How Roll-to-Roll Could Change PEM Fuel Cell Production: Cutting Cost with Smarter Catalyst Layers

Can we make high-performance fuel cells with less platinum and scalable manufacturing?

That is the central question addressed in the recent study “Investigation of fuel cell catalyst dispersion formulations for indirect roll-to-roll fabrication of catalyst coated membranes for proton exchange membrane fuel cells”. The research explores a less common but promising manufacturing route for proton exchange membrane fuel cells (PEM-FCs) known as the indirect catalyst coated membrane process.

In this method, the catalyst layer is first coated onto a decal foil, dried, and then transferred to the membrane using heat and pressure. This approach avoids some of the drawbacks of other manufacturing routes such as membrane swelling during direct coating or poor contact in gas diffusion electrode methods. The team examined three catalyst dispersion formulations, studied their properties along the full process chain, and tested their electrochemical performance in fuel cells.

The study shows that with the right formulation it is possible to match the performance of a commercial reference while reducing platinum content by around 25 percent. This combination of high performance and lower cost could be an important step toward scalable roll-to-roll manufacturing.

Key Highlights

Indirect process route validated for PEM-FC catalyst coated membrane production.

Three dispersion formulations tested with varying ionomer/catalyst ratios and alcohol/water content.

Best results achieved with a high ionomer-to-catalyst ratio and high alcohol content.

Achieved performance equal to commercial CCMs while reducing platinum loading by ~25 percent.

Detailed analysis covered dispersion stability, coating quality, transfer efficiency, and electrochemical performance.

Hot-pressing parameters found to be critical for transferability and microstructure.

Poor drying behavior in high-water formulations led to cracks and defects in catalyst layers.

Results form a steppingstone for scaling to roll-to-roll production.

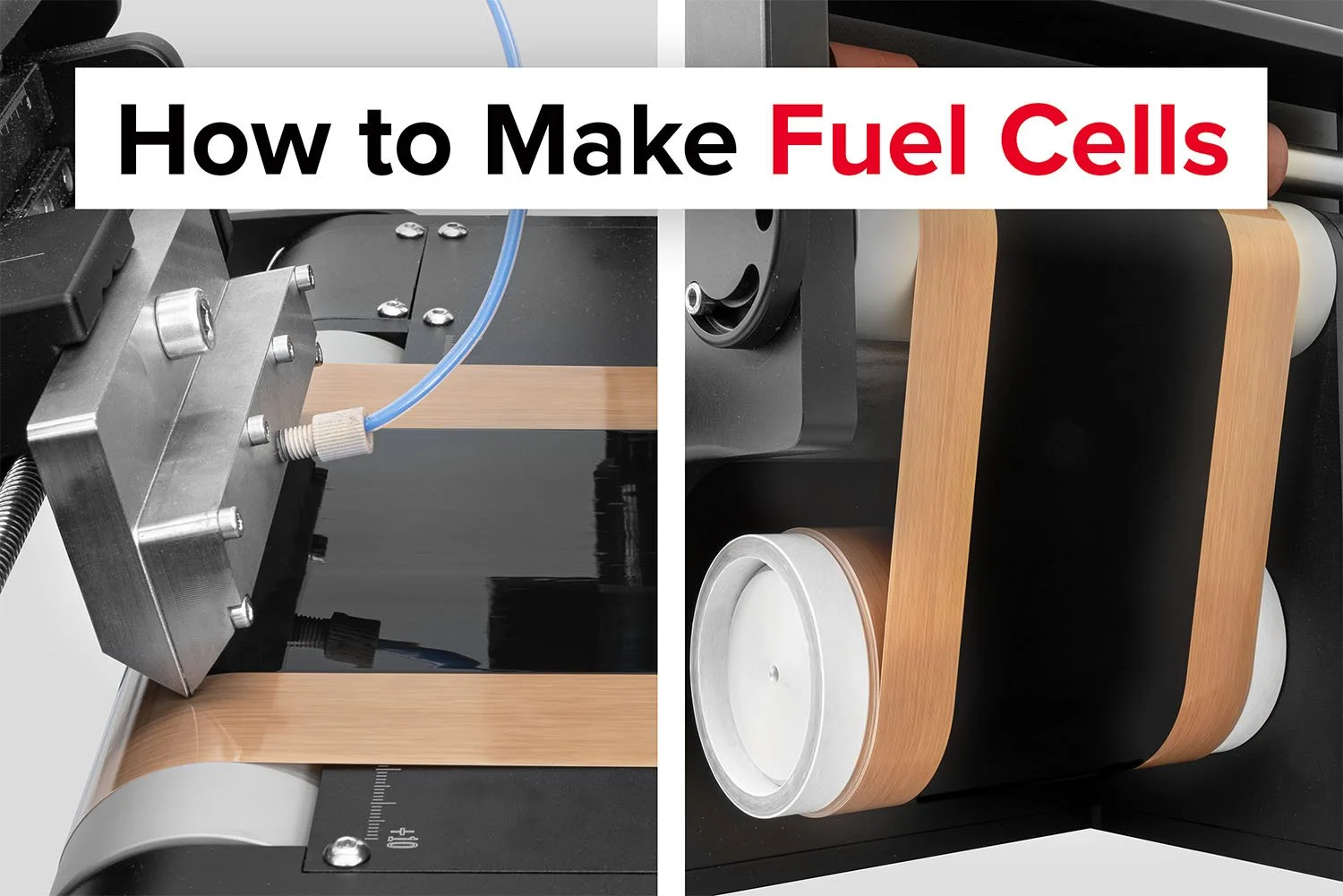

Achieve uniform fuel cell layers effortlessly with roll-to-roll slot-die coating.

