How to Clean a Slot-Die Head: A Comprehensive Guide

Cleaning a slot-die head is a critical aspect of maintaining its performance and ensuring the longevity of your equipment. Whether you're using a slot-die head for laboratory, pilot, or industrial-scale applications, proper cleaning is vital for achieving high-quality coatings, reducing cross-contamination between different materials, and avoiding clogging. In this guide, we’ll take you through the steps for effectively cleaning your slot-die head, including the necessary tools, safety precautions, and maintenance tips to ensure optimal performance.

Why Is Cleaning Your Slot-Die Head Important?

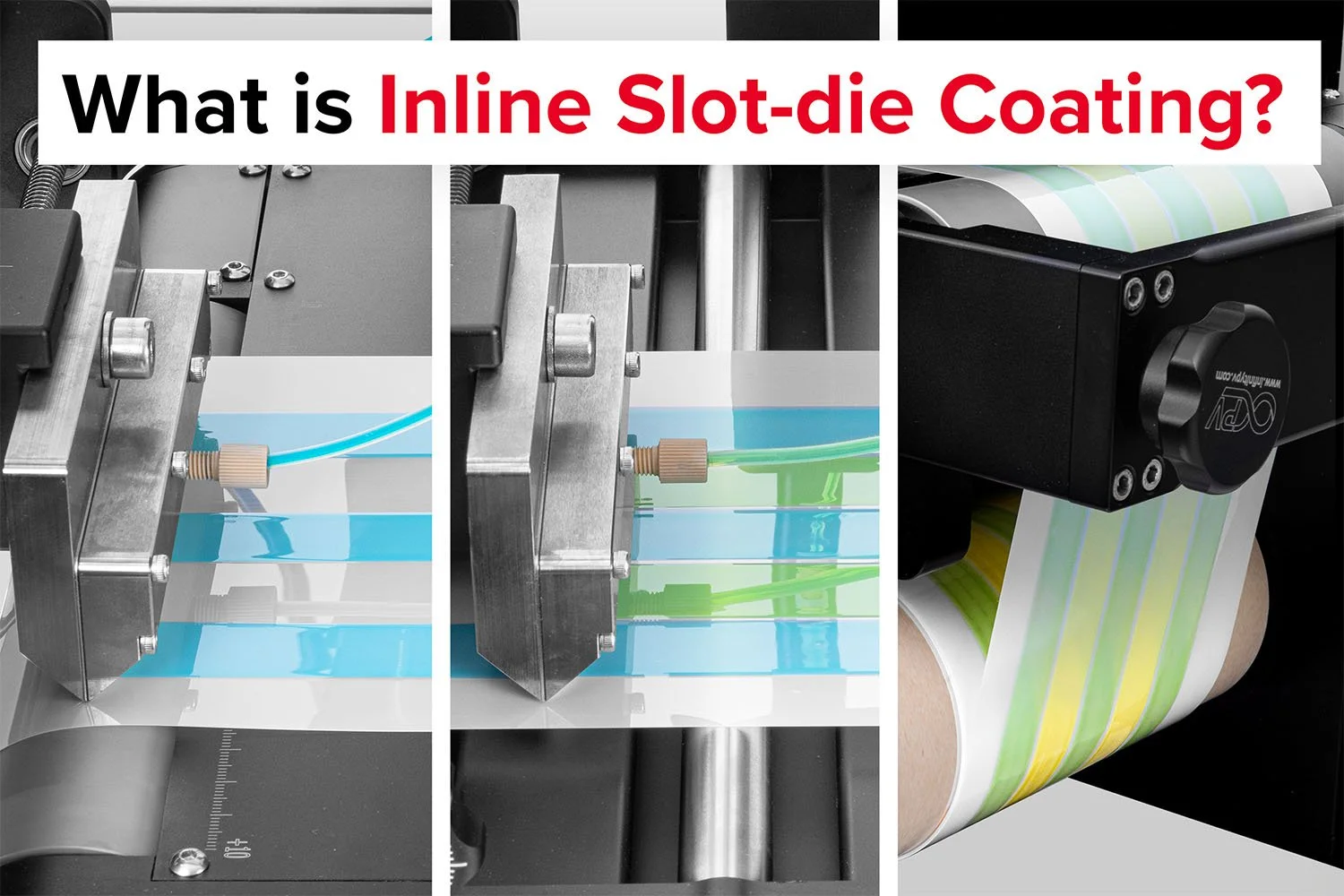

Slot-die heads are used in various thin-film coating processes, including the application of materials such as inks, coatings, adhesives, and more. Over time, residues from these materials can accumulate within the head, affecting the consistency of the coating, causing blockages, and potentially damaging the equipment. Cleaning ensures:

Consistent Coating Quality: Prevents contamination between different materials, ensuring uniform deposition.

