Adaptive Slot Die Coating: A Leap Toward Sustainable Battery Manufacturing

How can we make battery production more efficient and sustainable, especially as demand skyrockets?

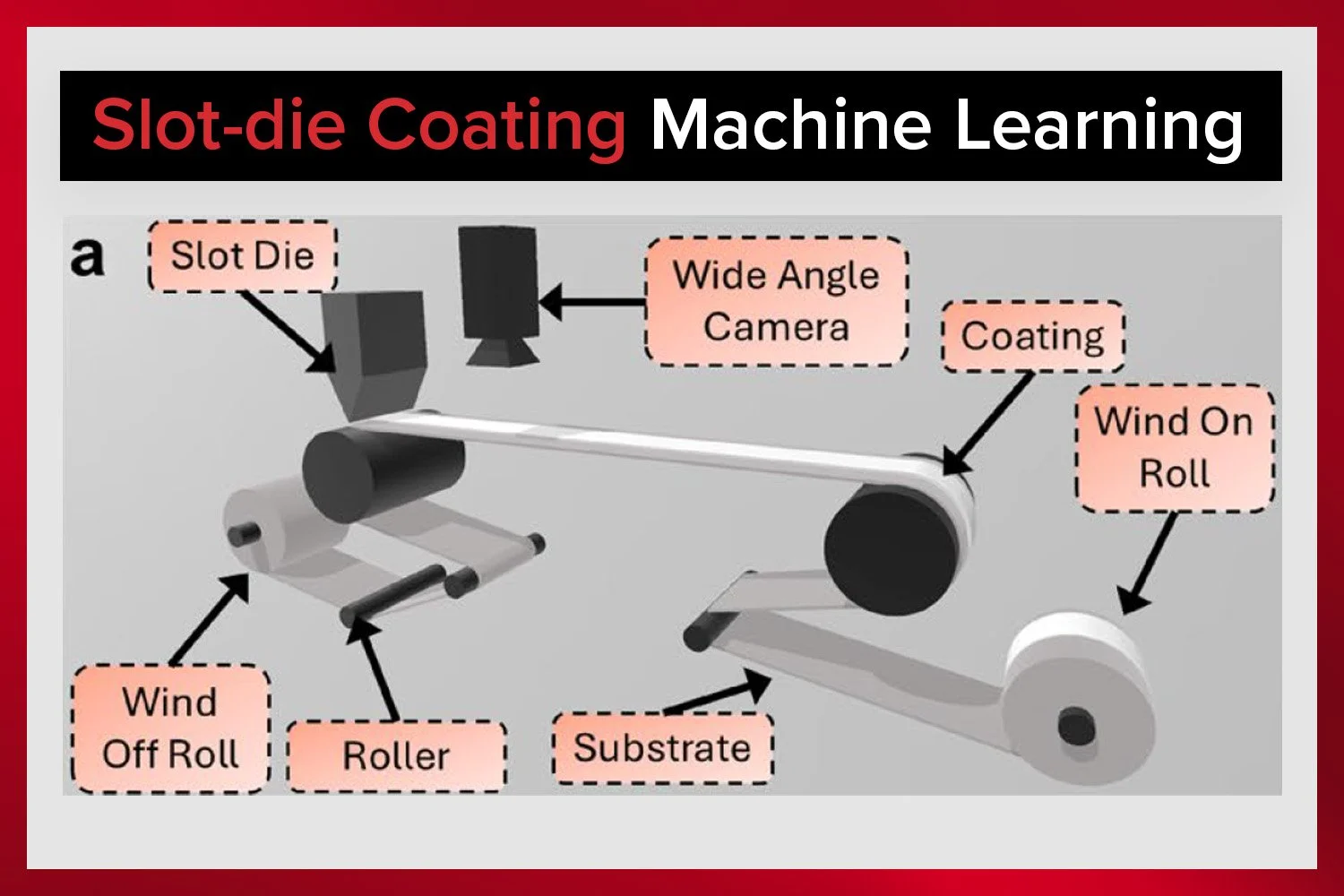

A recent conference article titled "Implementation of a Fuzzy Controller for Battery Electrode Coating with a Slot Die" explores exactly that. As battery manufacturing ramps up to meet global electrification goals, waste reduction and process adaptability become increasingly important. The researchers from the Karlsruhe Institute of Technology (KIT) propose a promising solution: a fuzzy logic-based controller for the slot die coating process in lithium-ion battery production.

