Breakthrough in Perovskite Stability: 0.75 nm Alumina Layer Prevents Degradation

Can an Invisible Layer Make All the Difference?

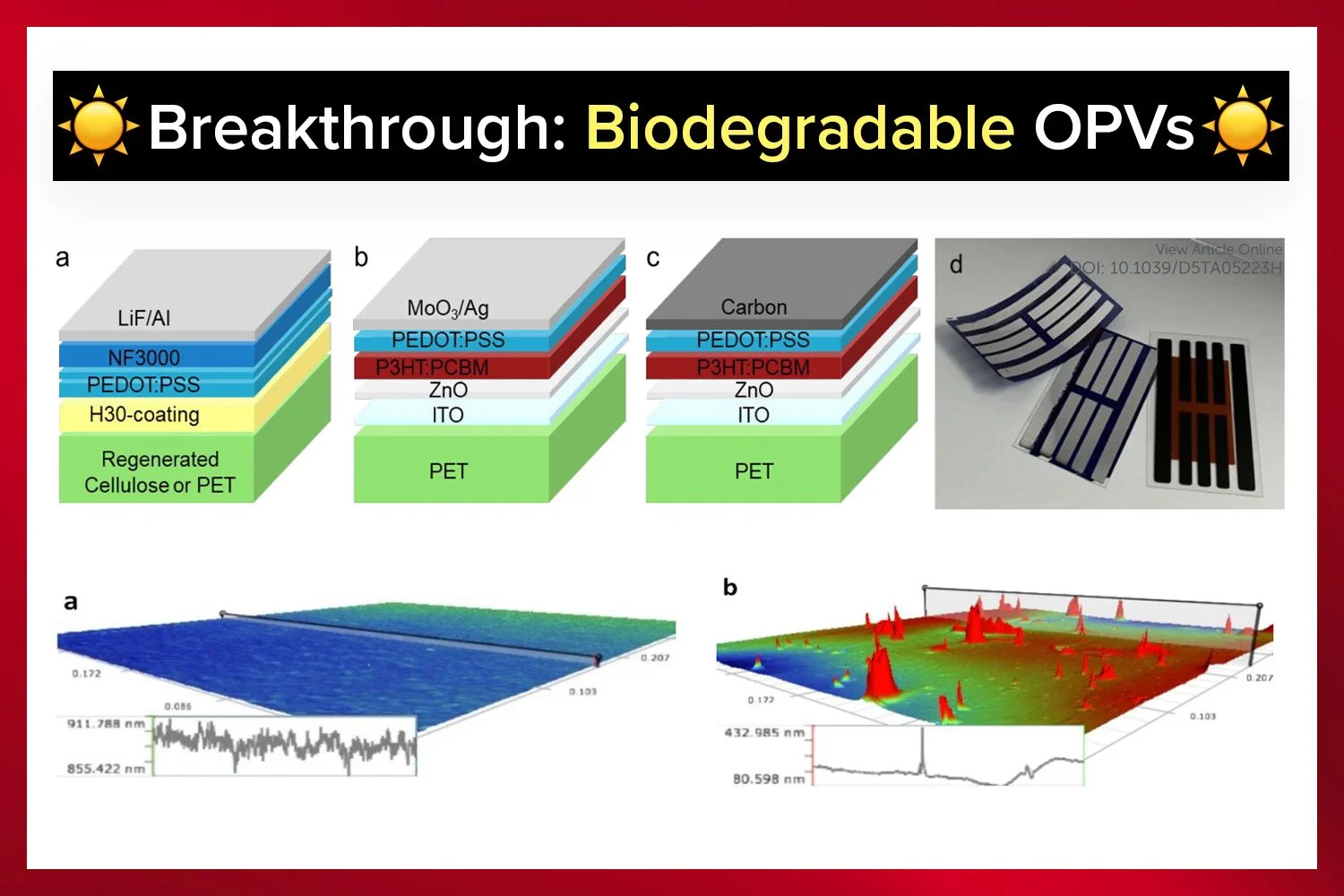

Perovskite solar cells (PSCs) are on the brink of revolutionizing the solar industry. Their promise? High efficiency, low cost, and easy manufacturing. But there's a catch: stability. While PSCs achieve impressive power conversion efficiencies, they degrade rapidly when exposed to environmental stressors like moisture, oxygen, and light.