Extended Equipment Life: Regular cleaning minimizes wear and tear, keeping your slot-die head functioning for longer.

Improved Efficiency: Reduces the risk of clogs and blockages that can lead to downtime.

Materials You Will Need

Before you begin cleaning, ensure you have the following tools and materials on hand:

Solvents (depending on the coating material):

Water (for water-based coatings)

Organic solvents (such as ethanol, acetone, or isopropyl alcohol) for non-water-based materials

Cleaning Brushes: Use soft-bristled brushes to remove residue from delicate surfaces.

Compressed Air: For drying and clearing out debris.

Lint-Free Wipes: To prevent any fibers from contaminating the slot-die head.

Gloves: To protect both your hands and the equipment from any contamination.

Plastic or Non-Abrasive Scrapers: To gently remove hardened materials without damaging the surface.

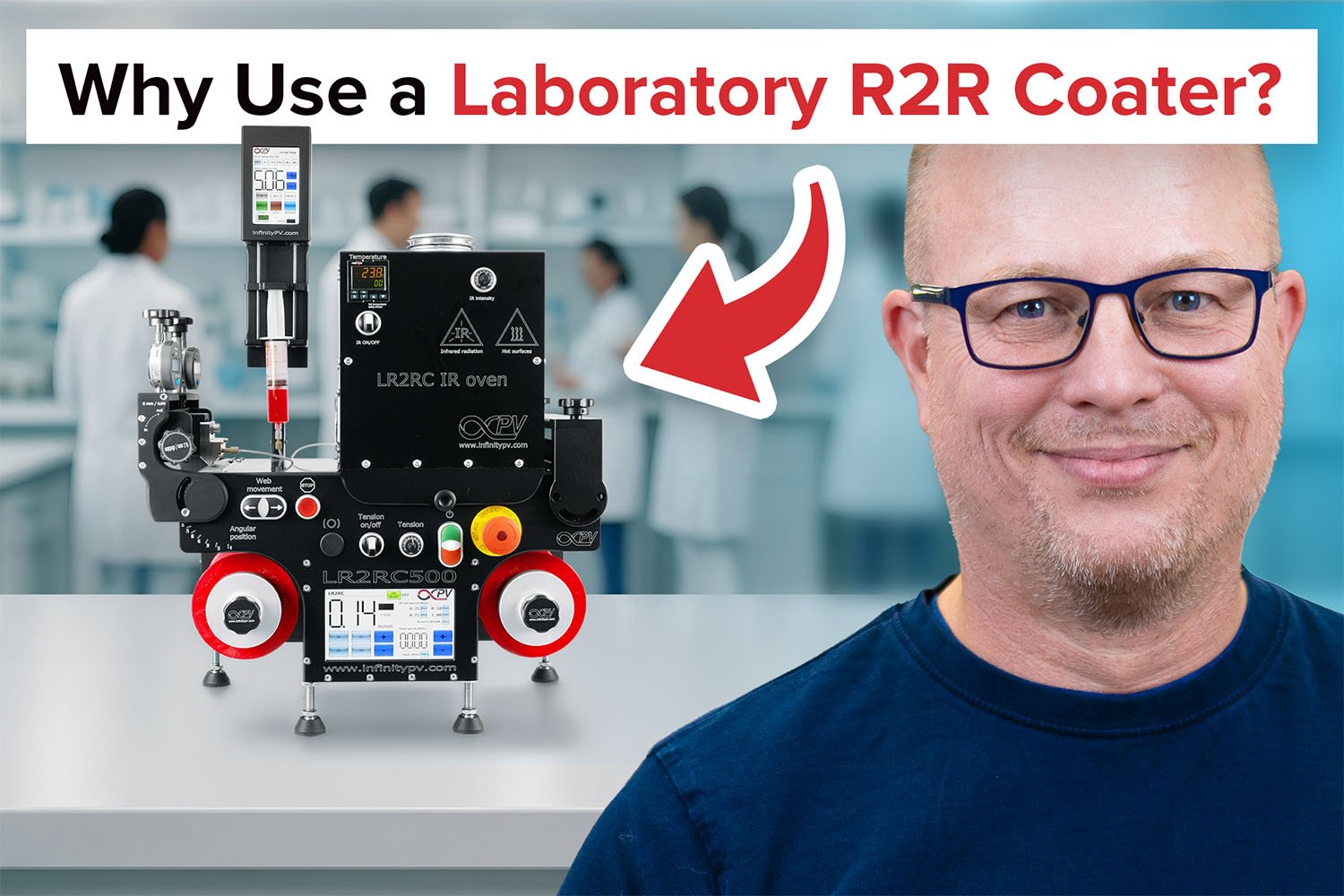

The Laboratory Roll-to-Roll Coater fits in on a workbench, glovebox and fume hood.

Step-by-Step Guide to Cleaning a Slot-Die Head

1. Power Off and Disassemble

Turn off all equipment: Disconnect the slot-die head from power sources, air supplies, and any other connections.

Remove the slot-die head from the coating system. Handle with care to avoid damaging delicate parts.

