Breakthrough in Perovskite Solar Cells: You Can Now Draw Solar Cells with a Pen

Can You Really Write Solar Panels with a Marker Pen?

What if you could build a solar panel with nothing more than a marker pen? That is the provocative question posed by a new study titled "Marker pen writing of perovskite solar modules," published by Song et al. in Nature Communications in 2025.

The idea is simple but revolutionary. Instead of relying on complex, costly equipment to produce solar cells, this research introduces a new way to manufacture them using common marker pens. By engineering these pens to carry special inks, the study demonstrates how efficient, scalable, and customizable solar devices can be drawn directly onto surfaces.

Why does this matter?

Traditional methods for making perovskite solar cells can be expensive and often wasteful. Processes like spin coating or laser scribing require high-end equipment, controlled environments, and careful calibration. With marker pen writing, fabrication becomes cheaper, faster, and potentially available anywhere.

This breakthrough could change the way solar panels are produced and used, especially for applications where cost, portability, or flexibility is essential.

Key Highlights

Marker pens can be used to fabricate perovskite solar cells and modules

Achieves 20.4% efficiency in rigid cells and 19.0% in flexible cells

Eliminates the need for masks, lasers, and expensive equipment

Allows on-demand, ambient-condition fabrication—even on balloons or paper

Films can be patternable and scalable, ranging from 1 to over 100 cm²

Compatible with both annealed and annealing-free fabrication

Maintains high stability through thermal, mechanical, and operational tests

Enables applications in wearable electronics, emergency power, and biomimetic design

Learn how to fabricate solar cells using slot-die coating and flexo printing on a Slot-die Coater.

What Is Marker Pen Writing and Why Does It Matter?

Most solar cells today are manufactured using spin coating or other deposition techniques that require large amounts of energy, expensive machines, and technical skill. These techniques often waste more than 90 percent of the materials used. They are also difficult to apply to curved or flexible surfaces.

Marker pen writing, or MPW, presents an alternative. The method relies on modified marker pens that dispense perovskite ink through a porous tip. The tip serves not only as an applicator but also as a filter and homogenizer. This ensures that only uniform, fine particles reach the surface, resulting in consistent film quality.

This method can control the thickness, area, and pattern of the perovskite layer simply by changing the pressure, speed, and ink concentration. Because the process is manual or semi-manual, it is highly adaptable and portable.

The Significance of the Study: Why MPW Could Change Solar Manufacturing

The importance of this research lies in how it simplifies and broadens access to solar cell production. MPW removes the need for laser scribing, which typically involves high precision, strict controls, and expensive lasers. By eliminating this step and replacing it with simple, intuitive writing, the method enables a completely mask-free, laser-free, and room-temperature process.

The method also works on surfaces that are typically challenging. Perovskite solar modules written with marker pens have been successfully applied to materials like flexible plastic, balloons, and even cellophane paper. The result is not just lab-grade efficiency but practical versatility.

From wearable electronics to emergency off-grid power, the ability to fabricate solar modules in real-time, directly onto a range of materials, opens a new chapter in how solar energy can be deployed.

Marker pen writing offers:

Simplicity: It bypasses costly fabrication steps like laser scribing.

Flexibility: It works on rigid and flexible substrates—including paper, balloons, and wearable surfaces.

Scalability: Patternable from tiny cells to over 100 cm² areas.

Accessibility: Potential for low-resource or on-site manufacturing, especially in remote areas.

How to test solar cells using a source measure unit and solar simulator.

Diving Into the Methods: How MPW Was Done

To test the feasibility of this approach, the team filled marker pens with specially formulated perovskite inks. Two solvent systems were used. The first, a mix of 2-methoxyethanol and N-methylpyrrolidone, required a brief heat treatment after writing. The second system, which included tetrahydrofuran instead of NMP, allowed for ambient, annealing-free crystallization.

