Goodbye to Plastics: How Slot-Die Coated Nanocellulose Could Change Packaging

Can nanocellulose replace plastics in packaging?

This question is at the center of a new study titled “Viscosity driven variations in slot die coating of nanocellulosic barrier layers,” published in the AIChE Journal (2025). The research, conducted by Lukas Maier, Heiko Briesen, and Daniel Schiochett Nasato from the Technical University of Munich, explores how viscosity affects the coating process of nanocellulose suspensions.

Nanocellulose has received significant attention in recent years because of its excellent barrier properties against oxygen, grease, and oils. These qualities make it an attractive and sustainable replacement for plastic coatings on paper packaging. But working with nanocellulose is not straightforward. The suspensions exhibit unusual flow behavior, such as high yield stress and strong shear-thinning, which complicates their use in industrial coating technologies.

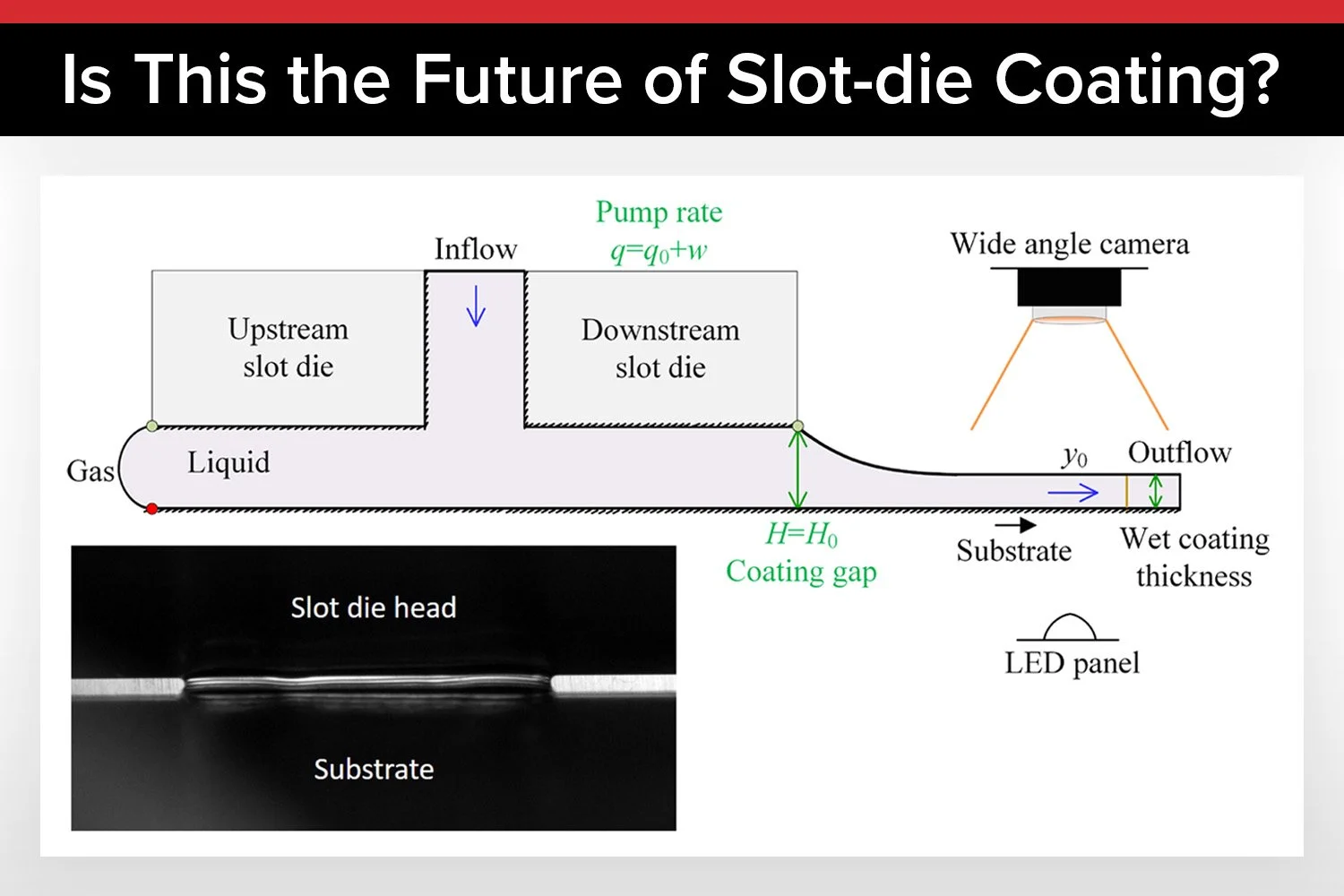

Slot-die coating, a precise and scalable technique already used in electronics, energy devices, and packaging, is considered one of the most promising methods for producing uniform nanocellulose films. Yet, one challenge stands in the way: viscosity. This study set out to determine how changes in viscosity reshape the coating window, the operational zone where defect-free films can be produced, and how industry might adapt to these limitations.

Key Highlights

Nanocellulose films could replace fossil-based plastics in packaging by offering strong barrier properties.

Slot-die coating is a prime candidate for scalable production of nanocellulose coatings.

The coating window, the safe zone of flow rate and substrate speed, is heavily influenced by viscosity.

Increasing viscosity shrinks the coating window, limiting production speeds.

Yield stress had less effect than viscosity on process stability.

Simulations showed viscosity dominates over surface tension in stabilizing the coating bead.

A modified theoretical model was proposed to better predict coating limits at high viscosities.

