Roll-to-Roll Slot-die Coating and Flexo Printing Enable Industrial-Scale Glucose Sensors: A Breakthrough in Organic Electronics

Can we make advanced glucose sensors affordable, disposable, and printable at scale?

A recent study titled “Upscaling laboratory organic electronic sensor devices to roll-to-roll printing: The effect of printable electrodes on device operation” explores exactly that. In the growing field of organic electronics, the promise of low-cost, flexible, and scalable devices is beginning to materialize. This work, published in Applied Physics Letters in April 2024, presents a major step forward. The researchers successfully translated a glucose biosensor from laboratory-scale fabrication to full roll-to-roll manufacturing. It is not just a theoretical exercise. It is a working, cost-effective prototype that retains high performance and is ready to be integrated into scalable medical technologies.

Below, we break down the study’s key insights, the technology behind it, and its broader significance for the printed electronics industry.

Key Highlights

The study demonstrates successful roll-to-roll (R2R) upscaling of an organic electrochemical glucose sensor

Printable silver nanoparticle-based electrodes replaced rigid indium tin oxide (ITO) electrodes

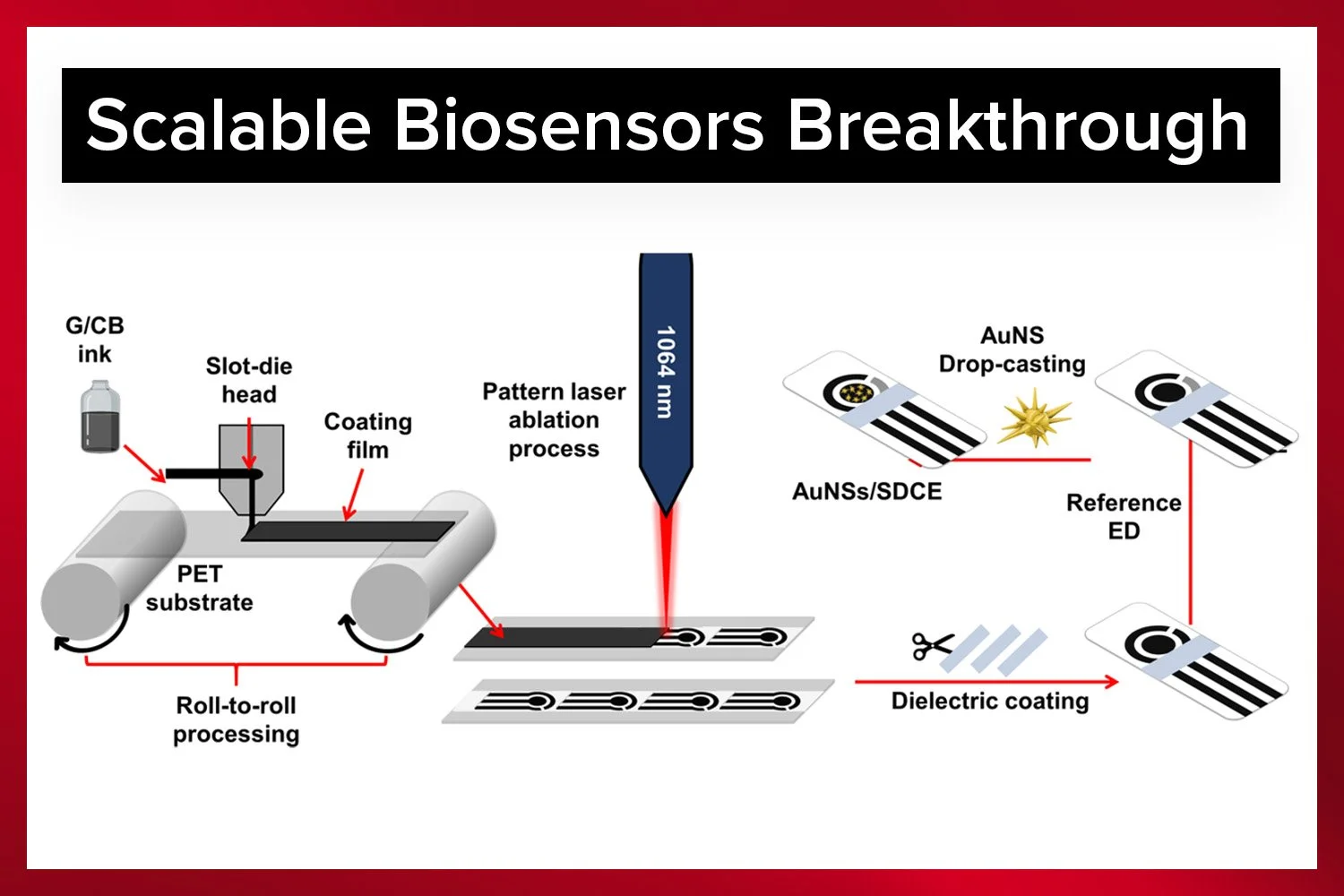

Flexographic printing, slot-die coating, and screen printing were combined to fabricate multilayered devices

