The infinityPV Roll-to-Roll Academy provides expert guidance and hands-on knowledge in slot-die coating and roll-to-roll processing, helping researchers and professionals unlock its full potential across advanced technologies. With deep experience in printed electronics, thin-film devices, and scalable manufacturing, we support innovation in areas such as next-generation batteries, fuel cells, printed solar cells, phamarceuticals, and flexible electronics, enabling faster development, better process control, and smoother paths to commercialization.

Learn how slot-die coating is used to create precise, uniform layers in thin-film battery manufacturing. Discover techniques, materials, drying methods, and troubleshooting tips for lithium-ion and solid-state batteries.

Learn the key differences between roll-to-roll (R2R) and sheet coating techniques. Discover their advantages, challenges, and ideal applications to choose the right coating method for your lab or production needs.

Explore solution-based deposition techniques for printed solar cells, including spin coating, slot-die coating, inkjet, and screen printing. Learn how these methods enable scalable, cost-effective production for perovskite and organic solar technologies.

Discover how rheology and wetting behavior influence slot die coating performance. Learn how viscosity, surface tension, and viscoelasticity can be optimized to reduce defects and achieve uniform, high-quality coatings.

Discover the benefits, working mechanism, and formulation of fast dissolving oral thin films (OTFs) and learn how slot-die coating enables scalable, precise drug delivery solutions for modern pharmaceuticals

Discover how lab-scale slot-die coating improves pharmaceutical and medical device development through precise, uniform coatings for testing and prototyping.

Discover how pristine clean surface coating eliminates defects by applying functional layers onto untouched substrates. Ideal for medtech, solar cells, OLEDs, and advanced electronics.

Discover how roll-to-roll coaters enable continuous thin-film deposition on flexible substrates. Learn about slot-die coating, scalability, and lab-to-production transition with expert tips from infinityPV.

Discover how lab-scale roll-to-roll processing supports battery innovation, enabling scalable production, reducing development risks, and speeding up time to market.

