Smarts EVs, Say Goodbye to Range Anxiety: New system improves battery life with smart energy distribution

Can EV Batteries Last Longer?

Electric vehicles (EVs) are reshaping how we think about transportation, but there is still one major question on everyone's mind: how long do EV batteries really last? A recent article titled "Enhancing electric vehicle battery lifespan: integrating active balancing and machine learning for precise RUL estimation", published in Scientific Reports, tackles this question head-on.

The article presents a dual approach to improve EV battery performance and lifespan. First, it proposes an active cell balancing system to maintain uniform state-of-charge (SOC) across all battery cells. Second, it evaluates machine learning models for predicting a battery's Remaining Useful Life (RUL). Together, these two innovations form a smart feedback system that not only optimizes charging and discharging but also helps forecast and extend battery life.

So, how exactly does this new approach work, and what does it mean for the EV industry?

Key Highlights

Introduces a novel active balancing system that equalizes SOC during both charging and discharging

Combines battery balancing with machine learning-based RUL prediction

k-Nearest Neighbors and Random Forest models showed the best accuracy for lifespan prediction

Demonstrated significant SOC improvements in a four-cell battery pack through simulation

Reduced thermal stress and improved energy efficiency compared to passive balancing

Offers a comprehensive framework that informs smarter maintenance and charging strategies

Uses real-world battery cycling data from the Hawaii Natural Energy Institute for model training