A modified voltage operation scheme was necessary to stabilize the silver electrodes

The resulting sensors showed sub-millimolar glucose sensitivity with stable performance

The estimated production cost is below $0.05 per sensor at pilot scale

Shelf-life testing showed over 90 percent functionality retention after 42 days

This work highlights critical challenges in translating laboratory designs to scalable manufacturing

Using a Slot-die Coater, making uniform thin-films has never been easier.

What Are OECT-Based Biosensors and Why Do They Matter?

Organic Electrochemical Transistors, or OECTs, are a class of devices that convert biological signals such as glucose levels into readable electrical outputs. These devices operate at low voltages, are compatible with soft and flexible materials, and are particularly attractive for health monitoring applications like glucose sensing. With diabetes prevalence rising globally, there is an urgent need for affordable and reliable point-of-care diagnostics.

However, most biosensor innovations stay confined to laboratories. Translating these devices to commercial-scale manufacturing without compromising on sensitivity or stability remains a major challenge. This is where roll-to-roll production becomes a game changer.

From Glass Slides to Flexible Films: Why This Work Is a Big Deal

Previous versions of OECT-based glucose sensors were built on glass using techniques like spin coating and inkjet printing. These approaches are too slow and expensive for mass production. The innovation presented in this study lies in completely redesigning the sensor for roll-to-roll manufacturing using scalable and cost-effective industrial tools.