Slot die coating is a key step in roll-to-roll battery manufacturing, but current systems often produce high scrap rates during process ramp-ups or material changeovers. Traditional control systems are inflexible, relying heavily on manual adjustments. This new approach introduces fuzzy logic to manage coating parameters like gap distance and angle of attack, aiming to improve quality, reduce waste, and adapt easily to new materials.

Let us dive into what this means for roll-to-roll manufacturing and why it could mark a significant advancement in battery electrode production.

Key Highlights

High scrap rates (up to 50-70 percent) occur during battery line ramp-up and changeovers

Slot die coating is precise but manually controlled and inflexible

Fuzzy logic enables rule-based control without requiring mathematical modeling or large datasets

The new controller focuses on adjusting gap distance and angle of attack in real time

Built-in expert knowledge allows adaptability to different materials and coating setups

The system is implemented in Python and processes inputs in under 0.05 seconds

Edge elevation, film thickness, and coating width are monitored to maintain quality

Experimental setup shows promising accuracy and fast response times

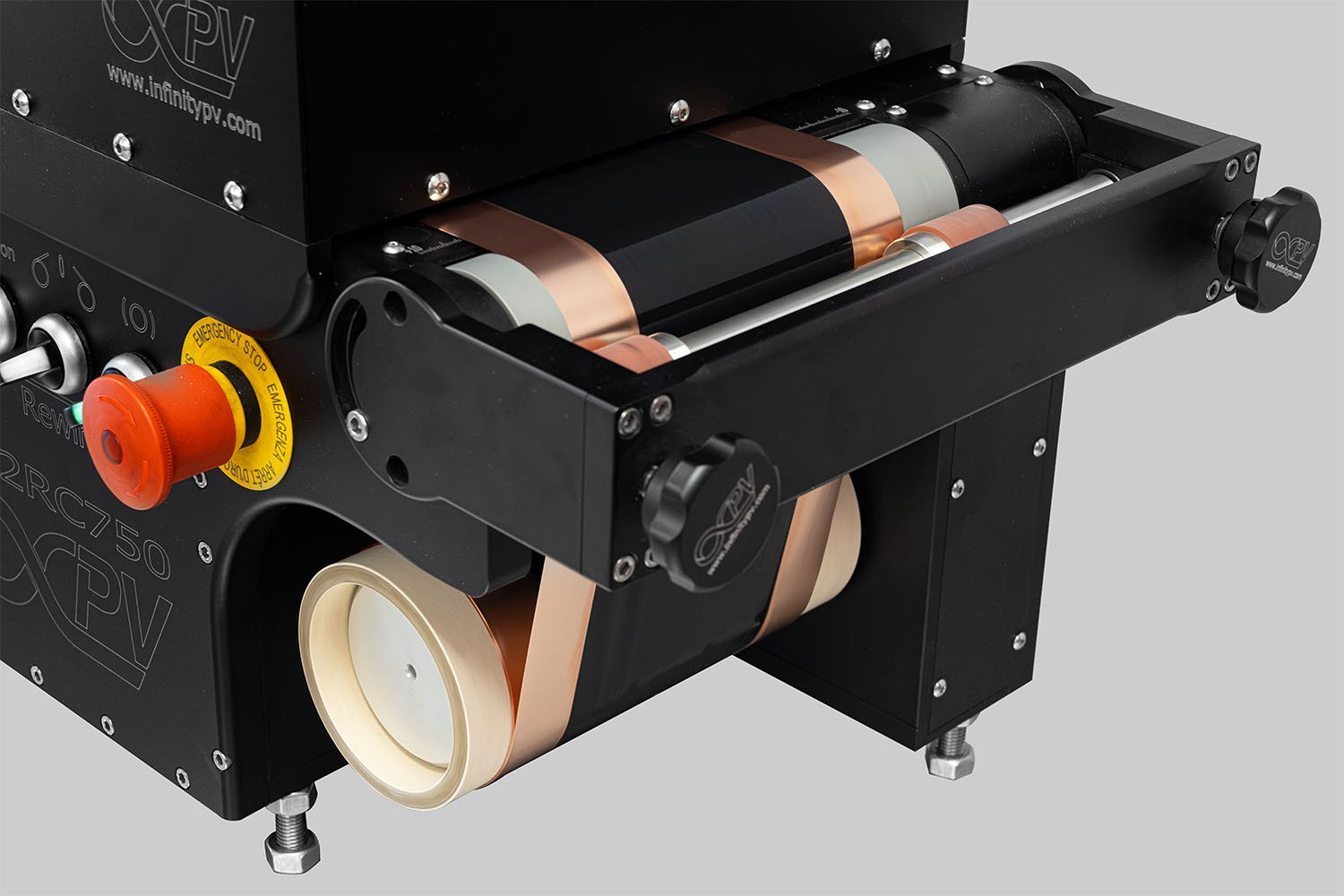

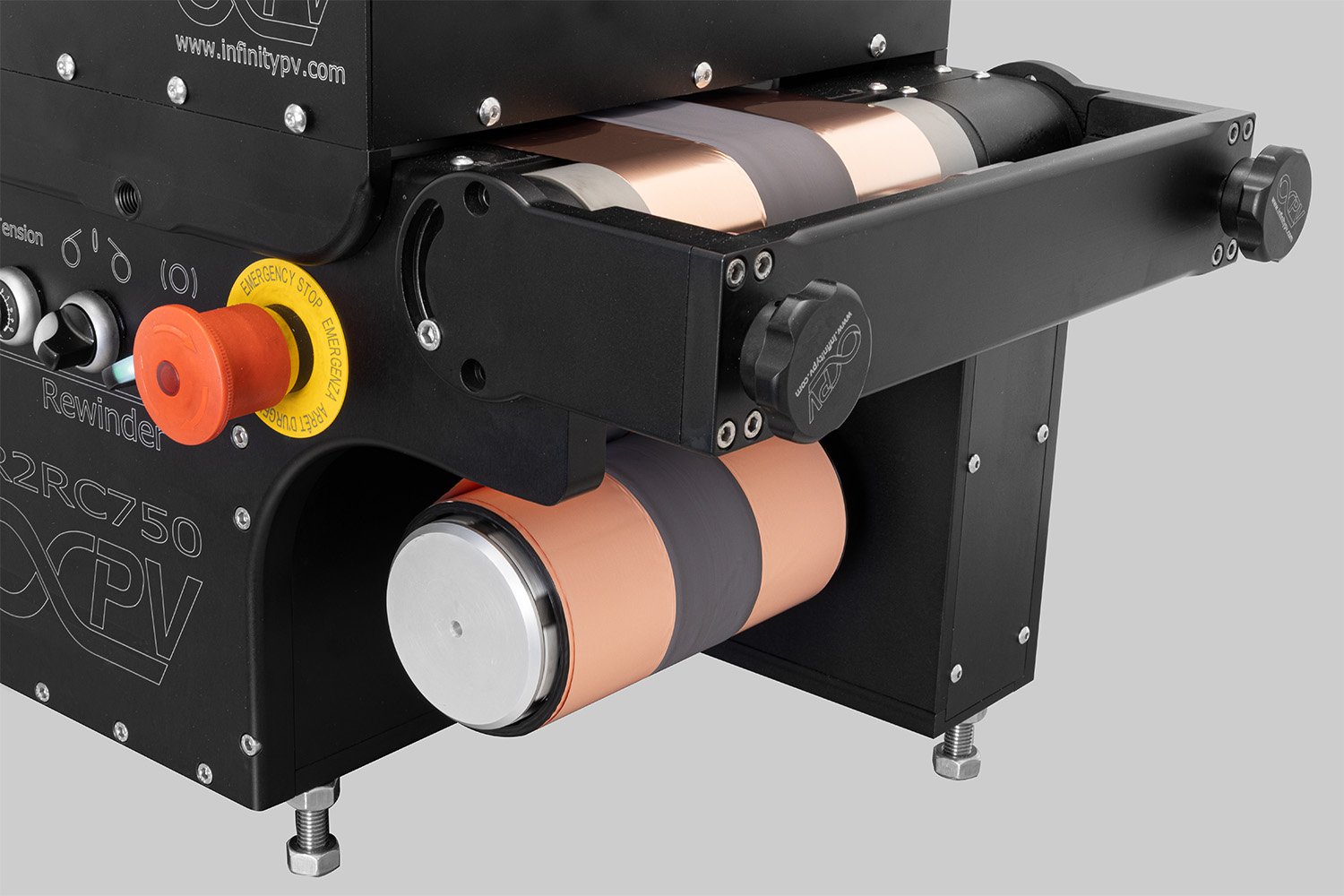

The Laboratory Roll-to-Roll Coater is the ideal coating machine for scaling up to roll-to-roll processing of battery electrode materials or for testing and optimizing battery electrode slurries.