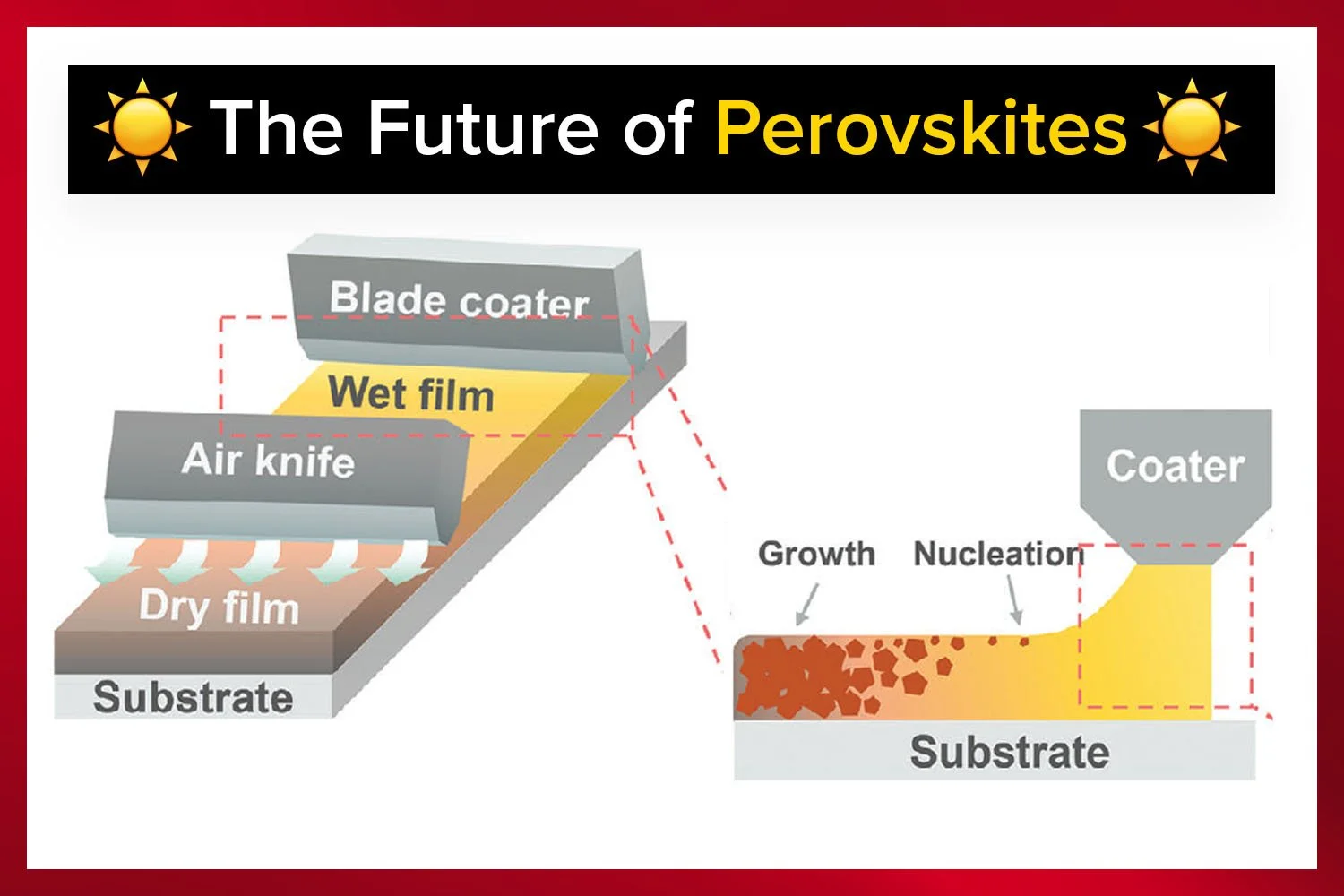

Writing was performed manually or with a simple mechanical setup. As the marker tip moved across a surface, ink was deposited evenly thanks to capillary action and tip pressure. Subsequent steps like gas quenching or mild annealing helped to form high-quality perovskite films.

Each layer of the solar device, from the electron transport layer to the perovskite absorber to the carbon electrode, could be applied using a marker pen or similar low-tech methods. The process allowed precise placement of materials with no need for masks or templates.

To ensure good electrical performance, the team also developed a staircase structure where each layer was slightly smaller than the one below it. This technique minimized electrical shorting and maintained layer separation.

The Technology in Action: Performance and Stability

Performance results were impressive. Rigid cells that used annealed perovskite layers achieved a peak power conversion efficiency of 20.4 percent. Flexible cells reached 19.0 percent, a record for carbon-electrode-based devices of this type. Even without annealing, cells written at room temperature achieved efficiencies as high as 18.0 percent for rigid formats and 16.4 percent for flexible ones.

The modules, composed of multiple sub-cells connected in series, reached efficiencies of 16.3 percent for rigid and 14.5 percent for flexible versions. These values surpass many conventional module technologies made with more expensive or time-consuming methods.

Stability was another strength. Devices retained over 90 percent of their original performance after 1,000 hours of exposure to ambient air or light, with no encapsulation. They also withstood mechanical bending, maintaining function after thousands of flex cycles.

A world’s first: We made solar cells from fungi using slot-die coating.

Future Outlook: Custom Solar Anywhere, Anytime

Marker pen writing enables solar technology to be used in completely new ways. It can create power sources for electronic watches, smart wristbands, mobile phones, and other wearable devices. The modules are thin, light, bendable, and can be twisted or folded without loss of performance.

The method also supports artistic or architectural applications. In one demonstration, solar cells were written in the shape of leaves and mounted on tree branches to mimic natural foliage while generating electricity.

The simplicity of the method means it could be used for rapid prototyping, education, or even emergency energy supply in remote areas. It may also be valuable for developing countries or disaster zones where traditional fabrication infrastructure is unavailable.

Conclusion

Marker pen writing of perovskite solar modules is more than a technical curiosity. It represents a practical and impactful step forward in the way solar devices can be designed, produced, and used. With minimal equipment, low material waste, and excellent performance, this method could democratize access to clean energy and bring photovoltaic technology to places it has never reached before.

By turning an everyday writing tool into a high-performance manufacturing device, this study reimagines the boundaries of solar engineering.

R2R slot-die coating for solar cells is easy with the Laboratory Roll-to-Roll Coater.

Authors

Yuhao Song

Miaosen Yao

Chen Dong

Sergey Dayneko

Gaogeng Wang

Dongyang Zhang

Yingying Deng

Junjie Tong

Qichao Wang

Gentian Yue

Yueyue Gao

Weifeng Zhang

Makhsud I. Saidaminov

Furui Tan

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Compact solar simulator (390–700 nm) with six tunable LEDs, Class A uniformity, and excellent temporal stability. Ideal for small to medium solar cells and controlled illumination experiments.