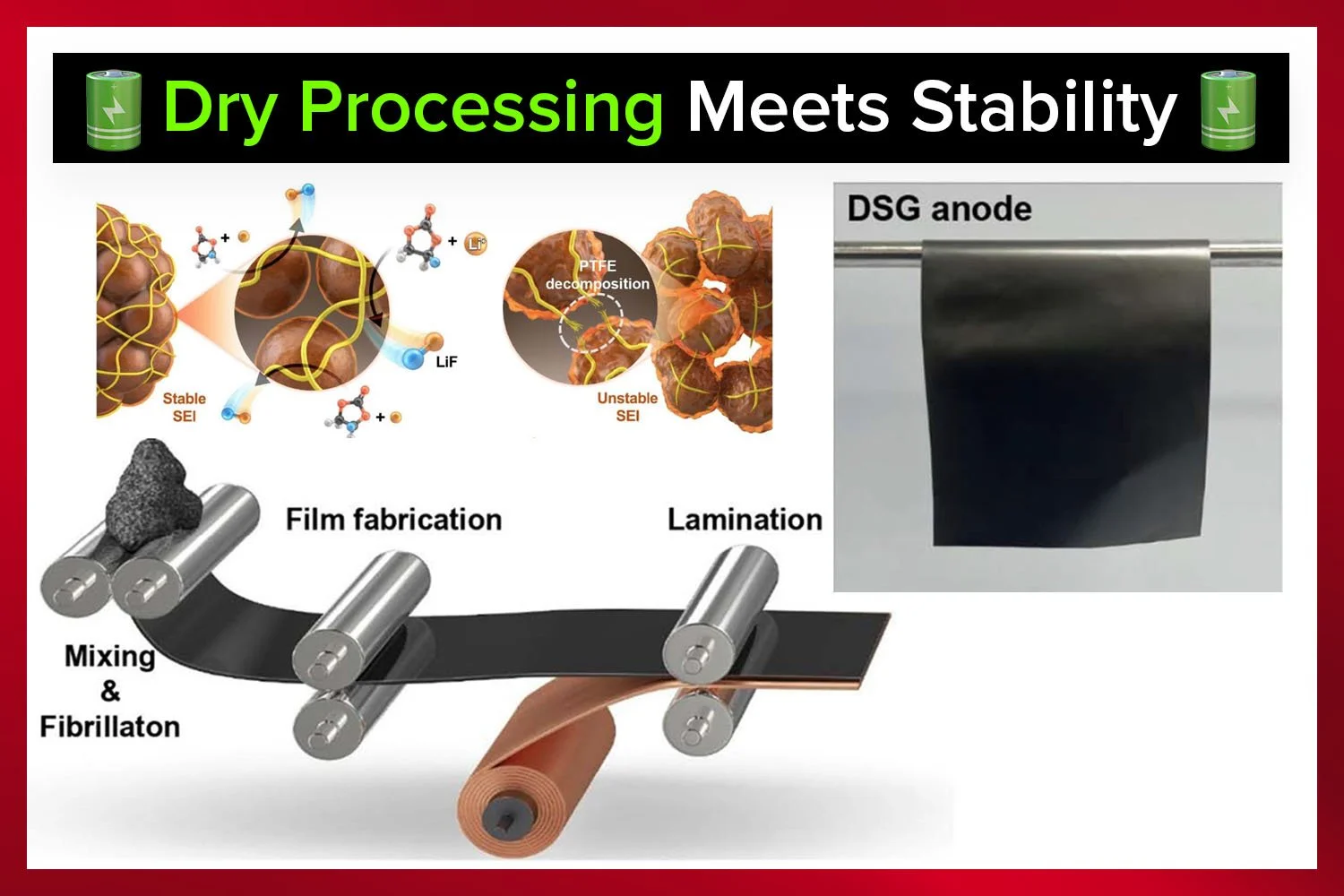

In battery manufacturing, the cathode slurry consists of a mixture of active materials, conductive additives, binders, and solvents. Achieving a uniform dispersion of these components is essential for producing high-quality electrodes. Traditional low shear mixing, commonly used in laboratory environments, often leads to uneven distribution and the formation of large particle agglomerates. This results in higher porosity and irregular coating quality.