What is the Indirect CCM Method and Why Does it Matter?

In PEM fuel cell production, the catalyst coated membrane is a critical component. Traditional approaches either coat the membrane directly with the catalyst dispersion or create a gas diffusion electrode which is then pressed onto the membrane.

The indirect CCM method takes a third path. A catalyst dispersion is coated onto a decal foil, dried, and transferred to the membrane under heat and pressure. This avoids excessive solvent exposure to the membrane, which can cause swelling and defects, and improves catalyst-membrane contact compared with many GDE methods. While the process introduces an additional step, it offers better scalability, more consistent quality, and compatibility with thin membranes designed for high-performance applications.

The Significance of the Study

Scaling up PEM fuel cell production while keeping costs down and maintaining performance is one of the major challenges in the hydrogen economy. Platinum remains a key cost driver, so reducing its use without lowering efficiency is highly desirable.

This research demonstrates that careful tuning of the dispersion formulation, particularly the ionomer-to-catalyst ratio and the balance of alcohol and water in the solvent, can improve coating quality, increase the efficiency of catalyst transfer, and maintain high performance with less platinum. For manufacturers aiming to implement roll-to-roll production, the results underline the importance of linking materials science with process optimization to achieve both cost and performance targets.

Enable precise deposition of catalyst and membrane layers for fuel cells using the Laboratory Roll-to-Roll Coater.

Diving into the Methods: How the Research Was Done

The team prepared three different catalyst dispersions. Dispersion A had a high ionomer-to-catalyst ratio and high alcohol content. Dispersion B had a lower ionomer-to-catalyst ratio but the same high alcohol content. Dispersion C had the same lower ionomer-to-catalyst ratio as B but a high water content.

Each dispersion was prepared using a combination of stirring and high-shear mixing. The dispersions were coated onto PET transfer foils with a doctor blade and dried under controlled conditions. They were then transferred to membranes by hot-pressing at specific temperature and pressure settings. The researchers measured properties at each stage, from particle stability and viscosity to adhesion strength, porosity, and electrochemical performance.

Testing methods included centrifugal adhesion analysis to assess transferability, optical profilometry and atomic force microscopy to examine surface features, mercury intrusion porosimetry to study pore structures, and full fuel cell tests including polarization curves, electrochemical impedance spectroscopy, and cyclic voltammetry.

What They Found: Formulation Matters

Dispersion A dried evenly, transferred efficiently, and produced catalyst layers with minimal surface defects. Dispersion B dried well but suffered from lower transfer efficiency, which reduced the amount of active catalyst in the final membrane. Dispersion C dried slowly, developed cracks, and showed poor adhesion, making it unsuitable for further testing.

In fuel cell tests, membranes made from Dispersion A matched the performance of the commercial reference up to current densities of 2 A/cm² despite having 25 percent less platinum. At higher current densities the lower platinum loading limited performance, but efficiency at lower loads remained excellent.

Your coating process is only as good as the slot-die head that delivers it. Our guide helps you evaluate your needs and choose the right slot-die head for optimal quality, efficiency, and cost-effectiveness. Read the selection guide here.

Future Outlook for the Industry

Although this study was conducted at laboratory scale, its findings have clear implications for industrial production. Further optimization of dispersion preparation time and hot-pressing conditions could lead to even better results. The indirect CCM process appears well suited to roll-to-roll manufacturing, especially for thin membranes, provided that the dispersion formulation and processing steps are carefully controlled.

Deeper analysis of pore structures and ionomer distribution could further improve catalyst layer design. If scaled successfully, the approach could help reduce both material costs and environmental impact by lowering platinum use and reducing the need for large quantities of solvents.

Conclusion

The study shows that the indirect CCM method can produce membranes for PEM fuel cells that rival commercial products while using significantly less platinum. The key lies in selecting the right dispersion formulation, ensuring smooth drying, achieving high transfer efficiency, and creating a favorable microstructure.

As demand for hydrogen technologies grows, advances in manufacturing methods like this will play a central role in making fuel cells more affordable, scalable, and sustainable.

Authors:

L. Grebener

A.S. Odungat

Y. Zhu

O. Pasdag

I. Radev

E. Nürenberg

A. Kubina

V. Peinecke

S. Kohsakowski

D. Segets

F. Özcan

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Streamline your fuel cell research with an intuitive design, making development and optimization effortless. It helps researchers turn innovative ideas into market-ready solutions.