What Is Slot Die Coating and Why Does It Matter?

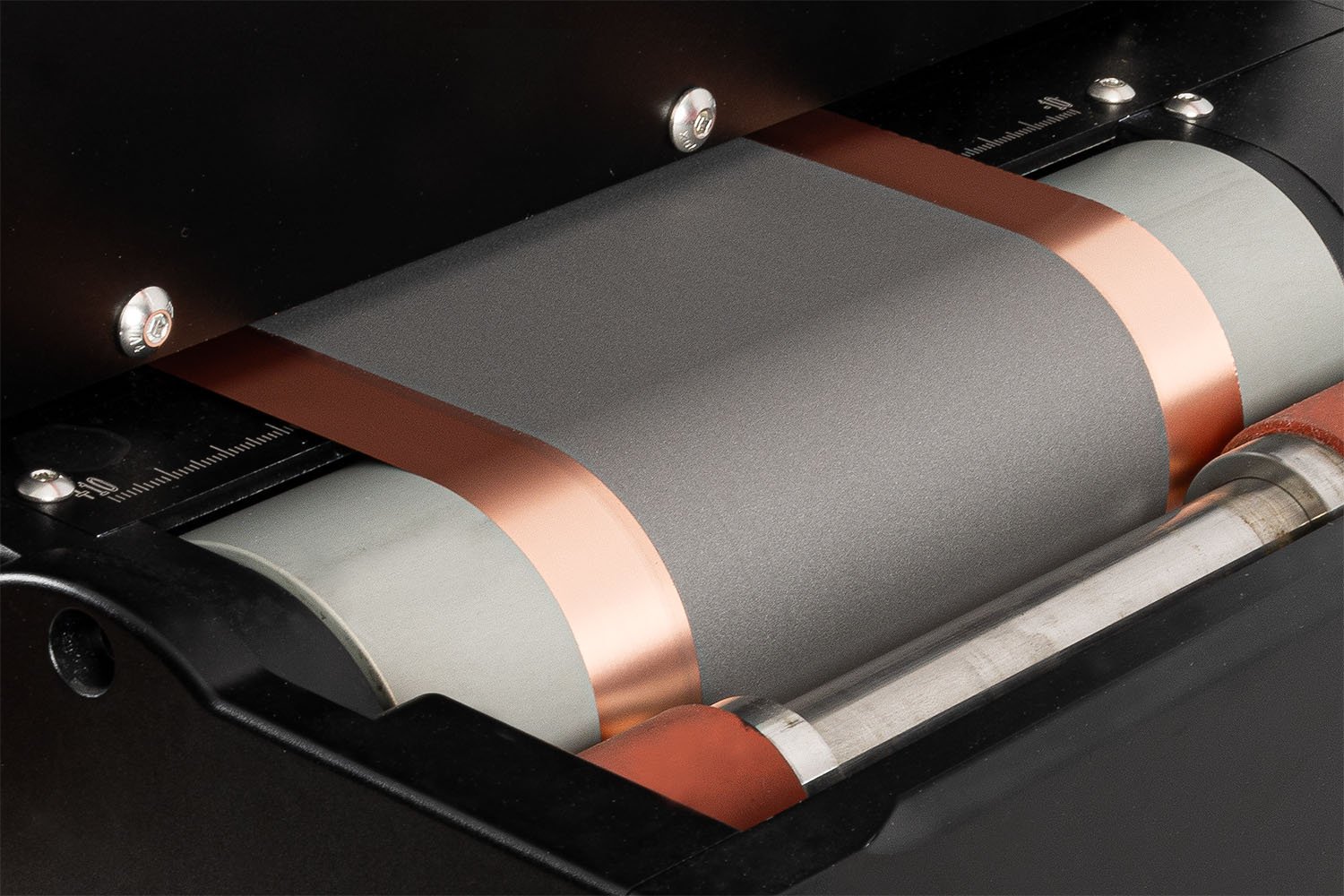

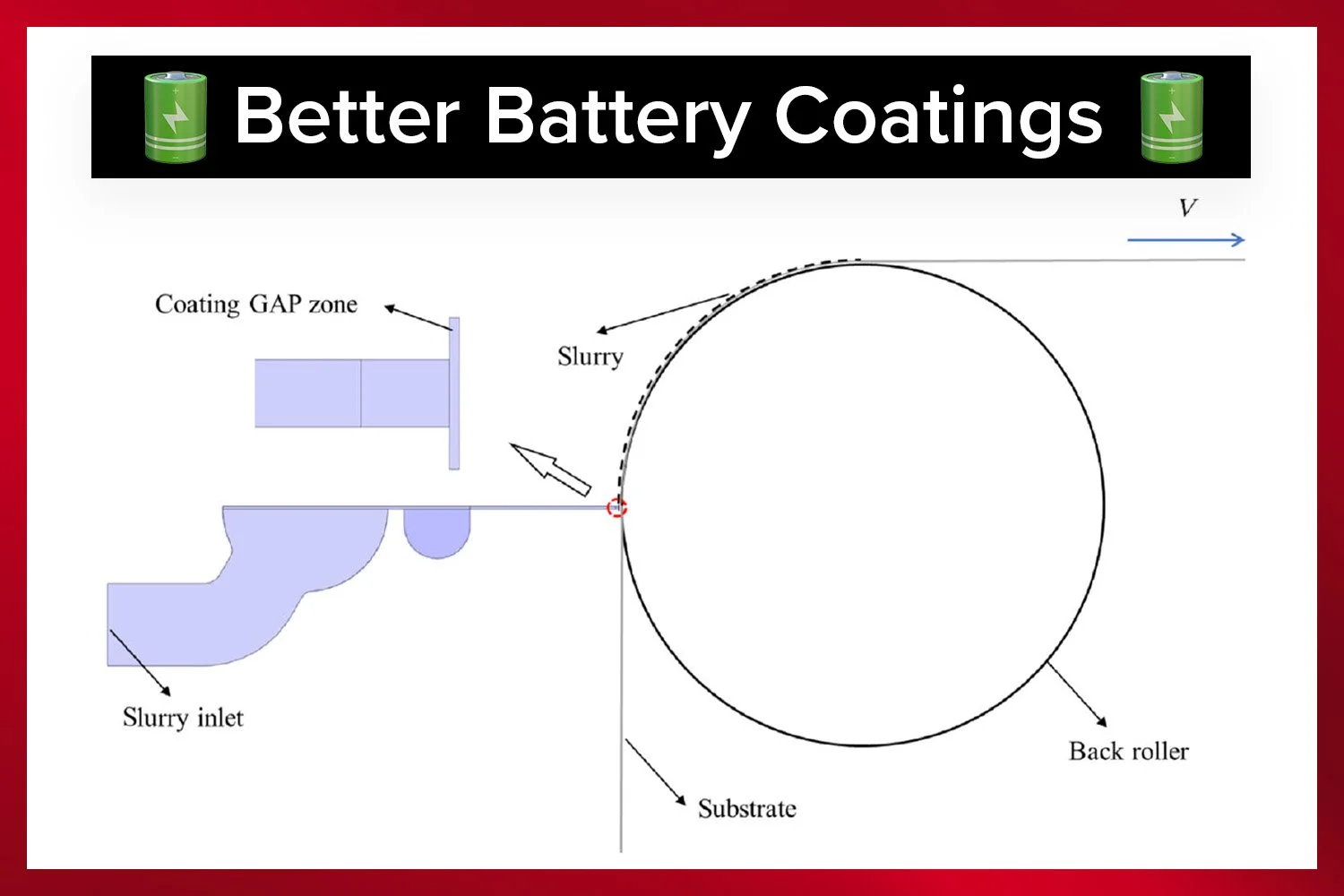

Slot die coating is a precision technique used to apply electrode slurry onto a substrate in battery production. It is highly efficient and ideal for roll-to-roll systems. However, even small deviations in parameters like gap distance or angle of attack can cause defects such as uneven thickness or edge buildup.