Applicable to both series and parallel battery configurations in EVs

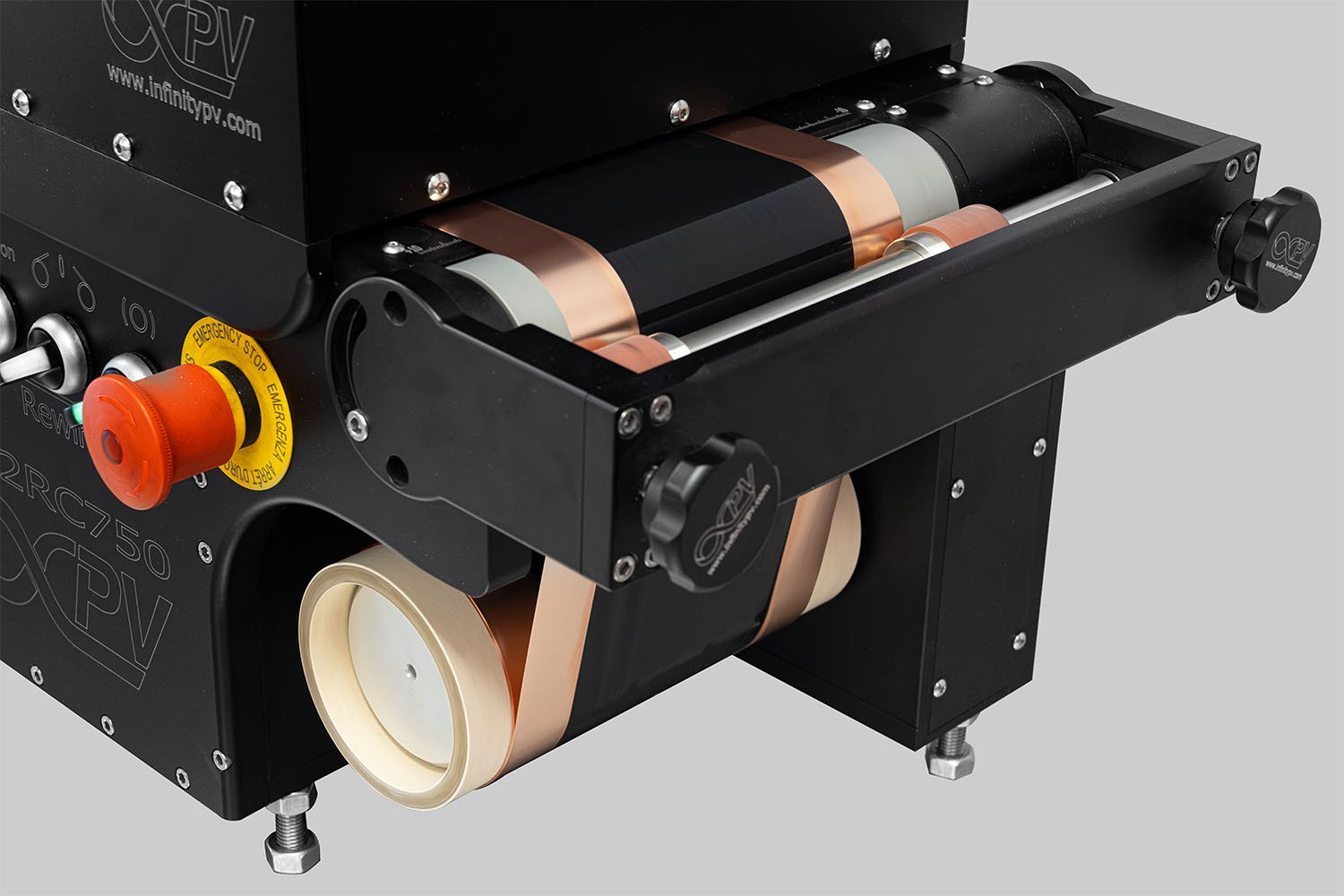