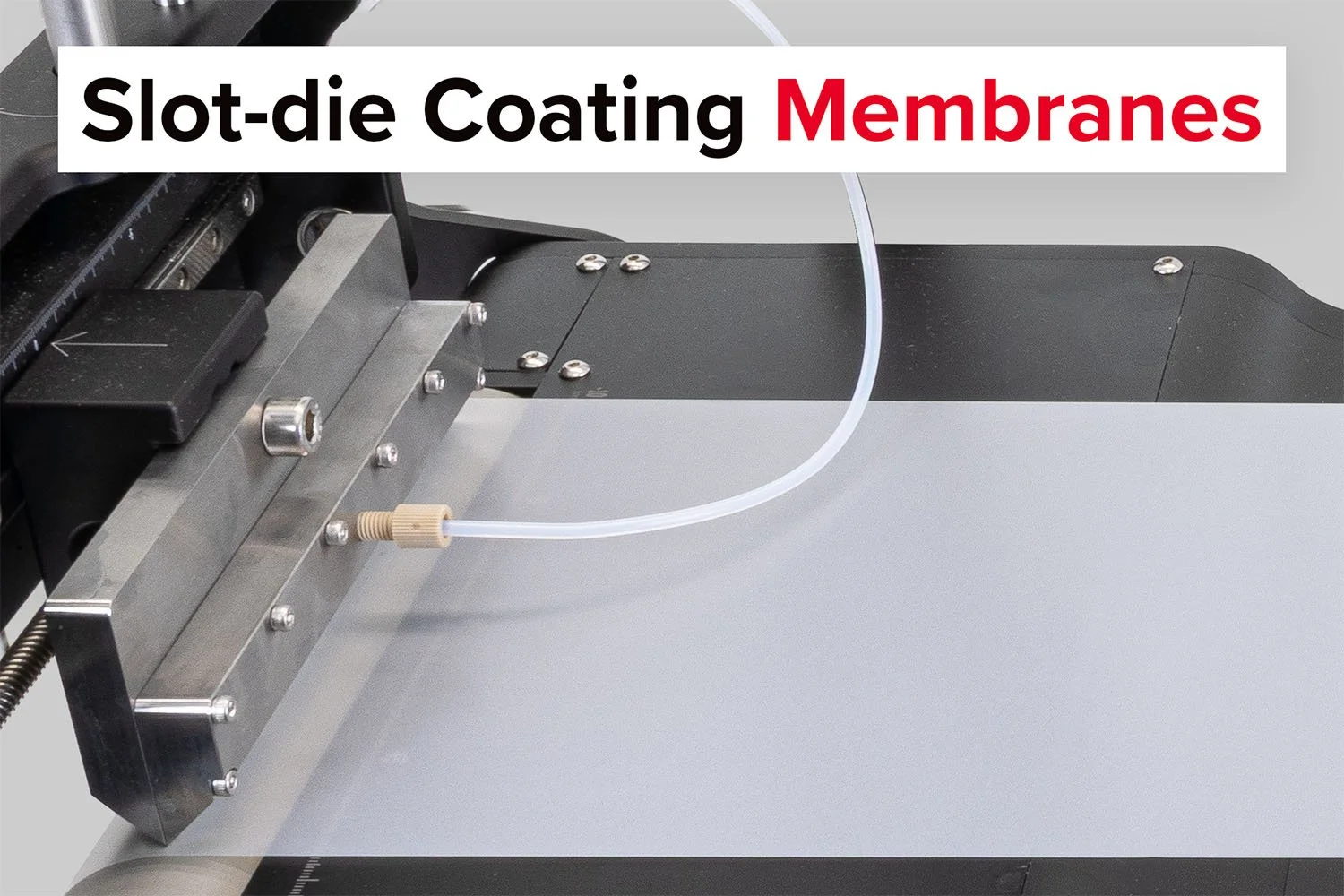

Disassemble as needed: Depending on the type of slot-die head, you may need to remove specific components, such as the shim, nozzle, and manifold. Make sure to keep track of all parts for reassembly.

2. Initial Rinse and Solvent Application

Rinse the slot-die head with an appropriate solvent. For water-based coatings, distilled water should be sufficient. For organic coatings or inks, use a solvent like acetone or isopropyl alcohol.

Pour or spray solvent directly into the slot-die head and allow it to sit for a few minutes. This will loosen any accumulated material.

Drain the solvent: Tilt the head to ensure all residue and solvent are drained out.

3. Brush Away Residue

Use a soft brush to scrub the surfaces of the slot-die head, including the nozzle, manifold, and shim areas.

Gently scrub to avoid damaging any sensitive components. Be thorough but not abrasive.

If needed, use plastic scrapers for stubborn residues, but avoid metal tools that may scratch the surface.

4. Flush the Slot-Die Head

Once you’ve scrubbed away the visible residue, flush the slot-die head with solvent again. Allow the solvent to pass through the head and flush out any remaining material from the internal channels.

Repeat the flushing process until the solvent comes out clean, ensuring no residues are left behind.

5. Use Compressed Air

Once you have flushed the slot-die head with solvent, use compressed air to blow out any remaining solvent and ensure there is no moisture left inside the head.

Hold the slot-die head in a downward position to allow gravity to help remove any remaining liquid.

6. Wipe Down and Dry

After the air-drying process, use lint-free wipes to wipe down the exterior of the slot-die head and remove any solvent or debris.

Allow the slot-die head to air dry completely before reassembling it. This is essential to prevent any contamination from solvents or water that may still be trapped inside.

7. Reassemble the Slot-Die Head

Once all components are dry, carefully reassemble the slot-die head.