Strategies like reducing the coating gap (SWG) can expand the coating window and enable higher speeds.

What is roll-to-roll processing, and why is it revolutionizing the way we make flexible devices?

What is Slot-Die Coating and Why Does it Matter?

To understand the importance of this study, it helps to first understand slot-die coating itself. Slot-die coating is what engineers call a pre-metered coating method. This means that the thickness of the wet film is determined in advance, based on the flow rate of the fluid and the speed of the substrate moving beneath the die. Unlike other methods where the fluid spreads freely and thickness is harder to control, slot-die coating gives precise and repeatable results.

This is why it is used in many industries, from making electrodes for lithium-ion batteries and solar cells to producing protective layers in packaging. For nanocellulose, slot-die coating holds the potential to bring a sustainable, recyclable material into large-scale production.

The problem lies in the fact that nanocellulose suspensions do not behave like simple liquids. They are not Newtonian fluids such as water or alcohol but exhibit more complex behaviors including yield stress and shear thinning. These characteristics make it difficult to predict how they will behave under industrial coating conditions. That is where this research comes in: by simulating nanocellulose coatings under different viscosities, the team aimed to pinpoint what happens inside the narrow limits of the coating window.

The Significance of the Study: Why Viscosity is Key

The coating window can be thought of as the “sweet spot” where the process works. If the substrate moves too slowly or the flow rate is too high, excess liquid accumulates and begins dripping from the die. If the substrate moves too fast, the fluid can no longer wet the surface properly, leading to air entrainment or ribbing defects that ruin the film.

This study demonstrated that viscosity is the dominant factor determining the width of this coating window. When viscosity increased, the operational window shrank significantly, meaning that the range of defect-free coating conditions became narrower. In extreme cases, the window nearly collapsed entirely.

Interestingly, yield stress, which is the force required to initiate flow, played a much smaller role than viscosity. While yield stress did influence stability in subtle ways, it was the viscosity of the suspension at high shear rates that largely dictated whether the coating bead could be stabilized. This finding has important industrial implications. It suggests that the challenge of scaling up nanocellulose coatings is not simply about the material itself but about how its viscosity interacts with the coating process.

Diving Into the Methods: How the Study Was Conducted

The researchers combined rheological experiments with computational fluid dynamics (CFD) simulations to explore the problem. Rheological measurements were taken for three different types of nanocellulose: microfibrillated cellulose, cellulose nanofibrils, and cellulose nanocrystals. Each type displayed distinct viscosity profiles, which were then described using the Casson model. This model captures both the yield stress and shear-thinning nature of nanocellulose suspensions and provided accurate input for the simulations.

In the virtual coating setup, substrate speed and flow rate were systematically varied. The CFD simulations tracked when defects such as dripping, ribbing, or dynamic wetting failure occurred. This allowed the team to map coating windows for different viscosities and yield stresses. In addition, the results were compared against existing analytical models for coating stability, particularly the viscous model developed by Higgins and Scriven, to test whether current theory matched the behavior of nanocellulose suspensions.

Results: What the Simulations Revealed

The simulations provided a detailed picture of how viscosity reshapes the slot-die coating process. At low viscosities, coating windows were wide and stable, allowing higher substrate speeds without defects. As viscosity increased, however, the upper boundary of the coating window shifted downward, leaving less operational space before air entrainment occurred. The dripping boundary, by contrast, remained largely unaffected by viscosity, as it is driven more by inertia and gravity.

A critical capillary number around 0.4 was identified as a tipping point. Below this number, surface forces dominated and the meniscus of the coating bead stretched until it failed. Above this number, viscous forces took over, leading to dynamic wetting failure as air was entrained into the liquid. This transition explained why high-viscosity suspensions behave so differently from low-viscosity ones.

The researchers also proposed a modification to the existing viscous model to better account for high-viscosity cases. Their adapted model showed improved agreement with the simulation results, providing a more reliable way to predict process limits for nanocellulose suspensions.

Choose the right slot-die head for your application Read our guide to understand which slot-die head is right for you.

Future Outlook: Pathways for Industry

While the results highlight the challenges of coating nanocellulose suspensions at high viscosities, the study also points to practical solutions. One strategy is to reduce the slot-web gap (SWG). Narrowing the coating gap increases meniscus confinement, which stabilizes the coating bead and expands the coating window. This allows higher coating speeds without encountering air entrainment, even for thicker suspensions.

Another direction is to refine theoretical models that predict coating windows. The modified model developed in this study is one step in that direction, linking rheological measurements directly to coating performance. Future work could go further by incorporating the effects of nanocellulose fibrils themselves, since particle-fluid interactions are known to delay air entrainment.

For industry, these findings stress that scaling up nanocellulose coatings is not only a matter of material design but also one of process engineering. Success will come from carefully balancing viscosity, drying requirements, and coating conditions, with tools such as CFD simulations guiding the way.

Conclusion

This research offers an important step toward making nanocellulose-based barrier films a viable industrial reality. By systematically studying how viscosity influences slot-die coating, the authors revealed why higher solid contents, while attractive for drying efficiency, often lead to coating difficulties. They also showed that process modifications such as reducing the coating gap can counteract these problems.

For companies and researchers working on sustainable packaging or functional films, the message is clear: understanding viscosity is essential for designing successful roll-to-roll processes. As nanocellulose moves closer to commercialization, studies like this bridge the gap between laboratory-scale exploration and large-scale production.

Authors

Lukas Maier

Heiko Briesen

Daniel Schiochett Nasato

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.