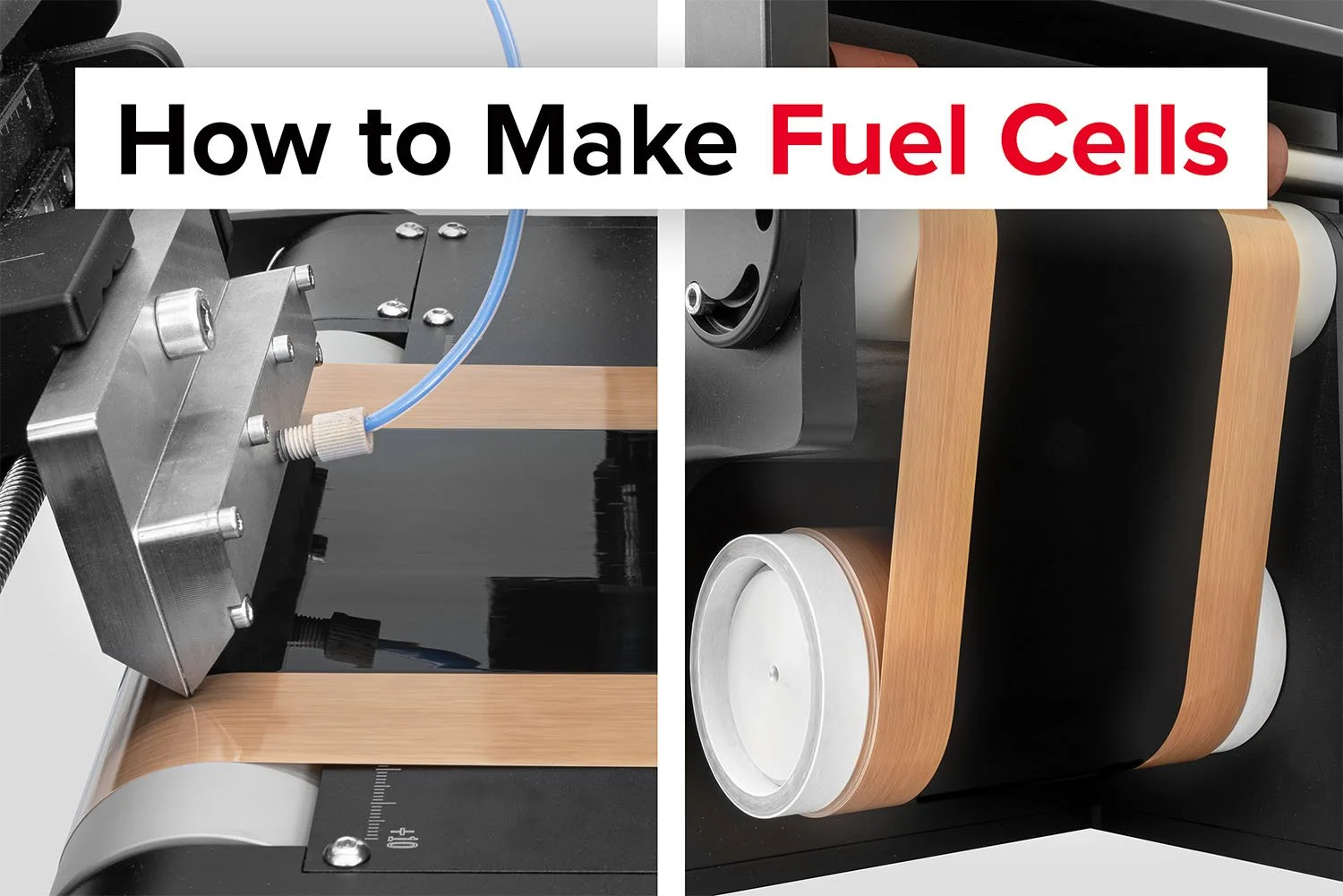

Discover how to make fuel cells using slot-die coating, a precise method for applying catalyst, electrolyte, and gas diffusion layers. Ideal for R&D and scalable production