A recent study titled "Mitigating the amorphization of perovskite layers by using atomic layer deposition of alumina" takes a deep dive into this issue. Researchers discovered that applying a nanoscopic 0.75 nm-thick layer of aluminum oxide (Al2O3), using atomic layer deposition (ALD), significantly improves both the performance and longevity of perovskite solar cells. By acting as a dual-function barrier, this ultra-thin coating not only enhances contact between layers but also blocks harmful ion migration, leading to dramatic improvements in device stability.

Key Highlights

An ultrathin (0.75 nm) ALD-Al2O3 layer enhances PSC performance from 19.1% to 20.5%

Devices retained 98% efficiency after 1500 hours of outdoor testing (vs. <10% for uncoated cells)

ALD layer acts as a two-way diffusion barrier, blocking ion migration in both directions

Prevents perovskite from transitioning into an amorphous, non-functional phase

Maintains stable interface with the hole-transport layer (spiro-OMeTAD)

Improves long-term stability without sacrificing charge transport efficiency

Offers conformal surface coverage, even at the grain boundaries

Enables shelf-aging and outdoor performance over extended periods without encapsulation

Demonstrates reduced interface recombination resistance, verified by EIS

Learn how to fabricate solar cells using slot-die coating and flexo printing on a Slot-die Coater.

What Is Atomic Layer Deposition and Why Does It Matter?

