Slot-die Coating Enhances Soft Robotics with High-Strain Actuators: New Study Shows 91% Actuator Retention

Can Slot-Die Coating Power the Next Generation of Soft Robots?

A recent study titled "Slot-Die-Printed Electroactive Polymer Actuators with High-Strain Sensitivity for Soft Robotic Applications" introduces a promising leap forward for soft robotics. The research team, led by Duanhao Lu and colleagues, combines innovative materials engineering with slot-die coating technology to fabricate highly responsive and durable electroactive polymer actuators. These actuators are designed for applications such as soft robotic fingers and wearable electronics—areas that demand lightweight, flexible, and efficient components.

What sets this work apart is how the team reimagines both the structure and the fabrication process of ionic electroactive polymer (IEAP) actuators. By using slot-die coating instead of conventional casting, they achieved more uniform gel layers with stronger integration between the gel and electrodes. They also enhanced the gel by introducing lactic acid (LA), which helped improve ion transport and flexibility.

This easy-to-replicate approach not only simplifies manufacturing but also delivers remarkable performance gains. These include faster response times, greater bending strain, and improved durability over thousands of cycles. Together, the fabrication method and material innovations move the field closer to scalable, real-world applications in soft robotics and beyond.

Key Highlights

First-time use of slot-die coating to fabricate gel actuation layers for IEAP actuators

Achieved a peak-to-peak displacement of 16.91 mm—1.65 times higher than traditional casting

Integrated lactic acid (LA) into CS-PVA-IL gel to enhance ion mobility and network flexibility

Response time improved to 0.92 seconds from 1.33 seconds

Maintained 91% actuation performance after 10,000 cycles

Improved ion conductivity (14.35 S m⁻¹) and reduced internal resistance

Strain sensitivity reached 0.35%, among the highest reported in the field

Slot-die coated layers exhibited fewer surface defects and better adhesion

Demonstrated potential applications: flexible touch interfaces and artificial muscles