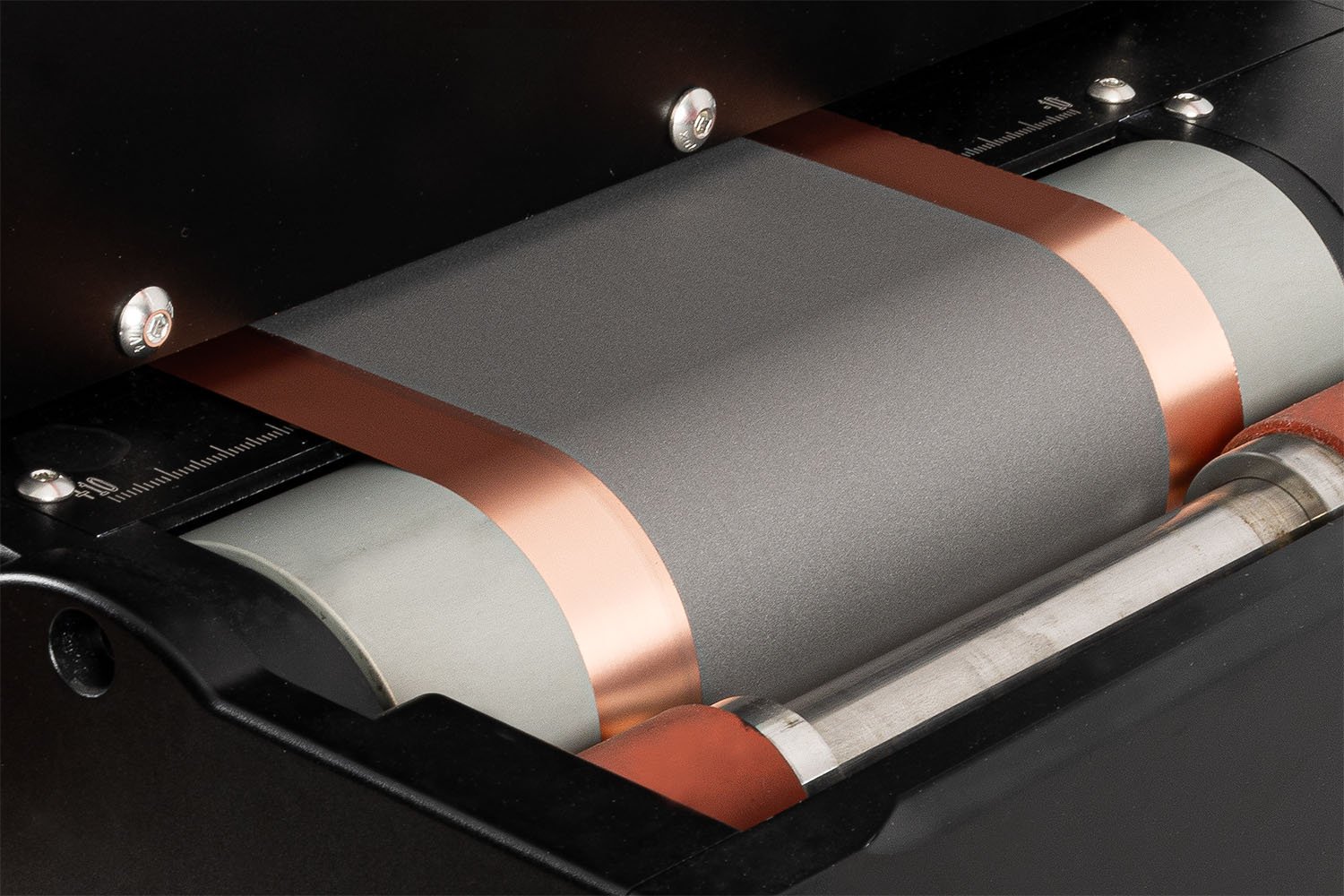

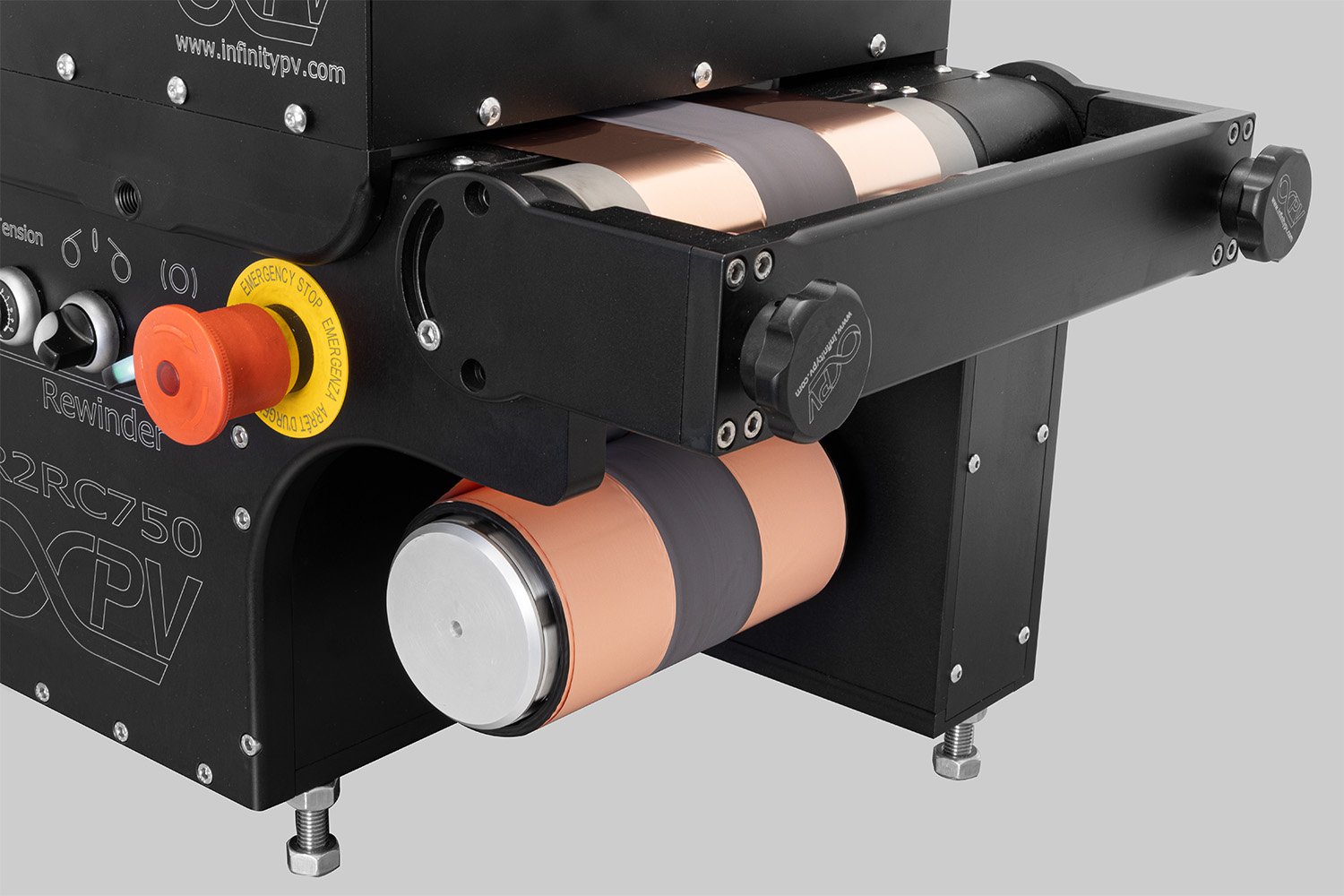

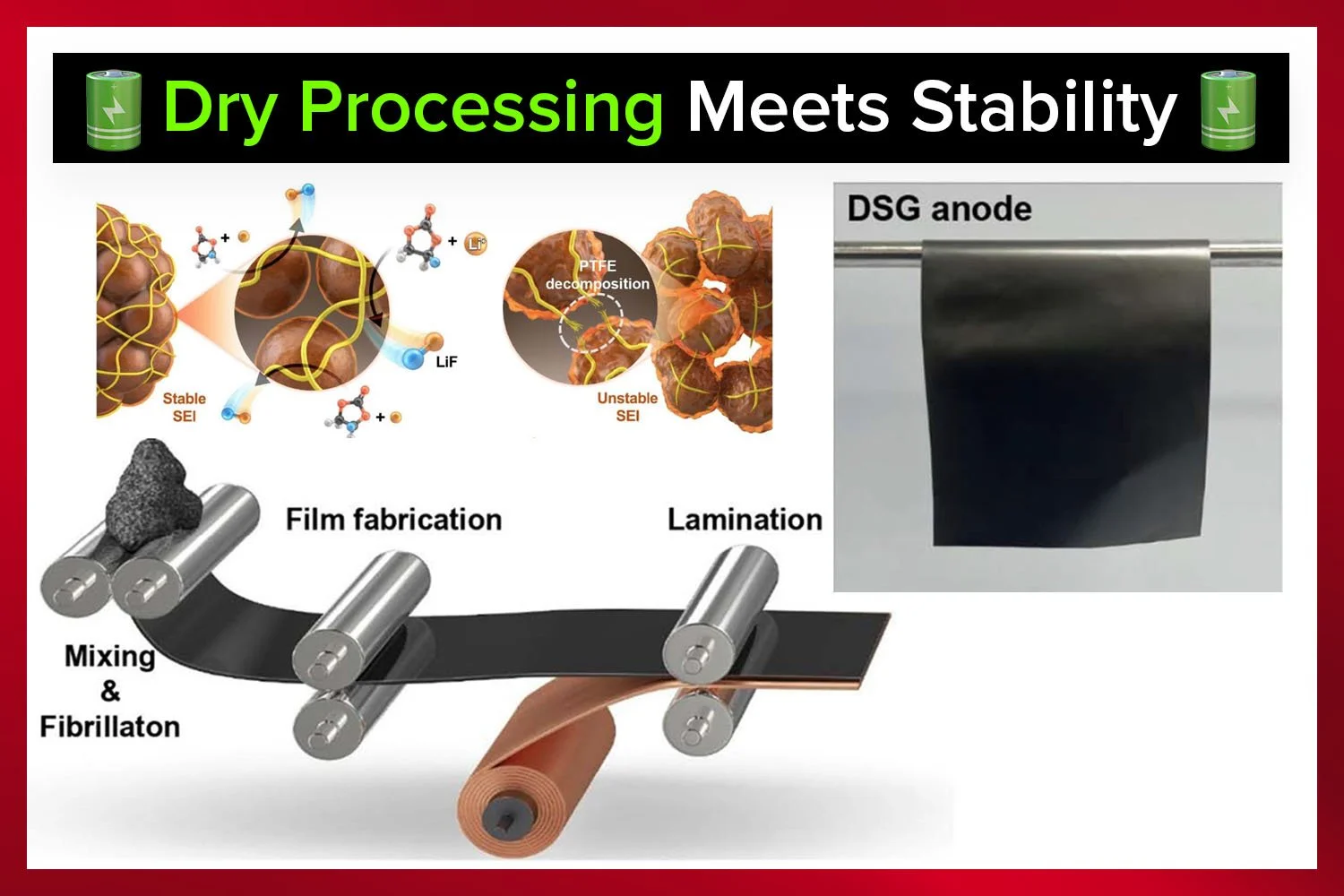