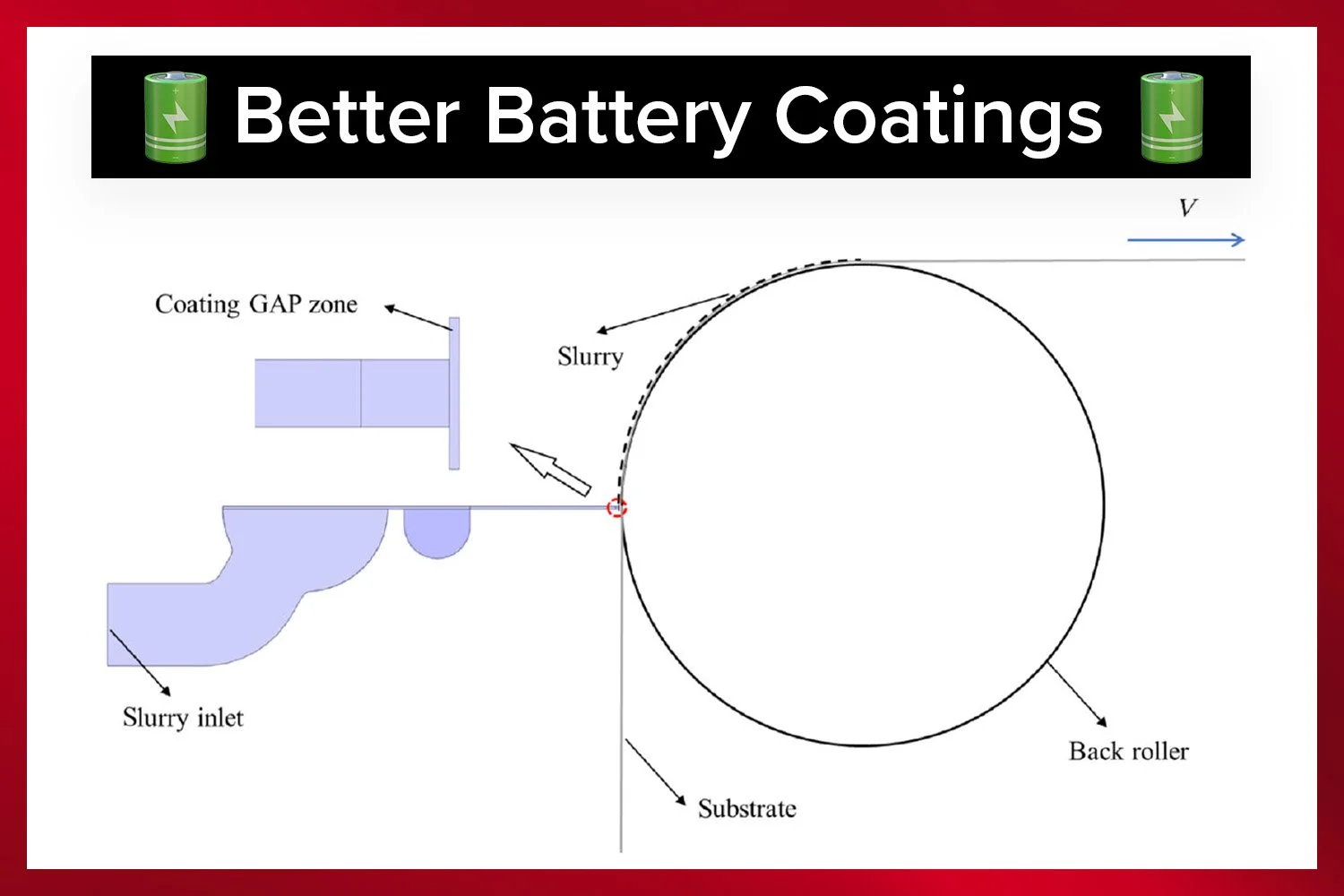

Rigid ITO glass electrodes were replaced with printed silver electrodes created via flexographic printing. The semiconductor and proton-conducting layers, P3HT and Nafion respectively, were deposited using slot-die coating. This method supports continuous and precise film deposition, making it ideal for organic electronics. Finally, the glucose-sensitive enzyme layer, glucose oxidase (GOX), was added through screen printing.

The result is a fully printed glucose sensor on a flexible PET substrate. It is inexpensive, disposable, and ready for integration into wearable or point-of-care health monitoring systems.

Your coating process is only as good as the slot-die head that delivers it. Our guide helps you evaluate your needs and choose the right slot-die head for optimal quality, efficiency, and cost-effectiveness. Read the selection guide here.

The Significance of the Study: Addressing Real-World Manufacturing Challenges

Upscaling a device from lab bench to industrial line introduces several new variables. One major issue encountered in this project was the instability of the printed silver electrodes under standard operating voltages. The researchers found that electrochemical reactions such as silver oxidation and dendritic growth could quickly degrade device performance.

To solve this, they developed a voltage modulation scheme. The sensor operates briefly at a higher voltage to initiate glucose detection, then switches to a lower voltage for the remainder of the test to avoid damaging the electrodes. This adjustment extended the operational stability and prevented failure during testing.

This is a strong example of how design and operation must adapt when scaling from lab to line. Materials that perform well at small scale may behave very differently in printed, flexible formats.

Diving Into the Methods: How Roll-to-Roll Printing Was Achieved

The devices were fabricated using a roll-to-roll printing line. The silver electrodes were deposited with flexographic printing using a nanoparticle-based silver ink. Thin, high-resolution patterns were essential for achieving the needed electrical performance while maintaining printability.

The P3HT semiconductor layer was applied by slot-die coating using a chloroform-based ink. This method was selected because it is non-contact and allows fine control over film thickness. It also avoids damaging previously deposited layers.

Nafion, the proton-transporting layer, was also slot-die coated. The ink was a custom mixture of Nafion solution and isopropanol. This formulation ensured proper adhesion and wetting without disrupting the P3HT layer below.