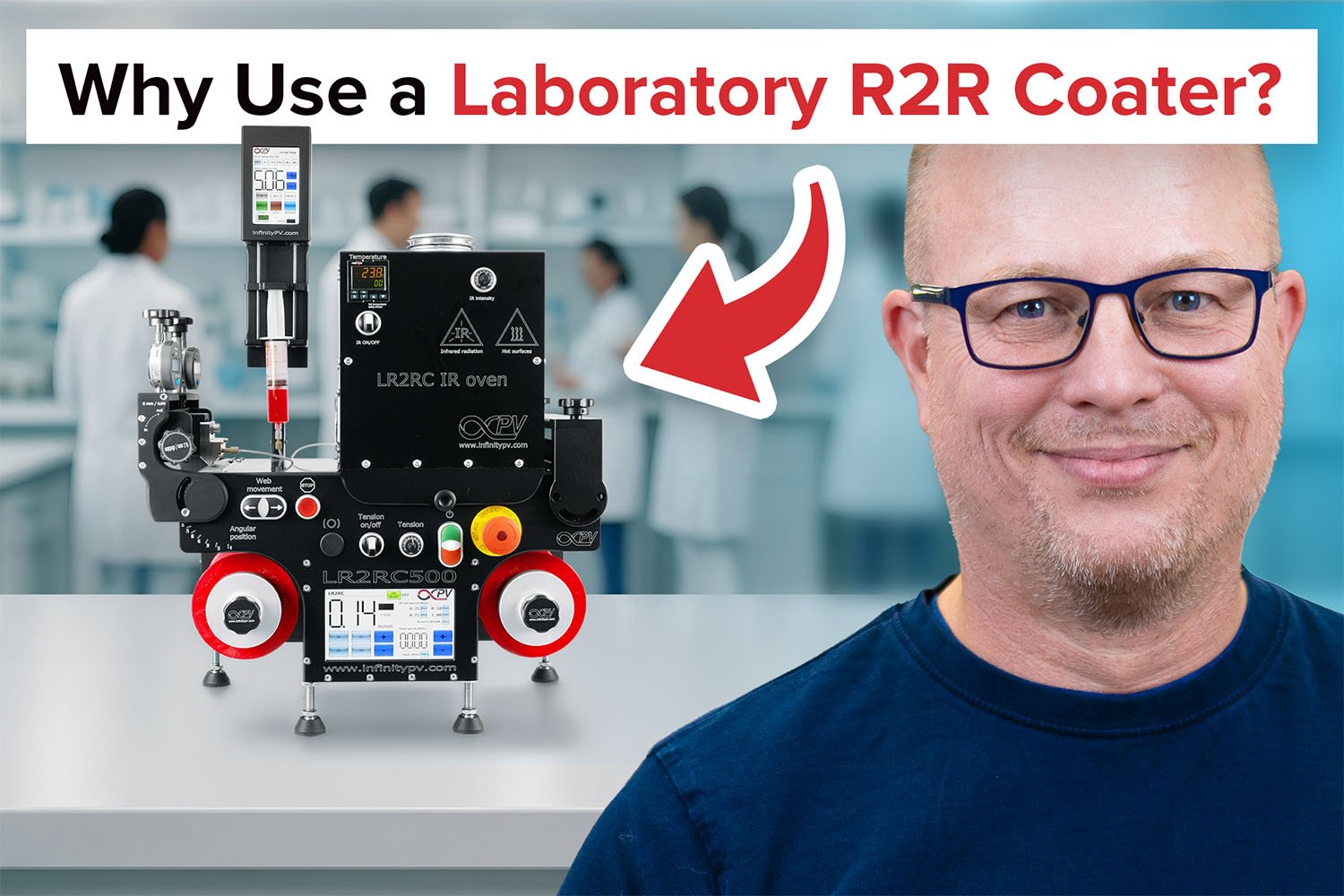

The Laboratory Roll-to-Roll Coater is the ideal coating machine for scaling up to roll-to-roll processing of battery electrode materials or for testing and optimizing battery electrode slurries.

Key Advances in Electroactive Polymer Actuators

The study demonstrates that slot-die coated actuators outperformed those made by traditional casting in nearly every measurable way. The researchers achieved a peak-to-peak displacement of 16.91 mm, which is 1.65 times higher than the displacement from casting methods. They showed that adding lactic acid to the chitosan-polyvinyl alcohol-ionic liquid (CS-PVA-IL) gel improved its ability to move ions, increased flexibility, and strengthened the internal polymer network. As a result, the actuator's response time improved to just 0.92 seconds, and it maintained 91 percent of its actuation performance even after 10,000 cycles.

The fabricated actuators also demonstrated exceptional bending strain, reaching up to 0.35 percent, which is among the highest reported values for similar systems. The improved conductivity and reduced internal resistance confirmed the enhancements. By optimizing both material composition and fabrication process, the study sets a new benchmark in actuator performance.

What Are Electroactive Polymer Actuators and Why Do They Matter?

Electroactive polymer actuators are materials that can bend or move when an electrical signal is applied. They are soft, lightweight, and flexible, making them especially useful in soft robotics, artificial muscles, medical devices, and wearable electronics. Among these, ionic electroactive polymer (IEAP) actuators are particularly promising because they operate under low voltages and can produce smooth and controlled motion.

Despite their potential, traditional IEAP actuators often suffer from poor performance due to uneven gel layers, poor bonding with electrodes, and limited ion transport. These issues restrict their mechanical movement and reduce their operational lifespan. The recent study tackles these challenges head-on by developing a more uniform and better-integrated gel layer using slot-die coating and a more effective polymer formulation enhanced with lactic acid.