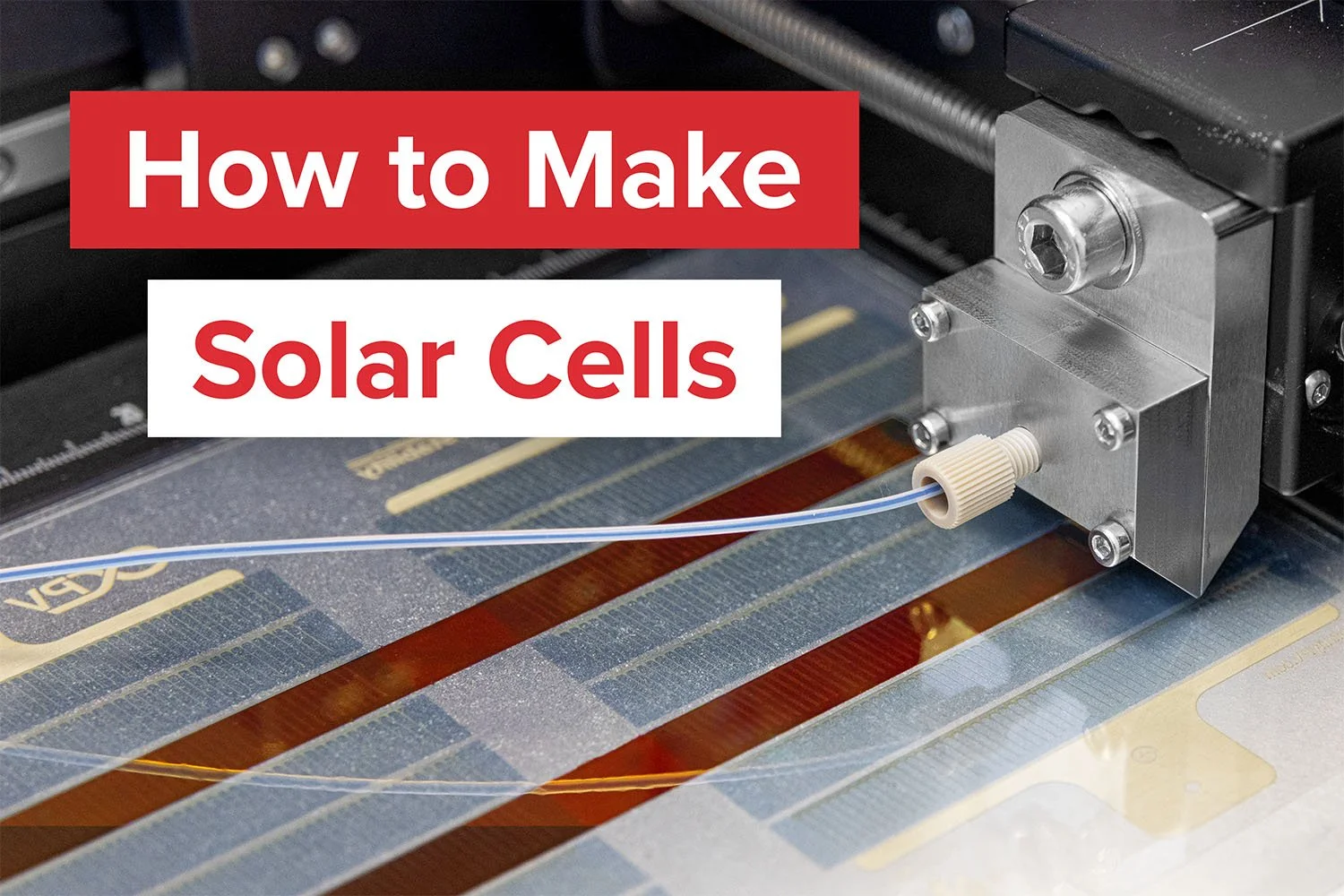

Discover how to fabricate solar cells using slot-die coating in this detailed, lab-focused guide. Learn about ink preparation, substrate handling, layer coating, and printing electrodes.

Learn how to properly mount a slot-die head on a slot-die coater with this step-by-step guide. Follow these tips for a secure, precise installation to ensure high-quality, consistent coatings every time.

Learn how to clean your slot-die head for optimal performance and longevity. This comprehensive guide covers tools, cleaning steps, and maintenance tips to keep your coating equipment in top condition.

Discover how Source Measurement Units (SMUs) are used to characterize solar cells, semiconductors, and electronic devices. Learn about I-V curve measurements, MPPT tracking, and stability testing for optimized performance.

Discover how organic batteries work, their advantages, and why they're the future of eco-friendly energy storage solutions.