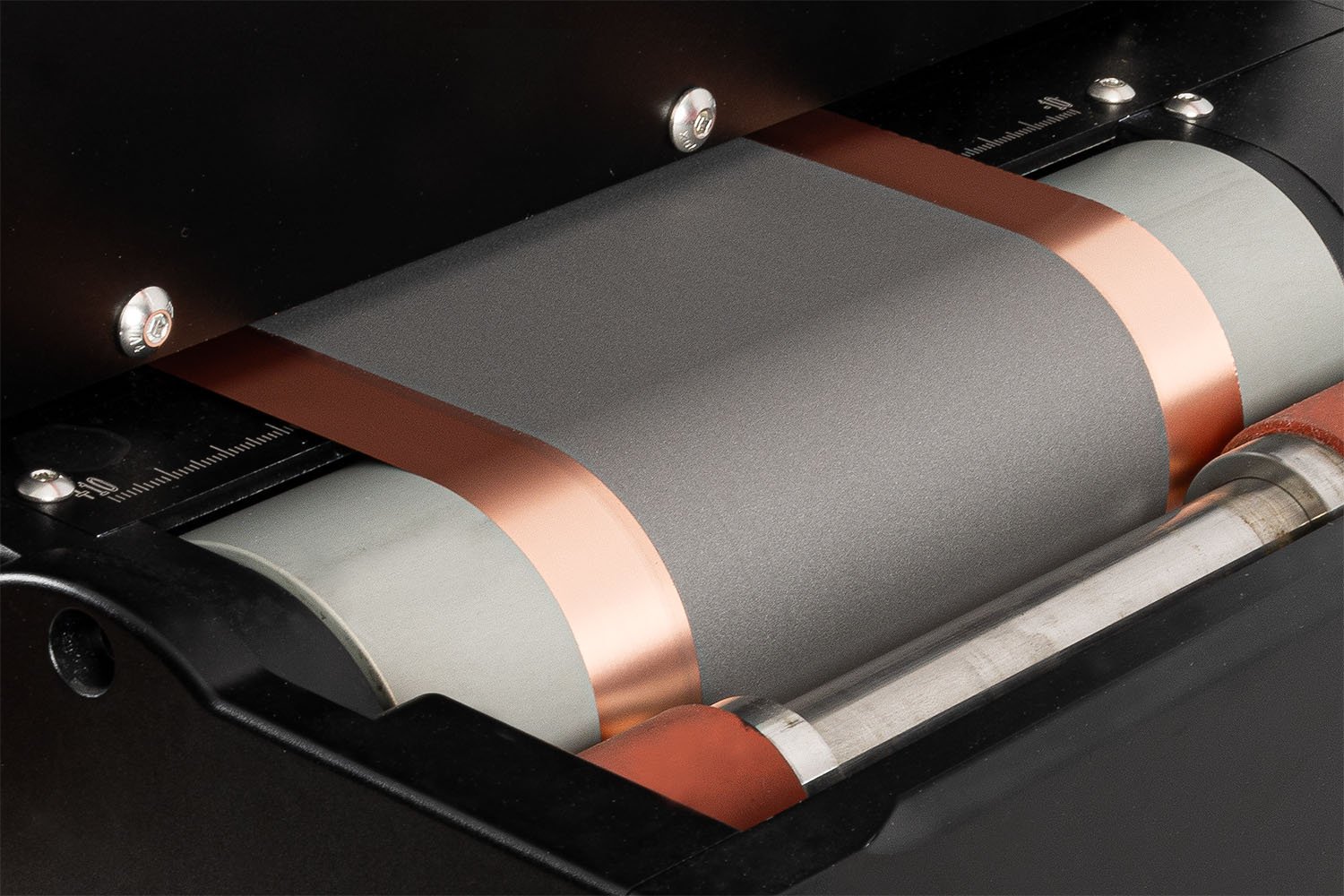

High shear dispersion addresses this by applying stronger mechanical forces that break apart particle clusters and ensure a more even distribution of materials. When this type of mixing is followed by slot-die coating using a roll-to-roll system, the result is a smoother and more compact electrode. Such cathodes are better suited for high-performance batteries, particularly when operating under practical, low-electrolyte conditions.

The Significance of the Study: A Practical Bottleneck Addressed

The lithium-sulfur battery is often described as a next-generation energy storage solution due to its high energy potential and the use of non-toxic, inexpensive materials. Despite this promise, real-world applications remain limited. One significant barrier has been the difficulty in translating promising laboratory results into industrial-scale production.

This study offers a solution to that challenge by examining how slurry mixing affects cathode morphology and battery behavior. While most research has focused on materials innovation or electrolyte optimization, this study highlights the manufacturing process itself. Specifically, it demonstrates that the shear force used during slurry blending plays a crucial role in determining cathode structure, and in turn, battery performance.