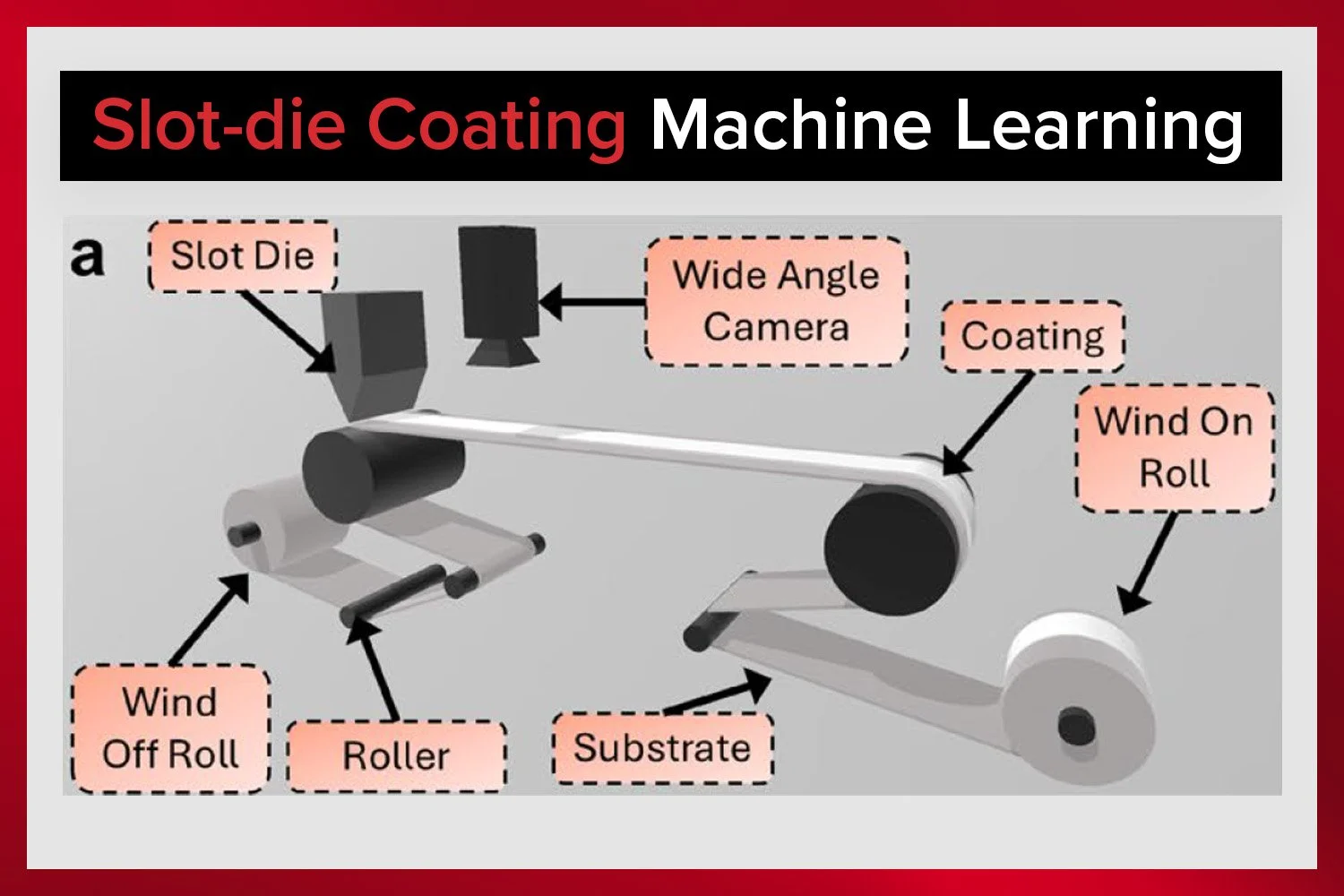

The Laboratory Roll-to-Roll Coater is the ideal coating machine for scaling up to roll-to-roll processing of battery electrode materials or for testing and optimizing battery electrode slurries.