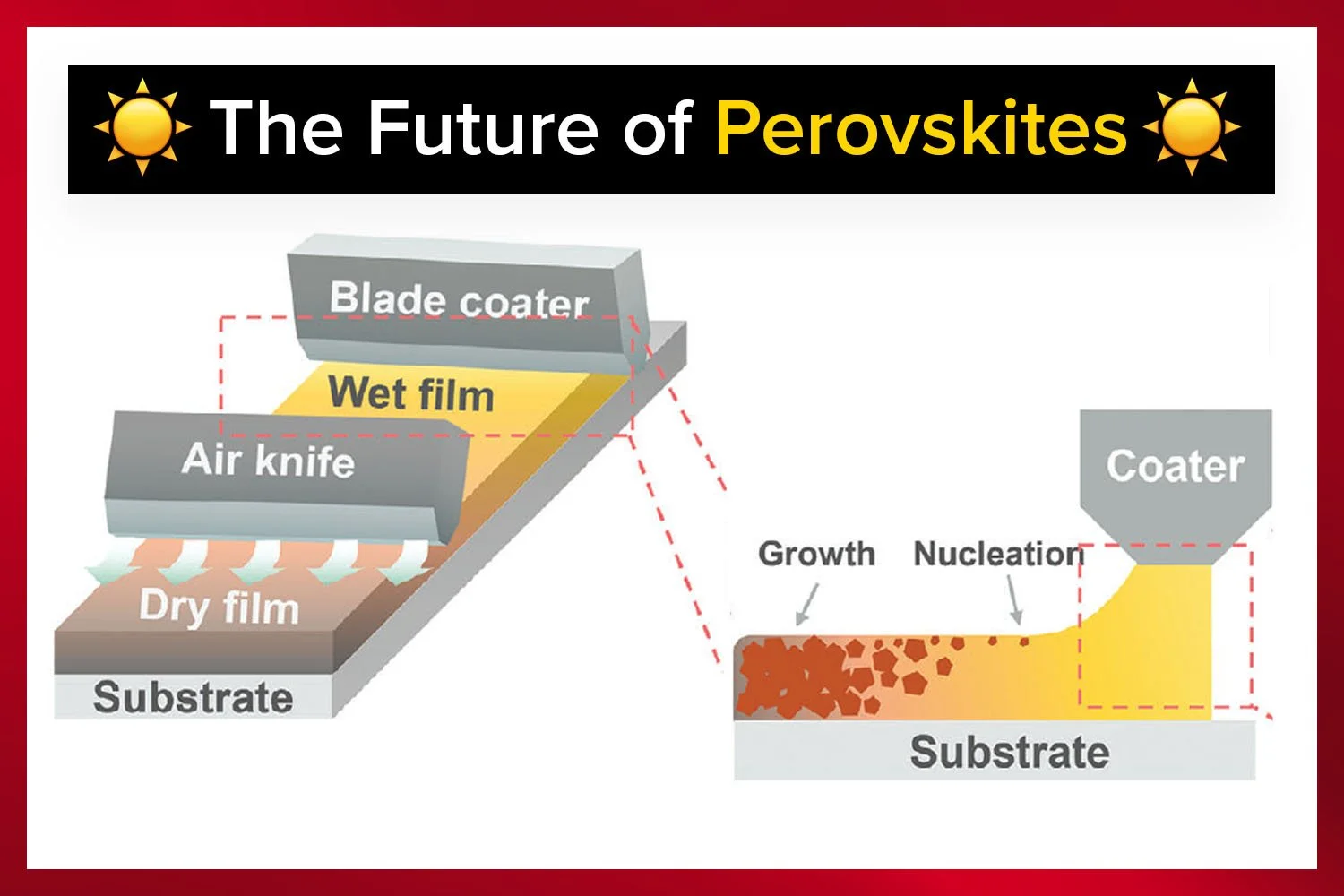

Atomic Layer Deposition (ALD) is a vapor-phase technique for depositing thin films one atomic layer at a time. In this study, researchers applied ALD at room temperature to create a precise, ultrathin coating of aluminum oxide on the perovskite layer. This controlled process ensures uniform and defect-free coverage, including at the crucial grain boundaries of the material.

Why does this matter? Traditional coatings can be inconsistent, leaving parts of the material exposed to degradation. ALD, by contrast, allows for near-perfect coverage, even on complex surfaces. In this case, the ALD layer acts as a gatekeeper, preventing both moisture and internal degradation products from disrupting the delicate perovskite structure.

The Significance of the Study: Why Perovskite Protection is Crucial

Despite their efficiency, PSCs have historically suffered from rapid performance loss due to interface degradation. This study shows that degradation doesn’t only come from outside forces like humidity—it also stems from within. The materials in the hole-transport layer (spiro-OMeTAD) can migrate into the perovskite, triggering its breakdown into an amorphous, non-functional phase.

With the ultrathin ALD-Al2O3 layer, the research team found that this degradation was significantly slowed. Even after 180 days of shelf-aging and 1500 hours of outdoor testing, the devices retained most of their initial efficiency. This represents a critical step toward commercial viability.