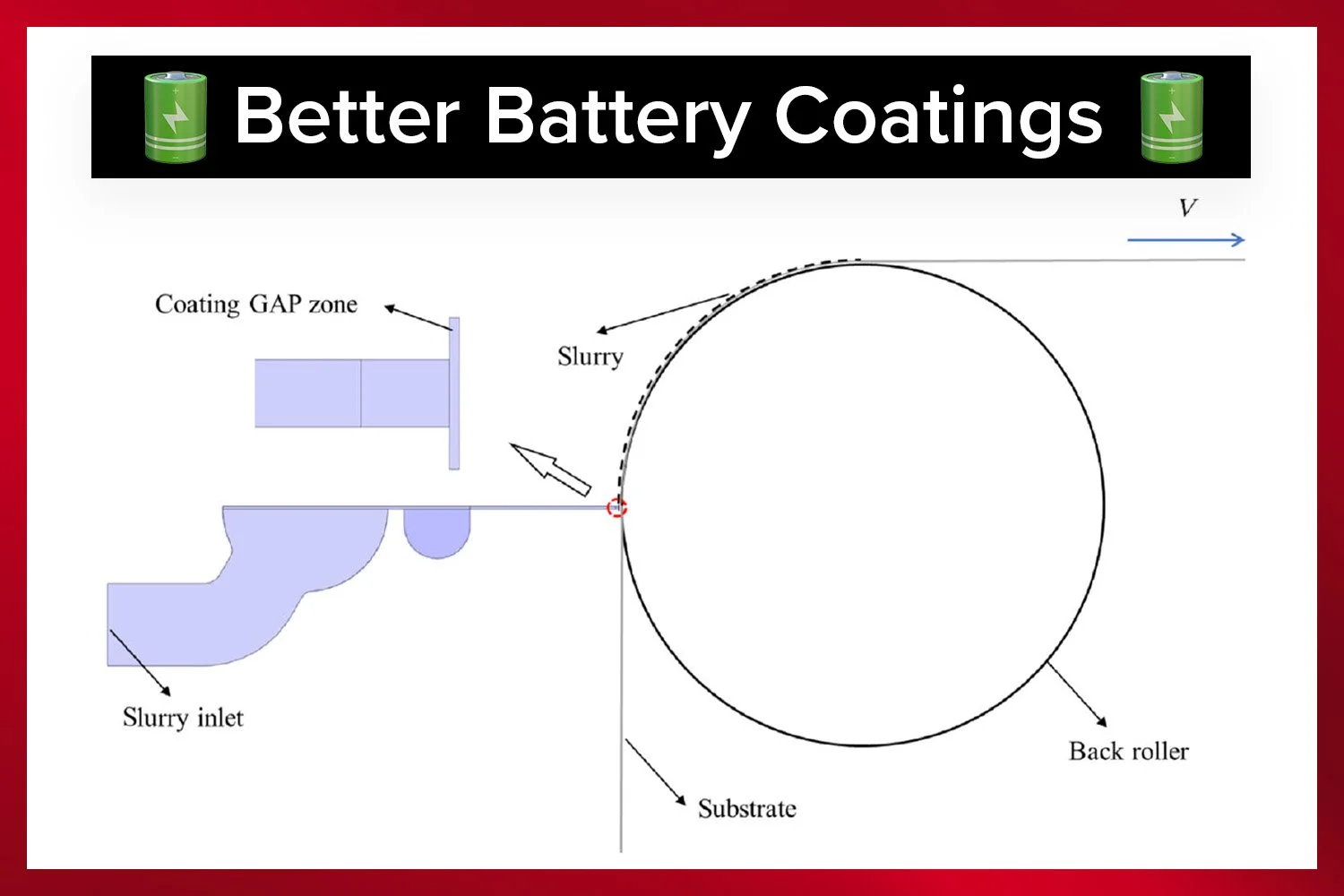

The Impact of Slot-die Coating on Actuator Design

Slot-die coating is a precision coating technique widely used in electronics and energy devices. It enables the uniform application of liquid materials onto flat surfaces. In this study, the slot-die coating method produced gel layers with consistent thickness and smooth surfaces, reducing surface roughness from 193 nanometers to just 71 nanometers.

This method allowed for seamless integration between the gel and the electrode layer. Compared to traditional casting, slot-die coating created a stronger bond between the two layers, confirmed by peel-off tests that showed more than double the adhesion strength. Better integration resulted in lower interface resistance, improved ion migration, and greater mechanical performance.

The researchers also found that slot-die coating reduced internal stress and improved the long-term stability of the actuators. Actuators made this way exhibited less deformation and damage over time, making them more reliable for long-term use in real-world applications.

How the Research Was Done

To create the actuator, the team prepared two types of gel layers: one using the standard CS-PVA-IL formulation, and one with lactic acid added. The gels were deposited either using slot-die coating or traditional casting methods. The resulting actuators were tested for bending displacement, response time, ion conductivity, internal resistance, and durability.

The addition of lactic acid played a crucial role. It helped form stronger bonds between the chitosan and polyvinyl alcohol molecules, resulting in a denser and more flexible polymer network. This made it easier for ions to move through the gel, enhancing the overall actuation performance. Testing confirmed that the actuator with lactic acid showed better displacement, faster response, and improved electrochemical properties.

Electrochemical Impedance Spectroscopy (EIS) and Cyclic Voltammetry (CV) were used to measure ion migration and charge storage. Surface and structural characterization included X-ray diffraction (XRD), differential scanning calorimetry (DSC), Fourier-transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and atomic force microscopy (AFM). These tools allowed the researchers to evaluate everything from molecular interactions to surface texture.

Double-sided battery coating on a Laboratory Roll-to-Roll Coater.

Looking Ahead: What This Means for the Industry

The study is important not only for its technical outcomes but also for its industrial implications. Slot-die coating is scalable and reproducible, making it an ideal method for manufacturing soft actuators at a larger scale. Because the materials used are affordable and environmentally friendly, such as chitosan and polyvinyl alcohol, this approach aligns with sustainability goals as well.

These actuators could be integrated into soft robotic systems, artificial touch interfaces, wearable sensors, and medical devices. Demonstrations included using the actuator to play piano keys on a smartphone and act as a touch-sensitive switch to light up bulbs. These practical applications show that the research isn’t just theoretical; it is ready for real-world testing and use.

Conclusion

This work marks a significant step forward in the design and fabrication of electroactive polymer actuators. By switching from casting to slot-die coating and enhancing the gel formulation with lactic acid, the researchers created actuators with better bending performance, faster response, and greater durability. The methods used are simple, cost-effective, and scalable, opening the door to industrial applications in soft robotics and flexible electronics. With its well-rounded approach to both material science and manufacturing, this study provides a strong foundation for the next generation of soft actuators.

Authors

Duanhao Lu

Ying Yu

Yuxin Zuo

Yong Lv

Tianyu Zhang

You Li

Zhangfeng Zhao

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.