Breakthrough in Fuel Cell Manufacturing: Roll-to-Roll Coating Shows Promise for Scalable Electrode Production

Can Fuel Cell Production Keep Up?

A recent study titled "Roll-to-roll coating methods for the manufacture of polymer electrolyte membrane fuel cell membrane electrode assemblies" brings new hope to one of clean energy’s biggest challenges. As the demand for fuel cells continues to grow, so too does the need for faster, more cost-effective manufacturing methods. In 2023, polymer electrolyte membrane fuel cells accounted for more than 60 percent of the global fuel cell market, and this figure is expected to increase.

But fuel cells, especially the membrane electrode assemblies that make them work, are costly and difficult to produce at scale. Traditional methods like spray-coating cannot meet the volume demands projected for the next decade. To address this, researchers are turning to a manufacturing solution that is already proven in other industries such as batteries and printed electronics. Roll-to-roll coating, a method known for high throughput and scalability, could provide the key to mass production.

This study explores two specific roll-to-roll coating methods: Microgravure and slot-die. The researchers tested each for their ability to fabricate gas diffusion electrodes, one of the core components of membrane electrode assemblies. Their findings could mark an important step toward the industrial-scale production of high-performance fuel cells.

Key Highlights

Roll-to-roll (R2R) coating is a promising alternative to spray-coating for manufacturing fuel cell electrodes

Microgravure and slot-die were evaluated for producing gas diffusion electrodes for polymer electrolyte membrane fuel cells

Microgravure achieved platinum loadings comparable to commercial targets for light-duty vehicles

Slot-die coatings showed greater issues with cracking but offer flexibility and precision with proper optimization

The study found that drying conditions significantly affect coating quality and fuel cell performance

Ink formulation and wettability are crucial in determining coating quality and uniformity

Microgravure delivered better MEA performance than slot-die and nearly matched spray-coating

Roll-to-roll techniques could enable the mass production needed for widespread fuel cell adoption

One of the key advantages of R2R processing for MEAs is its scalability. By eliminating the need for batch processing, R2R enables continuous production with high throughput, reducing manufacturing costs and improving overall efficiency.

What Is Roll-to-Roll Coating and Why Does It Matter?

Roll-to-roll coating is a continuous manufacturing method where a flexible substrate is coated as it passes between rolls. The process is already widely used in industries like solar cells and flexible electronics due to its efficiency and scalability. Bringing this method into fuel cell manufacturing could solve the pressing issue of how to produce high-quality components quickly and at lower cost.

Membrane electrode assemblies are at the heart of polymer electrolyte membrane fuel cells. They contain a catalyst layer that is currently applied using techniques such as spray-coating. This works at the lab scale but becomes impractical for large-scale production. To meet future demand, researchers estimate that production speeds of 20 square meters per minute will be necessary. Spray-coating, by comparison, operates at a fraction of that speed.

Roll-to-roll coating methods like Microgravure and slot-die offer the potential to meet these requirements. They are already proven in other thin-film applications and can be integrated into automated production lines.

The Significance of the Study

The main barrier to commercial fuel cell adoption is cost. More than half of the production cost of a polymer electrolyte membrane fuel cell comes from the platinum catalyst. Until non-platinum alternatives are viable, reducing the cost of applying the catalyst is critical.

This study is significant because it evaluates two scalable techniques that could drastically improve manufacturing speed while maintaining or improving performance. It also highlights the challenges that still need to be overcome, especially regarding drying and defect control.

By testing Microgravure and slot-die side by side, the researchers provide valuable insights into which method may be best suited for specific fuel cell applications. Their work lays the foundation for future development toward large-scale production.

Roll-to-roll processing is perfect for scaling up fuel cell production.

Diving Into the Methods: How the Study Was Done

The researchers used benchtop roll-to-roll systems to apply catalyst inks to gas diffusion layers. They compared two methods.

Microgravure is a self-metered technique that uses an engraved roller to transfer ink onto the substrate. The engraved pattern controls the volume of ink, and the speed of the roller relative to the substrate affects the final layer thickness. A major advantage of Microgravure is that it requires fewer parameters to control, which simplifies the process.

Slot-die is a pre-metered technique where pressurized ink is pushed through a narrow slit onto a moving substrate. This method allows precise control over the amount of ink applied and is ideal for producing uniform coatings, but it requires very tight control of multiple parameters including ink viscosity, flow rate, and web speed.

The coated electrodes were then assembled into membrane electrode assemblies and tested for performance, including current density, power output, and electrochemical surface area.

Results and Observations

Microgravure performed well, achieving platinum loadings of up to 0.29 milligrams per square centimeter, close to the target range for heavy-duty fuel cells. However, higher loadings led to cracking in the catalyst layer due to drying issues. The researchers noted that the surface of the coating begins to dry faster than the interior, trapping solvents and causing cracks to form.

Slot-die coatings faced greater challenges. Despite its potential for precision, the method produced catalyst layers with more extensive surface cracking. These defects negatively impacted the fuel cell’s performance, as the cracks disrupt gas flow and increase resistance.

In head-to-head comparisons, membrane electrode assemblies made with Microgravure-coated electrodes performed nearly as well as those made using spray-coating. In some cases, Microgravure even outperformed spray-coated samples at certain voltages. Slot-die assemblies, on the other hand, showed lower performance metrics across the board, largely due to surface cracking and coating defects.

The study also emphasized the importance of ink formulation. Inks with poor wettability or incompatible rheological properties produced suboptimal coatings regardless of the method used. Adjusting the ink’s alcohol-to-water ratio and incorporating additives showed promise in reducing contact angles and improving film quality.