Diving Into the Methods: How the Research Was Done

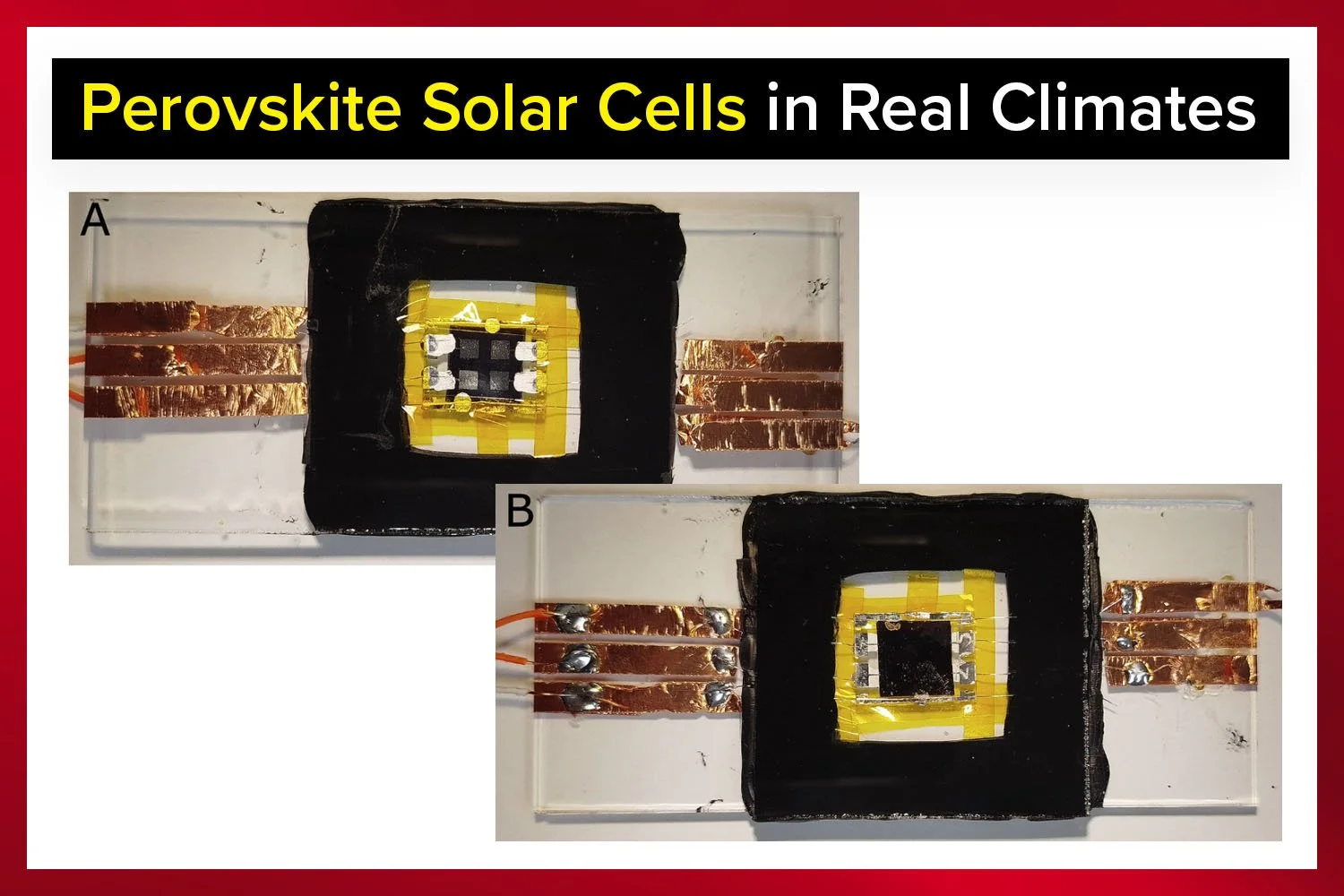

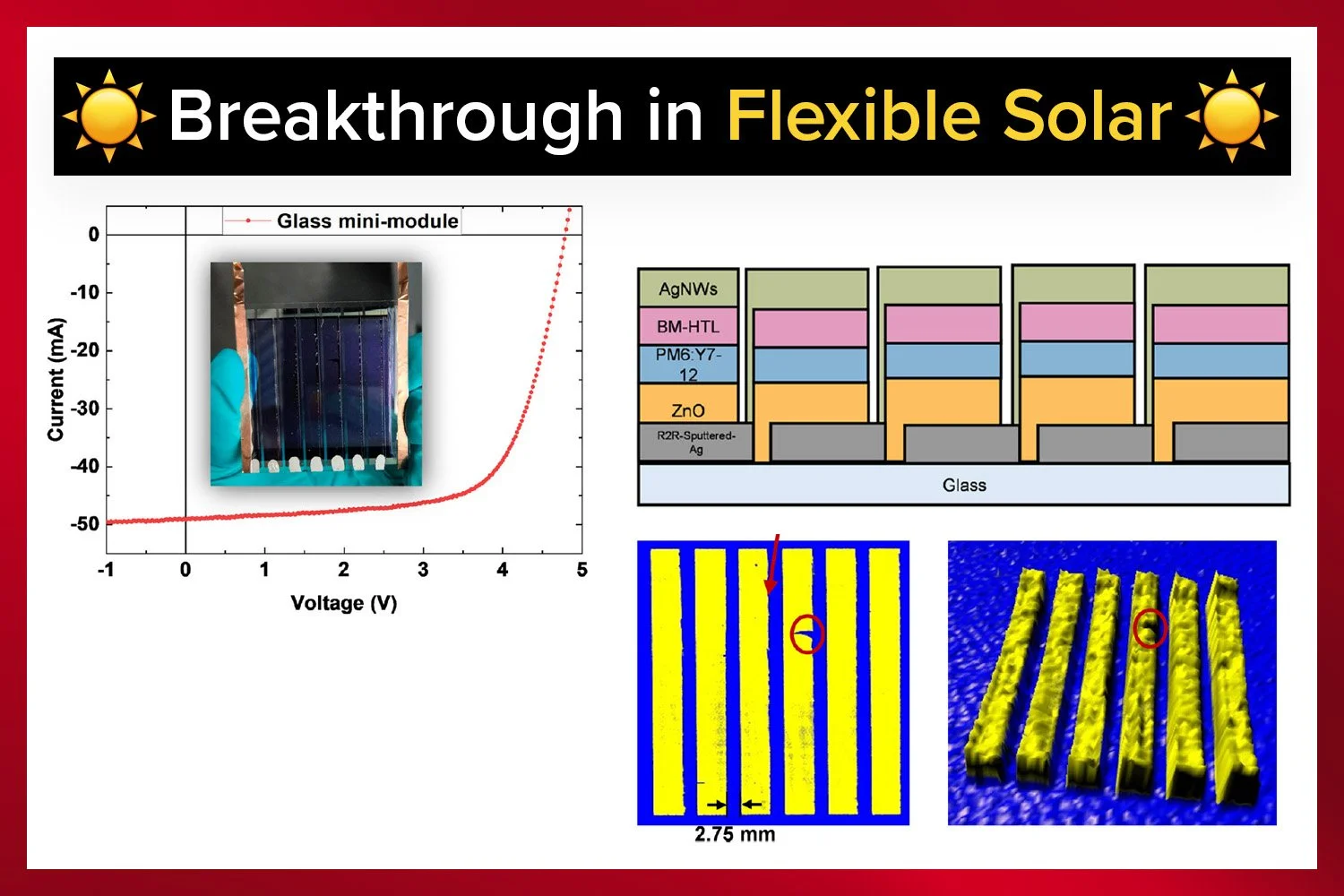

The study involved creating a triple-cation perovskite layer coated with either no ALD, 0.75 nm ALD, or 2 nm ALD alumina. Using a suite of tools including spectroscopic ellipsometry, atomic force microscopy (AFM), X-ray diffraction (XRD), and time-of-flight secondary ion mass spectrometry (ToF-SIMS), the team verified the uniformity, electrical behavior, and elemental stability of the coatings.

Performance was rigorously tested under both indoor and outdoor conditions. Devices were subjected to shelf-aging for 180 days and then stressed under light and ambient conditions for 1000 minutes. Electroluminescence (EL) mapping showed visible degradation in control devices, while ALD-protected cells maintained structural integrity and charge generation properties.

How to test solar cells using a source measure unit and solar simulator.

The Role of the Source Measure Unit (SMU) in Device Evaluation

One key instrument used to evaluate device performance over time was the Source Measure Unit (SMU), specifically the infinityPV SMU. This device enabled precise measurement of electrical characteristics while the solar cells were under stress.

During Maximum Power Point Tracking (MPPT), the SMU continuously adjusted the operating point of the solar cell to ensure it was running at maximum efficiency. The researchers used the SMU to log voltage, current, and power output in real-time under ambient and outdoor conditions, including varying humidity and temperature.

The SMU played a crucial role in:

Capturing real-time power output trends over 1000 minutes of operation

Measuring efficiency degradation across 1500 hours of outdoor exposure

Providing feedback on short-circuit current (Jsc), open-circuit voltage (Voc), and fill factor (FF) during accelerated aging tests