What is Active Balancing and Why Does it Matter?

In a battery pack, cells often degrade at different rates due to manufacturing inconsistencies or varying operating conditions. Over time, this creates imbalance, where some cells are undercharged while others are overcharged.

Passive balancing, a common technique, simply bleeds off excess energy as heat from high-charge cells. While simple, it is inefficient. In contrast, active balancing intelligently transfers charge from high SOC cells to those with lower SOC, conserving energy and maintaining battery health.

This article presents a sophisticated active balancing system that operates during both charging and discharging. It employs an inductor-based energy transfer method controlled via PWM circuits to redistribute energy in real time. This reduces energy loss and extends battery longevity.

The Significance of the Study: A Smart, Two-Way Solution

What sets this work apart is its integration of SOC balancing with machine learning-based RUL prediction. These components create a feedback loop where balanced SOCs improve data consistency, consistent data enhances machine learning accuracy, and accurate RUL predictions guide future balancing decisions.

In essence, it is a self-improving system. This could mean fewer unexpected battery failures and optimized energy use, which are crucial for EV reliability and user confidence.

Diving Into the Methods: How it Works

The active balancing strategy centers around a four-cell series-connected lithium-ion battery pack. An inductor serves as an energy storage unit that helps redistribute energy. The circuit uses MOSFET switches and diodes to direct current flow, depending on whether the system is charging or discharging.

Three control loops manage energy distribution. Loop I and Loop II manage energy flow from high SOC cells to the rest of the pack during charging. Loop III manages redistribution from an auxiliary power source to low SOC cells during discharge.

Simulation results show impressive balancing performance, with each cell approaching near-identical SOC levels. For example, one cell increased from 40 percent to 87 percent SOC after balancing.

Machine Learning Models: Predicting Battery Lifespan

Using real-world cycling data from 14 lithium-ion batteries, the authors trained seven machine learning models to predict Remaining Useful Life (RUL). Key input features included state-of-charge, temperature, and voltage and current patterns.

The models evaluated were Linear Regression, Ridge Regression, k-Nearest Neighbors (kNN), Random Forest, Polynomial Regression, Gradient Boosting, and a Dense Neural Network.

kNN and Random Forest outperformed the others, achieving R-squared values above 0.996 and very low Mean Absolute Errors. These models proved exceptionally accurate even when using limited feature sets.

Your coating process is only as good as the slot-die head that delivers it. Our guide helps you evaluate your needs and choose the right slot-die head for optimal quality, efficiency, and cost-effectiveness. Read the selection guide here.

Why This Matters for the EV Industry

Battery lifespan directly affects the cost, reliability, and environmental impact of EVs. Accurate RUL predictions and effective cell balancing can enable proactive maintenance, prevent unexpected failures, optimize energy usage, and reduce replacement costs.

For manufacturers, integrating this system into a Battery Management System (BMS) could improve product quality. For users, it means fewer surprises and better long-term performance.

Future Outlook: Smarter EV Batteries

The proposed approach is not just theoretical. The study's use of real-world data and simulation means it could be implemented in commercial EVs. With machine learning models constantly refining themselves with new data, the system becomes smarter over time.

This research paves the way for intelligent battery packs that adapt to usage patterns, environmental conditions, and degradation trends. Future advancements could incorporate cloud-based updates and predictive analytics to further improve performance and sustainability.

Double-sided coating using a Laboratory Roll-to-Roll Coater.

Conclusion

The article showcases a powerful new strategy for EV battery management by merging active cell balancing with machine learning-based RUL prediction. The synergy between these technologies provides a scalable, efficient solution to improve battery longevity, reduce maintenance costs, and enhance safety. As EV adoption continues to grow, innovations like this will be key in building a smarter and more sustainable future.

Get Professional Support for Your Battery Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

The SDC Battery Coater Pro is specifically designed for researchers dedicated to developing and optimizing battery materials. It facilitates a seamless transition from research to commercialization. View video.