Ensure that all parts, such as the shim and nozzle, are properly aligned and seated in their correct positions.

8. Final Inspection

Perform a final inspection of the slot-die head to ensure that no parts are loose and that all surfaces are clean and free from contaminants.

Check for any signs of wear or damage, such as worn-out seals or cracked components. If you identify any issues, consider replacing the damaged parts before use.

Build your own Laboratory Roll-to-Roll Coater today and get a quotation.

Maintenance Tips for Slot-Die Heads

In addition to regular cleaning, here are some tips to maintain the performance of your slot-die head:

Use a dedicated cleaning area: Set up a clean, designated space for cleaning slot-die heads to avoid contamination from dust or other materials.

Schedule routine cleaning: Establish a cleaning schedule based on the frequency of use and the type of materials being used. For high-viscosity or aggressive materials, more frequent cleaning may be necessary.

Check seals and gaskets: Regularly inspect the seals and gaskets of the slot-die head for wear and replace them as necessary. Damaged seals can lead to leaks and reduced coating quality.

Store properly: When not in use, store the slot-die head in a clean, dry environment to prevent contamination.

Conclusion

Cleaning your slot-die head is essential for maintaining high performance, preventing material contamination, and extending the lifespan of your equipment. By following the proper steps and using the right tools and solvents, you can ensure that your slot-die head remains in top condition, delivering consistent, high-quality coatings every time. Regular cleaning and maintenance are crucial practices for anyone working with coating technology, whether you're in a research laboratory, pilot production, or full-scale industrial manufacturing.

Implement these cleaning tips into your routine and keep your slot-die head working at its best!

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.