Without the SMU's high precision and stability, it would have been nearly impossible to observe the nuanced differences in performance between coated and uncoated devices. The instrument's ability to track changes under realistic operating conditions was vital for demonstrating the real-world potential of the ALD-protected solar cells.

Join our hands-on Printed Electronics Workshop and gain practical experience in every step of printed solar cell manufacturing, from ink preparation to testing and final integration

A Promising Outlook: What This Means for the Industry

This study paves the way for scalable, industrial applications of ALD in PSC manufacturing. By demonstrating that a layer thinner than a nanometer can offer real, measurable improvements in solar cell durability, the research validates the importance of precision engineering at the atomic level.

More importantly, this approach does not compromise performance. On the contrary, it enhances it. The findings open the door to high-efficiency, long-lasting perovskite solar modules that can survive real-world conditions—without the need for heavy encapsulation.

It also signals a shift in how the industry views interfacial engineering. No longer just a consideration for lab-scale devices, interlayer control may soon become standard practice in commercial module design.

Conclusion

With a conformal, 0.75 nm-thick ALD-Al2O3 layer, researchers have taken a major step toward solving perovskite solar cells' biggest challenge: stability. Acting both as a barrier against environmental threats and internal degradation, this ultra-thin alumina layer dramatically improves performance and longevity. As the solar industry looks to scale perovskites, innovations like this will be key to bringing lab breakthroughs into everyday use.

Authors:

Mayank Kedia

Chittaranjan Das

Malgorzata Kot

Yenal Yalcinkaya

Weiwei Zuo

Kenedy Tabah Tanko

Peter Matvija

Mikel Ezquer

Inaki Cornago

Wolfram Hempel

Florian Kauffmann

Paul Plate

Monica Lira-Cantu

Stefan A.L. Weber

Michael Saliba

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Customized for lab-scale research and development, this system facilitates the efficient application of battery electrode coatings.