The findings are particularly relevant for roll-to-roll production lines, which require scalable and repeatable processes. By showing that high shear mixing can reduce porosity and improve adhesion, the study offers a practical pathway to enhance Li–S battery performance in formats that are closer to commercial deployment.

Diving into the Methods: How the Study Was Conducted

The researchers used two different slurry preparation methods: one involving a low shear laboratory mixer (EL1) and the other a high shear mixer (HSM). Both methods produced aqueous carbon-sulfur slurries containing sulfur, porous carbon, multi-walled carbon nanotubes (MWCNTs), and a combination of CMC and SBR binders.

These slurries were coated onto aluminum current collectors using a roll-to-roll slot-die coater, a process that mimics industrial conditions. After drying, the electrodes were evaluated through a series of structural and electrochemical tests.

The characterization included measurements of particle size distribution, viscosity, surface roughness, density, volume resistivity, and tensile strength. Coin cells were assembled using two types of electrolytes: a conventional DME/DOL-based formulation and an alternative HME/DOL mixture with reduced polysulfide solubility. Multi-layered pouch cells were also built to evaluate the real-world implications of the findings, especially under lean electrolyte conditions.

Results: Comparing Coin Cells and Pouch Cells

In coin cell tests, the differences between the two electrode types became immediately apparent. With the DME/DOL electrolyte, the high shear cathodes initially showed slightly lower capacity due to their reduced porosity, which limited polysulfide solubility. However, over repeated cycles, they outperformed the low shear cathodes, maintaining more stable performance and demonstrating lower internal resistance.

When tested with the HME/DOL electrolyte, which favors solid-solid conversion rather than solution-phase polysulfide reactions, the high shear electrodes performed better from the start. Their uniform structure and reduced agglomeration supported improved sulfur utilization and more efficient charge transport.

The advantages of high shear dispersion became even more pronounced in pouch cell tests. Under generous electrolyte conditions, both types of cathodes performed similarly at first. Over time, however, the low shear cells exhibited significant degradation after around 25 cycles. In contrast, the high shear cells continued to function effectively for over 90 cycles.

Under lean electrolyte conditions, the high shear electrodes again outperformed their counterparts. While both types of cells experienced some capacity loss, the low shear cells failed much sooner. The higher porosity in these electrodes contributed to faster electrolyte depletion and higher internal resistance. The dense and homogeneous structure of the high shear cathodes helped retain electrolyte and maintain capacity for significantly longer

Your coating process is only as good as the slot-die head that delivers it. Our guide helps you evaluate your needs and choose the right slot-die head for optimal quality, efficiency, and cost-effectiveness. Read the selection guide here.

Industry Outlook: Relevance for Scalable Battery Manufacturing

As the energy storage industry seeks to move beyond lithium-ion, lithium-sulfur batteries are gaining increasing attention. They offer significant benefits in energy density and sustainability but are often seen as difficult to manufacture reliably at scale.

This study offers a clear path toward overcoming one of the key manufacturing hurdles. By adopting high shear dispersion methods during slurry preparation, manufacturers can produce cathodes that are more robust, more uniform, and better suited to commercial cell formats.

The process is compatible with existing roll-to-roll production techniques, making it highly attractive for companies aiming to commercialize lithium-sulfur batteries. Furthermore, the findings could influence production strategies for other next-generation battery chemistries that rely on slurry-based electrode fabrication.

Conclusion

This study demonstrates that seemingly minor changes in the battery manufacturing process can have a profound impact on performance. By applying higher shear forces during cathode slurry mixing, the researchers were able to produce electrodes with improved morphology, reduced porosity, and enhanced durability.

These improvements translated directly into better performance in both coin cells and pouch cells, particularly under low electrolyte conditions. The findings validate the importance of blending techniques and open new possibilities for the scalable production of high-performance lithium-sulfur batteries.

As the industry continues to push toward higher energy density and more sustainable materials, innovations like high shear mixing could prove to be essential tools for turning laboratory research into commercial reality.

Authors

Ralf Schmidt

Tom Boenke

Paul Härtel

Susanne Dörfler

Thomas Abendroth

Holger Althues

Stefan Kaskel

Get Professional Support for Your Battery Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

The SDC Battery Coater Pro is specifically designed for researchers dedicated to developing and optimizing battery materials. It facilitates a seamless transition from research to commercialization. View video.