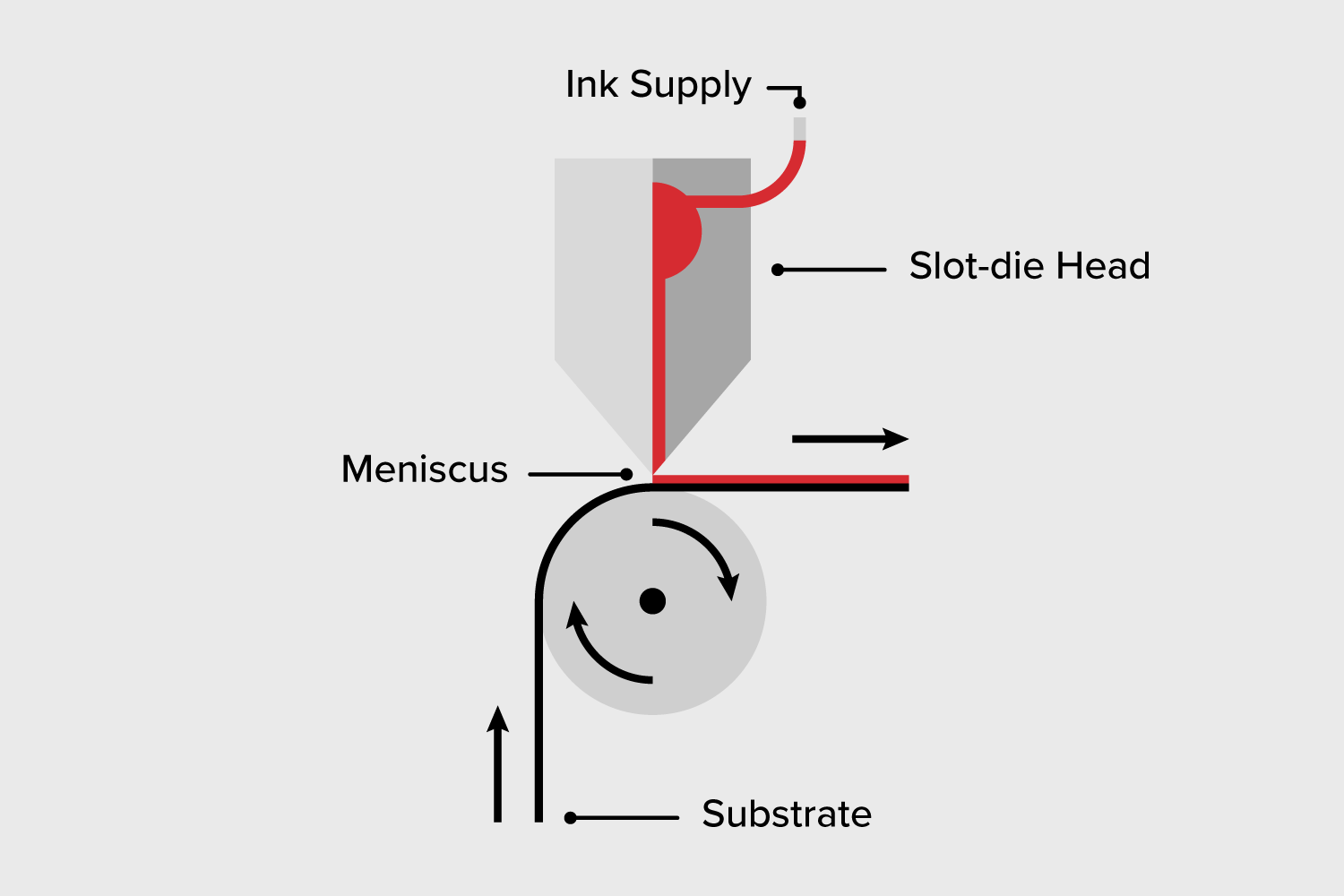

Discover what a slot-die coater is and how it’s used for precision thin-film deposition in industries like energy storage, printed electronics, and more. Learn about its key benefits, applications, and the difference between compact and large-scale systems.

Master slot-die coating with these 5 helpful tips. Avoid common pitfalls, improve coating precision, and ensure smooth, consistent results. Perfect for beginners and experienced professionals alike.

Drying is a critical step in roll-to-roll (R2R) processing, ensuring the stability and performance of thin films. This article compares convection and infrared (IR) ovens, highlighting their advantages, limitations, and best use cases for efficient and high-quality drying.

Lamination is a crucial manufacturing process that enhances durability, flexibility, and performance across various industries. From printed electronics and solar cells to fuel cells and flexible packaging, lamination, often combined with roll-to-roll processing and slot-die coating, plays a key role in ensuring product quality and efficiency.

Organic solar cells (OSCs) offer a promising solution to the limitations of traditional solar panels, with their flexible, lightweight design suitable for applications in wearable electronics, building-integrated technology, and portable devices.

A sheet coater is an essential lab-scale tool for thin film deposition, enabling precise and uniform coatings on substrates for applications like printed electronics, solar cells, and batteries.

Explore the differences between OLED and LED technologies in this comprehensive guide. Learn how both technologies function through electroluminescence, their history, applications, and the advantages and disadvantages of each.

Learn how to assemble, disassemble, and clean your slot-die head in our step-by-step guide. Perfect for ensuring precision and maintaining the longevity of your slot-die coating equipment. Watch the accompanying video for a visual walkthrough and get practical tips for optimal performance.

Discover how Dry Battery Electrode (DBE) technology is transforming the battery manufacturing industry. Learn about the benefits of DBE methods, including eco-friendly production, improved energy density, and cost efficiency.

Solar cells convert light directly into electricity, transforming energy production and its integration into society. This article covers the working principles of solar cells, the importance of semiconductors, and the different generations of solar cell technology, from silicon-based to emerging organic and perovskite solutions.

Explore the science of solar cell efficiency, from PCE to IPCE. Understand key parameters like Jsc, Voc, and Fill Factor (FF), and discover how advanced metrics like EQE and IPCE provide deeper insights into solar technology performance

LBIC plays a key role in the MADRAS project by providing high-resolution mapping of organic photodetectors and solar cells. This technique uncovers defects caused by the injection-moulding process, enabling targeted improvements in flexible electronics.

Silver nanowires (AgNWs) are ultra-thin, highly conductive materials redefining the future of electronics. With applications in touchscreens, flexible displays, solar cells, and sensors, their unique properties offer a sustainable alternative to traditional materials like indium tin oxide.

Choosing the right pump for slot-die coating is crucial for achieving precise and consistent results. Our guide covers various pump types, including syringe, gear, and peristaltic pumps, and explains how each contributes to efficient ink delivery, ensuring high-quality coatings for applications such as solar cells, batteries, and printed electronics.

Surface treatment technologies like plasma and corona are crucial for enhancing the adhesion of inks, coatings, and adhesives, particularly when working with non-porous materials like plastics and polymers.

Slot-die Heads for High-Performance Precision Coating

Whether you're working on batteries, pharmaceuticals, solar cells, or other thin-film technologies, this video guides you through the full process of using infinityPV’s slot-die heads—from assembly and mounting to precision adjustment, coating, and cleaning. Available in stainless steel, titanium, and PEEK, and in widths from 40 to 305 mm, these slot-die heads are engineered for accuracy, repeatability, and compatibility with all infinityPV platforms.

We Are Ready to Help You

With decades of experience in printed electronics, our team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project. Contact us to discuss how we can support your solar cell development.

Build Your Own R2R Slot-die Coater

With its modular design, the Laboratory Roll-to-Roll Coater empowers you to customize your system with the components you need. Choose between slot-die heads, flexographic printers, slurry coaters, air knives, drying and curing units, knife cutters, laminators, laser systems and more.