In battery production, the quality of the coating has a direct impact on how the final cell performs and how safe it is. If the coating is poor, it leads to a large amount of wasted materials and higher production costs. Since material expenses make up around 75 percent of total cell production costs, cutting down on scrap is not only good for business but also essential for sustainability.

The Significance of the Study: Why Fuzzy Logic?

Most battery production lines today are designed for a single high-output setup and do not handle changes well. As a result, any change in materials or design often leads to a sharp drop in yield.

This study tackles the issue by introducing a fuzzy logic controller that can adapt to different conditions. Traditional controllers often require complex mathematical models or large amounts of training data, which are not always available or easy to create. In contrast, fuzzy logic relies on expert knowledge and qualitative rules.

With fuzzy logic, the system can understand and act on inputs described in natural language, such as "too thick" or "slightly narrow." These linguistic inputs are converted into specific control actions, allowing for more human-like reasoning in automated processes. This makes the system far more adaptable and easier to implement.

Diving Into the Methods: How the Controller Was Built

To improve coating quality, the controller adjusts two key mechanical parameters: the gap distance between the slot die and the substrate, and the angle at which the die meets the substrate. These adjustments directly affect the height of the wet film, the buildup at the edges, and the overall coating width.

The team built a lab-scale version of the coating system using advanced sensors and motorized controls to fine-tune these parameters. The controller was programmed using Python, making it accessible and easy to integrate into existing setups.

Each quality measure is described using fuzzy linguistic terms, which reflect how a human expert might describe the coating. For instance, the film might be called "very thick," "optimal," or "too thin." The controller applies a set of 75 expert-defined rules to determine the right adjustment. These rules are evaluated continuously, and the system updates its settings every 0.04 seconds to maintain optimal coating conditions.

Roll-to-roll processing is perfect for scaling up fuel cell production.

Why This Matters for the Industry

As battery production technology rapidly evolves, manufacturing systems need to keep up. This is especially true with the growing interest in new battery chemistries like solid-state and sodium-ion. The fuzzy logic controller presented in this study provides a way to make production lines more flexible and future-ready.

Its scalable design means that the controller can be transferred easily across different equipment and material systems. By reducing scrap, it also contributes to more sustainable manufacturing practices, which is increasingly important from both environmental and economic perspectives. Furthermore, the ability to minimize manual adjustments helps companies save time and reduce errors, ultimately improving overall efficiency.

Together, these benefits make the fuzzy logic controller a powerful tool for improving quality and adaptability in battery electrode production.

Future Outlook: Toward Fully Autonomous Coating

The researchers plan to move beyond the lab and test the controller in real production environments. They aim to see how quickly the system stabilizes when starting from different initial conditions.

While some tuning may be needed to match specific product tolerances, the core logic and rule base of the fuzzy controller are expected to remain unchanged. This gives manufacturers a plug-and-play solution that can adapt to new materials and designs without needing to reinvent the control system.

Looking ahead, integrating fuzzy logic with other forms of automation could lead to fully autonomous coating lines. These systems would not only respond to changing conditions but could potentially learn and evolve with each new production run.

Your coating process is only as good as the slot-die head that delivers it. Our guide helps you evaluate your needs and choose the right slot-die head for optimal quality, efficiency, and cost-effectiveness. Read the selection guide here.

Conclusion

Battery manufacturing needs to become faster, cleaner, and smarter. The fuzzy logic controller introduced in "Implementation of a Fuzzy Controller for Battery Electrode Coating with a Slot Die" presents a forward-thinking solution for improving how we coat battery electrodes. By capturing expert knowledge in a form that can be used automatically and flexibly, this approach helps roll-to-roll processes meet the demands of a fast-changing energy landscape. It is a clear step toward more sustainable and efficient battery production.

Authors

Florian Denk

Lukas Burg

Sebastian Schabel

Jürgen Fleischer

Get Professional Support for Your Battery Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

The SDC Battery Coater Pro is specifically designed for researchers dedicated to developing and optimizing battery materials. It facilitates a seamless transition from research to commercialization. View video.