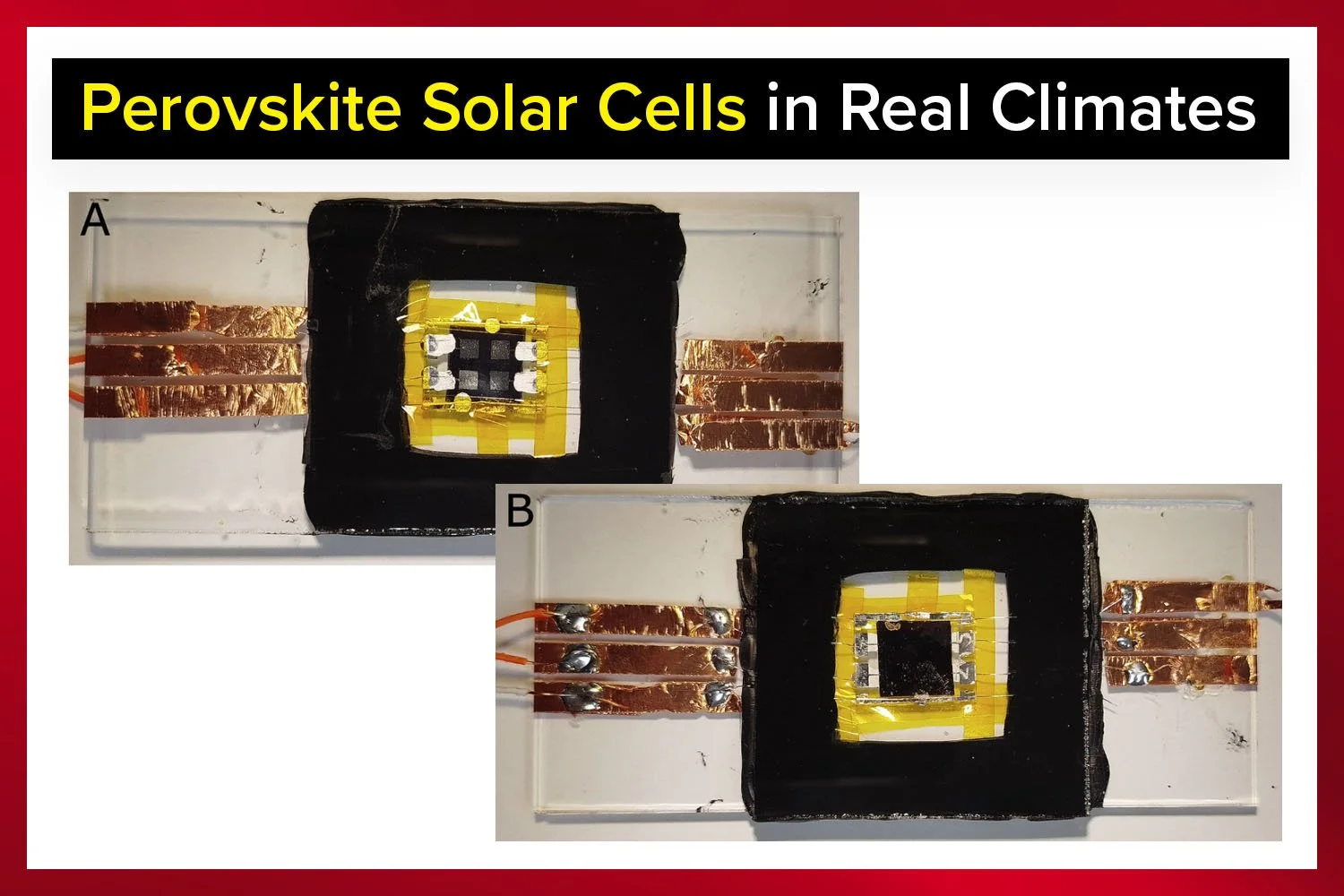

The final GOX layer was applied using screen printing from an aqueous ink. This allowed accurate placement of the enzyme without disturbing the underlying layers. Microscopy and scanning electron imaging confirmed that the resulting multilayer structure was uniform and free of defects.

Applying printed silver electrodes using a flexo roller.

Future Outlook and Relevance to the Industry

This work provides a detailed case study on how to upscale functional printed electronics, and it sets a precedent for other organic devices such as wearable biosensors, flexible displays, or environmental monitors.

The sensor is low-cost, with pilot-scale cost estimates under $0.05 per unit. It is disposable and flexible, ideal for point-of-care medical applications. Its fabrication relies entirely on scalable industrial printing techniques, meaning the path to commercial production is clear and achievable.

Moreover, this study confirms that thoughtful engineering at the design and process levels can overcome the barriers that typically prevent lab devices from entering real-world markets. For anyone involved in the printed electronics ecosystem, this is a signal that the technology is ready to mature.

Double-sided roll-to-roll coating using a Laboratory Roll-to-Roll Coater.

Conclusion: A Blueprint for Scalable Biosensor Manufacturing

This study successfully translates a lab-scale glucose sensor into a fully printed, roll-to-roll manufactured device. The sensor maintains high sensitivity, stability, and reliability, all while reducing production costs. The authors achieved this by rethinking materials, redesigning the electrode structure, and solving voltage-related degradation problems through an adaptive operation scheme.

The project demonstrates not only the potential of organic electronic biosensors, but also the practical steps required to bring them to market. It represents a milestone in printed sensor development and provides a valuable framework for future work in the field.

Authors

Daniel C. Elkington

Nathan A. Cooling

Swee-Lu Lim

Nguyen T. Trinh

Alaa Al-Ahmad

Tim Lewis

Kristofer L. Thompson

Riku Chowdhury

Warwick Belcher

Paul C. Dastoor

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.