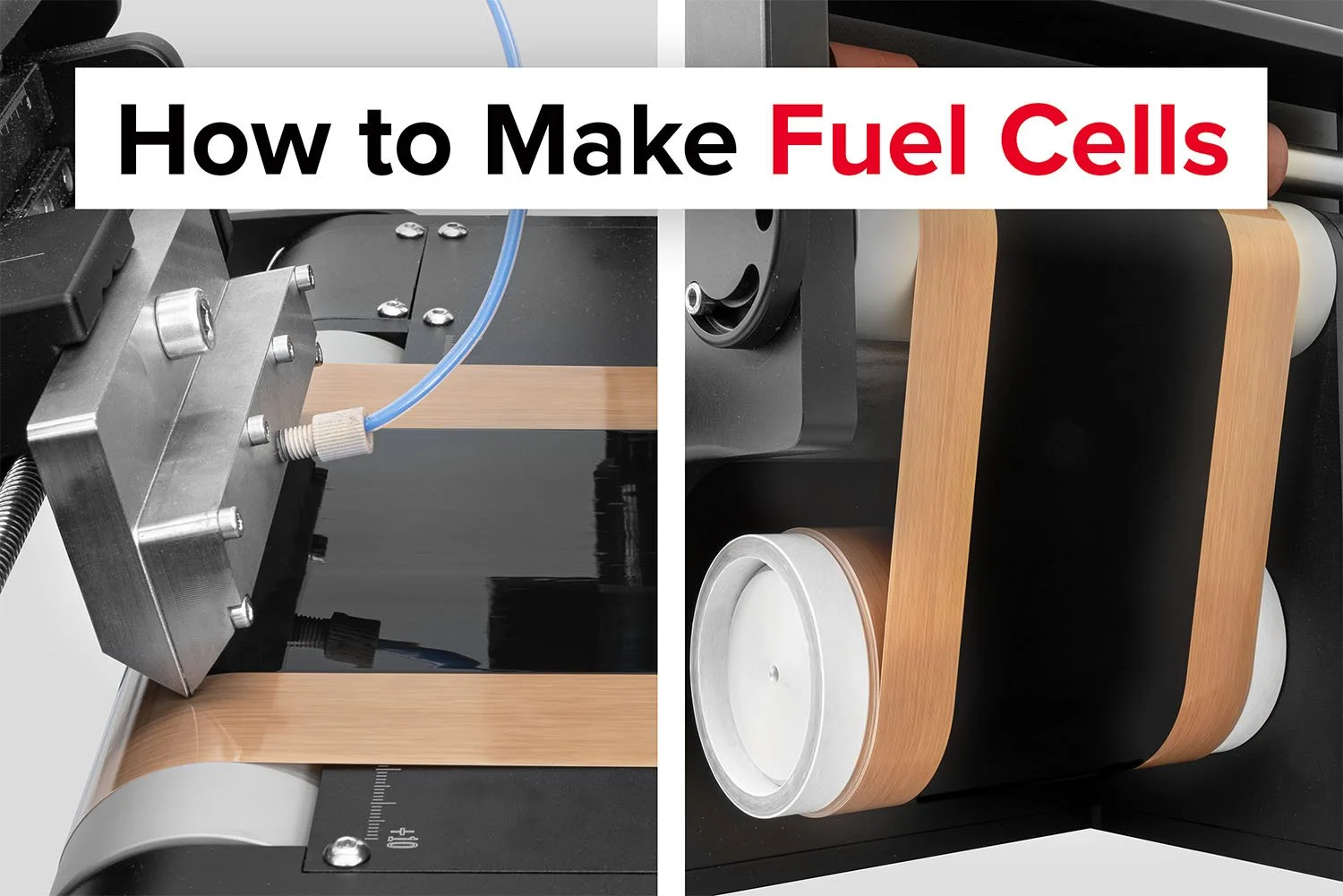

The Laboratory Roll-to-Roll Coater is the ideal coating machine for scaling up to roll-to-roll processing of battery electrode materials or for testing and optimizing battery electrode slurries.

Future Outlook and Industry Relevance

As fuel cell adoption grows in both light-duty and heavy-duty applications, the need for scalable and reliable manufacturing methods becomes more urgent. This study suggests that Microgravure is already close to being production-ready for certain applications. Slot-die, while more complex, offers flexibility that may become advantageous with further process optimization.

Future work will need to focus on improving drying strategies and refining ink formulations. Using higher boiling point solvents and crack-inhibiting additives may reduce the risk of defects. Improving equipment precision and establishing stable coating windows for different ink compositions will also be critical.

Ultimately, integrating these roll-to-roll methods into industrial-scale production lines could be a key step in reducing the cost of polymer electrolyte membrane fuel cells and supporting the transition to a hydrogen-based economy.

Double-sided battery coating on a Laboratory Roll-to-Roll Coater.

Conclusion

The study successfully demonstrates that roll-to-roll coating methods can play a central role in the future of fuel cell manufacturing. Microgravure offers a relatively simple and effective solution for high-throughput electrode production, while slot-die holds promise with further optimization. Both methods represent a significant departure from traditional spray-coating and may enable the scale-up necessary to meet global clean energy goals.

By investigating not only the benefits but also the limitations of each technique, the researchers provide a clear path for future development. With continued innovation in materials, coating technologies, and process control, roll-to-roll methods may become the standard for membrane electrode assembly production.

Authors

C. Felix, Advanced Materials Division, Mintek

O. Barron, Advanced Materials Division, Mintek

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Tailored for lab-scale research and development, this system enables the efficient lab scale application of slot-die coating fuel cell using roll-to-roll (R2R) processing.